service MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 1256 of 1708

GENERAL SERVICE INFORMATION d INSTALLATION Checking pre-weld measurements and matching Align to the standard reference dimensions, based upon the body dimensions illustration, so that new parts are installed at the correct position. Welding notes Welding should be performed in accordance with the following reference standards. Note a) Plug welding should be performed by the CO2 gas shielded-arc welding method. b) Panel connections by brazing should be only at the indicated locations. Original welding Repair welding Pitch: 50mm Pitch: within 35mm (1.97 in) Original number of Spot welding welds x 1.3 or more Original spot welding Repair welding If 3rnm (0.12 in) or more Original number of welds or more Plug welding Spot welding notes OXXX Original spot weld @Before spot welding, make a trial weld; If satisfactory, proceed with the actual weld- ing. the tip contact surface and facing surfaces ~~[l/jLJL!= @Before spot welding, check once again that - Em -- to be welded are completely clean. @Because the weld strength is affected by the / shape of the spot welder tip, the tip should always be properly maintained, and, in ad- Hammer and chisel Test piece method method dition, in order to minimize problems caused by overheating, a certain amount of cooling time should be allowed after each 5 or 6 weld points. @Spot welds should, as a general rule, be & U made at points other than the originally Center diameter: lr welded points. w 3mm (0.12 in) n 2 Yi'%%Lr: 415 of tip Gartner Banana

Page 1257 of 1708

GENERAL SERVICE INFORMATION L ANTI-CORROSION TREATMENT When replacing body panels, always apply body sealer, anti-rust treatment. or undercoating ac- cording to the requirements of the market. Application of surface agent and body sealer After first applying the coating of surfacing agent, apply body sealer where necessary. Note For locations where application of body sealer is difficult after installation, apply .t-before the installation. Application of rust inhibitor Undercoating Apply rust inhibitor to the back of welded areas, Use antirust treatment for underbody welding using an installation hole or a gap near that spots and wheel housings. section. Gartner Banana

Page 1258 of 1708

GENERAL SERVICE INFORMATION JACK AND SAFETY STAND POSITIONS FRONT Jack position: Center of crossmember REAR Jack position: Center of differential Safety stand positions: Side sills I Safety stand positions: Side sills VEHICLE LIFT (2-SUPPORT TYPE) POSITIONS FRONT Frame Side sills REAR Frame Side sills Gartner Banana

Page 1259 of 1708

u GENERAL SERVICE INFORMATION TIEDOWN HOOK - FRONT /'-- TIEDOWN HOOK - REAR -?-A TOWING Proper towing equipments are necessary to prevent damage to the vehicle during any towing operation. Laws and regulations applicable to vehicles in tow must always be observed. Release the parking brake, place the shift lever in neutral, and set the ignition switch in the ACC posi- tion. As a rule, towed vehicles should be pulled with the driving wheels off the ground. WITH MANUAL TRANSMISSION If the transmission, rear axle, and steering system are not damaged, the vehicle may be towed on all four wheels. If any of these components are damaged, use a towing dolly. CAUTION The power assist for the brakes and steering are inoperable while the engine is off. Do not use the tiedown hooks under the front or rear of the vehicle for towing. These hooks are designed ONLY for transport tiedown. If the tiedown hooks are used for towing, the front or rear skirt and bumper will be damaged. IDENTIFICATION NUMBER LOCATIONS VEHICLE IDENTIFICATION NUMBER (VIN) ENGINE MODEL AND NUMBER L i Gartner Banana

