SECTION T MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 1094 of 1708

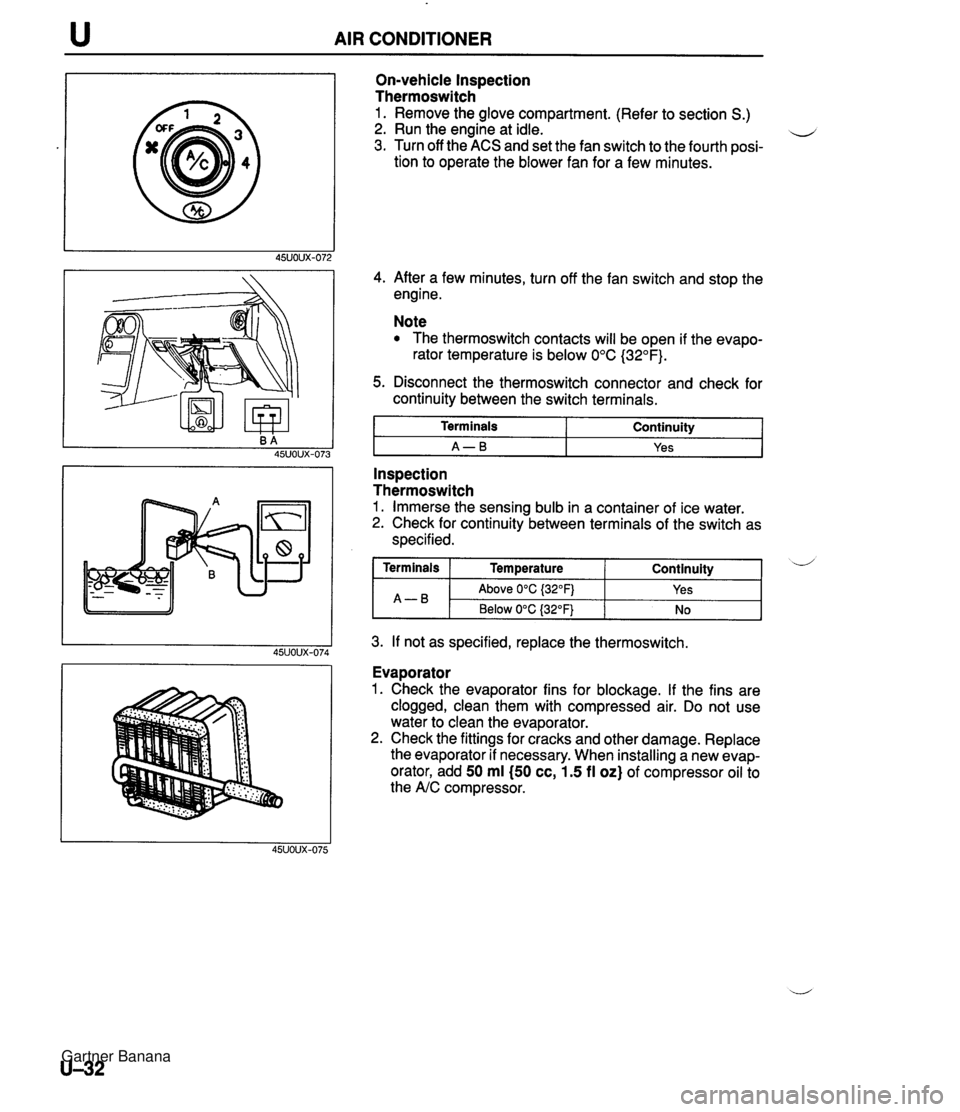

AIR CONDITIONER On-vehicle Inspection Thermoswitch 1. Remove the glove compartment. (Refer to section S.) 2. Run the engine at idle. u 3. Turn off the ACS and set the fan switch to the fourth posi- tion to operate the blower fan for a few minutes. 4. After a few minutes, turn off the fan switch and stop the engine. Note The thermoswitch contacts will be open if the evapo- rator temperature is below 0°C (32°F). 5. Disconnect the thermoswitch connector and check for continuity between the switch terminals. I Terminals I Continuity I I A-B I Yes I - -- Inspection Thermoswitch 1. Immerse the sensing bulb in a container of ice water. 2. Check for continuity between terminals of the switch as specified. 3. If not as specified, replace the thermoswitch. Continuity ( Terminals I Temperature A-B Evaporator 1. Check the evaporator fins for blockage. If the fins are clogged, clean them with compressed air. Do not use water to clean the evaporator. 2. Check the fittings for cracks and other damage. Replace the evaporator if necessary. When installing a new evap- orator, add 50 ml (50 cc, 1.5 fl oz) of compressor oil to the A/C compressor. d Above 0°C {32OFj Below 0°C (32°F) Yes No Gartner Banana

