SECTION T MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 948 of 1708

CRUISE CONTROL SYSTEM T T P N L JHF B T P N L JHF B CRUISE CONTROL UNIT Removal 1. Remove the passenger side kick panel. 2. Remove the nut and the control unit. Installation Install in the reverse order of removal. Inspection 1. Check the terminal voltages of the control unit. Discon- nect the CIS control unit connector before measuring the voltage at terminal J. 2. If the terminal voltages are correct, replace the control unit. B+: Battery positive voltage berminail Wire color I Connected to I Test condition 1~~ecificationl Action A B C E F (GN) ' (GIB) (G/O) (R) (YIB) G H PCMT (LGIB) J Cruise actuator Cruise actuator Cruise actuator Main switch Main switch (Y) Ignition switch OFF lanition switch ON Main switch OFF Main switch ON Main switch OFF Main switch ON Main switch OFF Main switch ON Main switch OFF Main switch ON Main switch OFF Main switch ON Brake switch (BIL) (BWW) OV B+ Shift to "N" or "P" range Shift to other range Clutch pedal depressed Clutch pedal released ParkINeutral switch Clutch switch OV 9V OV 9V ov 9V B+ OV OV B+ Check AT control unit (Refer to section K) - Brake pedal depressed Brake pedal released Check cruise actuator (Refer to page T-107) Check main switch (Refer to page T-106) OV 5V OV B+ OV 9V Check parWneutral switch (Refer to section K) Check clutch switch (Refer to page T-105) Check brake switch (Refer to page T-105) Gartner Banana

Page 959 of 1708

AUDIO Cassette tape player Name Tape slot Playlreverse button Stopleject button APC (automatic program control) button Dolby noise reduction bunon*' Fast forwardlrewind button lllustration Operation Insert a tape into tape slot to begin tape operation When tape is inserted, system determines tape type by identification hole in cassette pack; if metal or chromium tape, METAL is shown on display Press button during tape playback to play reverse side of tape Press button during fast forwardlrewind mode to play tape Press button during modes other than tape playback or tape Player OFF to select tape mode and play tape Press button during fast forwardlrewind mode to cancel mode; select tape playback mode, if desired Press button during tape playback to stop play Press again to eject tape Press button during tape playback and APC appears on display In this condition, press FF button skip to beginning of next program Press REW button during tape playback to rewind tape to beginning of current tune APC detects silence of more than 15 seconds and skips forward to next recorded section Press button when playing tape encoded with Dolby NR Dolby alternately turns ONIOFF with each press Press REW button to rewind tape Press FF button to fast forward tape The Dolby noise reduction system is manufactured under license of the Dolby Laboratory Licensing Corporation. -,, DOLBY and 00 are registered trade marks of Dolby Laboratory Licensing Corporation. Compact disc (CD) player Caution Never use mini CDs (8 cm (3.1 in)) because they may dislodge from the adapter and damage the disc or player. Use only standard CDs (12 cm (4.7 in)). Name Illustration Disc slot Playlstop button Lightly push disc, label-side up, into slot; auto loading mechanism will take over to set disc and begin play During loading, DlSC SET flashes on display When loading completed, DlSC SET displayed Press this button while disc is being played and play will pause Press again and play will resume Press button during tape or radio mode to play loaded disc Press button to eject disc Disc SET flashes on display Press again and disc is reloaded Gartner Banana

Page 962 of 1708

AUDIO T Cassette Player Tape slot Name APC (automatic program control) button Illustration U~ldown button I Tape button Playlreverse button Tape eject button 7 Dolby noise reduction button 'I -- - Operation Insert a tape into tape slot to automatically begin tape operation When tape is inserted, system determines tape type by identification hole in cassette pack; if metal or chromium tape, METAL is shown on display Press button during tape playback to enter APC mode; APC appears on display In this mode, press ( A ) button to skip to beginning of next program Press (V ) button during tape playback to rewind tape to beginning of current tune When APC detects silence of more than 15 seconds, it automatically skips forward to next recorded section Press (V ) button to rewind tape; press button again to play tape Press (A ) button to fast forward tape; press button again to play tape Press button during fast forward/rewind mode to cancel mode Press button to begin play Press button during tape playback to play reverse side of tape Press button to eject cassette tape Press button when playing tape encoded with Dolby NR Dolby alternately turns on or off with each press *l The Dolby noise reduction system is manufactured under license of the Dolby Laboratory Licensing Corporation. DOLBY and 00 are registered trade marks of Dolby Laboratory Licensing Corporation. Gartner Banana

