ignition MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 1047 of 1708

SRS AIR BAG SYSTEM Possible cause Defective air bag module Defective clock spring Ddfective S-sensor Defective D-sensor Defective diagnostic module Defective wiring harness Service Code 13 Flowchart No.14 Note When fault code 13 sets, the air bag unit blows an internal non-replaceable thermal fuse to prevent accidental deployment of the air bag. The air bag unit must be replaced once code 13 has set, but should not be replaced until the cause for the fault is repaired. Symptom Step 1 Carry out "Before Servicing" procedure under GEN- ERAL PROCEDURES, page T-1 60. Step 2 1. Remove the air bag module. 2. Install a 1 -ohm (rated power 1 W) resistor between termi- nals B and C of the air bag module connector. 3. Connect the negative battery cable. 4. Turn the ignition switch to ON and check the service d 1 code. 1 Other I Go to Step 3 Service code 51 Step 3 1. Turn the ianition switch to LOCK. Action Replace air bag module and then replace diagnostic module 2. ~isconnegt the diagnostic module connector. 3. Check for continuity between terminal 2F (GY) of the diagnostic module connector and ground. I Continuity Action 1 Step 4 1. Disconnect the clock spring connector. 2. Check for continuity between terminal 2F (GY) of the diagnostic module connector and ground. Yes No Continuity Yes Go to Step 4 Go to Step 6 Gartner Banana

Page 1051 of 1708

SRS AIR BAG SYSTEM DRIVER-SIDE AIR BAG MODULE Removal I Installation Warning 4 Handling the air bag module improperly can accidently deploy the air bag, which may serious- ly injure you. Read SERVICE WARNINGS, page T-159, before handling the air bag module. 1. Carry out "Before Servicing" procedure under GENERAL PROCEDURES, page T-160. 2. Remove in the order shown in the figure. 3. Install in the reverse order of removal. 4. Follow the troubleshootina flowchart (page T-160) to verify that the air bag system is operating normally. 1. Bolts 2. Support rope 3. Driver-side air bag module Installation note . . . . . . . . . . . . . . . . . below Installation note Driver-side air bag module 1. Connect the blue and orange clock spring connectors. 2. Connect the negative battery cable. 3. Turn the ignition switch to ON and verify that service code 32 is set. 4. If another service code is set, troubleshoot the system. 5. If service code 32 is set, turn the ignition switch to OFF and disconnect the negative battery cable. 6. Disconnect the orange and blue clock spring connec- tors. 7. Install the driver-side air bag module. Gartner Banana

Page 1052 of 1708

SRS AIR BAG SYSTEM T PASSENGER-SIDE AIR BAG MODULE Removal I Installation b Warning Handling the air bag module improperly can accidently deploy the air bag, which may serious- ly injure you, Read SERVICE WARNINGS, page T-159, before handling the air bag module. 1. Carry out "Before Servicing" procedure under GENERAL PROCEDURES, page T-160. 2. Remove the glove compartment. 3. Remove in the order shown in the figure. 4. Install in the reverse order of removal. 1. Bolts 2. Support rope 3. Passenger-side air bag module Installation note . . . . . . . . . . . . . . . . . below Installation note Passenger-side air bag module 1. Connect the blue and orange clock spring connectors. 2. Connect the negative battery cable. 3. Turn the ignition switch to ON and verify that service code 33 is set. 4. If another service code is set, troubleshoot the system. 5. If service code 33 is set, turn the ignition switch to OFF and disconnect the negative battery cable. 6. Disconnect the orange and blue clock spring connec- tors. 7. Install the driver-side air bag module. Gartner Banana

