MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 891 of 1865

TROUBLESHOOTING (G4A-EL) 7B

Item Indication Condition Possible cause

BRAKE LIGHT SW ON Brake pedal depressed Brake light switch or

wiring BRAKE LIGHT SW

OFF Brake pedal released

Brake light switch or

wiring

WATER TEMP SW ON Coolant temperature 72°C (162°F) or above Water temp switch or wiring WATER TEMP SW

OFF Coolant temperature lower than 65°C (149°F)

Water temp switch or wiring

ATF TEMP SW ON ATF temperature 150°C (302°F) or above Fluid temperature switch or wiring ATF TEMP SW

OFF ATF temperature lower than 143°C (289°F)

Fluid temperature switch or wiring

CRUISE CONTROL SW Not used — —

Input (Digital display)

THROTTLE SENSOR

EC-AT control unit terminal voltage All the time Throttle sensor, idle switch or wirings

VEHICLE SPEED*

Vehicle speed calculated from speed sensor signal

All the time Vehicle speed sensor, speedometer cable, or wiring

DRUM SPEED* Drum speed All the time Pulse generator or wirings

Output (Light)

1-2 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring 1-2 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 1-2 shift sol., or wiring

2-3 SOLENOID VALVE*

ON Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring 2-3 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table Control unit, 2-3 shift sol., or wiring

3-4 SOLENOID VALVE*

ON

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring 3-4 SOLENOID VALVE* OFF

Refer to page 7B—26 solenoid valve operation table

Control unit, 3-4 shift sol., or wiring

LOCK-UP SOLE-NOID VALVE*

ON Lock-up condition Control unit, lock-up sol., or wiring LOCK-UP SOLE-NOID VALVE* OFF Non-lock-up condition

Control unit, lock-up sol., or wiring

HOLD INDICATOR ON Hold mode Control unit, Hold switch, or wiring HOLD INDICATOR OFF Other modes

Control unit, Hold switch, or wiring

MODE INDICATOR ON Power or economy mode Control unit, hold switch, mode switch, or wiring MODE INDICATOR