Page 1120 of 1708

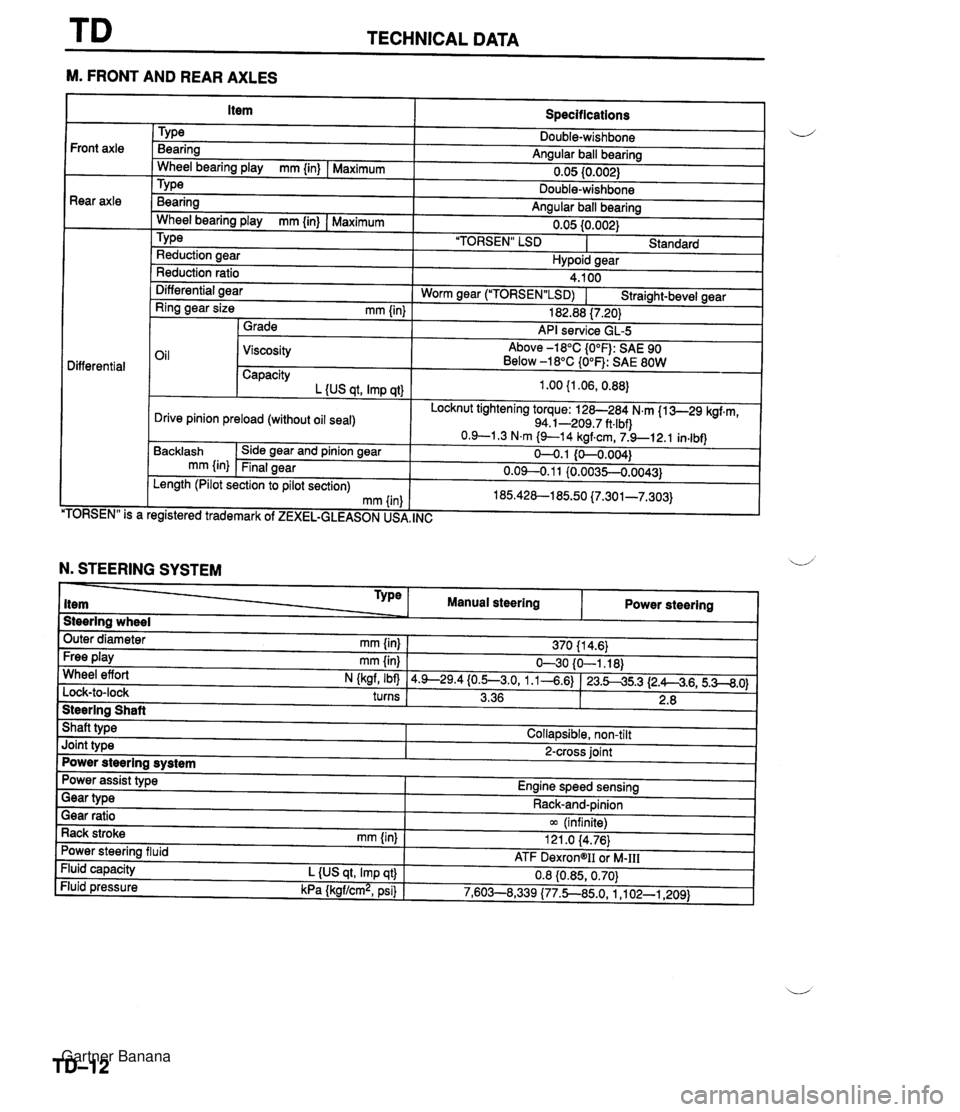

TECHNICAL DATA --- M. FRONT AND REAR AXLES Specifications TY pe Bearing Angular ball bearing 0.05 10.002) Front axle Rear axle - Wheel bearing play mm {in) I Maximum Bearina Anaular ball bearina . .. Wheel bearina plav mm {in) I Maximum " " 0.05 {0.002) 'TORSEN" LSD I Standard TY pe Reduction aear Hvpoid sear Reduction ratio Differential aear 4.100 Worm near ("1ORSEN"LSD) I Straiaht-bevel gear - - Ring gear size mm {in) 1 Grade 182.88 17.201 API service GL-5 Oil 1 Viscosity Above -18°C {O°F): SAE 90 Below -18°C {O°F): SAE 80W Differential Capacity L {US at. Imp at) Locknut tightening torque: 128-284 N.m {I 3-29 kgf.m, 94.1-209.7 ft.lbf) Drive pinion preload (without oil seal) TORSEN" is a Backlash mm {in) . , egistered trademark of ZEXEL-GLEASON US, Side gear and pinion gear Final gear , INC Length (Pilot section to pilot section) mm (in N. STEERING SYSTEM Steering wheel Outer diameter mm {in} 1 370 11 4.6) Type item Free play mm {in) I 630 {O-1.18) Wheel effort N (kaf, Ibfl 14.9--29.4{0.5--3.0, 1.1-4.6) 123.545.3 12.A4.6,5.3--8.0) turns I 3.36 1 2.8 I 1 Manual steering Steering Shaft Shaft type I Collapsible, non-tilt Power steering Joint type I 2-cross joint Power steering system Gear ratio 1 m (infinite) Rack stroke rnm {in) I 121 .O 14.76) Power assist type Engine speed sensing Power steering fluid Fluid capacity L {US qt, Imp qt} Fluid pressure kPa {kgf/cm2, psi) Gear type - - ATF DexrongII oi M-111 0.8 {0.85,0.70) 7,603--8,339 (77.5850, 1 ,I 02-1,209) Rack-and-pinion Gartner Banana