Page 1063 of 1708

Before beginning any service procedure. refer to section T of this manual for I air bag system service warnings and audio antitheft system alarm conditions . HEATER AND AIR CONDITIONER SYSTEMS ....................................... INDEX U- 2 ................................... HEATER U- 2 AIR CONDITIONER ......................... U- 3 TROUBLESHOOTING ......................... U- 4 CIRCUIT DIAGRAM ......................... U- 4 TROUBLESHOOTING GUIDE ................ U- 5 ..................................... HEATER U-15 ........................ STRUCTURAL VIEW U-15 HEATER UNIT .............................. U-16 BLOWER UNIT ............................. U-18 HEATER CONTROL UNIT .................... U-20 AIR CONDITIONER ........................... U-23 PREPARATION ............................. U-23 STRUCTURAL Vl EW ........................ U-23 SERVICE WARNINGS ....................... U-24 SERVICE CAUTIONS ........................ U-24 REFRIGERANT SYSTEM SERVICE PROCEDURE .............................. U-25 COOLING UNIT ............................. U-30 CONDENSER AND RECEIVER DRIER ........ U-33 REFRIGERANT LINES ....................... U-35 CONDENSER FAN .......................... U-36 AIC RELAY ................................. U-37 ................... CONDENSER FAN RELAY U-37 REFRIGERANT PRESSURE SWITCH ......... U-37 NC COMPRESSOR ......................... U-38 45U0Ux-001 Gartner Banana

Page 1069 of 1708

TROUBLESHOOTING u 7- Symptom: Magnetic clutch does not operate I Normal operation of magnetic clutch The PCME controls the operation of the condenser fan and magnetic clutch, depending on engine load. (Refer to section F.) The magnetic clutch is supplied with battery positive voltage as follows: 1. The ACS and fan switch are turned on. 2. The PCME receives a signal that the ACS and fan switch are on and creates a ground circuit. 3. The A/C relay is magnetized and the contact is closed. 4. Battery positive voltage is applied to the magnetic clutch and the clutch locks. WIPER 20A AD FAN 20A FUSE BLOCK MAIN FUSE BLOCK Step 1 1. Check the following fuses. I Fuse I Amperage I Location I I I . - I WIPER I 20A 1 In fuse block I I AD FAN I 20A 1 In main fuse block I 2. If the fuses are OK, go to Step 2. 3. If a fuse is burned, check for a short circuit in the harness before replacing it. Step 2 1. Run the engine at idle. 2. Turn on the ACS and fan switch. 3. Measure the voltage at the A terminal wire of the mag- netic clutch connector. B+: Battery positive voltage I Terminal I Voltage I Action 1 Step 3 1. Start the engine. 2. Turn on the fan switch and ACS. 3. Measure the voltage at terminal C and A of the A/C relay connector. B+: Batterv positive voltaae - -- A 1 Terminal I V0lta0e 1 Action I I C I Other I Repair wiring harness (AD FAN 20A fuse - AIC relay) I B+ Other I 1. -. B+ I GO to step 4 Replace magnetic clutch Go to Step 3 I A 1 Other I Repair wiring harness (WIPER 20A fuse - AIC relay) I Gartner Banana

