SECTION T MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 752 of 1708

FRONT SUSPENSION (DOUBLE-WISHBONE) CROSSMEMBER Removal I Inspection 1 lnstallation Note 4 Use a container or rags to collect the power steering fluid when disconnecting the power steering pipes. 1. Jack up the vehicle. 2. Remove the wheels and the undercover. 3. Support the engine with a hoist. 4. Lower the crossmember and other suspension parts as an assembly, and then separate the parts. 5. Remove in the order shown in the figure. 6. lnspect all parts and repair or replace as necessary. 7. Loosely tighten the stabilizer bracket, upper arm, and lower arm bolts. Tighten all other nuts and bolts to the specified torques. 8. Lower the vehicle. 9. With the vehicle unloaded, tighten the stabilizer bracket, upper arm, and lower arm bolts to the specified torques. 10. Adjust the front wheel alignment. (Refer to page R-6.) 11. Bleed the air from the brake system. (Refer to section P.) 12. Bleed the air from the Power Steering System. (Refer to section N.) Q - re-no ~L1.3--11.W, Okl-m} 94-1;2 (9.Cll.5,69--83) 1 &26 {1.&2.7,14--19) 1 S21 (1 3-- 1. Brake pipe Removal / lnstallation . . . . . . . . . Section P 2. Pinion shaft bolt Removal / lnstallation . . . . . . . . Section N 3. Power steering pipe Removal 1 lnstallation . . . . . . . . Section N 4. Shock absorber bolt 5. Stabilizer bracket bolt 6. Upper arm bolt 7. Performance rod 8. Adjusting cam bolt 9. Steering gear bracket bolt 10. Front crossmember assembly lnspect for damage Gartner Banana

Page 758 of 1708

R REAR SUSPENSION (DOUBLE-WISHBONE) CROSSMEMBER Removal I Inspection I Installation 1. Jack up the vehicle and support it with safety stands. 2. Remove the wheels and tires. d 3. Remove the differential and the power plant frame. (Refer to section M.) 4. Lower the crossmember and other suspension parts as an assembly, and then separate the parts. 5. Remove in the order shown in the figure. 6. lnspect parts and repair or replace as necessary. 7. Install in the reverse order of removal. 8. Loosely tighten the stabilizer bracket, upper arm, and lower arm bolts. Tighten all other nuts and bolts to the specified torques. 9. Lower the vehicle. 10. With the vehicle unloaded, tighten the stabilizer bracket, upper arm, and lower arm bolts to the specified torques. 11. Adjust the rear wheel alignment. (Refer to page R-9.) 12. Bleed the air from the brake system. (Refer to section P.) 13. Adjust the parking brake lever stroke. (Refer to section P.) 1. Differential mounting pipe 6. Shock absorber bolt 2. Parking brake cable 7. Stabilizer bracket Removal / Installation . . . . . . . . . Section P 8. Upper arm bolt 3. Brake pipe 9. Adjusting cam bolt Removal / Installation . . . . . . . . . Section P 10. Rear crossmember assembly 4. Brake pipe joint Inspect for damage 5. Battery cable bracket Gartner Banana

