MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 881 of 1865

TROUBLESHOOTING (G4A-EL) 7B

STEP 1 (WARNING CODE RETRIEVAL)

Self-diagnosis Function

The self-diagnosis system, which is integrated in the EC-AT control unit, diagnoses malfunction of the

main sensors (input) and solenoid valves (output), and the EC-AT control unit.

Malfunctions which have happened or are continuing are memorized in the EC-AT control unit as specific

codes.

The EC-AT Tester is used to retrieve these warning codes. Each malfunction is indicated by a code

number and buzzer as shown the table below.

Code Number

Code number Location of malfunction Buzzer

06 Vehicle speed sensor or circuit JliUli c

12 Throttle sensor or circuit rui r

55 Pulse genelator or circuit nnnnruiii r

60 1-2 shift solenoid valve or circuit jinnnnn r

61 2-3 shift solenoid valve or circuit nnnnnruL_[

62 3-4 shift solenoid valve or circuit nnnnnn nn r

63 Lock-up solenoid valve or circuit

_ 1 0,4 sec

rnnnnn ihi J r1.2sec J | _1.fi sec

76G07B-213

EC-AT Tester

Assembly of EC-AT tester

1. Set the plate (49 G019 912) onto the EC-AT tester

body (49 G019 901 A).

2. Connect the adapter harness (49 G019 911) to

the EC-AT tester body.

3. Select the code select switch to A position.

4. Select the select switch to NEW 626 position.

76G07B-603

7B—15

Page 882 of 1865

7B TROUBLESHOOTING (G4A-EL)

Components

EC-AT Tester (49 G019 9A2) Plate 49 G019 912

Tester body

49 G019 901A

Adapter harness

49 G019 911

86U07B-013

7B-16

Page 883 of 1865

TROUBLESHOOTING (G4A-EL) 7B

06 4 second period

55 4 second period

63

-*•

4 second period

Repeats above

General Note

1. If there is more than one malfunction, the code

numbers will be displayed on the tester one by one

in a numerical order. In the case of malfunctions,

55, 06, and 63, the code numbers are displayed

in an order of 06, 55, then 63. The display is as

shown.

86U07B-018

When the service connector

is not grounded

Malfunctions YES

NO

Hold indicator YES

flashing NQ

YES

NO

Memory in control unit

2. The hold indicator flashes to indicate the same pat-

tern as the buzzer of the EC-AT Tester when the

EC-AT service connector is grounded.

When the EC-AT service connector is not ground-

ed, the indicator flashes in a constant frequency

while a malfunction is occurring and goes out

if

the

malfunction recovers. However, the warning code

is memorized in the EC-AT control unit.

76G07B-015

Sensors-

Solenoid-valve

Fail-safe program Proces--\Out sing -v puts

The EC-AT control unit has a built-in fail-safe func-

tion for the throttle sensor, the pulse generator, and

the 1-2, 2-3, and 3-4 shift solenoid valves.

If a malfunction occurs, the EC-AT control unit will

control operation of the remaining components ac-

cording to a preset fail-safe program.

The vehicle may still be driven, although the driv-

ing performance will be slightly affected.

79G07C-062

4. The memory of warning codes is canceled by dis-

connecting the negative battery terminal for ap-

prox. five seconds.

79G07C-063

7B-17

Page 884 of 1865

7B TROUBLESHOOTING (G4A-EL)

Retrieval Procedure

1. Locate the service connector.

86U07B-019

76G07B-214

11 IDLFC

5» O | || KICK DOWNS* _ If, DEPRESS

|[BRAKE UORRSW

MNMWE STF *

° M CRUISE CONTROL SW

CDS®> *• PI ^ SPEED DROPS

Gf Aft

•

OO ou

I I

w

6019 HI NOW* XIKI

CO , LTQ

MUX

IN

JAP"

76G07B-016

2. Ground the ground connector of the EC-AT

Tester.

3. Connect the 6-pin connector of the EC-AT Tester

to the service connector.

Note

The service connector is blue-colored con-

nector.

4. Ground the 1 pin service connector.

Note

The service connector is blue-colored con-

nector.

5. Turn the ignition switch ON.

6. Check that "88" flashes on the digital display and

the buzzer sounds for three seconds after turning

the ignition switch ON.

7. If "88" does not flash, check the service connec-

tor wiring.

8. If "88" flashes and the buzzer sounds continuously

for more than 20 seconds, check wiring to 2M ter-

minal of the EC-AT control unit for short-circuit then

replace the EC-AT control unit and repeat steps

3 and 4.

9. Note the code numbers and check for the causes

by referring to the Inspection Procedure shown on

pages 7B—19 to 7B—21, repair as necessary.