Page 1071 of 1708

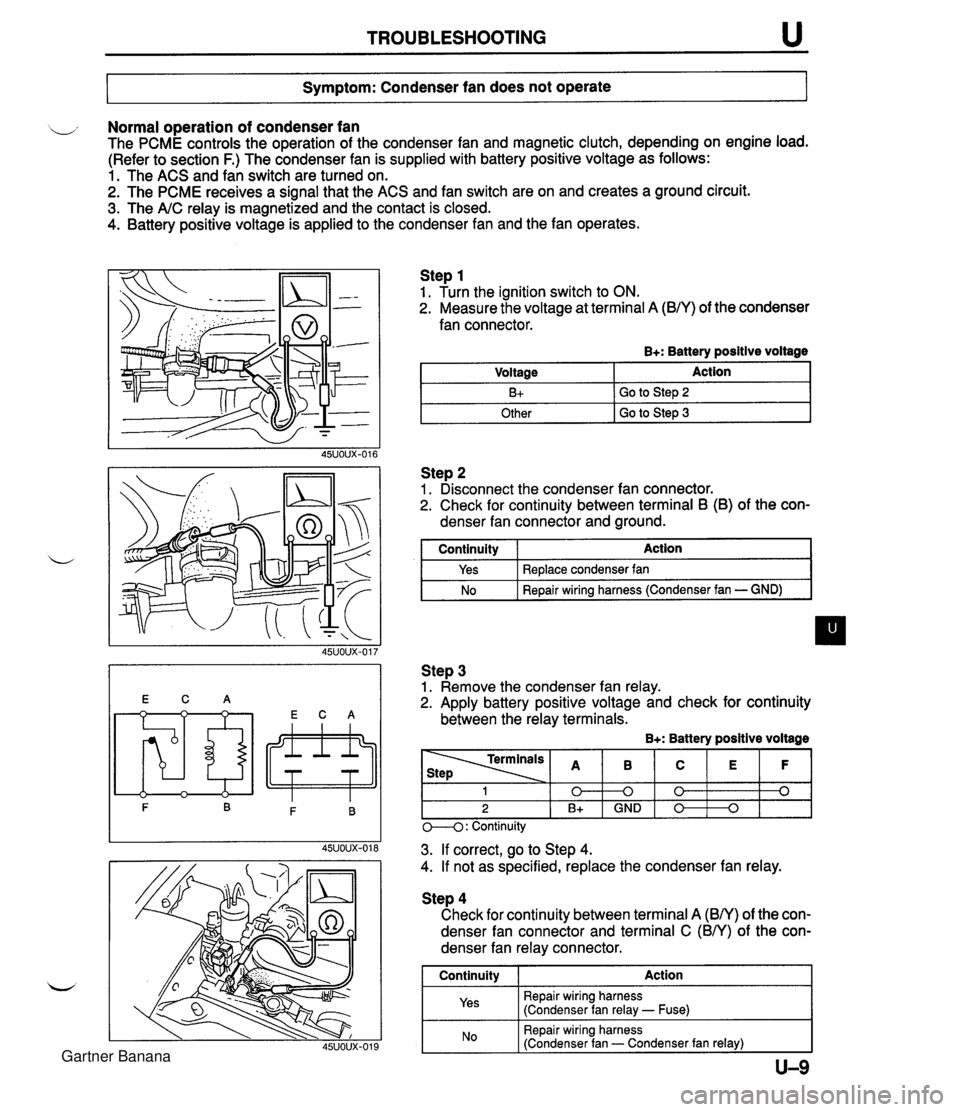

TROUBLESHOOTING u Symptom: Condenser fan does not operate Normal operation of condenser fan The PCME controls the operation of the condenser fan and magnetic clutch, depending on engine load. (Refer to section F.) The condenser fan is supplied with battery positive voltage as follows: 1. The ACS and fan switch are turned on. 2. The PCME receives a signal that the ACS and fan switch are on and creates a ground circuit. 3. The A/C relay is magnetized and the contact is closed. 4. Battery positive voltage is applied to the condenser fan and the fan operates. Step 1 1. Turn the ignition switch to ON. 2. Measure the voltage at terminal A (B/Y) of the condenser fan connector. B+: Battery positive voltage Step 2 1. Disconnect the condenser fan connector. 2. Check for continuity between terminal B (B) of the con- denser fan connector and ground. Voltage B+ Other I GO to step 3 Action Go to Step 2 I continuity I Action I Step 3 1. Remove the condenser fan relay. 2. Apply battery positive voltage and check for continuity between the relay terminals. B+: Battery positive voltage Yes No Replace condenser fan Repair wiring harness (Condenser fan - GND) M: Continuity - - - 3. If correct, go to Step 4. 4. If not as specified, replace the condenser fan relay. 1 0 2 B+ Step 4 Check for continuity between terminal A (BN) of the con- denser fan connector and terminal C (BN) of the con- denser fan relay connector. I Continuity I Action 1 Repair wiring harness (Condenser fan relay - Fuse) B 0 GND I Repair wiring harness (Condenser fan - Condenser fan relay) I C 0 0 E 0 F 0 Gartner Banana