Page 1260 of 1708

GENERAL SERVICE INFORMATION VEHICLE DIMENSIONS d Measurement I I Overall height mm (in) I Overall length mm (in) Overall width mm (in) 3,948 (155.4) 1,676 (65.9) WHEEL ALIGNMENT Front wheel alignment (Unloaded*) 2,266 (89.2) 1,410 (55.5) 1,428 (56.2) Wheelbase mm (in) Rear wheel alignment (Unloaded*) Tread Total toe-in Front mrn (in) Rear mm (in) mm (in) degree Camber angle I 0'24' f 30' 3 + 3 (0.12 f 0.12) 0°18' + 18' Maximum steering angle Inner Outer I 37'23' f 2O 32O32' f 2O Caster angle * Fuel tank full; radiator coolant and engine oil at specified levels; and spare tire, jack, and tools in designated positions. 4O4Y f 45' 1 1°20' 3 * 3 (0.12 f 0.12) 0'18' + 18' King pin angle Camber angle Total toe-in -0'43' f 30' mm (in) degree Gartner Banana

Page 1688 of 1708

2-C06 2-C07 2-E07 2-F07 2-60 7 2-107 2-LO7 2-CO8 2-EOB 2-E09 2-GO9 2- JOY 2-H09 2-El0 ncAn LunDlnmIAun ~~nra LICENSE LAHPS ORNAMENTS REAR FINISHER BONNET TRUNK LID FRONT PANELS FENDER 6 WHEEL APRON PANELS DASH 6 COWL PANELS SIDE PANELS FLOOR PANELS FLOOR ATTACHMENTS (HOLE COVERS ) FLOOR ATTACHHENTS DASHBOARD EOUIPUENTS METtK HOOD SPEEDOMETER CABLE METER COMPONENTS DASHBOARD L RELATED PARTS CONSOLE VENTILATUR SEATS SEAT BELTS AIR BAG FRONT DOORS FRONT DOOR MECHANISMS FRONT DOOR TRIMS L RELAIED PAR T S SUNROOF SWITCHES 6 RELAYS (ENGINE) DASHBOARD SWITCHES COMB l !?AT1 ON SWITCH RELAYS 6 UNIT (BODY) DOOR SWITCH & HORNS AUTO CRUISE CONTROL SYSTEM AUDIO SYSTEMS (RADIO & TAPE DE CK 1 AUDIO SYSTEMS (ANTENNA & SPEAK ER) WIRING HARNESSES(FR0NT & REAR 1 WIRING HARNESSES(ENG1NE 6 T/HI SSION) WIRING HARNESSES(DASuYGARD> WIRING HARNESSES(DOOR,FLOOR/CE ILING) WIRING HARNESS CLAMPS WINDSHIELD WASHER (W/O ANTI LOCK BRAKE SYSTEM) WINDSHIELD WASHER (ANTI LOCK BRAKE SYSTEM) WINDSHIELD WIPERS WIPER MOTOR COMPOHENTS(FR0NT) FRONT HEADER TRIK 6 PILLAR TRI ns TRIMS b SCUFF PLATES FLOOR MATS X PhDS SERVICE TOOLS VISORS,ASSiST HAHOCES 8 HIRROK S DATE. 1995-04 PAGE. 3 Gartner Banana