OFF Hold mode

Control unit, hold switch, mode switch, or wiring

NO LOAD SIGNAL Not used — —

76G07B-028

7B-25

Page 892 of 1865

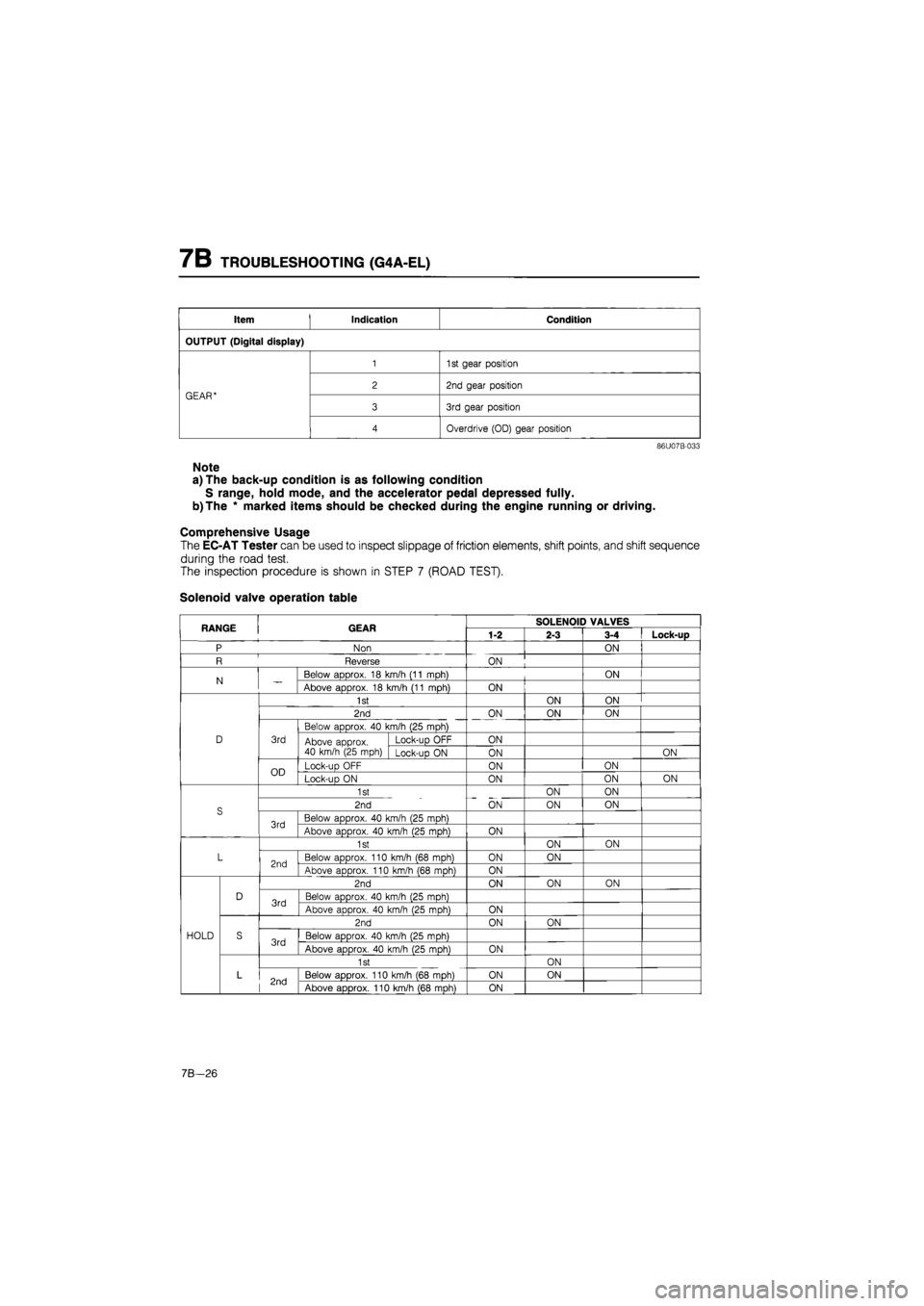

7B TROUBLESHOOTING (G4A-EL)

Item Indication Condition

OUTPUT (Digital display)

1

1

st gear position

GEAR* 2 2nd gear position GEAR*

3 3rd gear position

4 Overdrive (OD) gear position

86U07B-033

Note

a) The back-up condition is as following condition

S range, hold mode, and the accelerator pedal depressed fully.

b)The * marked items should be checked during the engine running or driving.

Comprehensive Usage

The EC-AT Tester can be used to inspect slippage of friction elements, shift points, and shift sequence

during the road test.

The inspection procedure is shown in STEP 7 (ROAD TEST).

Solenoid valve operation table

RANGE GEAR SOLENOID VALVES RANGE GEAR 1-2 2-3 3-4 Lock-up

P Non ON

R Reverse ON

N Below aDDrox. 18 km/h (11 mDh) ON N Above approx. 18 km/h (11 mph) ON

1st ON ON

2nd ON ON ON

Below approx. 40 km/h (25 mph)

D 3rd Above approx. 40 km/h (25 mph)

Lock-uo OFF ON Above approx. 40 km/h (25 mph) Lock-up ON ON ON

OD Lock-up OFF ON ON OD Lock-uo ON ON ON ON

1st ON ON

S 2nd ON ON ON S

3rd Below approx. 40 km/h (25 mph) 3rd Above approx. 40 km/h (25 mph) ON

1st ON ON

L 2nd Below approx. 110 km/h (68 mph) ON ON 2nd Above approx. 110 km/h (68 moh) ON

2nd ON ON ON

D 3rd Below approx. 40 km/h (25 moh) 3rd Above approx. 40 km/h (25 moh) ON

2nd ON ON

HOLD S 3rd Below approx. 40 km/h (25 mph) 3rd Above approx. 40 km/h (25 mph) ON

1st ON

L 2nd Below approx. 110 km/h (68 mph) ON ON 2nd Above approx. 110 km/h (68 mph) ON

