clutch MAZDA 626 1987 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 767 of 1865

STARTOR (DIESEL ENGINE, 2.0 kW TYPE) 5

Coil spring and steel ball installation

1. Install the coil spring and steel ball to the magnet-

ic switch before installing the over-running clutch

assembly.

2. Assemble the retainer and roller to the idler gear.

4BG04X-100

Brush

(

+

)

Brush installation

1. Assemble the brush holder to the yoke.

2. Assemble the two brushes on the yoke side to the

brush holder.

4BG05X-101

Magnetic switch installation

Align the cut out part with the projection of the mag-

netic switch.

4BG05X-102

INSPECTION

Armature Coil

1. Ground of the armature coil

(1) Check for continuity between the commutator

and the core by using a circuit tester.

(2) Replace the armature if there is continuity.

4BG05X-081

5-61

Page 773 of 1865

5 STARTER (DIESEL ENGINE, 2.0 KW TYPE)

REMOVAL AND INSTALLATION

Removal is as follows:

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Remove the starter.

Install in the reverse order of removal.

Tightening torque:

Bolts 64—89 N-m

(6.5—9.1 m-kg, 47—66 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

76G05X-046

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly in the reverse order of disassembly.

4BG05X-107

1. Magnetic switch 7. Lever

2. Rear cover 8. Cover

3. Brush-holder assembly 9. Drive pinion and over-running

4. Yoke clutch assembly

5. Armature 10. Reduction gear

6. Front housing 11. Center bracket

5—67

Page 775 of 1865

STARTER (DIESEL ENGINE, 2.2 KW TYPE) 5

36G05X-034

36G05X-035

36G05X-036

5. Remove the front cover, and remove the lever and

springs (two).

6. Separate the yoke and center bracket.

7. Remove the cover and pull out the snap ring and

washer.

8. Remove the pinion, over-running clutch assembly

and reduction gear from the center bracket.

