service MAZDA MX-5 1994 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 1050 of 1708

SRS AIR BAG SYSTEM Possiblecause Defective wiring harness Defective S-sensor Defective diagnostic module Flowchart No.16 Step 1 Carry out "Before Servicing" procedure under GEN- ERAL PROCEDURES, page T-1 60. Step 2 1. Disconnect the diagnostic module connector. 2. Check for continuity between terminal 1 H (GIB) of the diagnostic module connector and ground. Continuity Action I Symptom Yes I Go to Step 3 I Service Code 52 Step 3 1. Disconnect the orange and blue S-sensor connectors. 2. Check for continuity between terminal B of the S-sensor and ground. No Replace diagnostic module (Refer to page T-208) I No 1 Re~lace wirina harness I Continuity Yes Action Replace S-sensor (Refer to page T-213) Possible cause Internal failure of diagnostic module Flowchart No.17 Remedy Replace the diagnostic module. (Refer to page T-208.) Symptom Service Code 53 Gartner Banana

Page 1051 of 1708

SRS AIR BAG SYSTEM DRIVER-SIDE AIR BAG MODULE Removal I Installation Warning 4 Handling the air bag module improperly can accidently deploy the air bag, which may serious- ly injure you. Read SERVICE WARNINGS, page T-159, before handling the air bag module. 1. Carry out "Before Servicing" procedure under GENERAL PROCEDURES, page T-160. 2. Remove in the order shown in the figure. 3. Install in the reverse order of removal. 4. Follow the troubleshootina flowchart (page T-160) to verify that the air bag system is operating normally. 1. Bolts 2. Support rope 3. Driver-side air bag module Installation note . . . . . . . . . . . . . . . . . below Installation note Driver-side air bag module 1. Connect the blue and orange clock spring connectors. 2. Connect the negative battery cable. 3. Turn the ignition switch to ON and verify that service code 32 is set. 4. If another service code is set, troubleshoot the system. 5. If service code 32 is set, turn the ignition switch to OFF and disconnect the negative battery cable. 6. Disconnect the orange and blue clock spring connec- tors. 7. Install the driver-side air bag module. Gartner Banana

Page 1052 of 1708

SRS AIR BAG SYSTEM T PASSENGER-SIDE AIR BAG MODULE Removal I Installation b Warning Handling the air bag module improperly can accidently deploy the air bag, which may serious- ly injure you, Read SERVICE WARNINGS, page T-159, before handling the air bag module. 1. Carry out "Before Servicing" procedure under GENERAL PROCEDURES, page T-160. 2. Remove the glove compartment. 3. Remove in the order shown in the figure. 4. Install in the reverse order of removal. 1. Bolts 2. Support rope 3. Passenger-side air bag module Installation note . . . . . . . . . . . . . . . . . below Installation note Passenger-side air bag module 1. Connect the blue and orange clock spring connectors. 2. Connect the negative battery cable. 3. Turn the ignition switch to ON and verify that service code 33 is set. 4. If another service code is set, troubleshoot the system. 5. If service code 33 is set, turn the ignition switch to OFF and disconnect the negative battery cable. 6. Disconnect the orange and blue clock spring connec- tors. 7. Install the driver-side air bag module. Gartner Banana

Page 1054 of 1708

SRS AIR BAG SYSTEM T 2-PIN CONNECTOR I CLOCK SPRING Inspection Warning Handling the air bag module improperly can accl- dently deploy the air bag, which may seriously in- jure you. Read SERVICE WARNINGS, page T-159, before handling the air bag module. 1. Carry out "Before Servicing" procedure under GENER- AL PROCEDURES, page T-160. 2. Remove the Driver-side air bag module. (Refer to page T-206.) 3. Check for continuity between terminals of the clock spring. 4. If not as specified, replace the combination switch. (Refer to page T-18.) 5. Connect the blue and orange clock spring connectors. 6. Check if the pin B of the clock spring connector (harness- side) is broken. 7. If pin B is broken, replace the wiring harness. 8. Check if the pin B of the driver-side air bag module con- nector (on clock spring) is broken. 9. If pin B is broken, replace the combination switch. 10. Disconnect the diagnostic module connector. Terminals 11. Connect the blue and orange clock spring connectors. A 0 12. Check for continuity between terminals B and C of the clock spring. 13. If continuity exists, replace the combination switch. 1 0---0: Continuity B 0 C n 2A n 28 0 3A 0 Gartner Banana

