lock MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 659 of 1708

N ENGINE SPEED SENSING POWER STEERING 7. Attach the SST to the pinion and install the plug assem- bly. Adjusting cover 1. Tighten the mounting bracket in a vise. 2. Set the rack to the center position. 3. Tighten the adjusting cover to 4.9 N.m (50 kgf.cm, 43 in4bf) with the SST three times, then return it 25". 4. Apply sealant to the threads of the locknut. 5. Attach the locknut. 6. Measure the pinion torque by using the SST and a pull scale. Standard Center of rack + 90": 1 .O-1 .I N-m {I 0-1 2 kgf-cm, 8.7-1 0.4 in-lbf) ii Scale reading: 1 .&I .2 kg (2.2-2.64 Ib) 7. If not within specification, repeat steps 3 through 6. 8. Install the locknut. Tightening torque: 59-74 N.m (6.0-7.5 kgf.m, 44--54 ftdbf) Hermetic sealing inspection 1. Connect the SST to the power cylinder section of the gear housing. 2. Apply 53.3 kPa (400 mmHg, 15.7 inHg) vacuum with a vacuum pump and verify that it is held for at least 30 seconds. 3. If the vacuum is not held, replace the oil seal. Tie rod 1. Secure the rack gear in a vise, and tighten the tie rods with the wrench. Tightening torque: 79-98 N.m (8.0-10.0 kgf-m, 58-72 ft-lbf) 2. Align the washer with the rack groove, and crimp the washer. Gartner Banana

Page 663 of 1708

N ENGINE SPEED SENSING POWER STEERING Disassembly Note Oil pump Use the SSTwhen securing the oil pump in a vise, so that force is not applied to the pulley or shaft. Inspection Pump body front, rear lnspect the front and rear of the pump body for cracks and damage, and the friction surface of the rotor for wear. Replace the pump assembly if a problem is found. Cam ring, rotor, blade, side plate 1. lnspect the blade friction surface of the cam ring for wear. 2. lnspect the pump body of the rotor and side plate friction surface for wear. 3. lnspect the cam ring friction surface of the blade for -, wear. 4. lnspect clearance between the rotor and blade. Control valve, spring 1. lnspect the control valve for cracks, damage and block- age, and the friction surface for wear. 2. lnspect the spring for damage. Assembly Note Rotor Install the rotor with the indentification mark facing upward. Gartner Banana

Page 666 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . BRAKING SYSTEM INDEX ....................................... P- 2 OUTLINE ..................................... P- 4 SPEClFlCATlONS ........................... P- 4 BRAKE SYSTEM ............................. P- 5 PREPARATION ............................. P- 5 TROUBLESHOOTING GUIDE ................ P- 6 AIR BLEEDING ............................. P- 7 BRAKE HYDRAULIC LINE ................... P- 7 BRAKE FLUID .............................. P- 8 ............................. BRAKE PEDAL P- 9 MASTER CYLINDER (STANDARD) ............ P-11 MASTER CYLINDER (ABS) .................. P-14 POWER BRAKE UNIT ....................... P-20 PROPORTIONING BYPASS VALVE ........... P-23 FRONT BRAKE (DISC) ...................... P-25 CALIPER ................................... P-28 REAR BRAKE (DISC) ........................ P-29 CALIPER ................................... P-32 PARKING BRAKE SYSTEM .................... P-34 TROUBLESHOOTING GUIDE ................ P-34 PARKING BRAKE LEVER .................... P-34 PARKING BRAKE CABLE .................... P-36 ANTILOCK BRAKE SYSTEM (ABS) ............ P-37 DESCRIPTION .............................. P-37 PREPARATION ............................. P-37 TROUBLESHOOTING GUIDE ................ P-38 CIRCUIT DIAGRAM ......................... P-52 HYDRAULIC UNIT ........................... P-53 ........................ ABS CONTROL UNIT P-55 RELAYS .................................... P-56 ABS WHEEL SPEED SENSOR (FRONT) ....... P-58 ABS SENSOR ROTOR (FRONT) .............. P-59 ABS WHEEL SPEED SENSOR (REAR) ........ P-60 ABS SENSOR ROTOR (REAR) ............... P-61 25UOPX-001 Gartner Banana

Page 668 of 1708

INDEX P ANTILOCK BRAKE SYSTEM (ABS) 1. Hydraulic unit 5. ABS sensor rotor (front) Removal / Installation ......... page P-53 Removal / Ins~ection / ................. Disassembly / Assembly ...... page P-54 Installation page P-59 2. ABS control unit 6. ABS wheel-speed sensor (rear) Removal I Installation ......... page P-55 Removal 1 Inspection I ................. 3. Relays Installation page P-60 Removal / Inspection / 7. ABS sensor rotor (rear) ......... ................. w Installation page P-56 Removal / Inspection page P-61 .................. 4. ABS wheel-speed sensor (front) Installation page P-62 Removal / Inspection / ................. Installation page P-58 Gartner Banana