Page 1078 of 1708

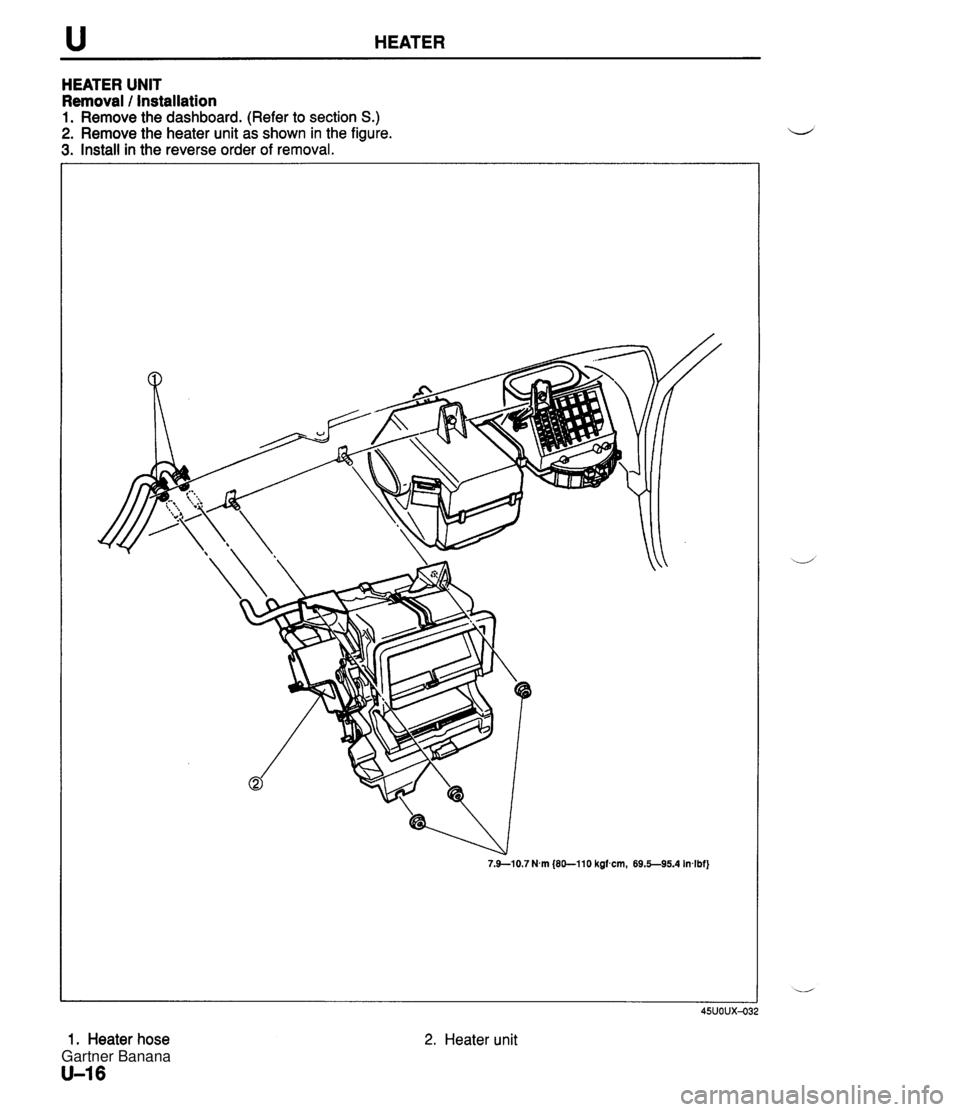

u HEATER HEATER UNIT Removal / Installation 1. Remove the dashboard. (Refer to section S.) 2. Remove the heater unit as shown in the figure. 3. Install in the reverse order of removal. 7.9-10.7 Nm (80-110 kgfcm, 69.5--95.4 In+bf] 1. Heater hose U-16 45UOUX4 2. Heater unit Gartner Banana

