MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 861 of 1865

INSTALLATION 7A

14. Install the clutch release cylinder.

Tightening torque: 19—26 N-m

(1.9—2.6 m-kg, 14—19 ft-lb)

76G07A-060

15. Install the gusset plates.

Tightening torque: 37—52 N-m

(3.8—5.3 m-kg, 27—38 ft-lb)

76G07A-061

16. Replace the clips at the end of the driveshafts and

joint shaft with new ones.

17. Install the joint shaft and right driveshaft as follows:

(1) Install and tighten the reamer bolts (A); then in-

stall and tighten the standard bolts (§).

Tightening torque:

® :7—10 N-m

(70—100 cm-kg, 43—61 in-lb)

(B) :42—62 Nm

(4.3—6.3 m-kg, 31—46 ft-lb)

76G07A-062

(2) Remove the SST and insert the shaft into the

transaxle.

(3) Pull the front hub outward and connect the

driveshaft to the joint shaft.

(4) Push the joint at the differential side to secure-

ly connect the driveshaft to the joint shaft.

Note

a) After installation, pull the front hub outward

to confirm that the driveshaft doesn't come

out.

b)Do not damage the oil seal.

86U07A-219

7A-55

Page 862 of 1865

7A INSTALLATION

76G07A-063

76G07A-064

18. Install the left driveshaft as follows:

(1) Pull the front hub outward and insert the

driveshaft into the transaxle.

(2) Push the joint at the differential side to connect

the driveshaft to the differential side gear.

Note

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to confirm that the driveshaft doesn't come

out.

19. Install the lower arm ball joints to the knuckles and

tighten the bolts and nuts.

Tightening torque: 43—54 N-m

(4.4—5.5 m-kg, 32—40 ft-lb)

20. Install the under cover, (except DOHC)

Note

Before installation, fill the notches with sili-

con as shown in the figure.

Tightening torque: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

21. Install the stabilizer bar control links as follows.

(1) Install the stabilizer bar control link.

(2) Adjust protrusion to 20.1 mm (0.79 in)

(3) Tighten bolt to specified torque.

Tightening torque: 16—23 N-m

(1.6—2.3 m-kg , 12—17 ft-lb)

76G07A-065

76G07A-066

22. Install the tie-rod ends and new cotter pine.

Tightening torque: 29—44 N-m

(3.0—4.5 m-kg, 22—33 ft-lb)

23. Install the splash shields.

Tightening torque: 8—11 N-m

(80—110 cm-kg, 69—95 in-lb)

24. Install the front wheels.

Tightening torque: 88—118 N-m

(9.0—12.0 m-kg, 65—87 ft-lb)

—56

Page 863 of 1865

INSTALLATION 7A

25. Install the grounds to the transaxle case.

Tightening torque:

8—11 N-m (80—115 cm-kg, 69—100 in-lb)

26. Connect the speedometer cable.

76G07A-067

76G07A-068

76G07A-069

76G07A-070

27. Install the intercooler pipe and hose. (RF-CX)

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

28. Install the brake vacuum pipe. (RF-CX)

Tightening torque:

8—11

N

m (80—110 cm-kg, 69—95 in-lb)

29. Connect the brake vacuum hose. (RF-CX)

30. Install the air cleaner assembly and connect the

air flow meter connector.

Tightening torque:

16—27 Nm (1.6—2.8 m-kg, 12—20 ft-lb)

31. Connect the distributor lead.

32. Connect the main fuse block.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

33. Install the battery carrier and battery.

34. Add the correct quantity of the specified transaxle

oil.

Specified

Type

A.T.F.: DEXRON II

Above 0°F:

API: GL-4 or GL-5

SAE 80W-90 or SAE 90

Capacity:

3.35 liters (3.6 US qt, 3.0 Imp qt)

7A-57

Page 864 of 1865

7A TRANSAXLE CONTROL

TRANSAXLE CONTROL

REMOVAL AND INSTALLATION

1. Jack up the vehicle and support it with safety stands.

2. Remove in the sequence shown in the figure.

3. Install in the reverse order of removal. 61G07X-165

86U07A-230

1. Change lever knob

2. Assist boot

3. Mounting rubber boot

4. Bolts and nuts

5. Change control rod

6. Bracket installation nuts

7. Nut and washer

8. Extension bar bracket as-

sembly and gasket

9. Bushing

10. Pipe

11. Change lever

12. Spring

13. Ball seat (upper)

14. Bushings

15. Boot

16. Holder

17. Ball seat (lower)

18. Extention bar

Note

Apply a coat of grease (lithium base, NLGI No. 2) to the change lever ball, the ball seats,

and each joint.