Page 1255 of 1708

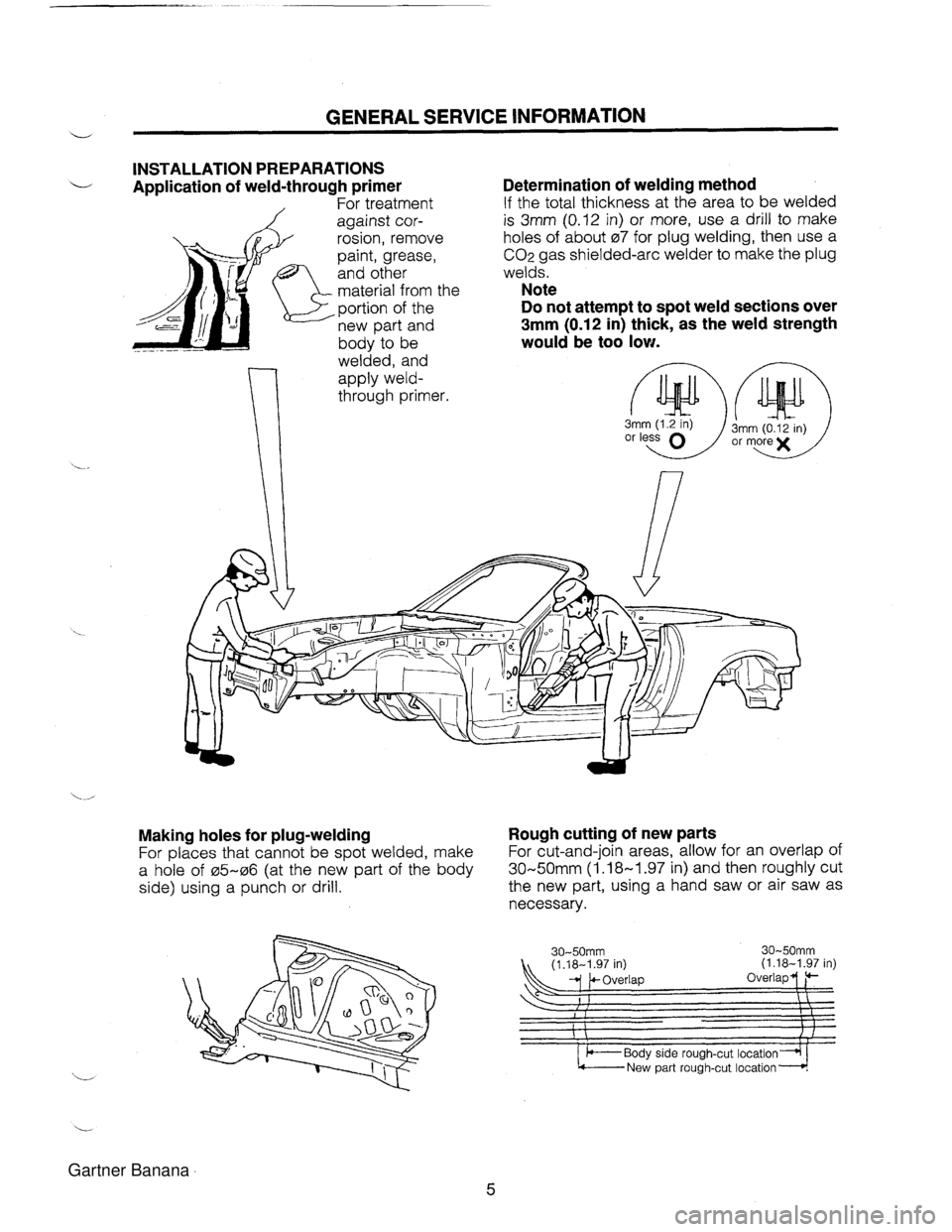

u GENERAL SERVICE INFORMATION INSTALLATION PREPARATIONS Application of weld-through primer 1 For treatment against cor- rosion, remove paint, grease, and other material from tl ,portion of the new part and body to be welded, and apply weld- Determination of welding method If the total thickness at the area to be welded is 3mm (0.12 in) or more, use a drill to make holes of about 07 for plug welding, then use a CO2 gas shielded-arc welder to make the plug welds. Note Do not attempt to spot weld sections over 3mm (0.12 in) thick, as the weld strength would be too low. or less Making holes for plug-welding Rough cutting of new parts For places that cannot be spot welded, make For cut-and-join areas, allow for an overlap of a hole of 05-06 (at the new part of the body 30-50mm (1.18-1.97 in) and then roughly cut side) using a punch or drill. the new part, using a hand saw or air saw as necessary. 30-50mm (1.18-1.97 in) (1.18-1.97 in) overlap Gartner Banana

Page 1257 of 1708

GENERAL SERVICE INFORMATION L ANTI-CORROSION TREATMENT When replacing body panels, always apply body sealer, anti-rust treatment. or undercoating ac- cording to the requirements of the market. Application of surface agent and body sealer After first applying the coating of surfacing agent, apply body sealer where necessary. Note For locations where application of body sealer is difficult after installation, apply .t-before the installation. Application of rust inhibitor Undercoating Apply rust inhibitor to the back of welded areas, Use antirust treatment for underbody welding using an installation hole or a gap near that spots and wheel housings. section. Gartner Banana

