oil pressure MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 924 of 1865

7B TROUBLESHOOTING (G4A-HL)

Line Pressure Test

Preparation

1. Connect the SST to the line pressure output point

(square head plug L).

2. Connect a tachometer to the engine.

3. Perform the preparation procedure shown in STEP

3 (STALL TEST).

STEP 6 (OIL PRESSURE TEST)

This step checks line, throttle, and governor pressures to check the operation of hydraulic compo-

nents and for oil leakage.

83U07B-047

Procedure

76G07B-062

1. Start the engine and check that the idle speed is 900 rpm.

2. Shift the selector lever to D range.

3. Read the line pressure at idle.

4. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

5. Read the line pressure as soon as the engine speed becomes constant, then release the accelera-

tor pedal.

Caution

Steps 4 to 5 must be performed within 5 seconds.

5. Shift the selector lever to N range and run the engine at idle for at least one minute.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7B—58

Page 925 of 1865

TROUBLESHOOTING (G4A-HL) 7B

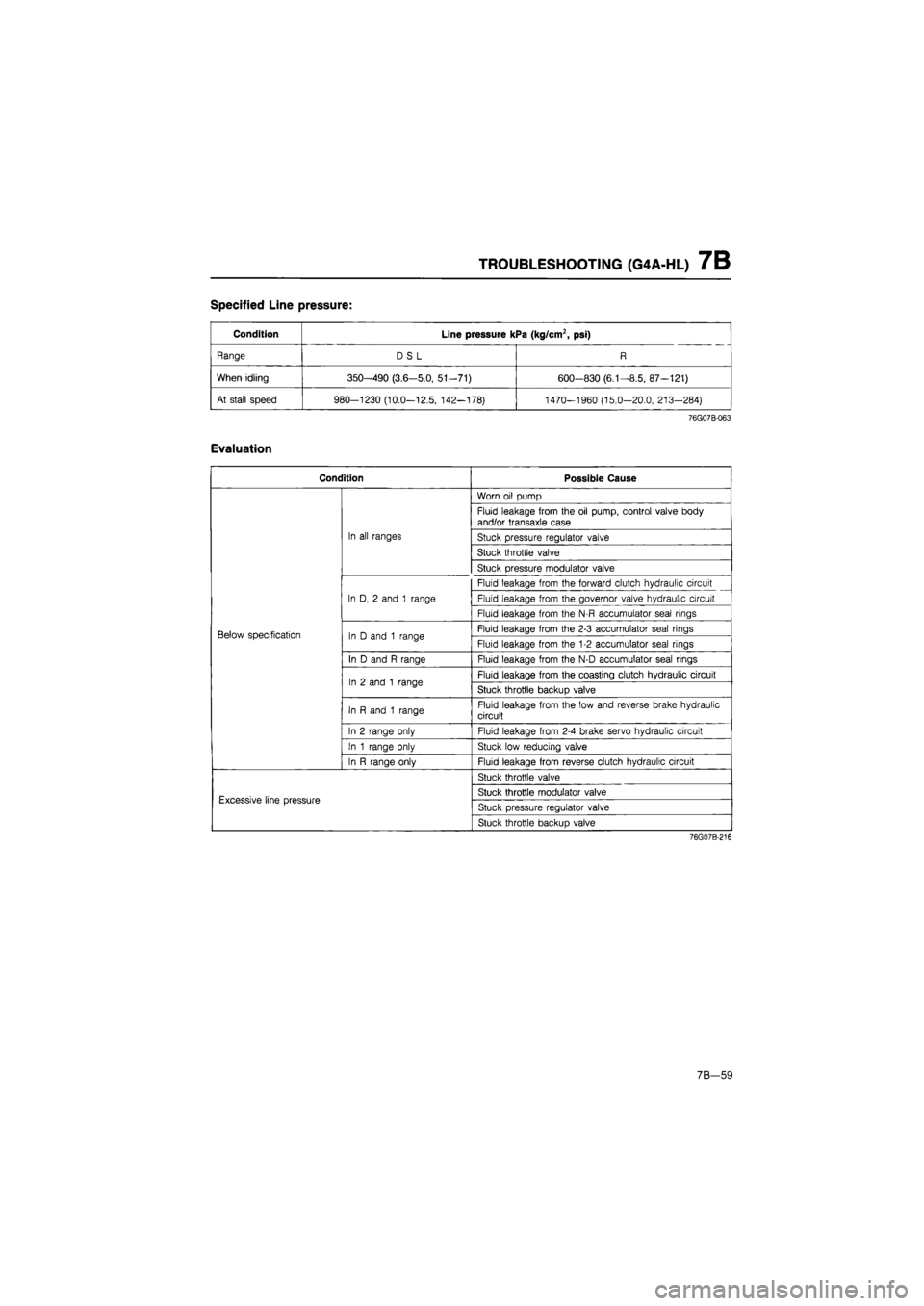

Specified Line pressure:

Condition Line pressure kPa (kg/cm2, psi)

Range DSL R

When idling 350-490 (3.6-5.0, 51-71) 600-830 (6.1-8.5, 87-121)

At stall speed 980-1230 (10.0—12.5, 142—178) 1470-1960 (15.0-20.0, 213-284)

76G07B-063

Evaluation

Condition Possible Cause

Below specification

In all ranges

Worn oil pump

Below specification

In all ranges

Fluid leakage from the oil pump, control valve body

and/or transaxle case

Below specification

In all ranges Stuck pressure regulator valve

Below specification

In all ranges

Stuck throttle valve

Below specification

In all ranges

Stuck pressure modulator valve

Below specification

In D, 2 and 1 range

Fluid leakage from the forward clutch hydraulic circuit

Below specification

In D, 2 and 1 range Fluid leakage from the governor valve hydraulic circuit

Below specification

In D, 2 and 1 range

Fluid leakage from the N-R accumulator seal rings

Below specification In D and 1 range Fluid leakage from the 2-3 accumulator seal rings Below specification In D and 1 range Fluid leakage from the 1-2 accumulator seal rings Below specification

In D and R range Fluid leakage from the N-D accumulator seal rings

Below specification

In 2 and 1 range Fluid leakage from the coasting clutch hydraulic circuit

Below specification

In 2 and 1 range Stuck throttle backup valve

Below specification

In R and 1 range Fluid leakage from the low and reverse brake hydraulic

circuit

Below specification

In 2 range only Fluid leakage from 2-4 brake servo hydraulic circuit

Below specification

In 1 range only Stuck low reducing valve

Below specification

In R range only Fluid leakage from reverse clutch hydraulic circuit

Excessive line pressure

Stuck throttle valve

Excessive line pressure Stuck throttle modulator valve Excessive line pressure Stuck pressure regulator valve Excessive line pressure