Page 1063 of 1708

Before beginning any service procedure. refer to section T of this manual for I air bag system service warnings and audio antitheft system alarm conditions . HEATER AND AIR CONDITIONER SYSTEMS ....................................... INDEX U- 2 ................................... HEATER U- 2 AIR CONDITIONER ......................... U- 3 TROUBLESHOOTING ......................... U- 4 CIRCUIT DIAGRAM ......................... U- 4 TROUBLESHOOTING GUIDE ................ U- 5 ..................................... HEATER U-15 ........................ STRUCTURAL VIEW U-15 HEATER UNIT .............................. U-16 BLOWER UNIT ............................. U-18 HEATER CONTROL UNIT .................... U-20 AIR CONDITIONER ........................... U-23 PREPARATION ............................. U-23 STRUCTURAL Vl EW ........................ U-23 SERVICE WARNINGS ....................... U-24 SERVICE CAUTIONS ........................ U-24 REFRIGERANT SYSTEM SERVICE PROCEDURE .............................. U-25 COOLING UNIT ............................. U-30 CONDENSER AND RECEIVER DRIER ........ U-33 REFRIGERANT LINES ....................... U-35 CONDENSER FAN .......................... U-36 AIC RELAY ................................. U-37 ................... CONDENSER FAN RELAY U-37 REFRIGERANT PRESSURE SWITCH ......... U-37 NC COMPRESSOR ......................... U-38 45U0Ux-001 Gartner Banana

Page 1077 of 1708

HEATER u HEATER STRUCTURAL VIEW 1. Heater unit 45UOUX401 3. Heater control unit Removal 1 Installation ......... page U-16 Removal I lnstallation ......... page U-20 Disassembly / Assembly ...... page U-17 Disassembly l Assembly ...... page U-21 Inspection ................... page U-17 Inspection ................... page U-22 2. Blower unit Adjustment .................. page U-22 Removal 1 Installation ......... page U-18 4. Cooling unit Disassembly I Assembly ...... page U-19 Removal I Installation ......... page U-30 Inspection ................... page U-19 Disassembly / Assembly ...... page U-31 w Note Even in vehicles not equipped with NC, there is a cooling unit. If it is necessary to remove this unit to service the heater, then be sure to reinstall the cooling unit into its original position after servicing is complete. Gartner Banana

Page 1086 of 1708

u AIR CONDITIONER SERVICE WARNINGS Storing Refrigerant The refrigerant container is highly pressurized. If it is subjected to high heat, it could explode, scattering u metal fragments and liquid refrigerant that can seri- ously injure you. Store the refrigerant at tempera- tures below 40°C (1 04°F). Handling Refrigerant Handling liquid refrigerant is dangerous. A drop of it on the skin can result in localized frostabite. When handling the refrigerant, wear gloves and safety goggles. If refrigerant splashes into the eyes, im- mediately wash them with clean water and consult a doctor. SERVICE CAUTIONS Compressor oil (ND-OILS) Do not spill compressor oil on the vehicle. A drop of compressor oil on the vehicle surface can eat away at the paint. If oil gets on the vehicle, wipe it off im- mediately. b PAG compressor oil (ND-OILS) has a higher mois- ture absorption efficiency than the previously used mineral oil. If moisture mixes with the compressor oil, the refrigerant system could be damaged. There- fore, install caps immediately after using the com- pressor oil or removing refrigerant system parts to prevent moisture absorption. Gartner Banana

