SECTION T MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 550 of 1708

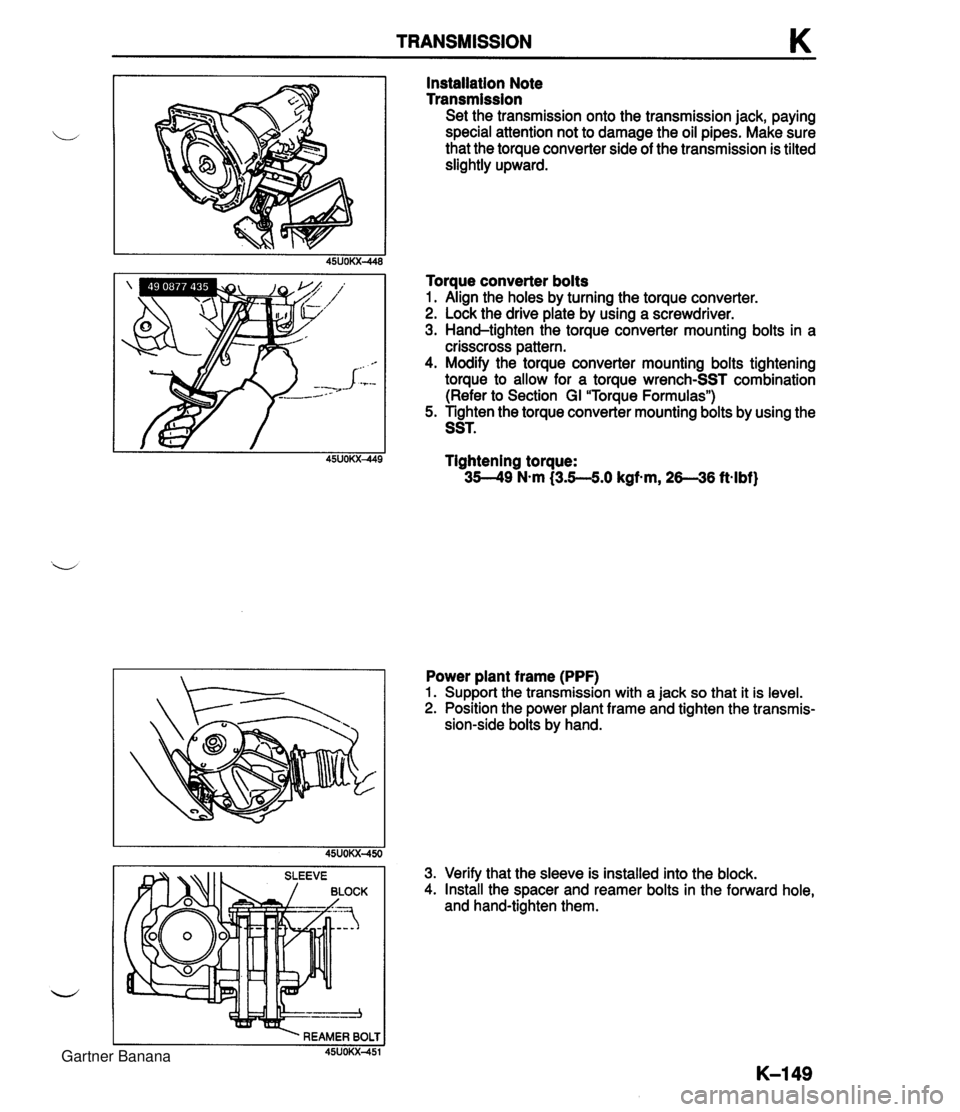

TRANSMISSION K Installation Note Transmission Set the transmission onto the transmission jack, paying special attention not to damage the oil pipes. Make sure that the torque converter side of the transmission is tilted slightly upward. Torque converter bolts 1. Align the holes by turning the torque converter. 2. Lock the drive plate by using a screwdriver. 3. Hand-tighten the torque converter mounting bolts in a crisscross pattern. 4. Modify the torque converter mounting bolts tightening torque to allow for a torque wrench-SST combination (Refer to Section GI "Torque Formulas") 5. Tighten the torque converter mounting bolts by using the SST. Tightening torque: 35-49 N-m (3.5-5.0 kgf-m, 26--36 ft-lbf) Power plant frame (PPF) 1. Support the transmission with a jack so that it is level. 2. Position the power plant frame and tighten the transmis- sion-side bolts by hand. 3. Verify that the sleeve is installed into the block. 4. Install the spacer and reamer bolts in the forward hole, and hand-tighten them. Gartner Banana

