lock MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 695 of 1708

BRAKE SYSTEM ADJUSTING BRAKE PADS Installation note Manual adjustment gear 1. Turn the manual adjustment gear clockwise until the brake pads just touch the disc plate. -1 2. Return the manual adjustment gear counterclockwise 113 turn. Removal 1 lnstallation (Caliper) 1. On level ground, jack up the rear of the vehicle and support it with safety stands. 2. Remove the wheels; then remove components in the order shown in the figure, referring to Removal Note. 3. Install in the reverse order of removal, referring to lnstallation Note. 4. Inspect all parts and repair or replace as necessary. 5. Tighten all nuts and bolts to the specified torques, referring to the figure. Parking brake cable Removal I Inspection 1 Installation ................. page P-36 Connecting bolt Brake hose Plug Manual adjustment gear Removal Note ............... page P-29 Installation Note ................. above Lock bolt 7. Caliper Disassembly I Inspection 1 Assembly .................. page P-32 8. Disc pad Replacement ................ page P-29 Inspection ................... page P-31 9. Bolt 10. Mounting support 11. Disc plate Inspection ................... page P-31 Gartner Banana

Page 697 of 1708

P BRAKE SYSTEM CALIPER Disassembly / Inspection / Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. Assemble in the reverse order of disassembly, referring to Assembly Note. REPLACE Up /REPLACE REPLACE kf'h \u b REPLACE 1. Dust seal lnspect for damage and poor sealing 2. Piston Disassembly Note ................ below Assembly Note .............. page P-33 lnspect for wear and rust 3. Manual adjustment gear 4. Snap ring 5. Adjusting bolt 6. O-ring 7. Connecting link 8. Piston seal Disassembly Note ............ page P-33 9. Spring 10. Operating lever 11. Boot 12. Cap and bleeder screw 13. Boot 14. Boot 15. Caliper body lnspect for damage and cracks Disassembly note Piston 1. Turn the manual adjustment gear clockwise with an Allen wrench. (Turn the manual adjustment gear until it turns easily.) 2. Remove the piston. Gartner Banana

Page 698 of 1708

BRAKE SYSTEM P Piston seal Remove the piston seal by using the SST. Assembly note Piston Insert the piston into the caliper and turn the adjustment gear counterclockwise with an Allen wrench to pull the piston in fully. (Turn the adjustment gear until it stops.) Gartner Banana

Page 700 of 1708

PARKING BRAKE SYSTEM P Removal 1 Inspection / lnstallation 1. Block the wheels firmly. 2. Release the parking brake. - 3. Remove in the order shown in the figure. 4. lnspect all parts and repair or replace as necessary. 5. Install in the reverse order of removal, referring to lnstallation Note. 6. After installation, adiust the arki in^ lever stroke. (Refer to page P-34.) 1. Screw 6. Release button 2. Cover 7. Spring 3. Bolt Inspect for weakness 4. Parking brake switch 8. Bolt lnstallation Note . . . . . . . . . . . . . . . . . below 9. Parking brake lever lnspect for damage and cracks 5. Adjusting nut and clip lnstallation note Parking brake switch 1. Install the parking brake switch so that it contacts the parking brake lever when the lever is fully released. 2. Turn the ignition switch ON, and verify that the parking brake warning light illuminates with the lever pulled up one notch. Gartner Banana

Page 701 of 1708

PARKING BRAKE SYSTEM PARKING BRAKE CABLE Removal / Inspection 1 Installation 1. Block the wheels firmly. 2. Release the parking brake. 3. Remove the parking brake lever. 4. On level ground, jack up the vehicle and support it evenly on safety stands. 5. Remove the parking brake cable in the order shown in the figure. 6. Install in the reverse order of removal. 7. After installation: (1) Adjust the parking brake lever stroke. (Refer to page P-34.) (21 Deoress the brake oedal a few times. (3j ve;ify that the rear brakes do not drag while the wheels are rotated by hand. 1. Adjusting nut and clip 2. Clip 3. Spring lnspect for weakness 4. Front cable lnspect for damage 5. Rear cable lnspect for damage Gartner Banana