Page 1087 of 1708

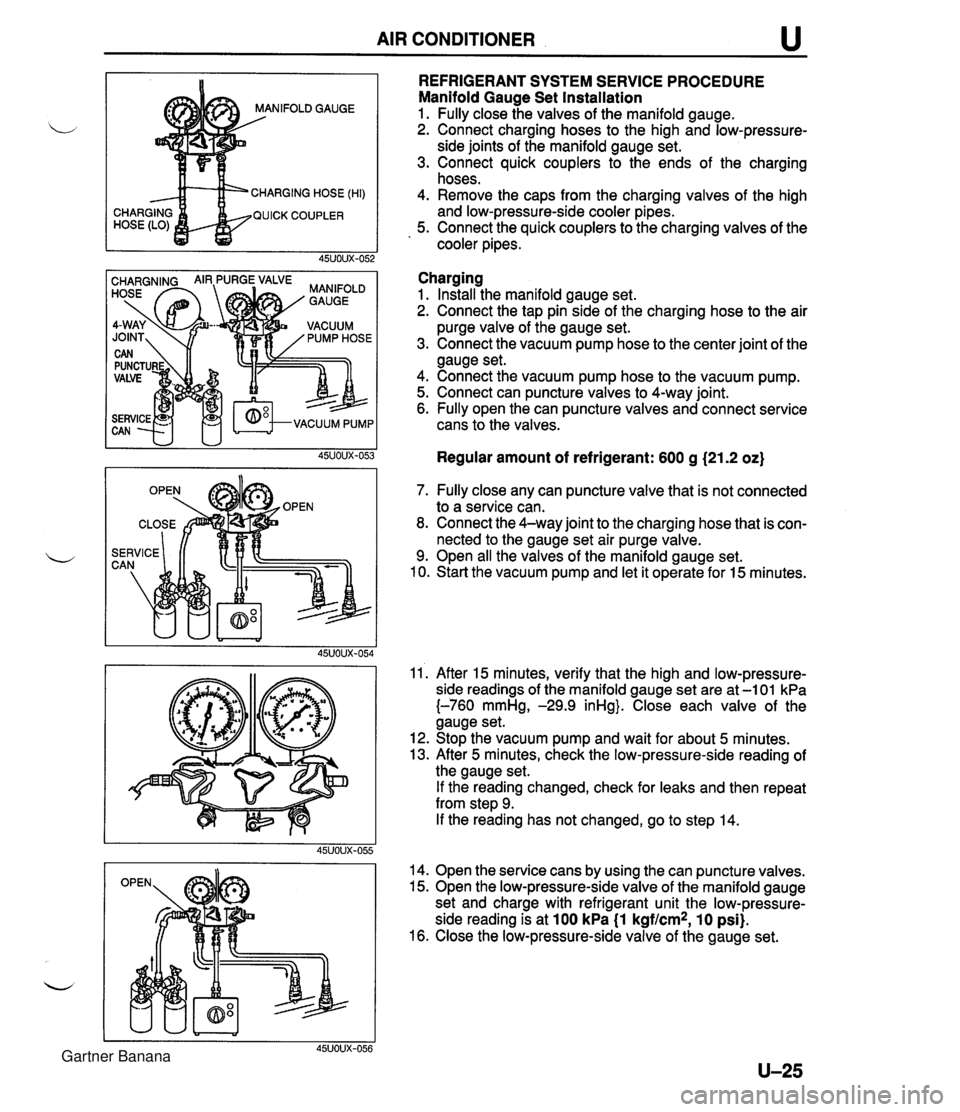

AIR CONDITIONER u NIFOLD GAUGE CHARGING HOSE (HI) QUICK COUPLER REFRIGERANT SYSTEM SERVICE PROCEDURE Manifold Gauge Set Installation 1. Fully close the valves of the manifold gauge. 2. Connect charging hoses to the high and low-pressure- side joints of the manifold gauge set. 3. Connect quick couplers to the ends of the charging hoses. 4. Remove the caps from the charging valves of the high and low-pressure-side cooler pipes. 5. Connect the quick couplers to the charging valves of the cooler pipes. Charging 1. Install the manifold gauge set. 2. Connect the tap pin side of the charging hose to the air purge valve of the gauge set. 3. Connect the vacuum pump hose to the center joint of the gauge set. 4. Connect the vacuum pump hose to the vacuum pump. 5. Connect can puncture valves to 4-way joint. 6. Fully open the can puncture valves and connect service cans to the valves. Regular amount of refrigerant: 600 g (21.2 oz) 7. Fully close any can puncture valve that is not connected to a service can. 8. Connect the 4-way joint to the charging hose that is con- nected to the gauge set air purge valve. 9. Open all the valves of the manifold gauge set. 10. Start the vacuum pump and let it operate for 15 minutes. 11'. After 15 minutes, verify that the high and low-pressure- side readings of the manifold gauge set are at -1 01 kPa {-760 mmHg, -29.9 inHg}. Close each valve of the gauge set. 12. Stop the vacuum pump and wait for about 5 minutes. 13. After 5 minutes, check the low-pressure-side reading of the gauge set. If the reading changed, check for leaks and then repeat from step 9. If the reading has not changed, go to step 14. 14. Open the service cans by using the can puncture valves. 15. Open the low-pressure-side valve of the manifold gauge set and charge with refrigerant unit the low-pressure- side reading is at 100 kPa (1 kgf/cm2, 10 psi). 16. Close the low-pressure-side valve of the gauge set. Gartner Banana