Page 759 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . BODY INDEX ............................. S- 2 HOOD ............................. S- 5 COMPONENTS ................... S- 5 DOOR ............................. S- 7 COMPONENTS ................... S- 7 WINDOW REGULATOR. GLASS. AND GUIDE ....................... S- 9 COMPONENTS ................... S- 9 ......... DOOR LOCK AND OPENER S-15 ................... COMPONENTS S-15 TRUNK LID ........................ S-16 COMPONENTS ................... S-16 .... TRUNK LID LOCK AND OPENER S-18 COMPONENTS ................... S-18 ......... POWER WINDOW SYSTEM S-19 .............. STRUCTURAL VIEW S-19 TROUBLESHOOTING ............. S-20 ........ b POWER WINDOW SWITCH S-22 ... POWER WINDOW REGULATOR S-22 ......... FUEL-FILLER LID OPENER S-23 COMPONENTS ................... S-23 FRONT BUMPER ................... S-24 COMPONENTS ................... S-24 REAR BUMPER .................... S-25 COMPONENTS ................... S-25 ........... MOLDING AND GARNISH S-27 COMPONENTS ................... S-27 OUTSIDE MIRROR ................. S-30 STRUCTURAL VIEW .............. S-30 ............. TROUBLESHOOTING S-31 POWER OUTSIDE MIRROR ....... S-33 POWER OUTSIDE MIRROR SWITCH ........................ S-33 COMPONENTS ................... S-34 WINDSHIELD WIPER AND WASHER . S-35 TROUBLESHOOTING ............. S-35 WIPER MOTOR .................. S-38 ................ WASHER MOTOR S-38 FRONT WIPER AND WASHER ........................ SWITCH S-38 ................... COMPONENTS S39 WINDSHIELD ...................... S-44 PREPARATION ................... S-44 ................... COMPONENTS S-44 REAR WINDOW GLASS ......... (DETACHABLE HARDTOP) S-48 PREPARATION ................... S48 ................... COMPONENTS S48 REAR WINDOW .............. (CONVERTIBLE TOP) S-52 ................... COMPONENTS S-52 ....... DASHBOARD AND CONSOLE S-56 ................... COMPONENTS S56 TRIM .............................. S-59 COMPONENTS ................... S-59 ................. FLOOR COVERING S-62 ................... COMPONENTS -21 SEAT BELT ........................ S-63 COMPONENTS ................... S-63 ...................... SEAT BELT S-64 ................ BUCKLE SWITCH S-64 SEAT .............................. S-65 ................... COMPONENTS S-65 ................ CONVERTIBLE TOP S-67 PREPARATION ................... S-67 ................... COMPONENTS S-67 ........... DETACHABLE HARDTOP S-81 COMPONENTS ................... S-81 BRACE BAR ....................... S-84 ................... COMPONENTS S-84 ......... UNDERBODY DIMENSIONS S-85 PROJECTED DIMENSIONS ........ S-85 ..... STRAIGHT-LINE DIMENSIONS S-87 45uoSx-001 Gartner Banana

Page 776 of 1708

s TRUNK LID LOCK AND OPENER TRUNK LID LOCK AND OPENER COMPONENTS Removal / Installation 1. Remove in the order shown in the figure. 2. Install in the reverse order of removal. Rear console 6. Rear combination light .................... Removal 1 Installation ....... page S-56 Removal Section T Opener lever 7. Rear finisher ............. Opener cable Removal Note page S-28 4. Trunk end trim 8. Key cylinder 5. Trunk lid lock assembly 9. Striker ..................... Adjustment below Adjustment Trunk lid lock assembly Verify that the trunk lid can be closed easily and that there is no looseness. If necessary, loosen the lock assembly mounting bolts and adjust the lock assembly. Gartner Banana

Page 782 of 1708

s FRONT BUMPER FRONT BUMPER COMPONENTS Removal 1 Installation 1. Raise the headlights. 2. Disconnect the negative battery cable. 3. Remove in the order shown in the figure. 4. Install in the reverse order of removal. Front combination light 6. Set plate Removal .................... Section T 7. Front fascia Front side marker light 8. Retainer Removal .................... Section T 9. Bumper reinforcement 3. Fender bracket 10. Spacer 4. Mud guard 11. Front bumper retainer 5. Grille cover 12. Front bumper bracket Gartner Banana

Page 783 of 1708

REAR BUMPER s REAR BUMPER COMPONENTS L Removal 1 Installation 1. Disconnect the negative battery cable. 2. Remove in the order shown in the figure. 3. Install in the reverse order of removal. 1. Rear side marker light 2. Splash shield Removal . . . . . . . . . . . . . . . . . . . . Section T 3. Rear bumper Gartner Banana