7B—26

Page 893 of 1865

TROUBLESHOOTING (G4A-EL) 7B

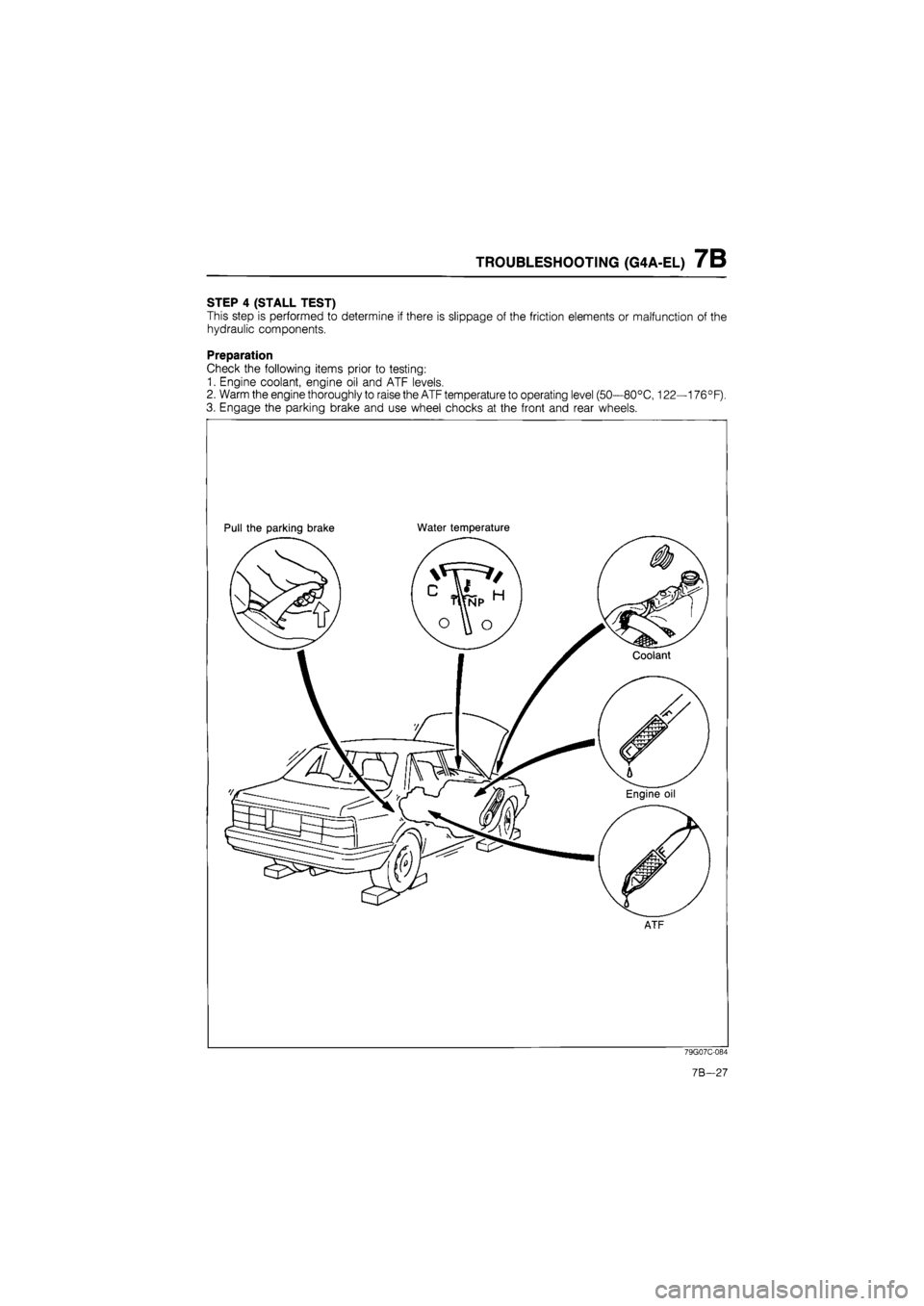

STEP 4 (STALL TEST)

This step is performed to determine if there is slippage of the friction elements or malfunction of the

hydraulic components.