Stuck throttle backup valve

76G07B-216

7B—59

Page 944 of 1865

7B ON-VEHICLE MAINTENANCE

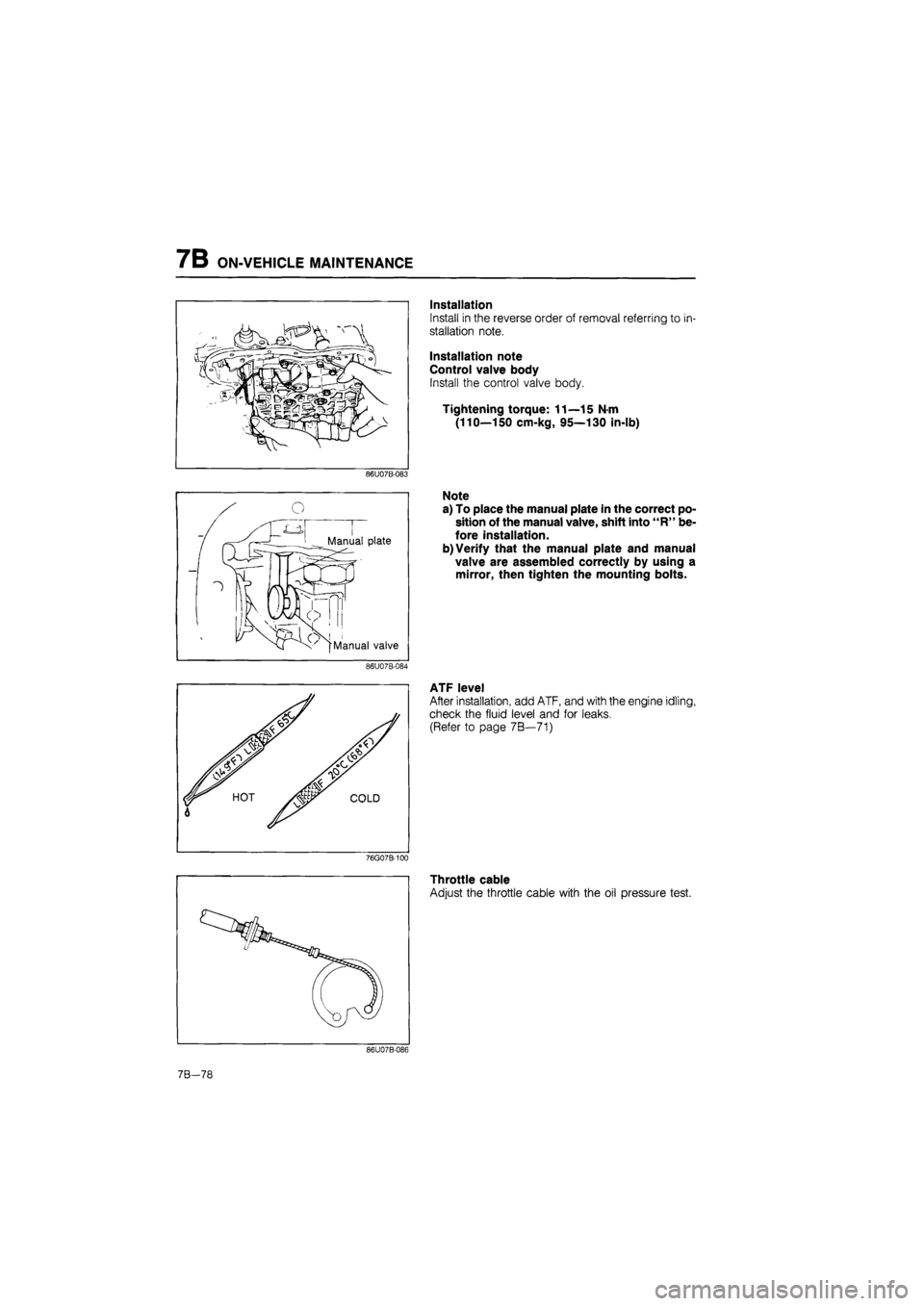

Installation

Install in the reverse order of removal referring to in-

stallation note.

Installation note

Control valve body

Install the control valve body.

Tightening torque: 11—15 N-m

(110—150 cm-kg, 95—130 in-lb)

86U07B-083

Note

a) To place the manual plate in the correct po-

sition of the manual valve, shift into "R" be-

fore installation.

b) Verify that the manual plate and manual

valve are assembled correctly by using a

mirror, then tighten the mounting bolts.

86U07B-084

w v

ATF level

After installation, add ATF, and with the engine idling,

check the fluid level and for leaks.

(Refer to page 7B—71)

76G07B-100

Throttle cable

Adjust the throttle cable with the oil pressure test.

86U07B-086

7B-78

Page 987 of 1865

INSPECTION AND REPAIR 7B

6. Check for the clutch operation as follows.

(1) Set the clutch assembly onto the oil pump.

(2) Check the clutch operation by applying com-

pressed air through the fluid passages as

shown.

Applied air pressure:

392 kPa (4.0 kg/cm2, 57 psi)

86U07B-217

(3) Pour in ATF so that the reverse piston, coast-

ing clutch drum, and coasting clutch piston are

fully submerged.

86U07B-218

(4) Check that no bubbles come from between the

piston and drum seal when applying com-

pressed air through the fluid passages as

shown.

Caution

The compressed air must be under 392 kPa

(4.0 kg/cm2, 57 psi), and should not applied

for over 3 seconds.

86U07B-219

7. Apply petroleum jelly to the thrust bearings to se-

cure them; then install them on both sides of the

reverse and forward drum.