7A-58

Page 865 of 1865

TRANSAXLE CONTROL 7 A

63U07A-151

61G07X-192

63U07A-153

Spring

Remove the spring by prying on the hooked part of

the spring with a screwdriver.

INSPECTION

Check the following, and replace if necessary:

1. Bent control rod.

2. Wear, damage, or malfunction of any joint.

3. Damaged gear shift lever ball.

4. Weak spring.

5. Wear or damage of bushing.

INSTALLATION

Install in the reverse order of removal and note the

following:

Extension Bar

First, install the extension bar to the floor, and then

install it onto the transaxle.

Tightening torque:

31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

Bracket Installation

Tighten the bracket installation nuts to the specified

torque.

Tightening torque: 7—10 N-m

(70—100 cm-kg, 61—87 in-lb)

76G07A-071

7A-59

Page 866 of 1865

7A TRANSAXLE CONTROL

Gear Shift Lever Ball

Apply grease to the ball seat surface, and install the

upper and lower ball seat, holder, and boot.

Note

Apply grease to all joints.

61G07X-193

Spring

Make sure that the hooked part of the spring is

properly seated in the bracket groove, as shown in

the figure.

63U07A-156

Bracket Cavity

Put grease in the bracket cavity.

63U07A-157

Change Control Rod

Install the change control rod so that its relationship

with the shift lever is as shown in the figure.

Tightening torque:

16—22

N

m (1.6—2.3 m-kg, 12—17 ft-lb)

61G07X-195

7A-60

Page 867 of 1865

7B

AUTOMATIC TRANSAXLE

(Electronically Controlled and 4-Speed)