Preparation

Check the following items prior to testing:

1. Engine coolant, engine oil and ATF levels.

2. Warm the engine thoroughly to raise the ATF temperature to operating level (50—80°C, 122—176°F).

3. Engage the parking brake and use wheel chocks at the front and rear wheels.

Pull the parking brake Water temperature

ATF

79G07C-084

7B-27

Page 894 of 1865

7B TROUBLESHOOTING (G4A-EL)

Procedure

86U07B-034

1. Block the wheels and apply the parking brake.

2. Connect a tachometer to the engine.

3. Shift the selector lever to R.

4. Firmly depress the foot brake with the left foot, and gently depress the accelerator pedal with the right.

5. When the engine speed no longer increases, quickly read the engine speed and release the ac-

celerator.

Caution

Steps 4 ->• 5 must be done within 5 seconds.

6. Move the selector lever to N and let the engine idle for at least one minute.

Caution

The reason for idling for at least one minute is to cool the ATF and to prevent deterioration

of the fluid.

7B-28

Page 895 of 1865

TROUBLESHOOTING (G4A-EL) 7B

7. Perform the stall test for the following ranges in the same manner.

(1) D range (4) L range

(2) D range (Hold) (5) L range (Hold)

(3) S range (Hold)

Caution

Be sure to allow sufficient cooling time between each stall test.

Engine stall speed: D.S.L range 2170—2270 rpm

R range 2130—2230 rpm

Note

The stall test can be performed with the EC-AT Tester in place of a tachometer.

Drum stall speed indication: 0 rpm

76G0/B-029

Evaluation

Condition Possible cause

Above specification

In all ranges Insufficient line

pressure

Worn oil pump

Above specification

In all ranges Insufficient line

pressure Oil leakage from oil pump, control valve, and/or transmission case

Stuck pressure regulator valve

Above specification

In forward ranges Forward clutch slipping One-way clutch 1 slipping

Above specification

In D range One-way clutch 2 slipping

Above specification

In S (Hold) and L (Hold) ranges Coasting clutch slipping

Above specification In D (Hold) and S (Hold) ranges 2-4 brake band slipping Above specification

In R, L and L (Hold) ranges Low and reverse brake slipping

Above specification

In R range

Low and reverse brake slipping Reverse cluch slipping Perform road test to determine whether problem is low and reverse brake or reverse clutch

a) Engine brake applied in 1st ...Reverse clutch

b) Engine brake not applied in 1st ...Low and reverse brake

Within specification All shift control elements within transmission are func-

tioning normally.

Below specification

Engine out of tune

Below specification One-way clutch slipping within torque converter

86U07B-036

7B-29

Page 896 of 1865

7B TROUBLESHOOTING (G4A-EL)