Page 1089 of 1708

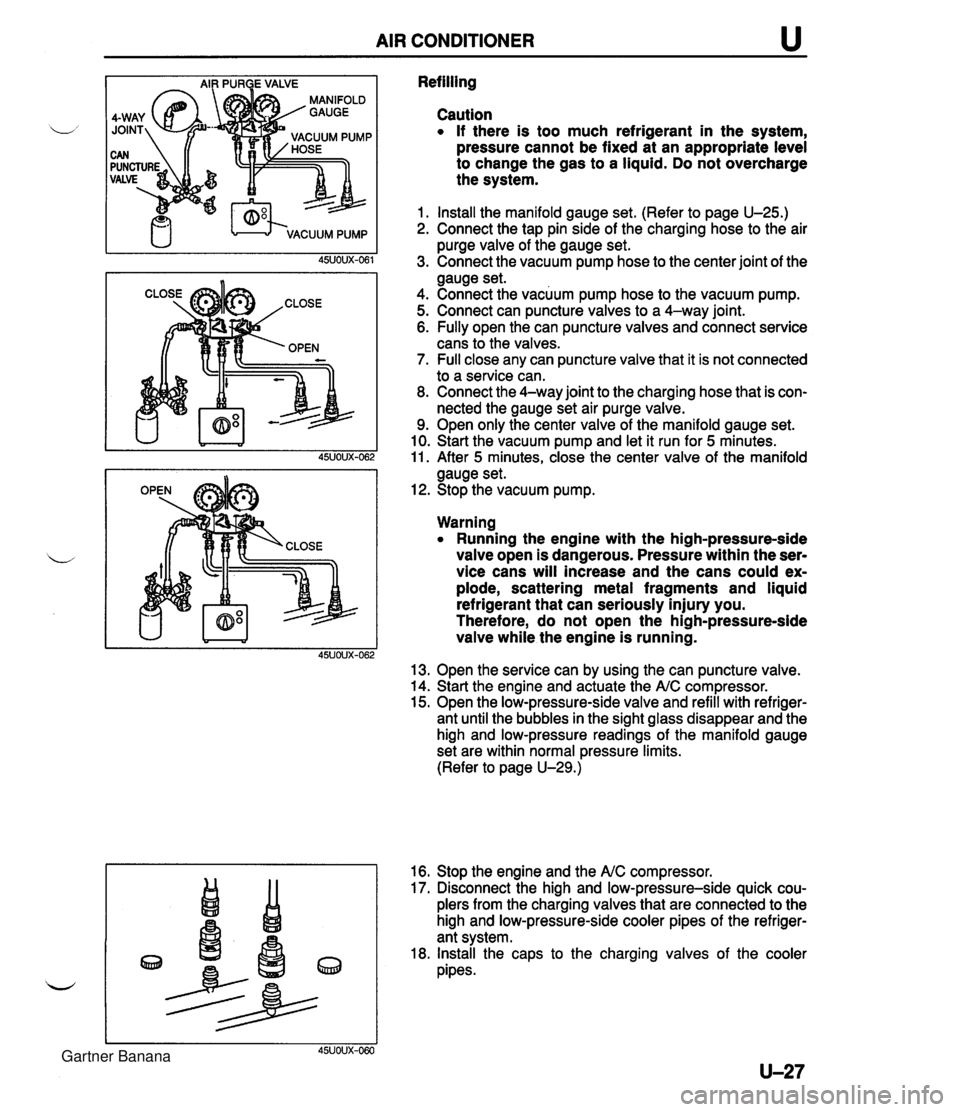

AIR CONDITIONER u Refilling Caution If there is too much refrigerant in the system, pressure cannot be fixed at an appropriate level to change the gas to a liquid. Do not overcharge the system. 1. Install the manifold gauge set. (Refer to page U-25.) 2. Connect the tap pin side of the charging hose to the air purge valve of the gauge set. 3. Connect the vacuum pump hose to the center joint of the gauge set. 4. Connect the vacuum pump hose to the vacuum pump. 5. Connect can puncture valves to a 4-way joint. 6. Fully open the can puncture valves and connect service cans to the valves. 7. Full close any can puncture valve that it is not connected to a service can. 8. Connect the 4-way joint to the charging hose that is con- nected the gauge set air purge valve. 9. Open only the center valve of the manifold gauge set. 10. Start the vacuum pump and let it run for 5 minutes. 11. After 5 minutes, close the center valve of the manifold gauge set. 12. Stop the vacuum pump. Warning Running the engine with the high-pressure-side valve open is dangerous. Pressure within the ser- vice cans will increase and the cans could ex- plode, scattering metal fragments and liquid refrigerant that can seriously injury you. Therefore, do not open the high-pressure-side valve while the engine is running. 