Page 1698 of 1708

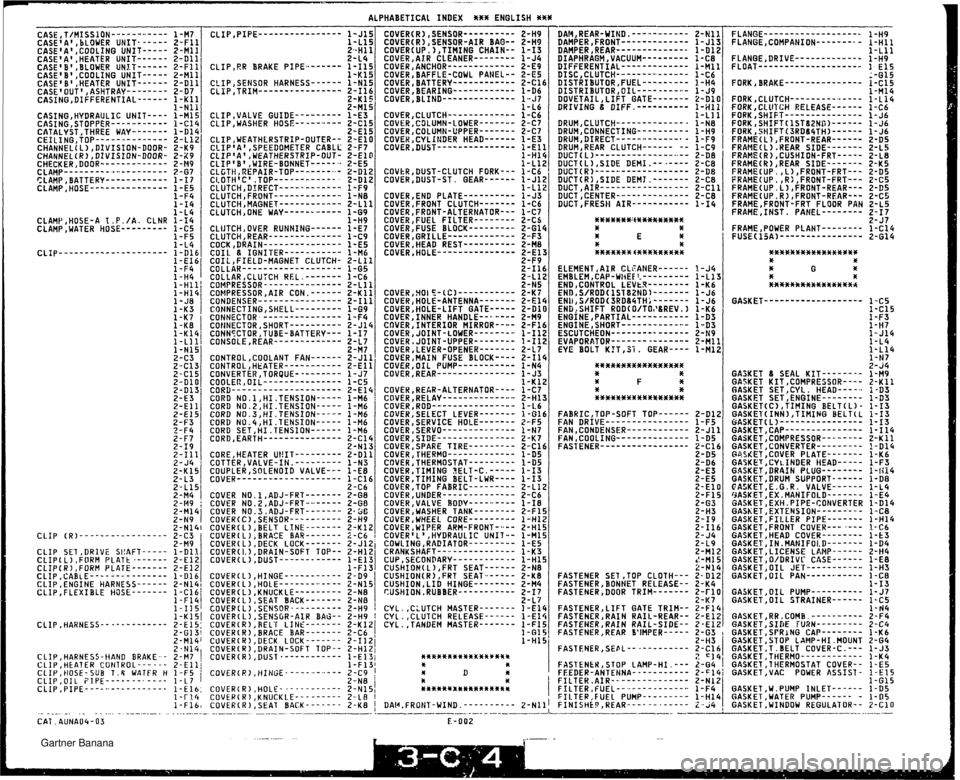

ALPHABETICAL INDEX *%* ENGLISH *** CASE,T/MISSlON------------ CASE'A' , LLOWER UNIT- ----- CASE'A',COOLING UNIT----- CASE'A1 ,HEATER UNIT------ CASEIB' ,BLOWER UNLT------ CASE'B' ,COOLING UNIT----- CASE'B9,HEATER UNIT------ CASE'OUT',ASHTRAY-------- CASING,DIFFERENTIAL------ CASING,HYDRAULIC UNIT---- CASING,STOPPER----------- CATALYST ,THREE WAY------- CEILING,TOP-----.--------- CHANNEL( L) DIVISION-DOOR- CHANNEL(R)lDIVISION-DOOR- CHECKER,DOOR------------- CLAMP---------.-..--------- CLAMP,BATTERY------------ CLAMP,HOSE--------------- 1-L11 DRUM,CLUTCH-------------- 1-N8 DRUM,CONNECTING---------- 1 -H9 DRUM,DIRECT------------.- 1-F9 DRUMIREAR CLUTCH------ -- 1-C9 DUCT(L)---------------..-- 2-DB DUCT(L1 ,SIDE DEMI .-- .---- DUCT(R)----..------------- 2-C8 2-DB DUCT(R1,SIDE DEMT,------- DUCT,AIR- ---- ------------ 2-C8 DUCT,CENTER-------------- 2-Cll 2-C8 DUCTIFRESII AIR----------- 1-14 CLIP,WEATHLRSTRIP-OUTER-- 2-El1 CLIPtA',SPEEDOMETER CABLL 2-F7 CLIPIA',WEATHERSTRIP-OUT- 2-El1 CLIPIB',WIRE-BONNET------ 2-E5 CLGTH,REPAIR-TOP-------..- 2-Dli CLAMt3,HOSE-A 1 .P. /A. CLNR CLAMP,WATER HOSE--------- ELEMENTIAIR CLEANER------ 1-J4 EMBLEM,CAP-WIiE€I.--------- 1-Ll;? END,CONTROL LEVtR-------- 1 -K6 ENDlS/ROD<1ST82ND)------- 1-J6 ENl)rS/ROD(3RDB4TH;------- 1-J6 ENG:SHIFf ROD(O/TOI'&REV.) 1-K6 ENGINE,PARTIAL----------- ENGINE,SHORT------------.- 1-D3 ESCUTCHEON--------------- 1-D3 EVAPORATOR--------------- 2-ti9 2-Mll EYE BOLT K?T,31. GEAR---- 1-M12 2-116 2-L12 2-N5 COVER,5OIE-CC1----------- 2-Ki COVER,HOLE-ANTENNA------- 2-El4 COVER,HOLE-LIFT GATE----- 2-Dl0 COVER,INNER HANDLE----.--- 2-M9 COVER,INTERIOR MIRRORm--- 2-F16 COVER,JOINT-LOWER-------- 1-112 COVER,JOINT-UPPER-------- 1-112 COVER,LEVER-OPENER------- 2-L7 COVER,MAIN FUSE BLOCK---- 2- I1 4 COVER,OIL PUMP----------- COVER,REAR--------------- 1-N4 1-J3 1-K12 COVEK,RE&R-ALTERNATOR---- 1-C7 CQVER,RELAy------------..