Page 556 of 1708

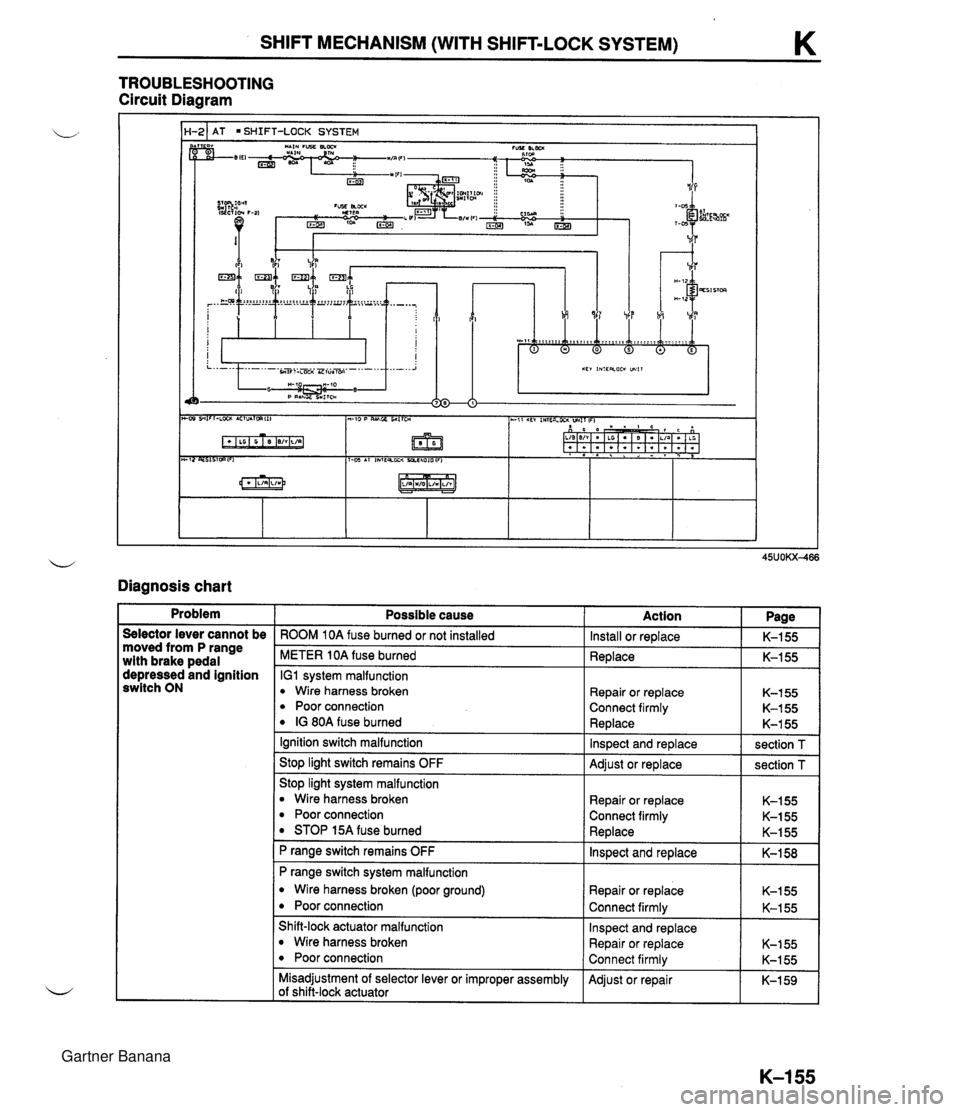

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K TROUBLESHOOTING Circuit Diagram - 1-21 AT SHIFT-LOCK SYSTEM Diagnosis chart Problem -- Selector lever cannot be moved from P range with brake pedal depressed and ignition switch ON Possible cause ROOM 1 OA fuse burned or not installed METER 10A fuse burned IG1 system malfunction Wire harness broken Poor connection IG 80A fuse burned Ignition switch malfunction Stop light switch remains OFF Stop light system malfunction Wire harness broken Poor connection STOP 15A fuse burned P range switch remains OFF P range switch system malfunction Wire harness broken (poor ground) Poor connection Shift-lock actuator malfunction Wire harness broken Poor connection Misadjustrnent of selector lever or improper assembly of shift-lock actuator Action I Page Repair or replace Connect firmly Replace Install or replace Replace K-155 K-155 Repair or replace K-155 Connect firmly K-155 Replace K-155 Inspect and replace Adjust or replace section T section T Repair or replace Connect firmly Inspect and replace Repair or replace Connect firmly Adjust or repair K-155 K-I55 K-155 K-155 K-159 Gartner Banana

Page 557 of 1708

K ' SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Problem Possible cause Selector lever can be ROOM 1OA fuse burned or not installed moved lrom nnp. [stop light switch remains ON with ignition switch ON, but without brake pedal I Shift-lock actuator malfunction depressed Misadjustment of selector lever or improper assembly of shift-lock actuator Selector lever can be ROOM 10A fuse burned or not installed range Ignition switch malfunction with ignition switch OFF and brake pedal de- Shift-lock actuator