13. Open the service can by using the can puncture valve. 14. Start the engine and actuate the A/C compressor. 15. Open the low-pressure-side valve and refill with refriger- ant until the bubbles in the sight glass disappear and the high and low-pressure readings of the manifold gauge set are within normal pressure limits. (Refer to page U-29.) 16. Stop the engine and the NC compressor. 17. Disconnect the high and low-pressure-side quick cou- plers from the charging valves that are connected to the high and low-pressure-side cooler pipes of the refriger- ant system. 18. Install the caps to the charging valves of the cooler pipes. 45UOUX-060 Gartner Banana

Page 1107 of 1708

AIR CONDITIONER u O-RING (2) Tighten the discharge valve body installation through bolts. Tightening torque: 10.8 N-m (110 kgf-cm, 95.5 in-lbf) (3) Tighten the discharge valve body installation bolts. Tightening torque: 10.8 N-m (110 kgf-cm, 95.5 in-lbf) 1 3. Pour compressor oil (ND-OILS) Pour compressor oil into the A/C compressor. Compressor oil amount: Same amount as drained, plus 20 ml(20 cc, 0.6 fl or) 14. Installation of service valve (1) Apply the compressor oil to the new O-rings. (2) Install the service valves to the compressor and tight- en the installation bolts. Tightening torque: 12.3 N-m (125 kgf-cm, 109 in-lbf) Gartner Banana