Page 1080 of 1708

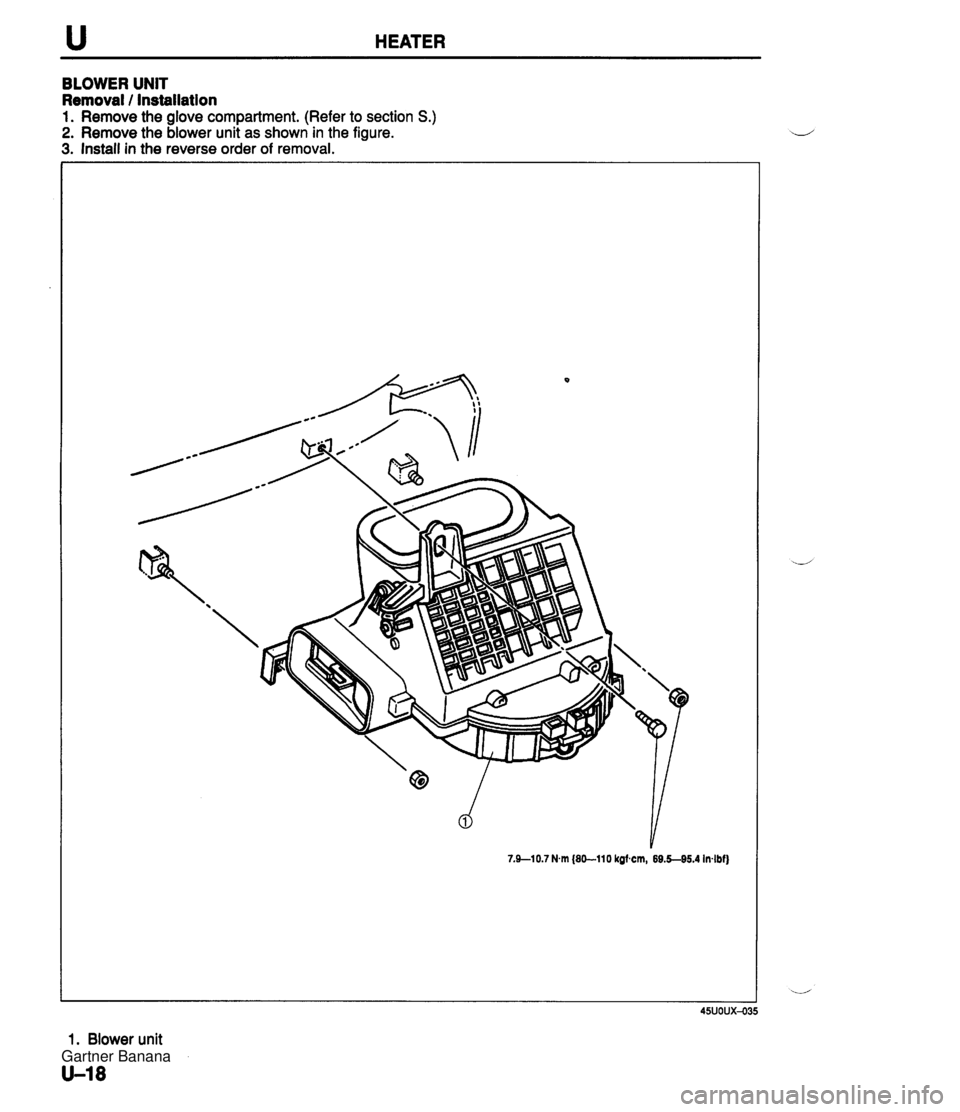

u HEATER BLOWER UNIT Removal / Installation 1. Remove the glove compartment. (Refer to section S.) 2. Remove the blower unit as shown in the figure. 3. Install in the reverse order of removal. 7.910.7 Nm (80-110 kof cm, 69.5-95.4 Inlbf) 1. Blower unit U-18 Gartner Banana

Page 1091 of 1708

AIR CONDITIONER u "C "F 26 24 22 20 18 16 14 12 10 40 59 60 70 RELATIVE HUMIDITY I ltem I Symptom 10. Read the dry thermometer at the air outlet, and calculate the difference between the inlet dry bulb and outlet dry bulb temperatures. 11. Verify that the intersection of the relative humidity and temperature difference is in the shaded zone. Checking Refrigerant Charge 1. Run the engine at a fast idle. 2. Operate the air conditioner at maximum cooling for a few minutes. 3. Determine the amount of refrigerant as shown below by observing the sight glass. 1 Bubbles present in sight glass 2 No bubbles present in sight glass Immediately after air conditioner turned OFF, refrigerant in sight glass stavs clear 141 When air conditioner turned OFF, re- frigerant foams, and then sight glass becomes clear -- Amount of refrigerant Insufficient refrigerant Action Check refrigerant pressure -- Too much or proper amount of refrig- erant Too much refrigerant Checking Refrigerant Pressure 1. Connect the manifold gauge set. (Refer to page U-25.) 2. Operate the engine at 1,500 rpm and set the air condi- tioner to maximum cooling. 3. Measure the low- and high-pressure sides. Turn air conditioner OFF, and watch bubbles (Refer to Items 3 and 4) Check refrigerant pressure Proper amount of refrigerant Stabilized condition Low-pressure side: 0.15-4.24 MPa {I .5--2.5 kgf/cm2, 22-35 psi) High-pressure side: 1.38-1.56 MPa (1 4.61 6.0 kgflcm*, 200-227 psi) Refrigerant amount normal Gartner Banana