malfunction pressed Misadjustrnent of selector lever or improper assembly of shift-iock actuator Shift-lock actuator op- P range switch remains ON eration heard when brake pedal depressed ' Misadjustment of selector lever or improper assembly with ignition switch ON of shift-lock actuator in other than P range Action -- Install or replace Adjust or replace lnspect and replace Adjust or replace Install or replace Inspect and replace inspect and replace Adjust or replace Inspect and replace Adjust or replace section T K-159 Selector lever remains locked when emergency override button oper- ated Emergency override button not pushed fully down Broken emergency override button lgnitlon key can be turned to lock position with selector lever in other than P range Push down fully and hold emergency override but- Misadjustment of indicator pedal ROOM 10A fuse burned or not installed Key interlock solenoid malfunction Wire harness broken Poor connection P range switch remains ON P range switch system malfunction Wire harness broken Poor connection lnspect and replace Repair or replace Connect firmly Adjust Install or replace K-161 - K-151 Inspect and replace Repair or replace Connect firmly I lanition kev cannot be I P ranae switch remains OFF I lns~ect and replace 1 K-158 I K-159 K-166 K-166 Key cylinder (push switch) malfunction Wire harness broken Poor connection Key interlock unit malfunction I ~~~~~$1~~~~ I Key iierlock solenoid malfunction I' I I Inspect and replace I K-158 I range Inspect and replace Repair or replace Connect firmly Inspect and replace Key cylinder (push switch) malfunction I Inspect and replace I section T section T K-155 K-155 section T I I Misadjustment of selector lever 1 Adjust I K-160 ] Gartner Banana