Page 702 of 1708

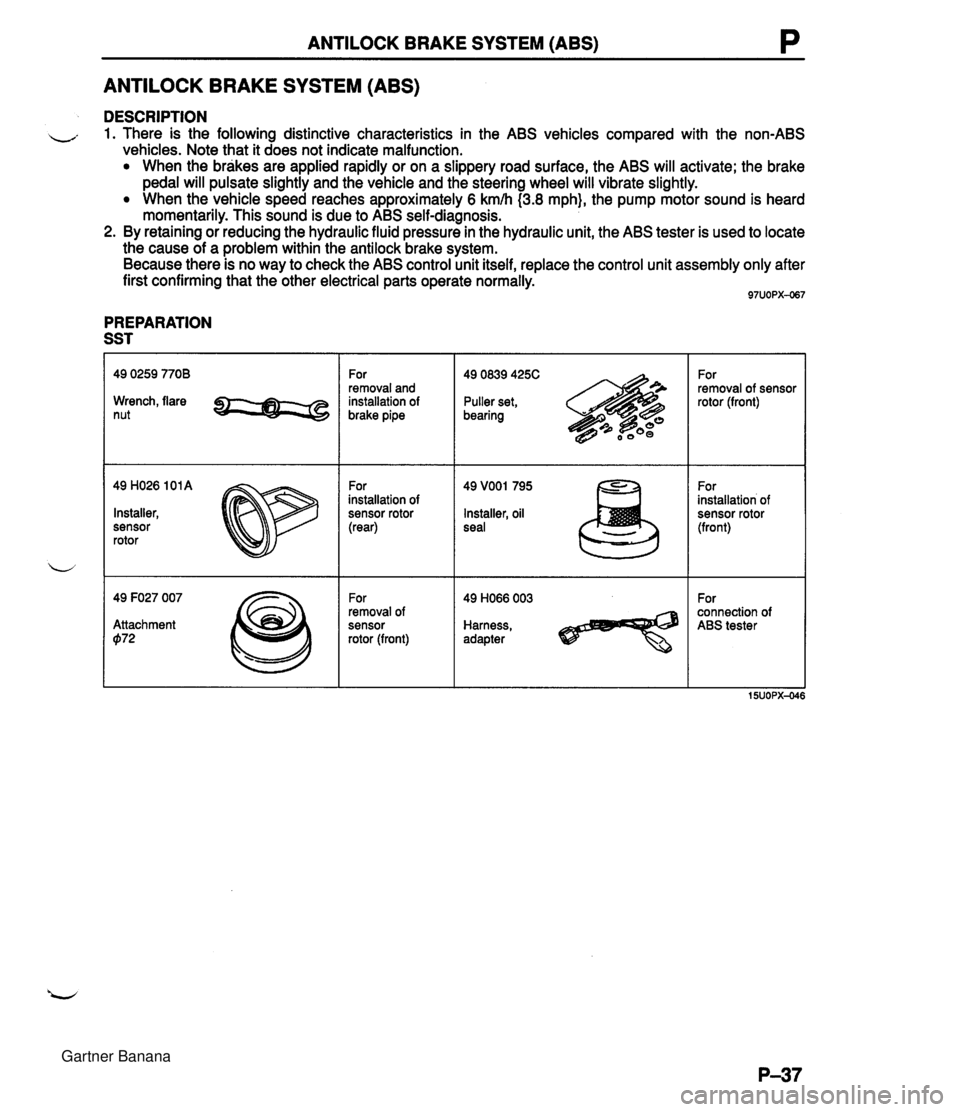

ANTILOCK BRAKE SYSTEM (ABS) P ANTILOCK BRAKE SYSTEM (ABS) DESCRIPTION - 1. There is the following distinctive characteristics in the ABS vehicles compared with the non-ABS vehicles. Note that it does not indicate malfunction. When the brakes are applied rapidly or on a slippery road surface, the ABS will activate; the brake pedal will pulsate slightly and the vehicle and the steering wheel will vibrate slightly. When the vehicle speed reaches approximately 6 kmh (3.8 mph}, the pump motor sound is heard momentarily. This sound is due to ABS self-diagnosis. 2. By retaining or reducing the hydraulic fluid pressure in the hydraulic unit, the ABS tester is used to locate the cause of a problem within the antilock brake system. Because there is no way to check the ABS control unit itself, replace the control unit assembly only after first confirming that the other electrical parts operate normally. PREPARATION SST Wrench, flare nut 49 H026 101 A Installer, sensor rotor 49 F027 007 Attachment 072 For removal and installation of brake pipe For installation of sensor rotor (rear) For removal of sensor rotor (front) 49 0839 425C Puller set, bearing Installer, oil seal Harness, adapter For removal of sensor rotor (front) For installation of sensor rotor (front) For connection of ABS tester Gartner Banana

Page 703 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) TROUBLESHOOTING GUIDE Troubleshooting Guide with ABS Tester ABS tester ADAPTER PART No.0000-42-0010 HYDRAULIC UNIT CONNECTOR POSSlTlVE BATTERY 97UOPX469 Connecting ABS tester 1. Turn the ignition switch OFF. 2. Connect the SST harness to an extension harness, and wrap the connection with electrical tape to prevent short- ing. 3. Connect the SST between the hydraulic unit wiring har- ness connectors and to the positive battery terminal. 4. Roll back the carpet and remove the protecter. 5. Connect the ABS tester to the control unit connector at harness side .using the adaptor. Warning Driving the vehicle while the tester is connected to the ABS control unit is extremely dangerous. The brakes could fail, resulting in death or seri- / -1 ous injury. Disconnect the tester from the ABS control unit before driving the vehicle. Gartner Banana