Page 1092 of 1708

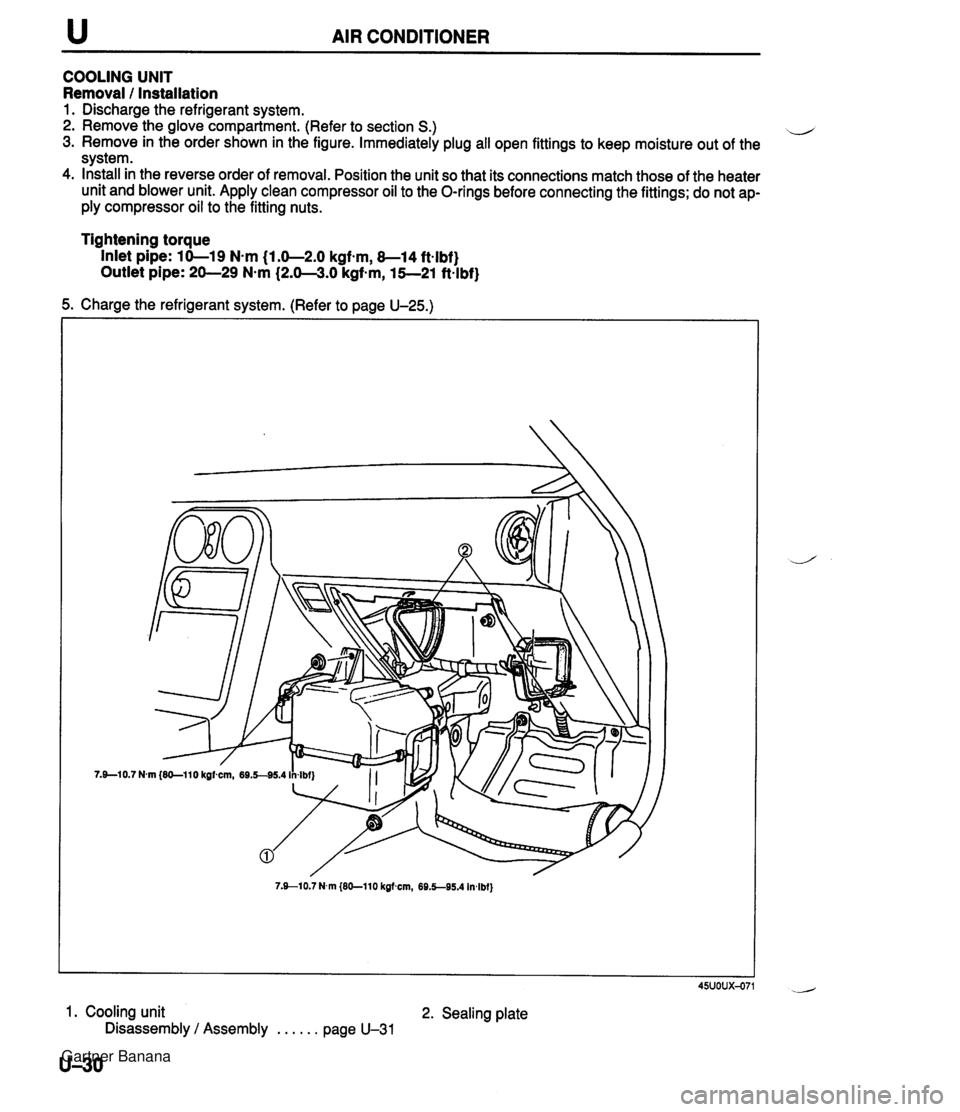

u AIR CONDITIONER COOLING UNIT Removal 1 Installation 1. Discharge the refrigerant system. 2. Remove the glove compartment. (Refer to section S.) il 3. Remove in the order shown in the figure. Immediately plug all open fittings to keep moisture out of the system. 4. Install in the reverse order of removal. Position the unit so that its connections match those of the heater unit and blower unit. Apply clean compressor oil to the O-rings before connecting the fittings; do not ap- ply compressor oil to the fitting nuts. Tightening torque Inlet pipe: 10-19 N-m (1.0-2.0 kgfsm, 8-14 ft-lbf} Outlet pipe: 20-29 N-m (2.0-3.0 kgf-m, 15--21 ft-lbf} 5. Charge the refrigerant system. (Refer to page U-25.) 7.910.7 N.m {EO-110 kgfmn, 69.5-95.4 In4bf} 45uoux-071 1. Cooling unit 2. Sealing plate Disassembly / Assembly . . . . . . page U-31 U-30 Gartner Banana