OUTLINE 7B— 2

SPECIFICATIONS 7B— 2

COMPONENT LOCATION 7B— 3

STRUCTURAL VIEW 7B— 5

OPERATION OF COMPONENTS 7B— 6

FLUID PASSAGE LOCATION 7B— 9

TROUBLESHOOTING (G4A-EL) 7B— 12

GENERAL NOTE 7B— 12

STEP 1

(WARNING CODE RETRIEVAL) 7B— 15

STEP 2

(PRELIMINARY INSPECTION) 7B— 22

STEP 3 (SIGNAL INSPECTION) 7B— 24

STEP 4 (STALL TEST) 7B— 27

STEP 5 (TIME LAG TEST) 7B— 30

STEP 6 (OIL PRESSURE TEST) 7B— 31

STEP 7 (ROAD TEST) 7B— 34

TROUBLESHOOTING (G4A-HL) 7B— 41

GENERAL NOTE 7B— 41

STEP 1

(PRELIMINARY INSPECTION) 7B— 44

STEP 2 (ELECTRICAL

SYSTEM INSPECTION) 7B— 47

STEP 3 (STALL TEST) 7B— 49

STEP 4 (TIME LAG TEST) 7B- 52

STEP 5 (ROAD TEST) 7B— 53

STEP 6 (OIL PRESSURE TEST) 7B— 58

ELECTRICAL SYSTEM

COMPONENTS 7B— 63

MODE SWITCH (G4A-EL) 7B— 63

HOLD SWITCH (G4A-EL) 7B— 63

OD OFF SWITCH (G4A-HL) 7B— 64

INHIBITOR SWITCH 7B- 65

WATER TEMPERATURE SWITCH 7B— 66

FLUID TEMPERATURE SWITCH

(G4A-EL) 7B— 66

BRAKE LIGHT SWITCH

(G4A-EL) 7B— 66

KICK-DOWN SWITCH (G4A-HL) 7B— 67

PULSE GENERATOR (G4A-EL) 7B- 68

VEHICLE SPEED SENSOR

(G4A-EL) 7B— 68

CRUISE CONTROL SWITCH

(CRUISE CONTROL UNIT) 7B— 68

IDLE SWITCH AND THROTTLE

SENSOR (G4A-EL) 7B— 68

OD RELEASE SOLENOID

VALVE (G4A-HL) 7B— 68

SOLENOID VALVES (G4A-EL) 7B— 69

NO LOAD SIGNAL (G4A-EL) 7B— 69

MODE, AND HOLD INDICATOR

LIGHT (G4A-EL) 7B— 69

OD OFF INDICATOR LIGHT

(G4A-HL) 7B— 69

EC-AT CONTROL UNIT

(G4A-EL) 7B— 69

ON-VEHICLE MAINTENANCE 7B— 71

AUTOMATIC TRANSAXLE

FLUID (ATF) 7B— 71

SELECTOR LEVER 7B— 72

THROTTLE CABLE 7B— 73

CONTROL VALVE BODY 7B— 77

OIL STRAINER 7B— 79

ADJUSTMENT OF 2-4 BRAKE

BAND 78— 80

REPLACEMENT OF

DRIVESHAFT OIL SEAL 7B— 80

OIL COOLER 7B— 81

GOVERNOR (G4A-HL) 7B— 82

REMOVAL 7B— 83

PRECAUTION 7B— 83

DISASSEMBLY 7B— 88

DISASSEMBLY-STEP 1 7B— 88

DISASSEMBLY-STEP 2 7B— 94

DISASSEMBLY-STEP 3 7B— 99

DISASSEMBLY-STEP 4 7B—103

INSPECTION AND REPAIR 7B—107

PRECAUTION 7B—107

TORQUE CONVERTER 7B—107

OIL PUMP 7B—108

CLUTCH ASSEMBLY 7B—113

SMALL SUN GEAR AND

ONE-WAY CLUTCH 7B—122

ONE-WAY CLUTCH AND

CARRIER HUB ASSEMBLY 7B-126

3-4 CLUTCH 7B—128

2-3 ACCUMULATOR 7B—132

GOVERNOR ASSEMBLY

(G4A-HL) 7B-133

LOW AND REVERSE BRAKE 7B—134

2-4 BRAKE BAND 7B—135

BAND SERVO 7B—135