Page 704 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P LISTED BELOW IS AN EXPLANATION OF THE 5B. BRAKE LIGHT SWITCH TEST PROCEDURE - INDICATES TESTER DISPLAY I u U ,INDlCAlES ( TESTER SWITCHES I PRESS BRAKE PEDAL FIRMLY AND HOLD PRESSURE.. . I IF NO FAULTS A'RE DETECTED. IF A FAULT I; DETECTED. TESTER WILL DISPLAY: TESTER WILL DISPLAY. TESTER WlLL GlVE INST RUCTIONSIINFORMATION. "THEN* INDICATES THE TESTER WlLL ALTERNATE THE TWO DISPLAYS. TESTER "ASKS A OUESTION" WHICH MUST BE ANSWERED BY PRESSING THE SWITCH UNDER THE DESIRED ANSWER. NOTE: IN THIS CASE. PRESS YES - TEST CONTINUES. PRESS NO - T ESTER DISPLAYS: PRESS BRK - - - - HOLD TESTER WlLL PROCESS INFORMATION. 1 IYES CONTINUE? NO[ TESTER WlLL GlVE NEW INStRUCTIONSllNFORMATI~ AND CONTINUE. Gartner Banana

Page 705 of 1708

P ANTILOCK BRAKE SYSTEM (ABS) Troubleshooting procedure 2. ALTEnuAtOR TEST START mtmE (ALTWJATOR TESTED BY RWNa ENQlNE) 3. A88 SYSTEM TEST TURN IGNITION K€Y ON (00 NOT ROES EWWE) - - 1. LOCATE ABS CONTROL UNIT. 2. DISCONNECT CONTROL UNlT HARNESS CONNECTOR FROM CONTROL UNIT. 3. CONNECT ABS TESTER HARNESS TO CONTROL UNlT HARNESS CON- NECTOR. 4. TURN IGNITION KEY TO ON POSITION. TESTER WlLL RAPIDLY DISPLAY SEVERAL MESSAGES DURING AN INITIAL SEGMENT CHECK I THEN 1 I MAZDA ABS 2 TEST 1 4 I YES ENG RUN? NO 1 I MAZDA ALT TEST I CHK ALTERNATOR NO FAULT DETECTED t I TURN OFF ENGINE I TESTER WlLL RAPIDLY DISPLAY SEVERAL MESSAGES DURING AN INITIAL SEGMENT CHECK. I THEN t 1 YES ENG RUN? NO t 1 MAZDA ABS 2 TEST I Gartner Banana

Page 706 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P 4.8Y8TW VOLTAQE CHECKS * AFTER DISPLAY INDICATES A FAULT MESSAGE. REFER TO APPLCABLE SHOP MANUAL FOR ADDITIONAL DIAGNOSTIC INF OR- MATION. (Cont .) I TESTER AUTOMATICALLY PERFORMS MULTIPLE SYSTEM VOLTAGE TESTS IF NO FAULTS ARE IF FAULTS ARE DETECTED. TESTER DETECTED. TESTER WILL DISPLAY THE CORRESPOND- WILL ADVANCE TO ING FAULT MESSAGE(S) AS SHOWN NEXT TEST. BELOW. VALVE +, iLeI1 Fronl Valve Ogln) RF VALVE OPEN ( (R9M Fronl Valve Open) IREAR VALVE OPEN/ CHK ABS DIODE (Check ABS 01ode) CHK CONT MOD GND (Chock Control Module Ground) CHK SYSTEM GND (Check Syslrm Ground) CHK LF SPD SENS (Check Left Fronl SpHd Sm.wl CHK RF SPD SENS (Check R9hl Fronl Sped Sonsor) CHK LR SPD SENS (Check Left bar Sp..d Smw) CHK RR SPD SENS (Check Rghl Rear S.nror) I TESTER DISPLAY WlLL ALTERNATE ABOVE MESSAGES WITH I /YES CONTINUE? NO[ - & TESTER WlLL DISPLAY PRESS: -0A- SAME FAULT MESSAGE. 1 IF NO ADDITlbNAL FAULTS IF ADDITIONAL FAULTS ARE ARE DETECTED. TESTER WlLL DETECTED, TESTER WlLL ADVANCE TO NEXT TEST. DISPLAY NEXT FAULT I MESSAGE. 1 (Cant.) Gartner Banana