Note

After repairs are made, recheck for code num-

bers by performing the "After-repair

procedure."

7B—18

Page 885 of 1865

TROUBLESHOOTING (G4A-EL) 7B

79G07C-068

Drive at 50

km/h

(31

mph)

Kick-down

Stop

the

vehicle

79G07C-069

After-repair Procedure

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery terminal for at least five sec-

onds, then reconnect it.

2. Remove the EC-AT tester if it is connected.

3. Drive the vehicle at 50 km/h (31 mph), then de-

press the accelerator pedal fully to activate kick-

down. Stop the vehicle gradually.

KICK goimsv

BRAKE LIGHTS*

CRUISE CONTROL

C V,. DEPRESS FULL*

Ox

azsa

ORUti rpn

"J

i"

•

rm uu

£ZL ofF

4. Reconnect the EC-AT tester to the 6-pin service

connector.

5. Ground the 1 -pin service connector with a jumper

wire.

6. Turn the ignition switch ON.

7. Check that no code numbers are displayed.

79G07C-070

Inspection Procedure

No. 06 code display (Vehicle speed sensor)

76G07B-017

7B-19

Page 886 of 1865

7B TROUBLESHOOTING (G4A-EL)

No. 12 code display (Throttle sensor)

76G07B-018

No. 55 code display (Pulse generator)

Is there poor connection at connector? YES Repair or replace.

NO

Does EC-AT Tester display drum speed? (Refer to STEP 3-Signal Inspection)

YES Pulse generator OK.

Cancel memory of code number.

NO

NO Is there 200—400 12 between terminals of pulse generator connector? (Refer to page 7B—68)

NO Replace pulse generator. Is there 200—400 12 between terminals of pulse generator connector? (Refer to page 7B—68)

YES YES Check for open or short-circuit in wiring. Check for open or short-circuit in wiring.

76G07B-019

No. 60, 61, 62, or 64 code display (1-2 shift, 2-3 shift, or 3-4 shift solenoid valve)

7B-20

Page 887 of 1865

TROUBLESHOOTING (G4A-EL) 7B

76G07B-020

No. 63 code display (Lock-up solenoid valve)

76G07B-021

7B—21

Page 888 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 2 (PRELIMINARY INSPECTION)

In this step, the fundamental points related to the automatic transaxle are checked. These points must

be kept in the correct condition at all times in order to assure proper operation of the automatic transaxle.

1. Automatic Transmission Fluid (ATF)

Check ATF level and condition. (Refer to page 7B—71)

2. Selector Lever

Check selector lever position and adjust if necessary. (Refer to page 7B—72)

76G07B-022

3. Throttle cable

(1) Check the inner and outer cable for damage.

(2) Make sure that the accelerator operates

smoothly.

76G07B-023

4. Idle Speed

Check idle speed. (Refer to Section 4B)

5. Tire Inflation Pressure

Check tire inflation pressure. (Refer to Section 12)

76G07B-024

6. Inhibitor Switch

Check the inhibitor switch for operation. (Refer to

page 7B—65)

76G07B-025

7B-22

Page 889 of 1865

TROUBLESHOOTING (G4A-EL) 7B

7. Oil Leakage

Check for oil leakage.

(1) Warm up the ATF.

(2) Apply the parking brake and block the wheels

to prevent the vehicle from rolling.

(3) Shift the selector lever to R range.

(4) Check if oil leaks from the following oil seals

or gaskets.

(5) If oil leaks, replace the oil seal or gasket.

76G07B-026

Check for fluid leaks; the following figure shows the locations where fluid leakage may possibly occur.

1. Oil pan

2. Control valve body cover

3. Oil pump

4. Inhibitor switch

5. Speedometer driven gear

6. Pulse generator

7. Oil filler tube

8. Throttle cable

9. Bearing cover

10. Driveshaft

11. Square head plug

12. Transaxle case

13. Drain plug

14. Oil cooler return pipe

15. Oil cooler outlet pipe

16. Fluid temperature switch

17. Blind plugs

76G07B-027

7B—23

Page 890 of 1865

7B TROUBLESHOOTING (G4A-EL)