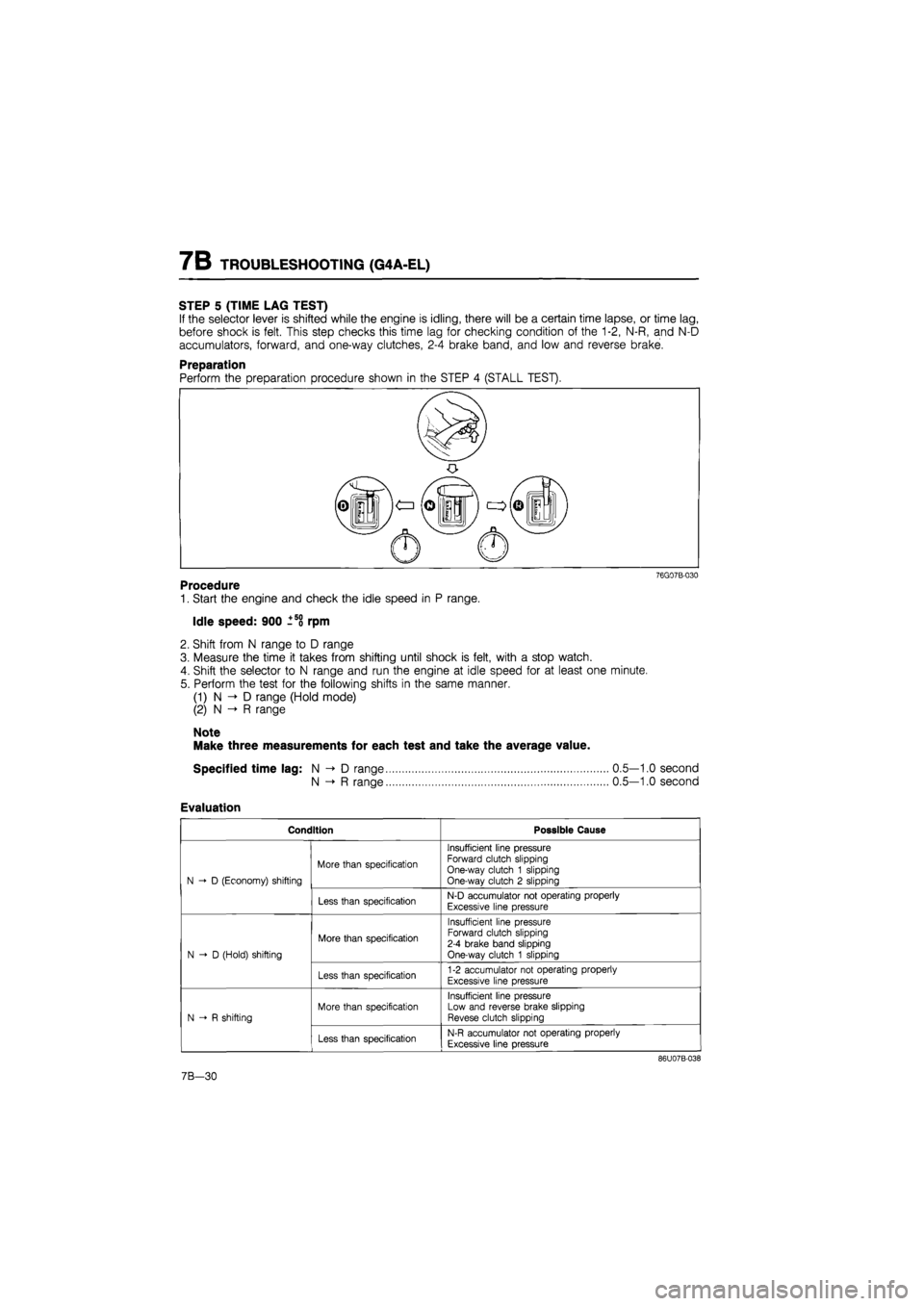

STEP 5 (TIME LAG TEST)

If the selector lever is shifted while the engine is idling, there will be a certain time lapse, or time lag,

before shock is felt. This step checks this time lag for checking condition of the 1-2, N-R, and N-D

accumulators, forward, and one-way clutches, 2-4 brake band, and low and reverse brake.

Preparation

76G07B-030

Procedure

1. Start the engine and check the idle speed in P range.

Idle speed: 900 ±58 rpm

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt, with a stop watch.

4. Shift the selector to N range and run the engine at idle speed for at least one minute.

5. Perform the test for the following shifts in the same manner.

(1) N D range (Hold mode)

(2) N -» R range

Note

Make three measurements for each test and take the average value.

Specified time lag: N -> D range

N -»• R range

Evaluation

Condition Possible Cause

N D (Economy) shifting

More than specification

Insufficient line pressure Forward clutch slipping One-way clutch 1 slipping One-way clutch 2 slipping N D (Economy) shifting

Less than specification N-D accumulator not operating properly

Excessive line pressure

N-D (Hold) shifting

More than specification

Insufficient line pressure Forward clutch slipping 2-4 brake band slipping One-way clutch 1 slipping N-D (Hold) shifting

Less than specification 1-2 accumulator not operating properly

Excessive line pressure

N R shifting

More than specification

Insufficient line pressure Low and reverse brake slipping Revese clutch slipping N R shifting