Page 1338 of 1708

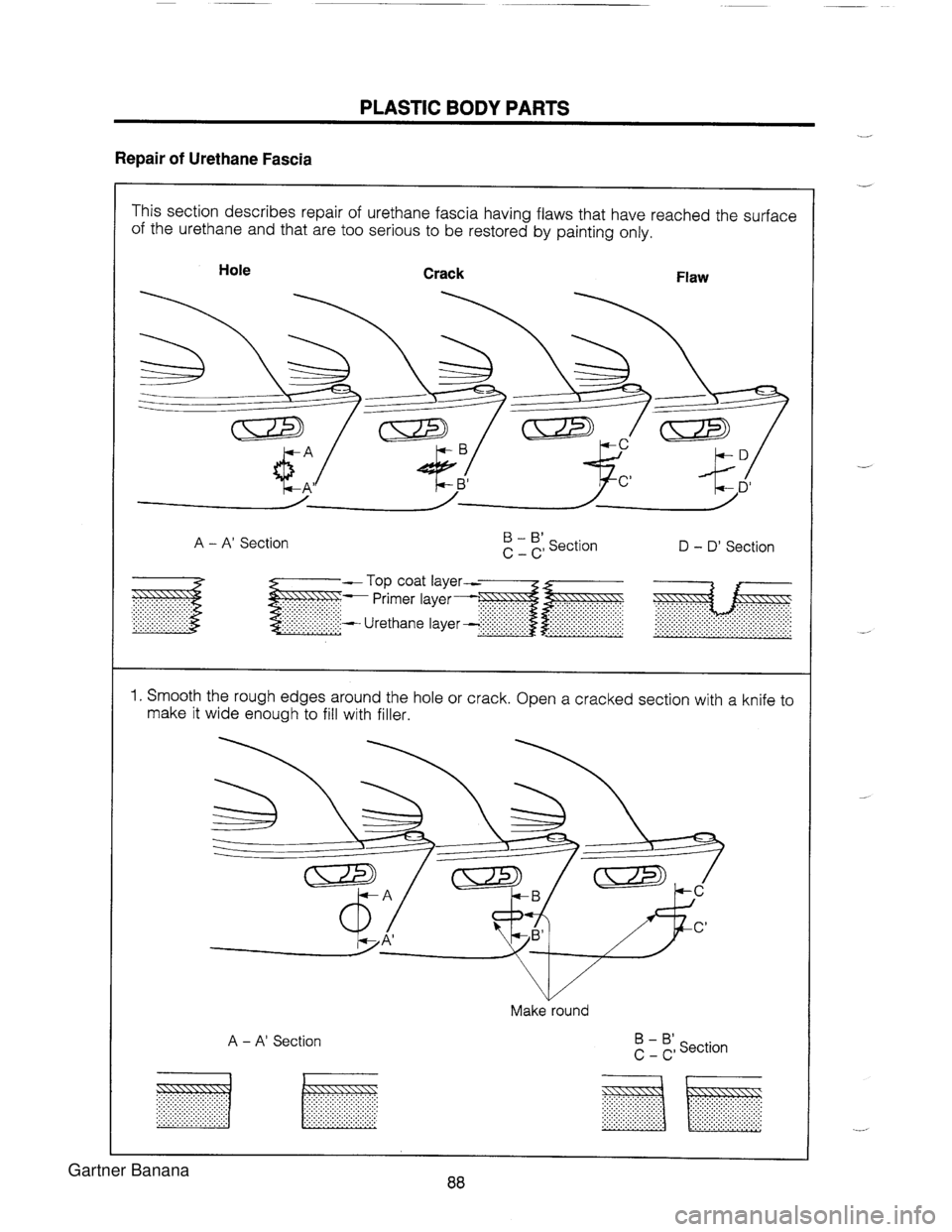

PLASTIC BODY PARTS Repair of Urethane Fascia This section describes repair of urethane fascia having flaws that have reached the surface of the urethane and that are too serious to be restored by painting only. Hole Crack Flaw A - A' Section - B' section C - C' D - D' Section - Top coat ............. 1. Smooth the rough edges around the hole or crack. Open a cracked section with a knife to make it wide enough to fill with filler. I Make round I A - A' Section - B' Section C - C' Gartner Banana