Page 786 of 1708

s MOLDING AND GARNISH Removal Note Front beltline molding Remove the outside mirror to remove the front beltline molding. (Refer to page S-34.) i/ Rear finisher Remove the rear combination light to remove the rear finisher. (Refer to Section T.) PRIMER 45UOSX42C I MOLDING I MOLDING Beltline molding Remove the convertible top to remove the beltline mold- ing. (Refer to page S-67.) Installation Note Windshield molding 1. Remove the windshield. (Refer to page S-44.) 2. Install the windshield. (Refer to page S-44.) 3. Apply primer with a brush to the bonding area of the new upper molding. Keep the bonding area free of dirt and -- grease, and do not touch the surface. Allow the primer to dry for approximately 30 minutes. 4. Align the center mark in the molding with the glass mark (0) 5. Install the upper portions of the molding into the body (Q) . 6. Push the corner of the molding into the body ((3). 7. Push the side portions of the molding into the body, beginning from the bottom (@). 8. Check for water leaks. If a leak is found, wipe the water off well and repeat the installation. Hardening time of repair sealant Time required until car Temperature Surface hardening time ,, be put into service 5°C (41 OF) Aoorox. 1.5 hr 12 hr I 35°C {95"F} I Approx. 10 rnin 2 hr 1 Gartner Banana

Page 794 of 1708

WINDSHIELD WIPER AND WASHER Wlper does not operate in Lo or Hi position 1 B+: Battery positive voltage - Check WIPER 20 A fuse Short circuit Turn ignition switch ON I OK 1 I Checkfor B+ at terminal-wire windphieldwiper.witchu Repair harness (Fuse box - Switch) 1 I connector I I I OK Check for B+ at terminal-wires (UR) and (VW) of switch connector with switch, as shown Lo : VW) B+ Hi : [uR) s+ Check windshield wiper switch (Refer to Section T) I 1 OK Check for continuity of motor terminal-wire (B) to ground Repair brush plate holder (Refer to page S-43) 1 Check for B+ at terminal-wi-(VR) Repair (UW) or (UR) wire harness 1 Check wiper motor (Refer to page 538) motor connector with switch, as shown Lo: VW) B+ Hi : [UR) B+ Wiper automatic park function does not work 1 (Switch-Wiper motor) Turn ignition switch ON t Repair harness (Fuse box - Wiper motor) Check wiper motor (Refer to page S-38) Gartner Banana

Page 795 of 1708

WINDSHIELD WIPER AND WASHER Intermittent function does not operate L I B+: Battery positive voltage Check for continuity of m Repair brush plate holder (Refer to page S-43) Oy Check windshield wiper switch (Refer to Section T) 45UOSX-036 Wiper continues to operate when switch is OFF Check windshield wiper switch (Refer to Section T) One-touch function does not operate Check windshield wiper switch (Refer to Section T) Washer does not operate (Wiper operates OK) L O5uoSX-050 Washer continues to operate when switch is OFF 1 Turn ignition switch ON Check windshield washer switch (Refer to Section T) Check for B+ at terminal-wire (UO) of windshield washer Check windshield washer switch (Refer to Section T) switch connector with washer switch ON I o5UosX-052 Check for B+ at terminal-wire (UO) of washer motor con- Repair harness (Switch - Motor) nector with washer switch ON I OK I I NGr I I Disconnect washer motor 2-pin connector; check for conti- Repair harness (Motor - Ground) nuity of terminal-wire (B) to ground Check washer motor (Refer to page S-38) 45UOSX-037 Gartner Banana