Page 586 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . FRONT AND REAR AXLES ....................................... INDEX M- 2 ..................................... OUTLINE M- 3 SPECIFICATIONS ........................... M- 3 TROUBLESHOOTING GUIDE .................. M- 4 ............................... FRONT AXLE M- 4 ................................ REAR AXLE M- 4 ............................. DIFFERENTIAL M- 4 ................................. FRONT AXLE M- 5 PREPARATION ............................. M- 5 WHEEL HUB. STEERING KNUCKLE .......... M- 6 .................................. REAR AXLE M-10 PREPARATION ............................. M-10 ......................... DISC BRAKE TYPE M-11 ................................ DRIVE SHAFT M-17 .................... DOUBLE OFFSET JOINT M-17 ............................... DIFFERENTIAL M-23 PREPARATION ............................. M-23 DIFFERENTIAL OIL ......................... M-25 ................. OIL SEAL (OUTPUT SHAFT) M-25 DIFFERENTIAL. STANDARD; DIFFERENTIAL. TORQUE SENSING LIMITED SLIP ("TORSEN" LSD) ........................... M-27 45UOMX-001 "TORSEN" is a registered trademark of ZEXEL-GLEASON USA . INC Gartner Banana

Page 587 of 1708

INDEX INDEX OIL SPECIFICATION ABOVE -1 8°C (O°F1: GL-5. SAE 90 / I 1 ,BELOW -1 8°C Ioo~: GL-5, SAE 80 ..-.. - - - - .. - ...... SERVICE, SECTION L REAR'BRAKE PROPELLER SHACT SERVICE, SECTION P FRONT-BRAKE SERVICE SECTION P 1. Front axle Inspection / Removal / Installation ............... page M- 6 Disassembly 1 Inspection / Assembly. ............... page M- 8 2. Rear axle Inspection / Removal / Installation ............... page M-1 1 Disassembly 1 Inspection / Assembly ................ page M-13 M-2 3. Drive shaft Ins~ection / Removal 1 ............... Installation page M-17 Overhaul .................. page M-19 4. Differential (Standard, Torque sensing limited slip differential) Differential oil .............. page M-25 . Oil seal (Output shaft) ...... page M-25 Removal 1 Installation ....... page M-27 Overhaul .................. page M-32 Gartner Banana

Page 589 of 1708

TROUBLESHOOTING GUIDE TROUBLESHOOTING GUIDE FRONT AXLE I Problem Posslbk Cause Worn or damaged wheel bearing Worn or damaged wheel bearing Steering wheel vibration braking Action Replace Replace REAR AXLE Page M- 6 M-6 I Problem Possible Cause Bent drive shaft Page Action Replace I Abnormal nolse Worn or damaged wheel bearing Worn drive shaft spline Worn or deteriorated upper arm bushing M-13 Replace I M-17 Body "rolls" I Replace section R Body leans Weak upper arm bushing Abnormal nolse from suspension system Worn or deteriorated upper arm bushing DIFFERENTIAL Problem Posrlble Cause lnsufficient differential oil Incorrect differential oil lmproperly adjusted ring gear backlash Poor contact of ring gear teeth Worn or damaged side bearing Worn or damaged ring gear Worn or damaged drive pinion bearing Worn or damaged pinion and side gear (STANDARD) Worn or damaged gear in LSD assembly ("TORSEN" LSD) Seized side gear and case Worn side gear spline Worn pinion shaft Worn thrust washer Worn or damaged needle bearing ("TORSEN" LSD) lmproperly adjusted side gear backlash lmproperly adjusted drive pinion gear preload Action Add oil Replace Adjust Adjust Replace Replace Replace Replace Replace Page M-25 M-25 M40 M4l M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-32 M-40 M-39 Abnormal nolse Replace Replace Replace Replace Replace Adjust Adjust Heat buildup lnsufficient differential oil lnsufficient drive pinion gear backlash Excessive bearing preload Add oil Adjust Adjust Oil leakage Excessive differential oil Loose differential carrier Worn or damaged oil seal Remove oil Tighten or repair Replace I - No dlfferentlal operation I Misassembled or damaged Repair Gartner Banana