Page 1339 of 1708

![MAZDA MX-5 1994 Workshop Manual L PLASTIC BODY PARTS 2. Sand away the old paint around the damaged area [in the range of 30-35mm (1.18-1.38 in)] with #40-#80 sandpaper. 30-35mti-l A - * Section 30-35mm (1.18-1.38 in) (1.18-1.38 in MAZDA MX-5 1994 Workshop Manual L PLASTIC BODY PARTS 2. Sand away the old paint around the damaged area [in the range of 30-35mm (1.18-1.38 in)] with #40-#80 sandpaper. 30-35mti-l A - * Section 30-35mm (1.18-1.38 in) (1.18-1.38 in](/img/28/57072/w960_57072-1338.png)

L PLASTIC BODY PARTS 2. Sand away the old paint around the damaged area [in the range of 30-35mm (1.18-1.38 in)] with #40-#80 sandpaper. 30-35mti-l A - *' Section 30-35mm (1.18-1.38 in) (1.18-1.38 in) - '' Section C - C' 30-35mm 30-35mm (1.18-1.38 in) (1.18-1.38 in) i D - D' Section 30-35rnm 30-35mrn (1.18-1.38 in) (1.18-1.38 in) Gartner Banana

Page 1340 of 1708

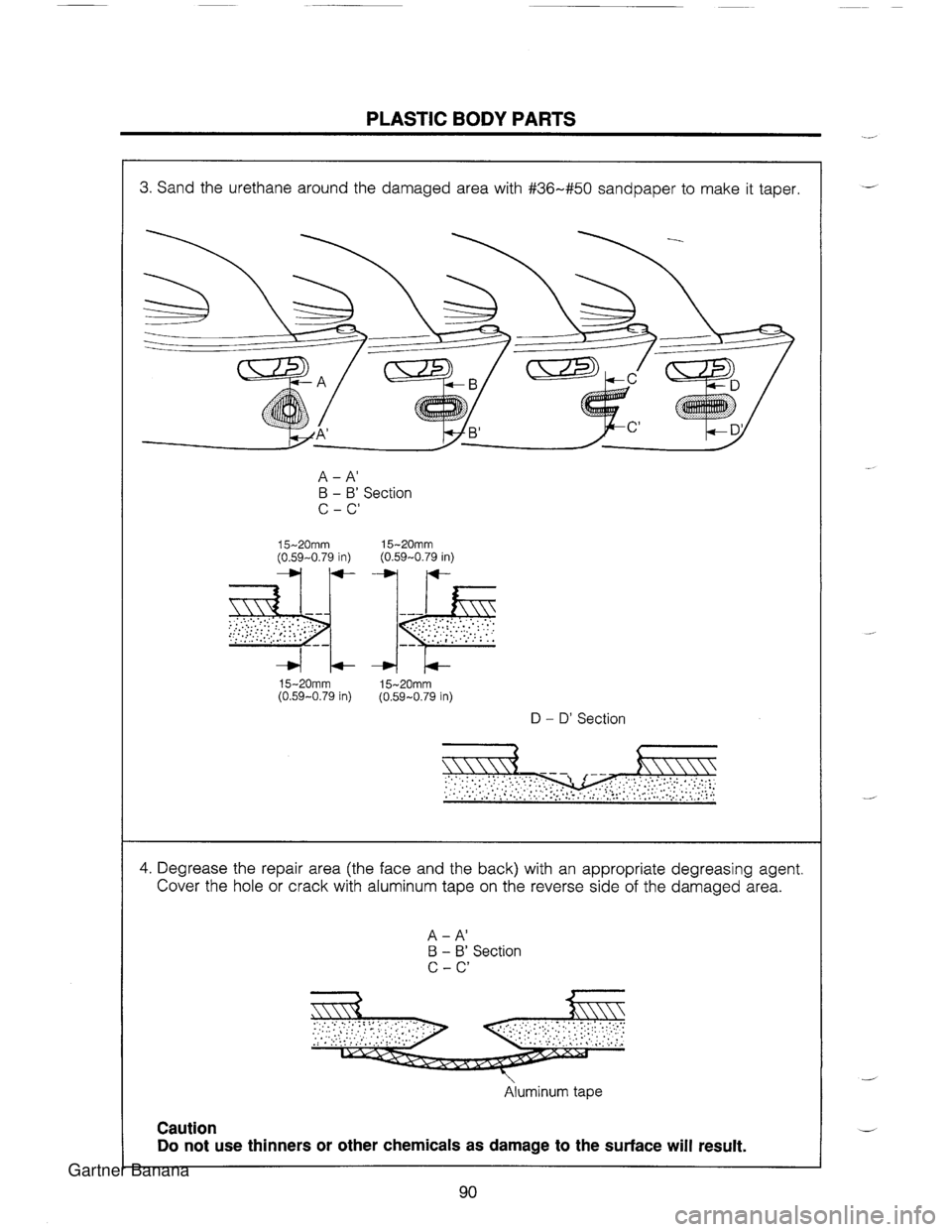

PLASTIC BODY PARTS 3. Sand the urethane around the damaged area with #36-#50 sandpaper to make it taper. A - A' B - B' Section C - C' 15-20mm (0.59-0.79 in) ............... 15-20mm (0.59-0.79 in) 15-20mm (0.59-0.79 in) 7 w 4 t+- 15-20mm (0.59-0.79 in) D - D' Section 4. Degrease the repair area (the face and the back) with an appropriate degreasing agent. Cover the hole or crack with aluminum tape on the reverse side of the damaged area. A - A' B - 8' Section C - C' I Aluminum tape Do not use thinners or other chemicals as damage to the surface will result. I Gartner Banana

Page 1341 of 1708