Less than specification N-R accumulator not operating properly

Excessive line pressure

86U07B-038

0.5—1.0 second

0.5—1.0 second

7B-30

Page 897 of 1865

TROUBLESHOOTING (G4A-EL) 7B

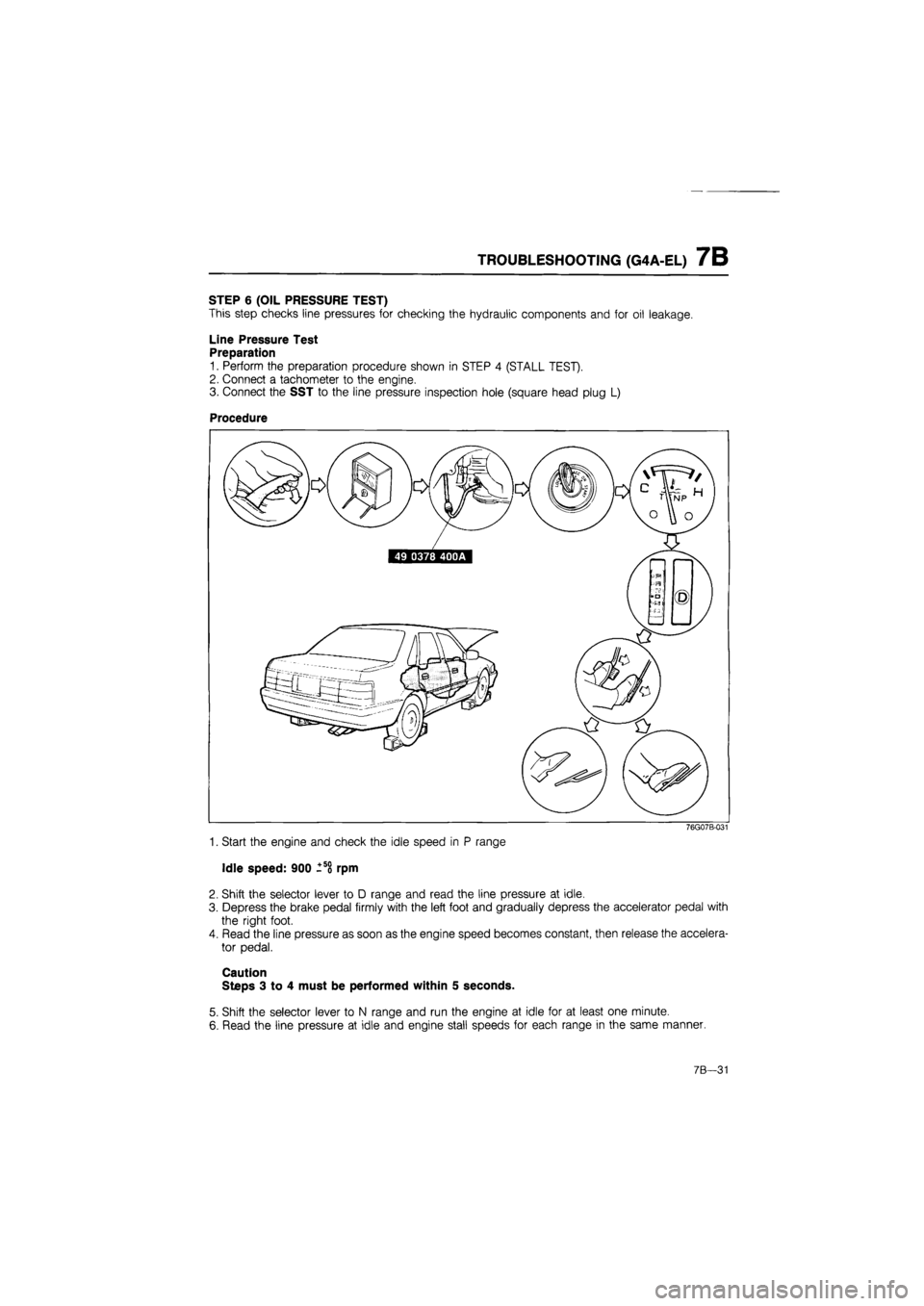

STEP 6 (OIL PRESSURE TEST)

This step checks line pressures for checking the hydraulic components and for oil leakage.