Page 591 of 1708

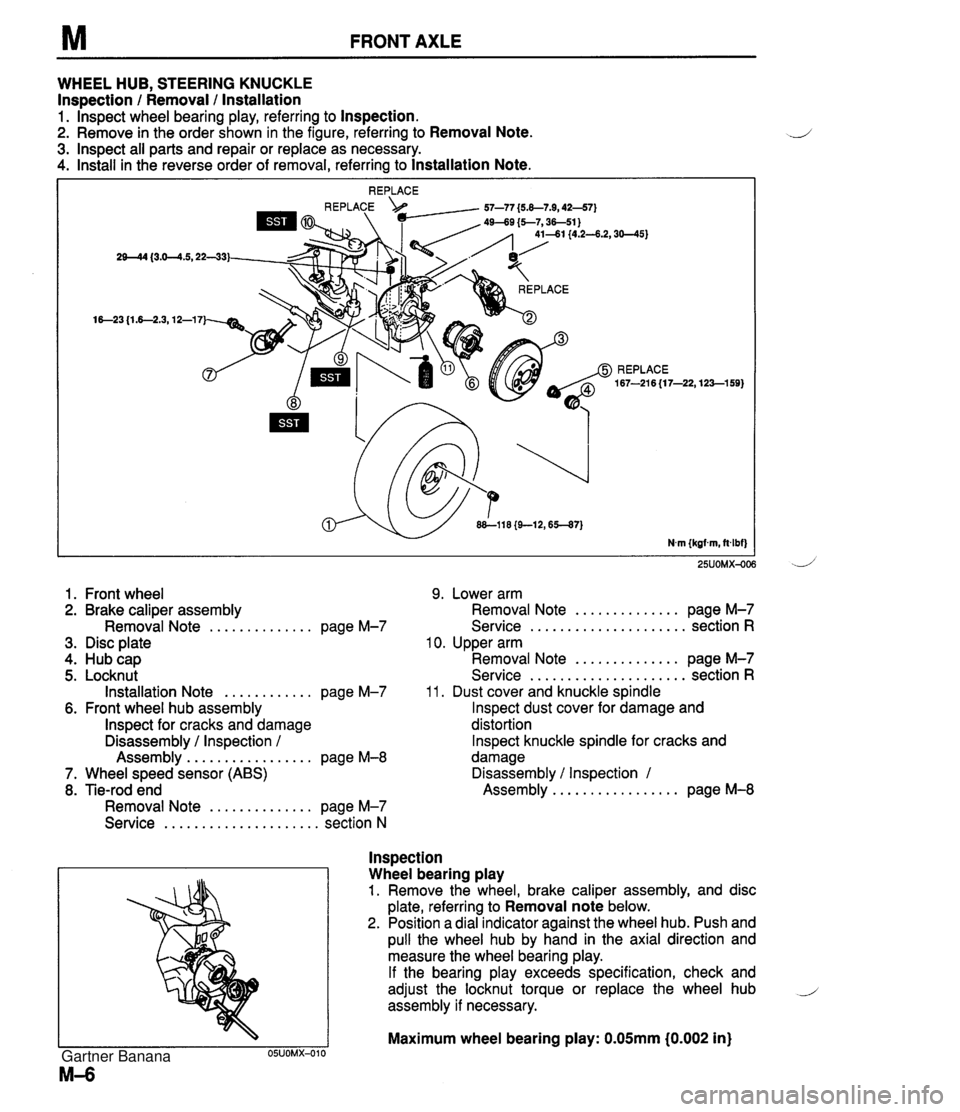

FRONT AXLE WHEEL HUB, STEERING KNUCKLE Inspection / Removal / lnstallation 1. lnspect wheel bearing play, referring to Inspection. 2. Remove in the order shown in the figure, referring to Removal Note. 3. lnspect all parts and repair or replace as necessary. 4. Install in the reverse order of removal, referring to Installation Note. 25UOMX-OC 1. Front wheel 9. Lower arm 2. Brake caliper assembly Removal Note .............. page M-7 3. Disc plate 4. Hub cap 5. Locknut Installation Note ............ page M-7 6. Front wheel hub assembly lnspect for cracks and damage Disassembly / Inspection / Assembly ................. page M-8 7. Wheel speed sensor (ABS) 8. Tie-rod end Removal Note .............. page M-7 Service ..................... section N .............. Removal Note page M-7 ..................... Service section R 10. Upper arm .............. Removal Note page M-7 ..................... Service section R 11. Dust cover and knuckle spindle lnspect dust cover for damage and distortion lnspect knuckle spindle for cracks and damage Disassembly / Inspection 1 ................. Assembly page M-8 lnspection Wheel bearing play 1. Remove the wheel, brake caliper assembly, and disc plate, referring to Removal note below. 