Thrust bearing outer diameter

Oil pump side: 86.0 mm (3.39 in)

Small sun gear and one-way clutch side:

56.1 mm (2.21 in)

86U07B-220

7B-121

Page 1011 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm (in)

Wire dia.

mm

(in) Spring color

Pressure modifier spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

Low reducing spring 8.7 (0.343) 38.3 (1.508) 0.9 (0.035) Black

1-2 shift spring 8.7 (0.343) 41.3 (1.626) 1.0 (0.039) Yellow

2-3, 3-4 shift spring 7.4 (0.291) 36.6 (1.441) 0.8 (0.031) Gray

Throttle backup spring 9.65 (0.380) 26.9 (1.059) 0.55 (0.022) Red

Throttle modulator spring 6.3 (0.248) 47.9 (1.886) 0.8 (0.031)

—

Throttle assist spring 5.15 (0.203) 32.3 (1.272) 0.55 (0.022) Dark green

Throttle spring 5.4 (0.213) 47.2 (1.858) 0.8 (0.031) Pink

Converter relief ball spring 6.9 (0.272) 24.1 (0.949) 0.9 (0.035) Maroon

Orifice check valve spring 5.0 (0.197) 12.5 (0.492) 0.23 (0.009)

—

76G07B-219

]

Assembly

1. Install the throttle adjust plug, throttle assist spring,

throttle valve, and throttle plug assembly.

86U07B-288

Caution

Install the throttle plug assembly with the

groove aligned with the bolt hole.