Line Pressure Test

Preparation

1. Perform the preparation procedure shown in STEP 4 (STALL TEST).

2. Connect a tachometer to the engine.

3. Connect the SST to the line pressure inspection hole (square head plug L)

Procedure

76G07B-031

1. Start the engine and check the idle speed in P range

Idle speed: 900 -so rpm

2. Shift the selector lever to D range and read the line pressure at idle.

3. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

4. Read the line pressure as soon as the engine speed becomes constant, then release the accelera-

tor pedal.

Caution

Steps 3 to 4 must be performed within 5 seconds.

5. Shift the selector lever to N range and run the engine at idle for at least one minute.

6. Read the line pressure at idle and engine stall speeds for each range in the same manner.

7B—31

Page 898 of 1865

7B TROUBLESHOOTING (G4A-EL)

Specified line pressure:

Line pressure kPa, (kg/cm2, psi)

Range DSL R

When idling 353-432 (3.6-4.4, 51-63) 598—942 (6.1-9.6, 87—137)

At stall speed 873-1040 (8.9-10.6, 127-151) 1668-2011 (17.0-20.5, 242-292)

76G07B-032

Evaluation

Line pressure Possible location of problem

Low pressure in every position

Worn oil pump

Fluid leaking from oil pump, control valve body, or transaxle case

Pressure regulator valve sticking

Low pressure in D and S only Fluid leaking from hydraulic circuit of forward clutch

Low pressure in R only Fluid leaking from hydraulic circuit of low and reverse brake