Page 1067 of 1708

TROUBLESHOOTING u TROUBLESHOOTING GUIDE I Symptom Blower motor does not operate Reference page Below Magnetic clutch does not operate I U-7 Condenser fan does not operate e Symptom: Blower motor does not operate I U-9 Insufficient cooling No cooling Intermittent cooling Normal operation of blower motor Blower motor speed is controlled by the fan switch and a resistor in the blower unit. When the fan switch L is in the OFF position, the motor ground circuit is open and the blower motor does not operate. When the switch is in the first (Low) position, current flow from the blower motor is restricted by the three resis- tors in the resistor, and the blower motor turns at low speed. Changing the fan switch to the second (Mid), third (high), or fourth (Super-high) position causes the cir- cuit resistance to decrease, and the blower motor speed becomes correspondingly faster. I l U-10 (-1 (rn) I I I RESET BUTTON FUSE BLOCK Step 1 1. Check the circuit breaker. 2. If the reset button is not out, go to Step 2. 3. If the reset button is out, check for a short circuit in the harness. Repair as necessary; then depress the reset button to reset the circuit breaker. circuit breaker HEATER Step 2 1. Turn the ignition switch to ON. 2. Turn the fan switch to the fourth position. 3. Measure the voltage at the A terminal wire of the blower motor connector. B+: Battery positive voltage I Terminal I Voltage Action I Amperage 30A Location Fuse block A U-5 Bt Other Go to Step 3 Repair wiring harness (Circuit breaker - Blower motor) Gartner Banana

Page 1068 of 1708

u TROUBLESHOOTING Step 3 1. Turn the ignition switch to ON. 2. Turn off the fan switch and ACS. 3. Measure the voltage at the terminal-wires of the resistor. u B+: Battery positive voltage I Terminal I Voltage I Action A (1-pin connector) A B C Step 4 1. Turn the ignition switch to ON. 2. Turn the fan switch to the fourth position. 3. Measure the voltage at the G terminal wire of the fan switch connector. .J B+: Battery positive voltage B+ , Other D CheckA terminal Replace blower motor B+ Other B+ Other B+ Other Step 5 1. Turn the ignition switch to ON. 2. Turn off the fan switch and ACS. Check B terminal Replace resistor Check C terminal Replace resistor Check D terminal Reolace resistor B+ Other Terminal G 3. Measure the voltage at the terminal-wires of the fan switch connector. Go to Step 4 Replace resistor B+: Battery positive voltage - Voltage B+ Other Action Repair wiring harness (Fan switch - GND) Go to Step 5 Gartner Banana