36G05X-037

5-69

Page 780 of 1865

5 STARTER (DIESEL ENGINE, 2.2 KW TYPE)

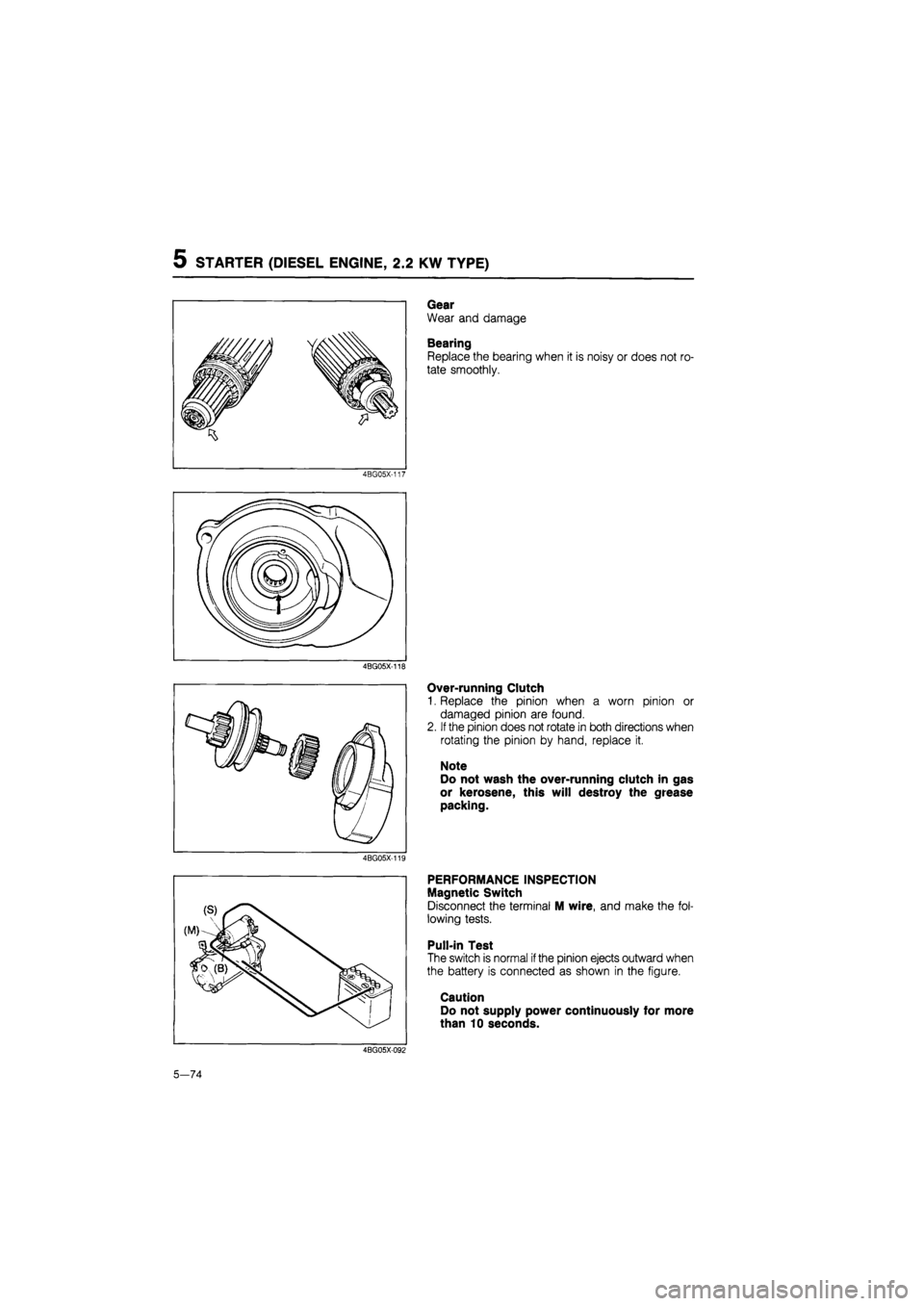

Gear

Wear and damage

Bearing

Replace the bearing when it is noisy or does not ro-

tate smoothly.

4BG05X-117

4BG05X-118

Over-running Clutch

1. Replace the pinion when a worn pinion or

damaged pinion are found.

2.

If

the pinion does not rotate in both directions when

rotating the pinion by hand, replace it.

Note

Do not wash the over-running clutch in gas

or kerosene, this will destroy the grease

packing.

4BG05X-119

PERFORMANCE INSPECTION

Magnetic Switch

Disconnect the terminal M wire, and make the fol-

lowing tests.

Pull-in Test

The switch is normal

if

the pinion ejects outward when

the battery is connected as shown in the figure.

Caution

Do not supply power continuously for more

than 10 seconds.