PLASTIC BODY PARTS L 5. Apply repairing filler A - A' B - B' Section Repair filler 7 C-C' / D - D' Section The repair filler is a two-part type filler composed of a main agent and a stiffening agent, and has the same flexibility as the urethane when hardened. In the case of air drying [18"C (65"F)], the part may be sanded after approx. 2 hrs. In the case of heat drying [50°C (122"F)], the part may be sanded after approx. 40 min. 6. Air dry or heat dry. Dry the applied repair filler completely. Drying time 7. After the repair filler has completely dried, and the repaired part with #I 20, #I80 and #240 sandpaper, respectively, to make it smooth. The effected part must not exceed 80°C (1 76"F), 120 or it may be deformed. ; go .- 3 - C 60 0 .- C h 3 0 30 0 A - A' B - B' Section , * n, --- - - : - - -- I I I ----- 1 -- - I I I --- --: --- I I I , - - - - - - - - - - -----; ----- L ----I I I I I I I I , I I I I - I 8 I I D - D' Section , 10 20 30 40 50 (50) (68) (86) (104) (122) Temperature "C (OF) Note If the repaired part is made concave, apply extra repair filler. Gartner Banana

Page 1342 of 1708

PLASTIC BODY PARTS - 8. Sand the paint around the damaged area with #240 sandpaper to make it smooth. Degrease with appropriate A - A' degreasing agent I3 - 6' Section ,/ ,.. -. Caution Do not use thinners or other chemicals as damage to the surface will result. 9. Spray primer (heat drying) or primer surfacer (air drying) only on the effected area of the part. (Spot spraying) A - A' I3 - 6' Section C - C' D - D' Section 10. Dry the part. 1) Primer (Forced drying) Uniformly heat the repaired part. Heating condition: 80°C (176OF) (The temperature of the part) x 20 minutes Gartner Banana