2. Position a dial indicator against the wheel hub. Push and pull the wheel hub by hand in the axial direction and measure the wheel bearing play. If the bearing play exceeds specification, check and adjust the locknut torque or replace the wheel hub i assembly if necessary. Maximum wheel bearing play: 0.05mm i0.002 in) Gartner Banana

Page 596 of 1708

REAR AXLE M DISC BRAKE TYPE Inspection 1 Removal 1 Installation 1. lnspect wheel bearing play, referring to Inspection. 2. Remove in the order shown in the figure, referring to Removal Note. 3. lnspect all parts and repair or replace as necessary. 4. Install in the reverse order of removal, referring to Installation Note. 5. After installation, adjust the rear wheel alignment. (section R.) @ REPLACE 21 6294 {2230,159-217) N.m {kgf m, Rlbf) 1. Rear wheel 2. Brake caliper assembly Removal Note . . . . . . . . . . . . . page M-12 3. Disc plate 4. Locknut Installation Note . . . . . . . . . . . page M-12 5. Wheel speed sensor (ABS) 6. Sensor bracket 7. Knuckle, wheel hub, and dust cover lnspect knuckle for cracks and damage lnspect wheel hub for cracks and damage lnspect dust cover for damage and distortion Disassembly / Inspection / Assembly . . . . . . . . . . . . . . . . page M-13 Gartner Banana