4BG05X-092

5—74

Page 787 of 1865

CLUTCH

OUTLINE 6— 2

STRUCTURAL VIEW 6— 2

SPECIFICATIONS 6— 3

TROUBLESHOOTING GUIDE 6— 3

ON-VEHICLE MAINTENANCE 6— 4

FLUID LEVEL 6— 4

PEDAL HEIGHT 6— 4

PEDAL FREEPLAY 6— 4

CLUTCH PEDAL 6— 5

REMOVAL 6— 5

INSPECTION 6— 6

INSTALLATION 6— 6

ADJUSTMENT 6— 6

CLUTCH MASTER CYLINDER 6— 7

REMOVAL 6— 7

DISASSEMBLY 6—8

INSPECTION 6— 9

ASSEMBLY 6— 9

INSTALLATION 6—11

CLUTCH RELEASE CYLINDER 6—11

REMOVAL 6—12

DISASSEMBLY 6-12

INSPECTION 6—13

ASSEMBLY 6—13

INSTALLATION 6—14

AIR BLEEDING 6—14

CLUTCH AND FLYWHEEL 6—15

REMOVAL 6—15

INSPECTION 6—16

INSTALLATION 6—19

76G06X-001

Page 788 of 1865

6 OUTLINE

OUTLINE

STRUCTURAL VIEW

LHD

86U06X-002

1. Clutch pedal 4. Clutch pipe 7. Clutch release bearing

2. Assist spring 5. Clutch release cylinder 8. Clutch cover

3. Clutch master cylinder 6. Clutch release fork 9. Clutch disc

6-2

Page 789 of 1865

TROUBLESHOOTING GUIDE 6

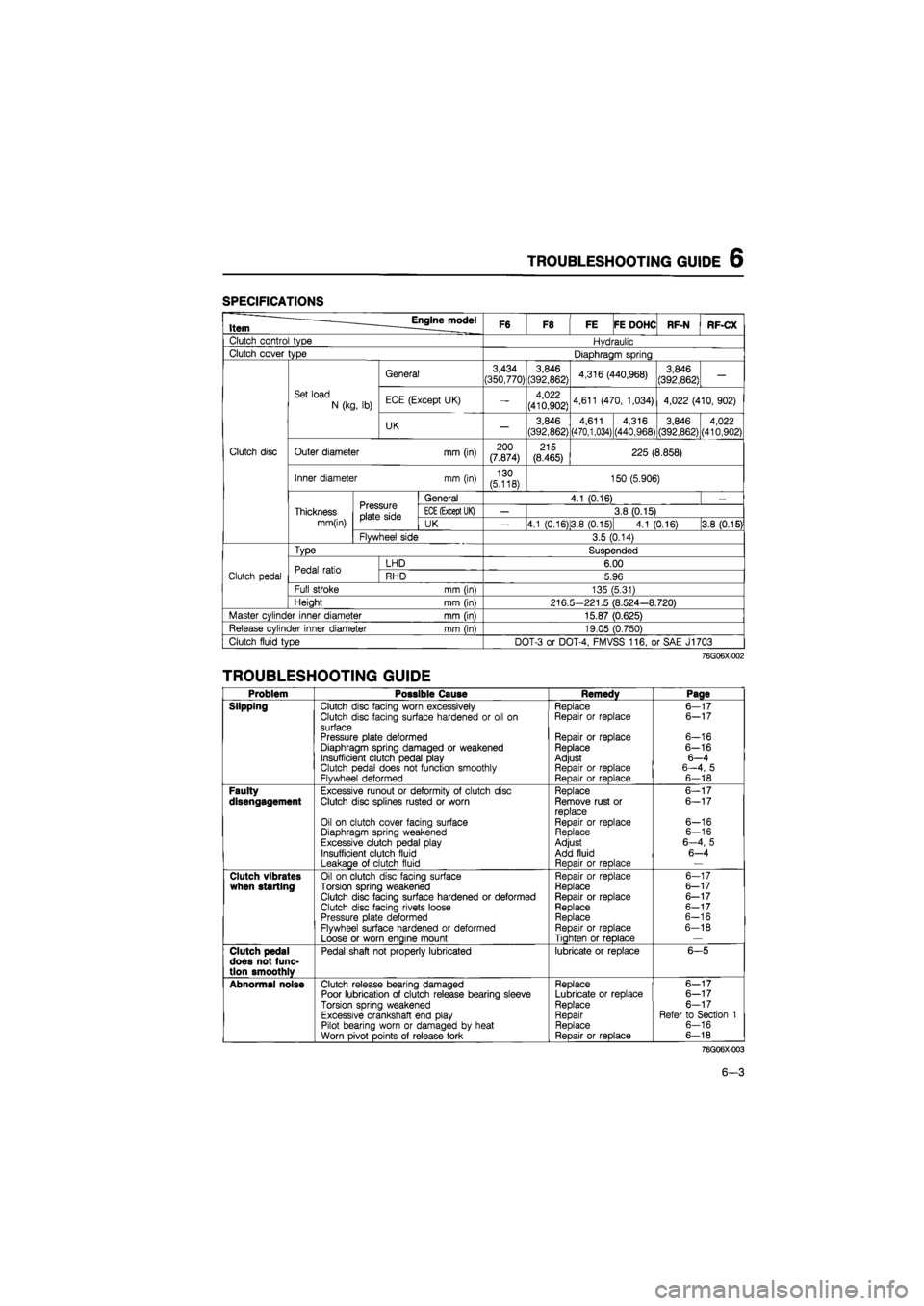

SPECIFICATIONS

Item Engine model F6 F8 FE FE DOHC RF-N RF-CX

Clutch control type Hydraulic

Clutch cover type Diaphragm spring

General 3,434

(350,770) 3,846

(392,862) 4,316 (440,968) 3,846

(392,862) —

Set load

N (kg, lb) ECE (Except UK) — 4,022

(410,902) 4,611 (470, 1,034) 4,022 (410, 902)

UK — 3,846

(392,862)

4,611 (470,1,034) 4,316

(440,968)

3,846 (392,862) 4,022 (410,902)

Clutch disc Outer diameter mm (in) 200 (7.874) 215 (8.465) 225 (8.858)

Inner diameter mm (in) 130 (5.118) 150 (5.906)

Pressure plate side

General 4.1 (0.16) —

Thickness Pressure plate side

ECE

(Except UK) — 3.8 (0.15)

mm(in)

Pressure plate side UK 4.1 (0.16)13.8 (0.15) 4.1 (0.16) 3.8 (0.15)

Flywheel side 3.5 (0.14)

Type Suspended

Pedal ratio LHD 6.00

Clutch pedal Pedal ratio RHD 5.96

Full stroke mm (in) 135 (5.31)

Height mm (in) 216.5-221.5 (8.524-8.720)

Master cylinder inner diameter mm (in) 15.87 (0.625)

Release cylinder inner diameter mm (in) 19.05 (0.750)

Clutch fluid type DOT-3 or DOT-4, FMVSS 116, or SAE J1703

76G06X-002

TROUBLESHOOTING GUIDE

Problem Possible Cause Remedy Page

Slipping Clutch disc facing worn excessively Replace 6—17 Clutch disc facing surface hardened or oil on Repair or replace 6-17

surface Pressure plate deformed Repair or replace 6-16 Diaphragm spring damaged or weakened Replace 6-16 Insufficient clutch pedal play Adjust 6—4 Clutch pedal does not function smoothly Repair or replace 6—4, 5 Flywheel deformed Repair or replace 6-18