Page 1346 of 1708

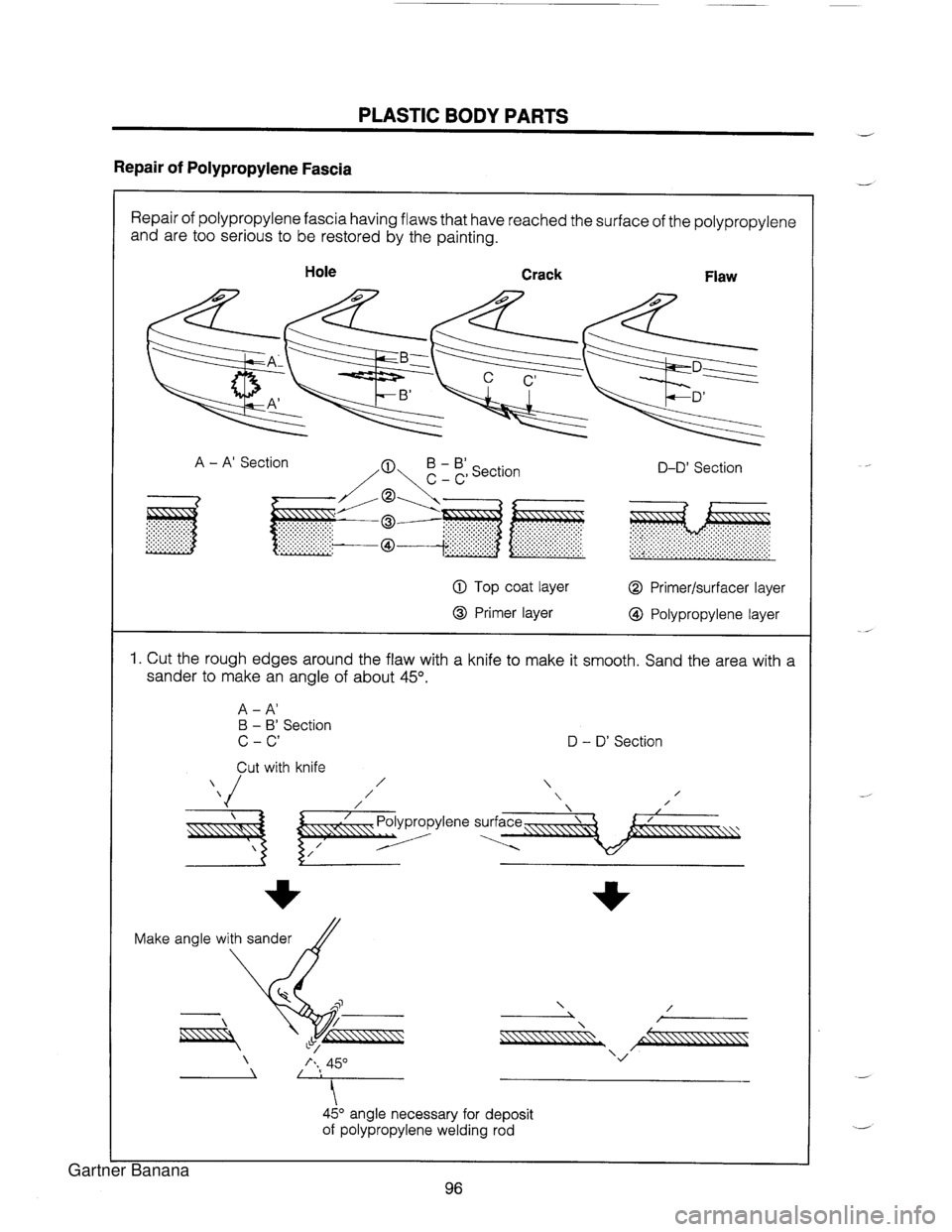

PLASTIC BODY PARTS d Repair of Polypropylene Fascia Repair of polypropylene fascia having flaws that have reached the surface of the polypropylene and are too serious to be restored by the painting. I Hole Crack Flaw A - A' Section B - B' /a - c, Section D-D' Section @ Top coat layer O Primerlsurfacer layer @ Primer layer @ Polypropylene layer I 1. Cut the rough edges around the flaw with a knife to make it smooth. Sand the area with a sander to make an angle of about 45". A - A' B - B' Section D - D' Section ,,/Cut with knife / / / / Make angle with sander - / I L h, 45" - 45" angle necessary for deposit of polypropylene welding rod Gartner Banana