- 2-H1! COVER,ROD---------------- 1-1.6 COVER,SELECT LEVER------- 1-616 COVERISERVICE HOLE------- Z-F5 COVER,SERVO-------------- COVER,SIDE--------------- 1-N7 2-K7 COVERISPARE TIRE--------- 2-Cl6 COVER,l'HERHO------------- 1-D5 CQVER,THERMOSTAT--------- 1-D5 COVER,TIMING EELT-C. ----- 1-13 GASKET------------------- 1-C5 1-C15 1 -F3 1-H7 1-J14 1-L4 1 - L 14 1-N7 2- ~4 GASKET 8 SEAL KIT-------- 1-M9 GASKET KIT,COMPRESSOR---- 2-K11 GASKET SET ,CYL HEAD----- i -D3 GASKET SETIENGINE-------- 1-DY GASKET(C1 ,TIMING BELTCL) - 1-13 GASKEl'(INN),TIHIHG BELTCL 1-13 BASKET(L)---------------- GASKET,CAP--------------- 1-13 1-114 GASKETICONPRESSOR-------- 2-K11 GASKET,CONVERTER--------- !-Dl4 G0.SKET ,COVER PLATE------- 1-K6 GASKET,CYl.INDER WEAD----- 1-F3 GASKET,DRAIN PLUG-------- 1-li14 GASKETIDRUM SUPPORT- ----- 1 - D8 CASKET.E.G.R. VALVE------ 1-L4 CORD NO.1,HI.TENSION----- 1 -M6 CORD NO.2.HI.TENSION----- 1 -M6 CORD NO.~;HI.TENSION----- 1 -M6 CORD NU.4,HI.TENSION----- 1 -M6 CORD SET,HI.TENSION------ 1 -M6 CORa,EARTH--------------- 2-c14 2-Nl:! CORE,HEATER Ub!IT--------- 2-Dl1 COTTER,VALVE-IN.--------- 1 -N3 COUPLERISOLENOID VALVE--- 1-E0 COVER-------------------- l-Cl6 2-C6 COVER NO.l,ADJ-FRT------- 2-66 COVER NO.2,ADJ-FRT-a+----- 2-60 COVER N0.3.ADJ-FRT------- 2. SC COVER(C),SENSOK---------- 2-H9 COVER(L),BELT LINE------- 2-Kli COVER(L).BRACE BAR------- 2-C6 COVER,UNDER-------------- 2-C6 COVER,VALVE BODY--------- 1-10 COVER,WASHER TANK-------- 2-F1E COVER,WHEEL CORE--------- 1-Hli COVER, WIPER ARM-FRONT--- - 2-H15 COVER'L1,HYDRAULIC UNIT-- 1-Ml5 COWLING,RADIATOR--------- CRANKSHAFT--.. -- ------ ---- 1-E5 1 -K3 CUPISECONDARY------------ 1-H15 CUSHION(L),FRT SEAT------ 2-N8 CUSHIOW(R),FRT SEAT------ 2-K8 CUSHION,LID HINGE-------- 2-H4 CUSHION.RUBBER----------- 2-17 2-Ll CYL.,CLUTCH MASTER------- I -El4 CYL.,CLUTCH RELEASE------ 1-El4 CYL,,TAHDEM MASTER------- 1-F15 1-61 5 1-H15 /~ASKET;EX.MANIFOLD------- 1-E4 GASKET,EXH.PIPE-CONVERTER 1-Dl4 GASKET,EXTENSION--------- 1-C8 GASKET,FILLER PIPE------- 1-H14 GASKET ,FRONT COVER--- .