Page 604 of 1708

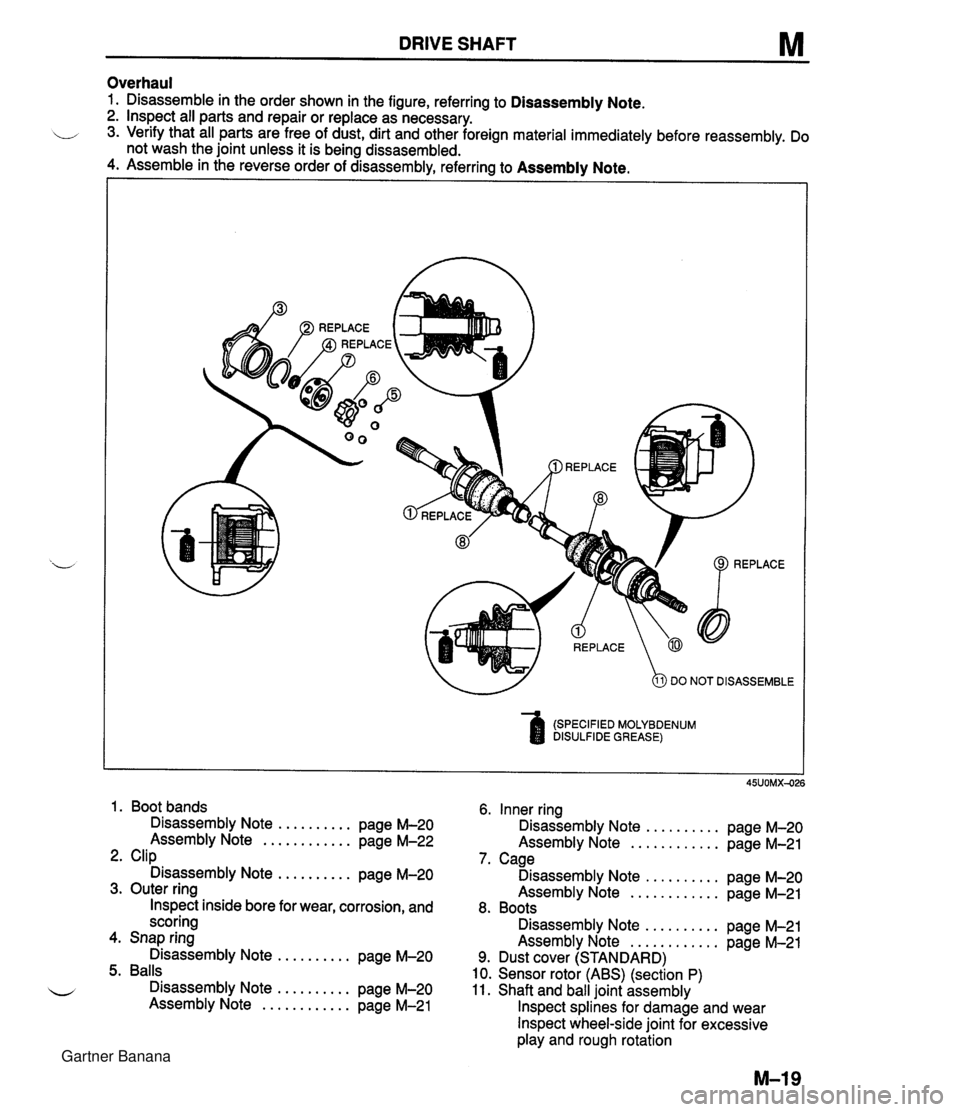

DRIVE SHAFT M Overhaul 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. lnspect all parts and repair or replace as necessary. -- 3. Verify that all parts are free of dust, dirt and other foreign material immediately before reassembly. Do not wash the joint unless it is being dissasembled. 4. Assemble in the reverse order of disassembly, referring to Assembly Note. 1. Boot bands 9 REPLACE J r DISASSEMBLE w DO NO' (SPECIFIED MOLYBDENUM DlSULFlDE GREASE) Disassembly Note .......... page M-20 Assembly Note ............ page M-22 2. Clip Disassembly Note .......... page M-20 3. Outer ring lnspect inside bore for wear, corrosion, and scoring 4. Snap ring Disassembly Note .......... page M-20 5. Balls .......... u Disassembly Note page M-20 Assembly Note ............ page M-21 45UOMX426 6. Inner rina ~isasiembl~ Note .......... page M-20 Assembly Note ............ page M-21 7. Cage Disassembly Note .......... page M-20 Assembly Note ............ page M-21 8. Boots Disassembly Note .......... page M-21 Assembly Note ............ page M-21 9. Dust cover (STANDARD) 10. Sensor rotor (ABS) (section P) 11. Shaft and ball joint assembly lnspect splines for damage and wear lnspect wheel-side joint for excessive play and rough rotation Gartner Banana

Page 611 of 1708

M DIFFERENTIAL 5. Separate the driveshaft from the differential and sus- pend it. 6. Remove the output shaft by using two pry bars as shown in the figure. J 7. Remove the oil seal. 8. Apply lithium-based grease to the new oil seal lip and install it by using'the SST. 9. Install the new clips. 10. Install the output shaft into the side gears by lightly tap- ping with a plastic hammer. 11. Verify that the output shaft is hooked into the side gears by pulling it by hand. ./ 12. Align the marks and install the drive shaft. Tightening torque: 54-64 N.m (5.5--6.5 kgf.m, 40-47 ft-lbf) 13. Install the upper arm installation bolt and nut. Tightening torque: 46-67 N.m (4.7-6.8 kgf.m, 34--49 ftlbf) 14. Add the specified oil. 15. Adjust the rear wheel alignment. (Refer to section R.) I Gartner Banana