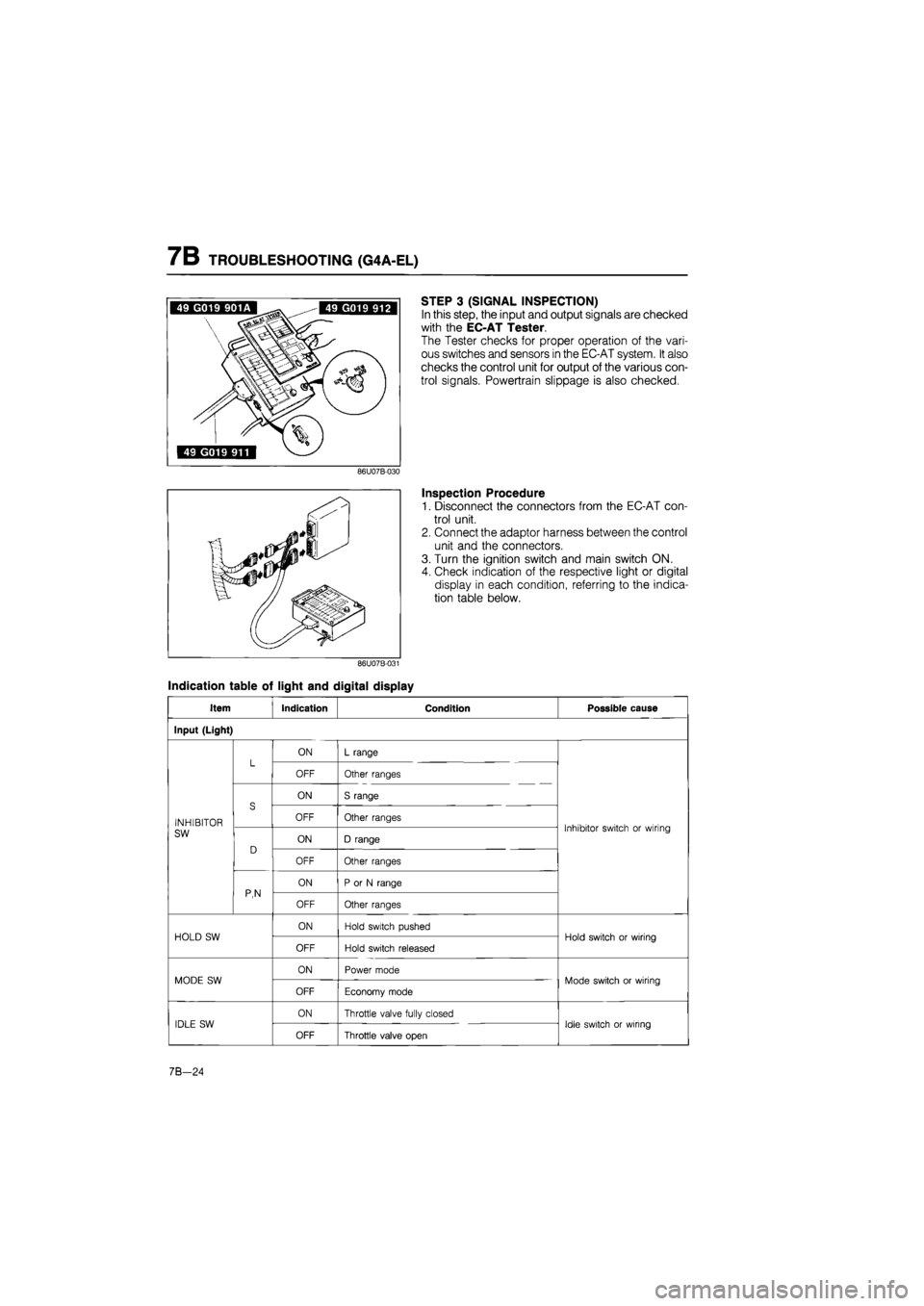

STEP 3 (SIGNAL INSPECTION)

In this step, the input and output signals are checked

with the EC-AT Tester.

The Tester checks for proper operation of the vari-

ous switches and sensors in the EC-AT system. It also

checks the control unit for output of the various con-

trol signals. Powertrain slippage is also checked.

Inspection Procedure

1. Disconnect the connectors from the EC-AT con-

trol unit.

2. Connect the adaptor harness between the control

unit and the connectors.

3. Turn the ignition switch and main switch ON.

4. Check indication of the respective light or digital

display in each condition, referring to the indica-

tion table below.

Indication table of light and digital display

Item Indication Condition Possible cause

Input (Light)

L ON L range L OFF Other ranges

S

ON S range

INHIBITOR

S OFF Other ranges Inhibitor switch or wiring SW

D ON D range

Inhibitor switch or wiring

D

OFF Other ranges

P,N

ON P or N range P,N OFF Other ranges

HOLD SW ON Hold switch pushed Hold switch or wiring HOLD SW

OFF Hold switch released

Hold switch or wiring

MODE SW ON Power mode Mode switch or wiring MODE SW

OFF Economy mode

Mode switch or wiring

IDLE SW ON Throttle valve fully closed Idle switch or wiring IDLE SW

OFF Throttle valve open

Idle switch or wiring

7B-24