Page 1071 of 1708

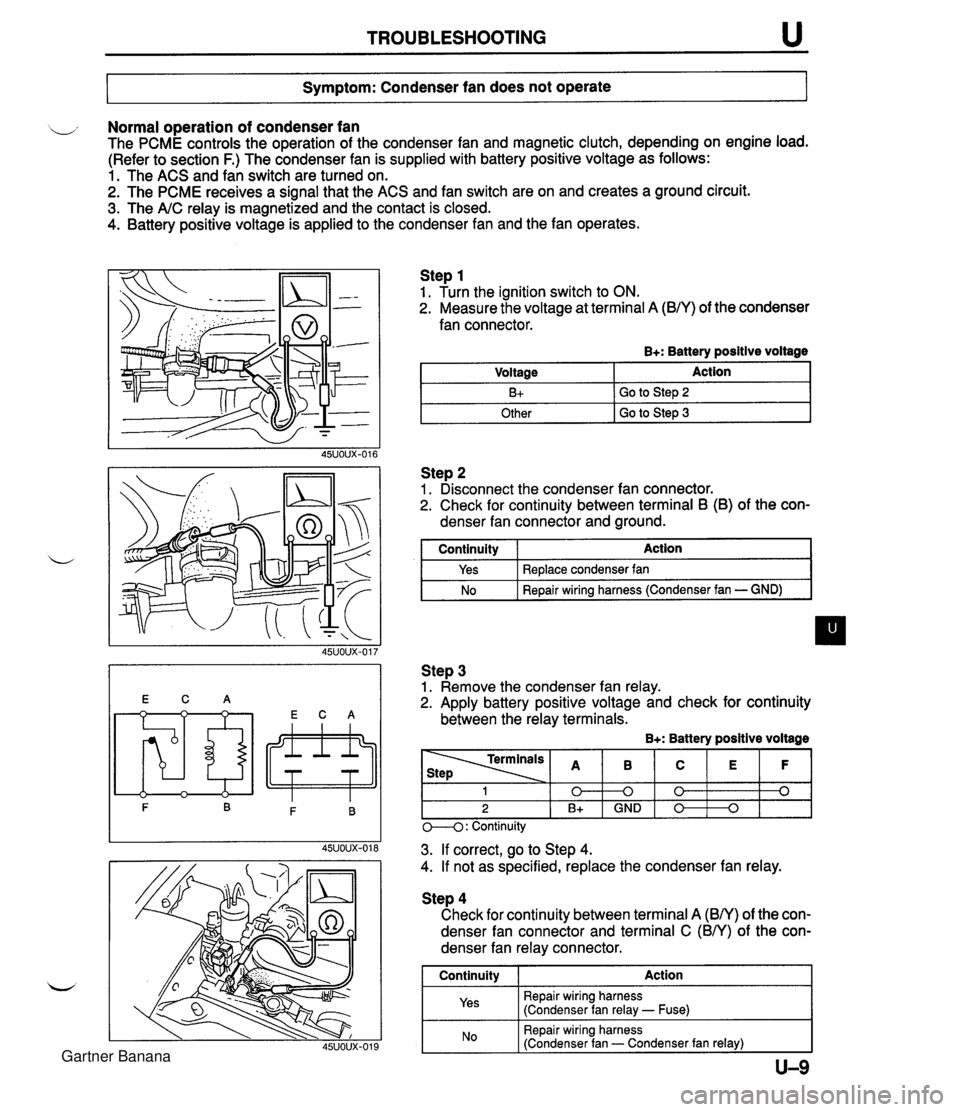

TROUBLESHOOTING u Symptom: Condenser fan does not operate Normal operation of condenser fan The PCME controls the operation of the condenser fan and magnetic clutch, depending on engine load. (Refer to section F.) The condenser fan is supplied with battery positive voltage as follows: 1. The ACS and fan switch are turned on. 2. The PCME receives a signal that the ACS and fan switch are on and creates a ground circuit. 3. The A/C relay is magnetized and the contact is closed. 4. Battery positive voltage is applied to the condenser fan and the fan operates. Step 1 1. Turn the ignition switch to ON. 2. Measure the voltage at terminal A (B/Y) of the condenser fan connector. B+: Battery positive voltage Step 2 1. Disconnect the condenser fan connector. 2. Check for continuity between terminal B (B) of the con- denser fan connector and ground. Voltage B+ Other I GO to step 3 Action Go to Step 2 I continuity I Action I Step 3 1. Remove the condenser fan relay. 2. Apply battery positive voltage and check for continuity between the relay terminals. B+: Battery positive voltage Yes No Replace condenser fan Repair wiring harness (Condenser fan - GND) M: Continuity - - - 3. If correct, go to Step 4. 4. If not as specified, replace the condenser fan relay. 1 0 2 B+ Step 4 Check for continuity between terminal A (BN) of the con- denser fan connector and terminal C (BN) of the con- denser fan relay connector. I Continuity I Action 1 Repair wiring harness (Condenser fan relay - Fuse) B 0 GND I Repair wiring harness (Condenser fan - Condenser fan relay) I C 0 0 E 0 F 0 Gartner Banana