OTHER INSPECTION 7B—135

CONTROL VALVE BODY

(G4A-EL) 7B-136

CONTROL VALVE BODY

(G4A-HL) 7B-155

DIFFERENTIAL 7B—177

OUTPUT GEAR 7B—181

IDLE GEAR 7B—182

BEARING COVER ASSEMBLY 7B—185

BEARING HOUSING 7B—186

ASSEMBLY 7B-187

PRECATION 7B—187

ASSEMBLY-STEP 1 7B—187

ASSEMBLY-STEP 2 7B—197

ASSEMBLY-STEP 3 7B—202

ASSEMBLY-STEP 4 7B—208

INSTALLATION 7B—215

TORQUE SPECIFICATIONS 7B—215

HYDRAULIC CIRCUIT (G4A-EL) 7B—221

HYDRAULIC CIRCUIT (G4A-HL) 7B—239

76G07B-001

Page 868 of 1865

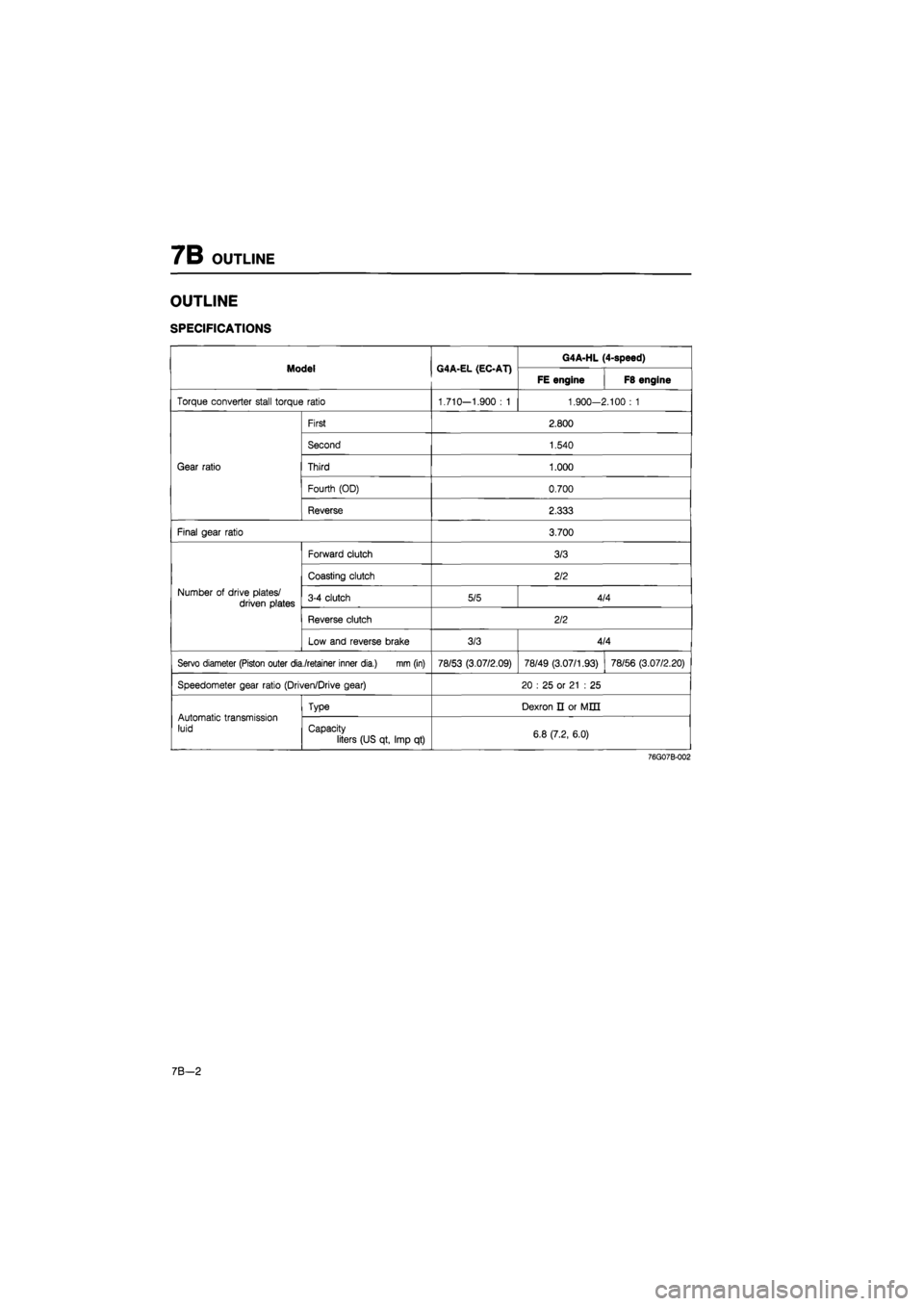

7B OUTLINE

OUTLINE

SPECIFICATIONS

Model G4A-EL (EC-AT) G4A-HL (4-speed) Model G4A-EL (EC-AT)

FE engine F8 engine

Torque converter stall torque ratio 1.710—1.900

: 1

1.900-2.100

: 1

Gear ratio

First 2.800

Gear ratio

Second 1.540

Gear ratio Third 1.000 Gear ratio

Fourth (OD) 0.700

Gear ratio

Reverse 2.333

Final gear ratio 3.700

Number

of

drive plates/ driven plates

Forward clutch 3/3

Number

of

drive plates/ driven plates

Coasting clutch 2/2

Number

of

drive plates/ driven plates 3-4 clutch 5/5 4/4 Number

of

drive plates/ driven plates

Reverse clutch 2/2

Number

of

drive plates/ driven plates

Low and reverse brake 3/3 4/4

Servo diameter (Piston outer dia./retainer inner dia.) mm (in) 78/53 (3.07/2.09) 78/49 (3.07/1.93) 78/56 (3.07/2.20)

Speedometer gear ratio (Driven/Drive gear) 20

: 25 or

21

: 25

Automatic transmission luid

Type Dexron

n or

MED

Automatic transmission luid Capacity

liters (US qt, Imp

qt)

6.8 (7.2, 6.0)

76G07B-002

7 B—2

Page 869 of 1865

OUTLINE 7B

COMPONENT LOCATION

G4A-EL

76G07B-003

1. Hold indicator light

2. EC-AT control unit

3. Vehicle speed sensor

4. Mode indicator light

5. Cruise control unit

6. Cruise control switch

7. Mode switch

8. Hold switch

9. Water temperature switch

10. Throttle sensor and idle

switch

11. Fluid temperature switch

12. EC-AT

13. Pulse genelator

14. Solenoid valves

15. Inhibitor switch

7B-3

Page 870 of 1865

7B OUTLINE

G4A-HL

1. OD OFF indicator light

2. OD OFF switch

3. Kick-down switch

4. Cruise control unit

5. Cruise control switch

6. Water temperature switch

7. Inhibitor switch

8. OD release solenoid valve

9. Automatic transaxle

76G07B-004

7B—4