Page 670 of 1708

BRAKE SYSTEM P BRAKE SYSTEM PREPARATION - SST Wrench, flare nut 49 0221 600C Expand tool, disc brake 49 8043 001 Adjust gauge 49 8043 004 Wrench, socket Gauge, oil pressure (Part of 49 U043 OAO) - 49 U043 006 Hose (Part of 49 U043 OAO) For removal and installation brake PIPS For installation of disc pads 49 F043 001 Adjust gauge For Adjustment of push rod clearance For adjustment of push rod clearance 49 0208 701 A Boot air out tool For adjustment of push rod clearance For inspection of brake fluid pressure For removal of piston seal 49 8043 003 Lock tool, turning For inspection of brake fluid pressure For adjustment of push rod clearance 49 U043 OAO Gauge set, oil pressure & - For inspection of brake fluid pressure 49 U043 005 Joint (Part of ,-, 49 U043 OAO) For inspection of brake fluid pressure Gartner Banana

Page 674 of 1708

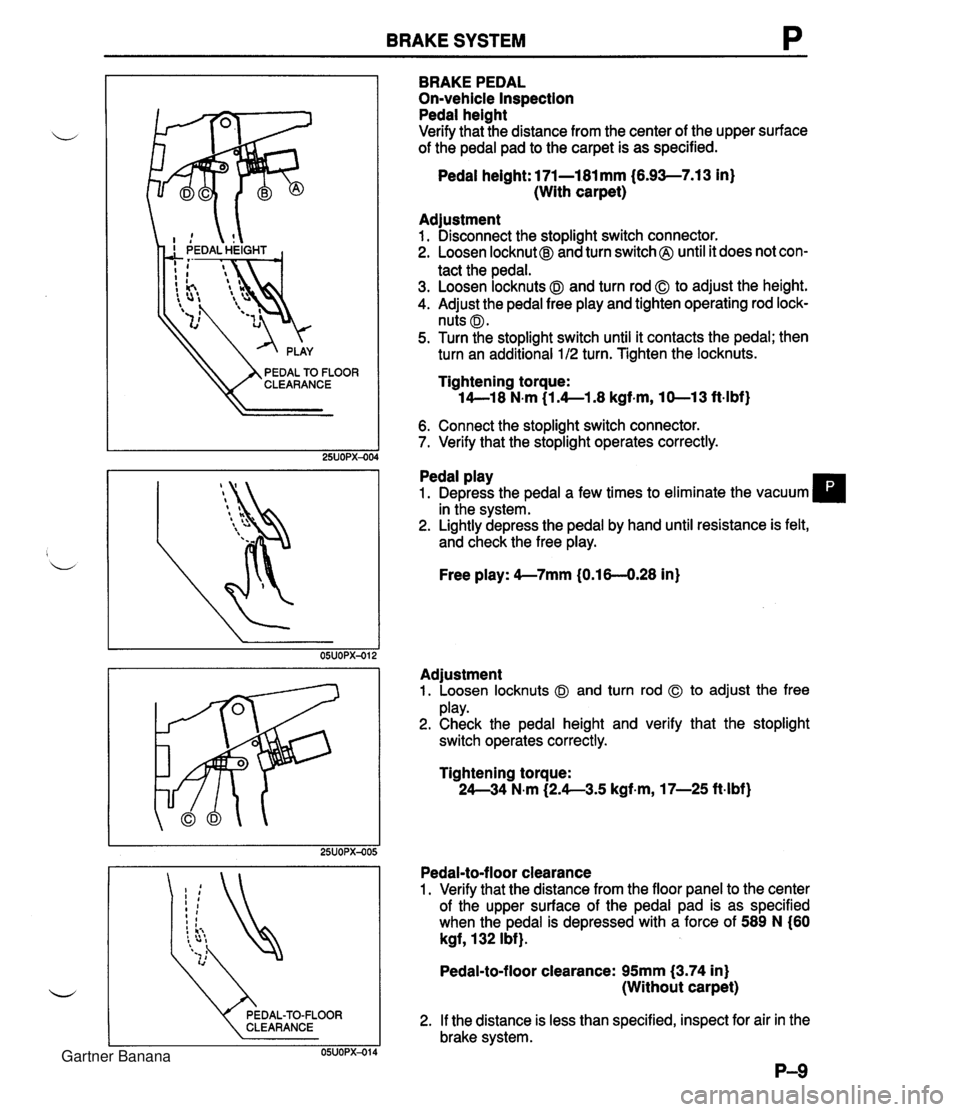

BRAKE SYSTEM P CLEARANCE BRAKE PEDAL On-vehicle Inspection Pedal height Verify that the distance from the center of the upper surface of the pedal pad to the carpet is as specified. Pedal height: l7l-l8l mm (6.93-7.13 in} (With carpet) Adjustment 1. Disconnect the stoplight switch connector. 2. Loosen locknut@ and turn switch @ until it does not con- tact the pedal. 3. Loosen locknuts @I and turn rod 0 to adjust the height. 4. Adjust the pedal free play and tighten operating rod lock- nuts @I. 5. Turn the stoplight switch until it contacts the pedal; then turn an additional 1 /2 turn. Tighten the locknuts. Tightening torque: 14--18 N.m (1.4--1.8 kgf-m, 10-13 ft-lbf) 6. Connect the stoplight switch connector. 7. Verify that the stoplight operates correctly. Pedal play 1. Depress the pedal a few times to eliminate the vacuum in the system. 2. Lightly depress the pedal by hand until resistance is felt, and check the free play. Free play: 4--7mm (0.16-4.28 in) Adjustment 1. Loosen locknuts @I and turn rod to adjust the free play. 2. Check the pedal height and verify that the stoplight switch operates correctly. Tightening torque: 24--34 N.m (2.4--3.5 kgf-m, 17-25 ft-lbf} Pedal-to-floor clearance 1. Verify that the distance from the floor panel to the center of the upper surface of the pedal pad is as specified when the pedal is depressed with a force of 589 N (60 kgf, 132 Ibf}. Pedal-to-floor clearance: 95mm (3.74 in} (Without carpet) 2. If the distance is less than specified, inspect for air in the brake system. Gartner Banana

Page 677 of 1708

P BRAKE SYSTEM ADJUSTING BOLT I ADJUSTING BOLT ' CKNUT Removal note Brake pipe Caution . Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off lm- mediately. 1. Modify the brake pipe tightening torque to allow for use of a torque wrench-SST combination. (Refer to section GI) "Torque Formulas'' 2. Disconnect/connect the brake pipe fromlto the master . . cylinder by using the SST. 3. Tighten the brake pipe by using the SST. Tightening torque: 13-22 N-m (1.3-2.2 kgfem, 9.4--16 ft-lbf) Installation note Master cylinder 1. Measure the clearance between the push rod of the power brake unit and the piston of the master cylinder. (1) Place the SST atop the master cylinder. Turn the adjusting bolt until it bottoms in the piston. i (2) Apply 66.7 kPa (500 mmHg, 19.7 inHg} vacuum to the power brake unit with a vacuum pump. (3) Invert the SST used in step 1, and place it on the power brake unit. (4) Measure the clearance between the end of the adjusting bolt and the push rod of the power brake unit. If it is not Omm (0 in}, loosen the push rod locknut and turn the push rod to make the adjustment. Gartner Banana