86U07B-289

7B-145

Page 1014 of 1865

7B INSPECTION AND REPAIR

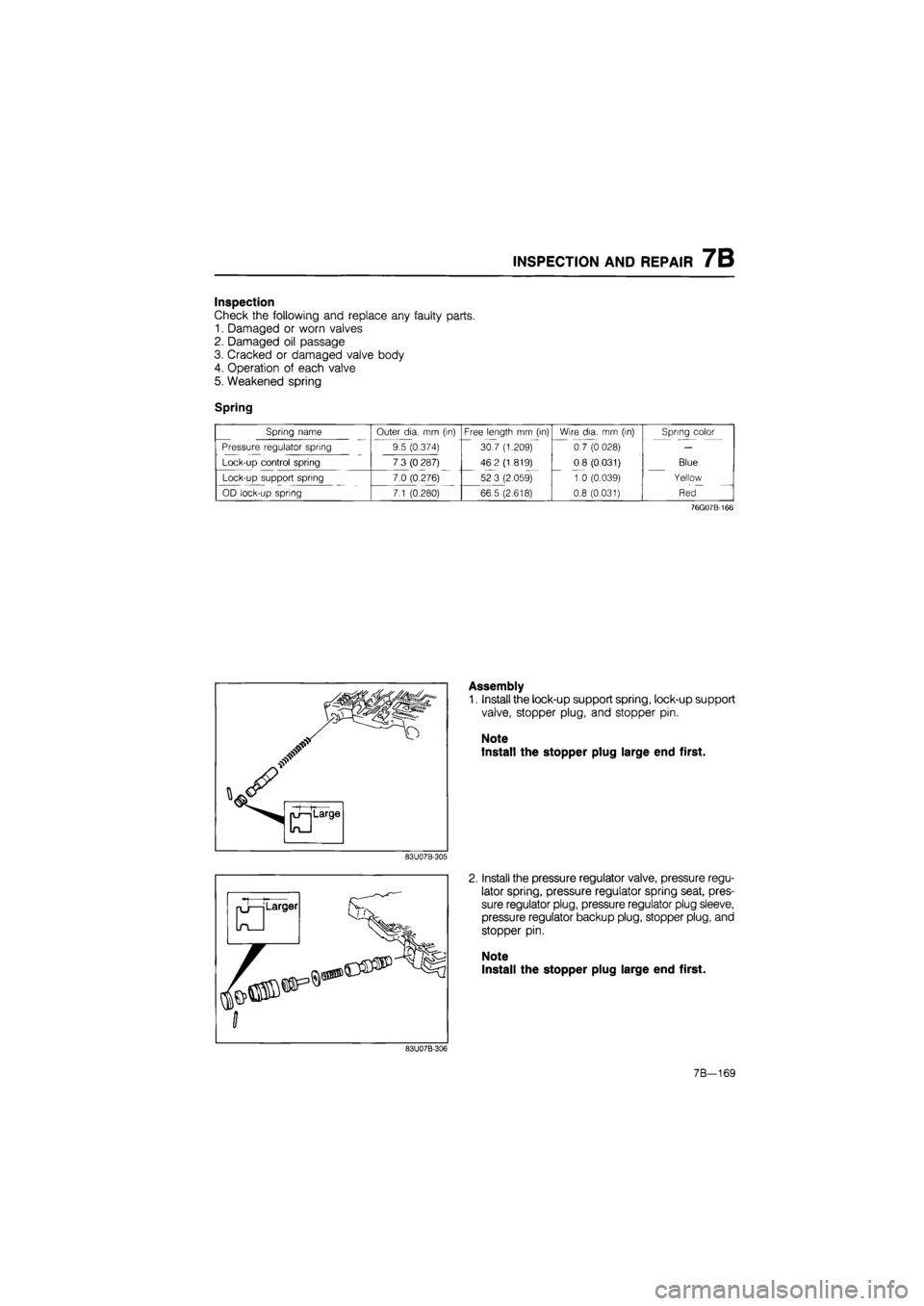

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

Pressure regulator spring 11.5 (0.453) 26.5 (1.043) 1.0 (0.039) Maroon

Lock-up control spring 5.0 (0.197) 35.2 (1.386) 0.6 (0.024) Purple

86U07B-295

Assembly

1. Install the lock-up control spring, lock-up control

valve, stopper plug, and stopper pin.

86U07B-296

Install the pressure regulator valve, pressure regu-

lator spring, pressure regulator spring seat, pres-

sure regulator plug, pressure regulator plug sleeve,

pressure regulator backup plug, stopper plug, and

stopper pin.

Note

Install the stopper plug larger end first.

86U07B-297

3. Install the manual valve.

86U07B-298

7B-148

Page 1035 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm (in)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

Wire dia.

mm (in)

Spring color

Blue

Yellow

Red"

Pressure regulator spring 9.5 (0.374)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

Lock-up control spring 7,3 (0 287)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

Lock-up support spring 7.0 (0.276)

Free length

mm

(in)

30.7 (1.209)

46

2

(1 819)

52

3

(2.059)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red" OD lock-up spring 7.1 (0.280) 66.5 (2.618)

0.7 (0 028)

0

8

(0.031)

1.0 (0.039)

0.8 (0.031)

Spring color

Blue

Yellow

Red"

76G07B-166

Assembly

1. Install the lock-up support spring, lock-up support

valve, stopper plug, and stopper pin.

Note

Install the stopper plug large end first.

83U07B-305

2. Install the pressure regulator valve, pressure regu-

lator spring, pressure regulator spring seat, pres-

sure regulator plug, pressure regulator plug sleeve,

pressure regulator backup plug, stopper plug, and

stopper pin.

Note

Install the stopper plug large end first.

83U07B-306

7B—169

Page 1085 of 1865

INSTALLATION 7B

86U07B-453

86U07B-454

76G07B-198

20. Install the tie-rod ends and cotter pins.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

21. Install the oil cooler outlet and inlet hoses.

22. Install the splash shields.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

23. Install the front wheels.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

24. Connect the throttle cable.

Note

Adjust the throttle cable with the oil pressure

test. (Refer to page 7B—75, 76)

25. Connect the selector cable.

Tightening torque:

Nut

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

Bolts

16—22 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

26. Connect the ground wires to the transaxle case.

Tightening torque:

8—11 N-m (80—115 cm-kg, 69—99 in-lb)

86U07B-456

7B—219

Page 1087 of 1865

OD

IV) K>

2-4 brake band

—Coasting clutch pressure brake pressure

To oil cooler

N-R accumulator 12-3 accumulator

2-3 Timingr valve 18 Coasting bypass valve Bypass valve Servo control y valve (Blocked)

Pressure modifier valve (Blocked)

3-4 shift valve

Low reducing valve

Pressure regulator valve 3-2 timing valve 3-2 Icapacity valve

Manual valve

Throttle valve

Oil pump

• Throttle pressure

1 Throttle modulated pressure

• Line pressure

I Torque converter pressure Forward clutch pressure\^

Reverse clutch pressure—_____

1-2 accumulator

Throttle back-up valve (Blocked)

-j Throttle J modulator I valve

Apply side 9

Lock-up control valve

-< O

u >

o

o

J3 o

Q >

• m

-< o

3D >

C n

O

O

J3 o

a •C* > • m

-si

CD

Page 1088 of 1865

Apply side 9

Throttle pressure

Throttle modulated pressure

Line pressure

Operating line pressure

1

Torque converter pressure

30 >

Z o m

U)

< O X >

o

o

55

o

0 >

1 m

I Oil pump