--- I-C6 GASKET,HEAD COVER-------- 1-fi3 GASKET,IN.MANIFOl.D------- 1-D4 GASKET.LICENSE LAMP------ 2-H4 COVER( L) ;DECK LOCK------- 2- Jli COVER(I.),DRAIN-SOFT TOP-- 2-Hli COVER(L),DUST------------ 1-El2 1-Fl? COVER(L),HINGE----------- 2-D9 COVER( L) ,HOLE----------- - 2-Nl! COVER(L),KNUCKLE--------- 2-NB COVER(L).SEAT BACK------- 2-N8 - ... CLIP SET,DRlVE SI!AFT----- 1-DlI CLIP(L1 ,FORM PLATt .------ 2-El2 CLIP(R),FORM PLATE------- CLIP,CABiE--------------- 2-El2 1-Dl6 CLIP ,ENGINE HARNESS------ 2-N141 CLIP,FLEXIBLE Hi3SE------- 1-C16' l-~ld I-Ml5 2-1314 FASTENER SET ,TOP CLOTH--- 2- Dl2 FASTENER,BONNET RELEASE-- 2-KG FASTENER,DOOR TRIM------- 2-rl0 2-#7 GASKET,OIL PUMP---------- 1- J7 GASKET ,OIL STRAINER-- ---- 1-C5 1-rJ4 GASKET.RR.COH0.---------- 2-F4 1-1jsl CQv~~(~);S~~so~-l-------- 2-H9 I I-K~SI COVER( L) ,SENSOR-AIR BAG-- 2-H9 CLIP,HAHNESS------------- 2-E15: COVER(R),REL'I LINE------- FKl4 2-G13! COVER(R),BRACE BAR------- 2-C6 , 2-M14' CUVER(W),DECK LOCK------- 2-1121 2-N14( COVERIR) ,DRAIN-SOFT TOP-- 2-HIZi CLlP,HARNESS-HAND BRAKE-- 2-M7 I COVERCR) ,DUST.----------- 1-E13i CLlP,HEATER COtITKOL--- - -- 2-Elli 1-F131 CLIP, HOSE- SUB T.8 VATFR H 1 -F5 i COVER(R) ,HINGE- ---------- 2-C9 ! CLIP,OIL FJPE-------. ---- 1-L7 I CLIP ,PIPE--- -..- ---------. 2-N8 j I-El6: COVER(R),HOLE------------ Z-N1S1 x-~I(+ COVER(RI,KNUCKLE--------- 2-18 I 1-Fl6, COVER(R) ,SEAT BACK------- 2-K8 I FASTEHERILIFT GATE TRIM-- 2-F14 FASTENERBRAIN RAIL-REAR-- %-Eli FASTEHER; RAIN FASTENER. REAR 1 SIDE TUXN- - .SPRANG CAP- FASTEYER,SEEL------------ 1- J3 1-K4 FASTENER, STOP LAMP-HI . --- II D f FEEDER-ANTENNA- - - - - -- - - - - 2-F14j GASKET~VAC POWER ASSIST- !-El5 I )t s FILTER ,AIR--------..------ 2 - N 12 1-G15 FILTER, FUEL- - ..- - - - - - ----.. ~%*t*~x*rfi**tf%%w 1-F4 1 SASK6T.W.PUMP INLET------ 1-D5 I FII.TEP,FUEL PUMP--------- 1-H14 GASKET,WATER PUMP------ - 1-05 IlAl~,FRONT-WIND.---------- 2-~111 FINISHEPIWEAR------.----- 2-i4 GASKET,WINDOW REGULATOR-- 2-C10 . . . . . . . -. . . . . . -- .. - -- ------- L.- -.- --- -.-- CAT. AUNA04-03 F.-002 Gartner Banana