Page 680 of 1708

BRAKE SYSTEM P I I TOUCHING 1 T~~H,IN~ I ADJUSTING NUT 97GOPX-O Removal note Brake pipe Cautlon Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off im- mediately. 1. Modify the brake pipe tightening torque to allow for use of a torque wrench-SST combination. (Refer to section GI) "Torque Formulas" 2. Disconnect~connect the brake pipe fromlto the master cylinder by using the SST. 3. Tighten the brake pipe by using the SST. Tightening torque: 13--22 N-m (1 3-2.2 kgf-m, 9.4--16 ft-lbf) Installation note Master cylinder Inspect the push rod clearance as follows. 1. Turn the nut of the SST clockwise to fully retract the SST gauge rod. Attach the SST to the power brake unit. Tightening torque: 9.8-15.7 N.m (1 .&I .6 kgf.m, 7.2-11.6 ft4bf) 2. Apply 66.7 kPa (500 mmHg, 19.7 inHg) vacuum using a vacuum pump. 3. Turn the adjusting nut of the SST counterclockwise until the gauge rod just contacts the push rod end of the power brake unit. Push lightly on the end of the gauge rod to be sure it is seated. Verify that there is no gap between the adjusting nut and SST body. Gartner Banana

Page 690 of 1708

BRAKE SYSTEM P FRONT BRAKE (DISC) Quick Inspection, On-vehicle Disc pad 1. On level ground, jack up the front of the vehicle and sup- port it with safety stands. 2. Remove the wheels. 3. Sight through the caliper inspection hole and verify the remaining thickness of the pad. Thickness: 1 .Omm (0.04 in) min. I I 05UOPX-034 Replacement (Disc pad) 1. Remove in the order shown in the figure, referring to Removal Note. 2. Install in the reverse order of removal, referring to Installation Note. 1. Lock bolt 3. Outer shim Removal Note ................... below 4. Inner shim 2. Disc pad 5. Guide plate Installation Note ............. page P-26 Removal note Lock bolt 1. Remove the lower lock bolt. 2. Rotate the caliper upward and support it with a piece of rope. Gartner Banana

Page 694 of 1708

BRAKE SYSTEM ,$, .... "P ...% REAR BRAKE (DISC) Quick Inspection, On-vehicle Disc pad 1. On level ground, jack up the rear of the vehicle and sup- port it with safety stands. 2. Remove the wheels. 3. Sight through the caliper inspection hole and verify the remaining thickness of the pad. Thickness: 1 .Omm (0.04 in} min. I I 05UOPX-043 Replacement (Disc pad) 1. Remove in the order shown in the figure, referring to Removal Note. 2. Install in the reverse order of removal, referring to Installation Note. 1. Plug 4. M-spring 2. Manual adjustment gear 5. Disc pad Removal Note ................... below Inspection ................... page P-31 Installation Note ............. page P-30 6. Shim 3. Lock bolt 7. Guide plate RETRACTING BRAKE PADS Removal note Manual adjustment gear Turn the manual adjustment gear counterclockwise with an Allen wrench to pull the brake caliper piston back. Gartner Banana