Page 796 of 1708

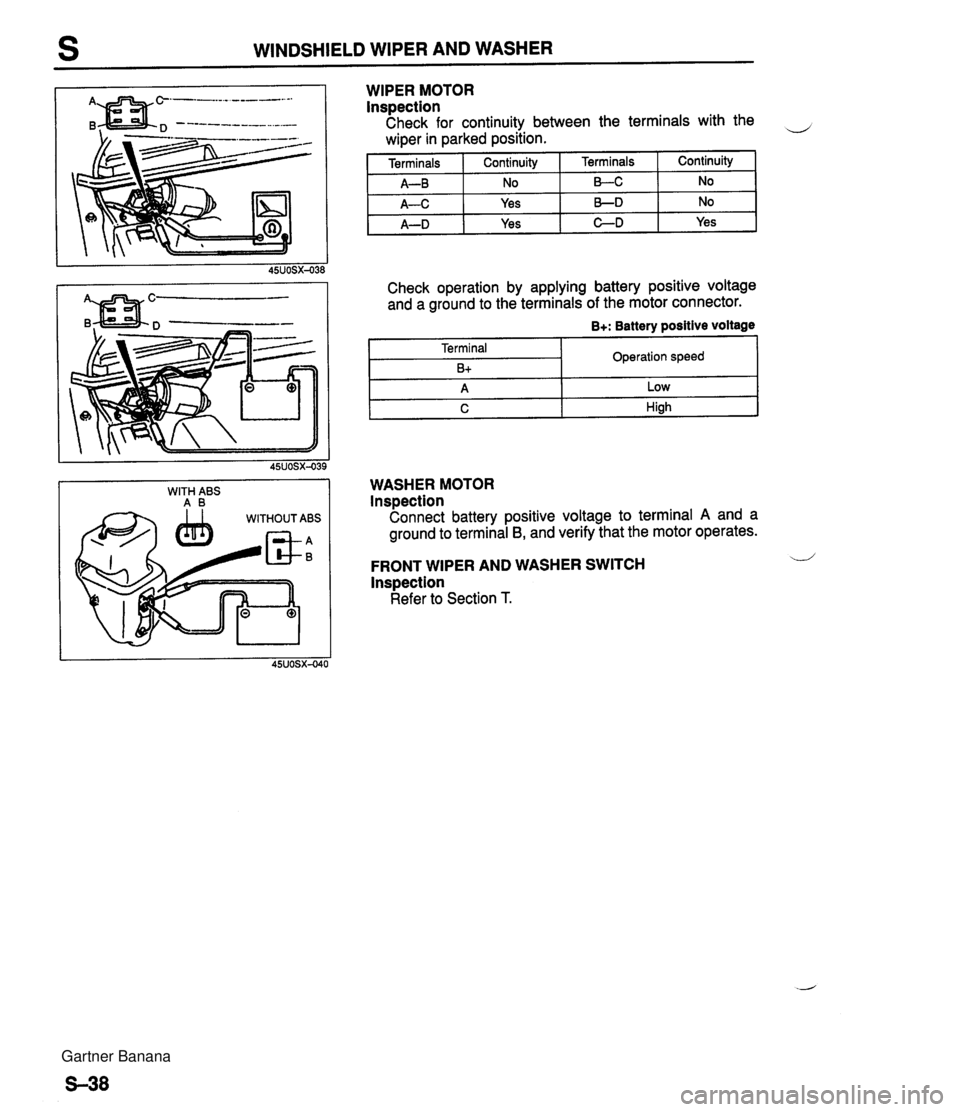

s WINDSHIELD WIPER AND WASHER WITH ABS A B WIPER MOTOR lnspection Check for continuity between the terminals with the wiper in parked position. Terminals A-B A-C A-D WASHER MOTOR lnspection Connect battery positive voltage to terminal A and a ground to terminal 6, and verify that the motor operates. Continuity NO Check operation by applying battery positive voltage and a ground to the terminals of the motor connector. B+: Battery positive voltage FRONT WIPER AND WASHER SWITCH lnspection Refer to Section T. Yes Yes Terminal B+ A Terminals B-C Operation speed Low Continuity NO B-D C-D No Yes Gartner Banana