Higher than specification

Throttle valve sticking

Throttle modulator valve sticking

Pressure regulator valve sticking

76G07B-033

7B—32

Page 899 of 1865

TROUBLESHOOTING (G4A-EL) 7B

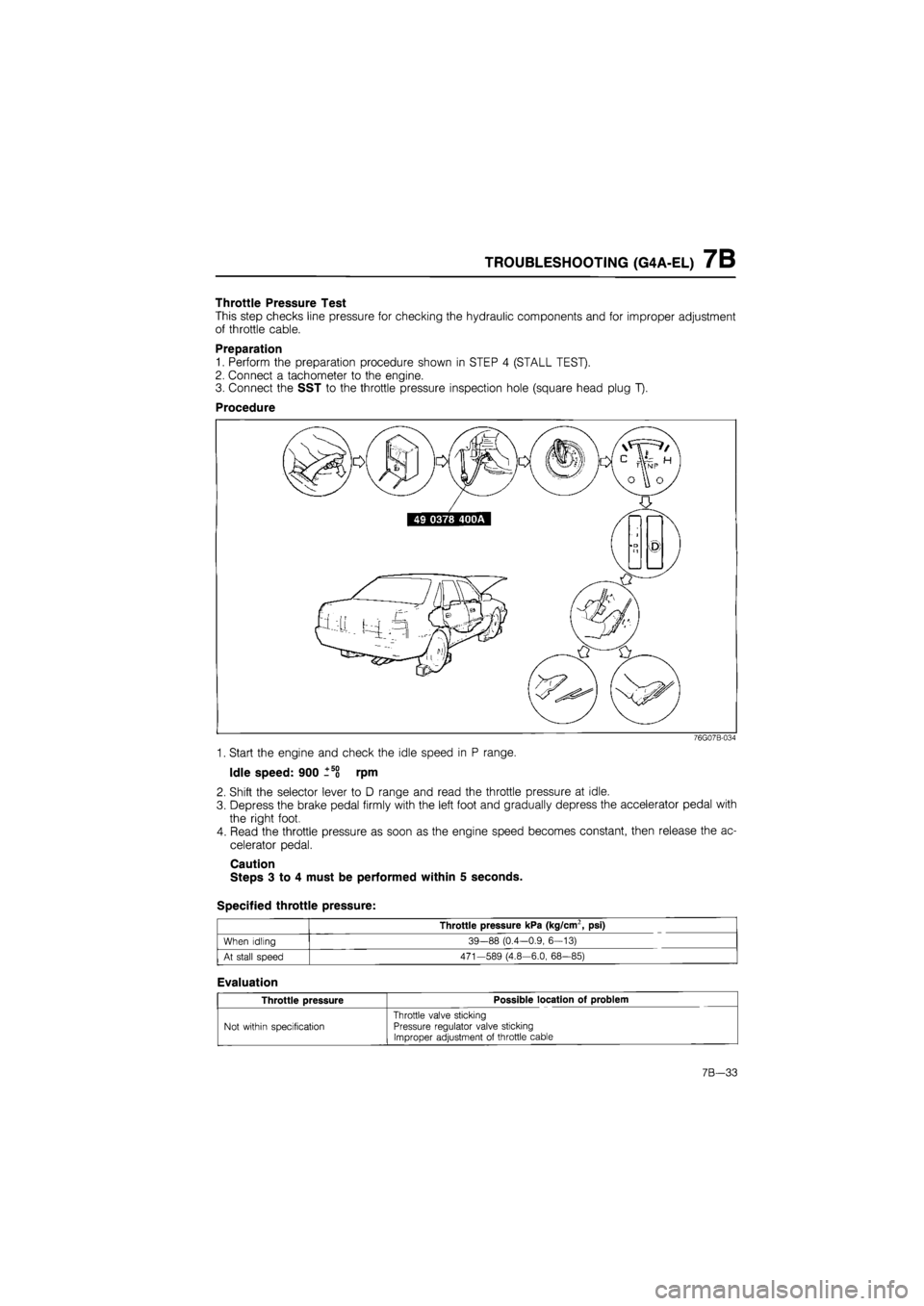

Throttle Pressure Test

This step checks line pressure for checking the hydraulic components and for improper adjustment

of throttle cable.

Preparation

1. Perform the preparation procedure shown in STEP 4 (STALL TEST).

2. Connect a tachometer to the engine.

3. Connect the SST to the throttle pressure inspection hole (square head plug T).

Procedure

76G07B-034

1. Start the engine and check the idle speed in P range.

Idle speed: 900 _5o rpm

2. Shift the selector lever to D range and read the throttle pressure at idle.

3. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with

the right foot.

4. Read the throttle pressure as soon as the engine speed becomes constant, then release the ac-

celerator pedal.

Caution

Steps 3 to 4 must be performed within 5 seconds.

Specified throttle pressure:

Throttle pressure kPa (kg/cm2, psi)

When idling 39-88 (0.4—0.9, 6—13)

At stall speed 471—589 (4.8—6.0, 68—85)

Evaluation

Throttle pressure Possible location of problem

Not within specification

Throttle valve sticking Pressure regulator valve sticking Improper adjustment of throttle cable

7B—33

Page 900 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 7 (ROAD TEST)

This step is performed to inspect for problems at the various ranges. If these tests show any problems,

adjust or replace by referring to the electronic system component or mechanical sections.

Caution

Perform the test at normal ATF operating temperature (50—80°C, 122—176°F).

D Range Test

Shift point, shift pattern, and shift shock

1. Shift the selector lever to D range and select the Power mode.

2. Accelerate the vehicle with half and full throttle valve opening.

Note

Throttle sensor voltage of the EC-AT Tester represents the throttle valve opening.

3. Check that 1-2, 2-3 and 3-OD up-shifts and downshifts and lock-up are obtained. The shift points

must be as shown in the D range (Power) shift diagram.

Note

a) Drum speed (rpm) of the EC-AT Tester represents the shift point.

b) Vehicle speed of the EC-AT Tester and speedometer and vehicle speed on a chassis

roller may not meet the specified shift pattern because of tire size. Therefore, check

the shift points with the Drum speed.

c) There is no lock-up when the coolant temperature is below 72°C (162°F).

d) There is no overdrive when the cruise control is operating and there is a 3 km/h (1.9

mph) difference between the pre-set cruise speed and vehicle speed, or set or resume

switch is ON.

e) There is no lock-up when the brake pedal is depressed.

4. Check the up-shifts for shift shock or slippage in the same manner.

5. While driving in OD, shift the selector lever to S range and check that 4-3 downshift immediately

occurs, then decelerate and check that engine braking effect is felt in only 3rd gear.

7B—34