Faulty Excessive runout or deformity of clutch disc Replace 6-17 disengagement Clutch disc splines rusted or worn Remove rust or 6—17 replace Oil on clutch cover facing surface Repair or replace 6-16 Diaphragm spring weakened Replace 6-16

Excessive clutch pedal play Adjust 6—4, 5

Insufficient clutch fluid Add fluid 6-4

Leakage of clutch fluid Reoair or reDlace —

Clutch vibrates Oil on clutch disc facing surface Repair or replace 6-17 when starting Torsion spring weakened Replace 6-17 Clutch disc facing surface hardened or deformed Repair or replace 6-17

Clutch disc facing rivets loose Replace 6-17 Pressure plate deformed Replace 6-16

Flywheel surface hardened or deformed Repair or replace 6-18

Loose or worn engine mount Tighten or replace —

Clutch pedal Pedal shaft not properly lubricated lubricate or replace 6-5 does not func-tion smoothlv

Abnormal noise Clutch release bearing damaged Replace 6—17 Poor lubrication of clutch release bearing sleeve Lubricate or replace 6-17

Torsion spring weakened Replace 6-17

Excessive crankshaft end play Repair Refer to Section 1 Pilot bearing worn or damaged by heat Replace 6-16

Worn pivot points of release fork • Reoair or replace 6-18

76G06X-003

6-3

Page 790 of 1865

6 ON-VEHICLE MAINTENANCE

6-4

ON-VEHICLE MAINTENANCE

FLUID LEVEL

1. Clean the area around the reservoir and the reser-

voir cap.

2. Check the fluid level. If the level is near or below

the "MIN" mark, add clutch fluid to the "MAX"

mark.

Fluid specification:

DOT-3 or DOT-4

(FMVSS 116, or SAE J1703)

PEDAL HEIGHT

Inspection

Measure the distance from the upper center of the

pedal pad to the firewall and ensure that the distance

is within specification.

Pedal height A:

216.5—221.5 mm (8.524—8.720 in)

Adjustment

To adjust the pedal height, loosen locknut and turn

stopper bolt or clutch switch.

PEDAL FREEPLAY

Inspection

Depress the pedal lightly by hand and measure the

freeplay to ensure that it is within specification.

Pedal freeplay: 5—13 mm (0.20—0.51 in)

Adjustment

1. Adjust the free play by loosening locknut C and

turning push rod D.

2. Check that the distance from the floor to the cen-

ter of the upper surface of the pedal pad is as

specified or more when the clutch is fully dis-

engaged.

Disengagement height B:

LHD 68 mm (2.7 in)

RHD 85 mm (3.3 in)

3. Tighten locknut C after adjustment.

Page 791 of 1865

CLUTCH PEDAL 6

CLUTCH PEDAL

REMOVAL

Remove in the sequence shown in the figure referring to the removal note.

1. Clip

2. Bolt and nut

3. Spring washer

4. Flat washer

5. Clutch pedal Assembly

6. Rod

7. Adjusting nut

8. Bushing

9. Spring seat

10. Assist spring

11. Spacer

12. Bushings

13. Clip

14. Pin

15. Spring seat

16. Bushing

17. Spacer

18. Bushing

76G06X-006

19. Clip

20. Wave washer

21. Pin

22. Push rod

23. Bushing

24. Stopper rubber

25. Pad

26. Clutch pedal

(p

U-U 0)

r Adjusting nut % £

/ I / Assist spring

"ci*

Removal Note

Before removing the clutch pedal, loosen adjusting

nut of the assist spring to relieve the spring tension.

76G06X-007

6-5

Page 792 of 1865

6 CLUTCH PEDAL

INSPECTION

Check the following, and repair or replace any faulty

parts.

1. Worn or damaged pedal bushing

2. Twisted or bent pedal

3. Worn or damaged pedal pad

76G06X-008

INSTALLATION

Install in the reverse order of removal referring to the

installation note.

Installation Note

Apply grease (lithium base, NLGI No.2) to the

bushings.

76G06X-009

ADJUSTMENT

1. Adjust the pedal height. (Refer to page 6—4.)

2. Check the pedal free play, and adjust if necessary.

(Refer to page 6—4.)

3. Adjust the installation length of the assist spring.

The installation length is adjusted by turning nut

A show in the figure and adjusting dimension B.

Standard dimension:

38.6—39.6 (1.520—1.559 in)

76G06X-010

6-6