Page 1115 of 1708

TECHNICAL DATA TI) G. ENGINE ELECTRICAL SYSTEM )ark current*' - Engine tem Voltage V 3attery Type and capacity (5-hour rate) Starter -. . BP DOHC MT mA 1 20.0 AT Tvm Ignition system 12, Negative ground S46A24L(S) (32 Ah) Maintenance-free A.C. ST- Output V-A Regulator type Regulated voltage V 12-65 Brush length mm {in) Drive belt deflection mm {in) 17.5 (0.69) 12.0 (0.471 - -- r-- I I hPe Spark plug 1 2-70 Standard Minimum New Used Brush length mm {in) BKR6E-11 (Standard ... MT) NIPPONDENSO : K16PR-U11 K20PR-U11 (Standard ... MT, AT) TYW OU~DU~ V-kW Standard 1 17.0 I0.67) Minimum 1 11.5 10.451 1 Type Spark advance control Ignition timing*2 BTDC ("CA)/rpm Transistorized (built-in voltage regulator) 14.3-1 4.9 21.5 (0.85) 8 I0.31) 5.5-7.0 {0.22--0.27) 6.0-7.5 {0.24--0.29) . . I . . Electronic spark advance (ESA) Powertrain control module (engine) controls spark advance Ignition coil H. CLUTCH Direct lot850 TY ~e Primary coil winding a Secondary coil winding ks2 . .- - Engine Item BP DOHC 1 Coaxial reduction 10/800 Molded (with igniter) - 8.7-1 2.9 NGK : BKR5E-11 *I Dark current is the.constant flow of current while the ignition switch is OFF. (i.e. powertrain control module (engine), audio, etc.) '2 With System Selector (49 B019 9AO) test switch at SELF TEST. , Plug gap mm (in) Firing order 124.95 1 .O-1.1 {0.040--0.043) 1-342 Clutch control Runout limit mm {in) 1 0.2 (0.008) I 12-1.4 Hydraulic Clutch pedal TYP Suspended A .- 6.13 120 (4.72) 175--185 {6.89--7.28) 0.G3.1 (0.02-0.12) 68 I2.68) Pedal ratio Full stroke mm {in) Height (with carpet) mm (in} Free play mm {in} Distance to carpet when clutch fully disengaged rnm [in Minimum Gartner Banana

Page 1259 of 1708

u GENERAL SERVICE INFORMATION TIEDOWN HOOK - FRONT /'-- TIEDOWN HOOK - REAR -?-A TOWING Proper towing equipments are necessary to prevent damage to the vehicle during any towing operation. Laws and regulations applicable to vehicles in tow must always be observed. Release the parking brake, place the shift lever in neutral, and set the ignition switch in the ACC posi- tion. As a rule, towed vehicles should be pulled with the driving wheels off the ground. WITH MANUAL TRANSMISSION If the transmission, rear axle, and steering system are not damaged, the vehicle may be towed on all four wheels. If any of these components are damaged, use a towing dolly. CAUTION The power assist for the brakes and steering are inoperable while the engine is off. Do not use the tiedown hooks under the front or rear of the vehicle for towing. These hooks are designed ONLY for transport tiedown. If the tiedown hooks are used for towing, the front or rear skirt and bumper will be damaged. IDENTIFICATION NUMBER LOCATIONS VEHICLE IDENTIFICATION NUMBER (VIN) ENGINE MODEL AND NUMBER L i Gartner Banana

Page 1702 of 1708

ALPHABETICAL INDEX *** ENGLISH **E SPRING,SHIFT ROD ENS----- SPRING,SHIFT ROD-REVERSE- SPRING,SYNCHRO. KEY------ SPRlNG.SYNCHR0 .KEY------- I-LB SPRING,3-4 SHIFT--------- 1-K8 STABILIZER,FRONT--------- 1-K13 STABXLIZER,RR------------ STARTER..----------------- 1-El2 1-E7 STATOR ---.-.---- - 1-67 1 -C7 STAY(L1,RR. RUMPER------- 2-H3 STAYCR) ,RR. BUMPER------- 2-H3 STA~,B~NNET-------------- 2-K4 STAY,LOCK-BONNET--------- 2-N4 STAY,MANIFOLD------------ 1-D4 S~EM,PJSTON-------------- 1-N7 STEH,PISTON BAND--------- STOPPER SET-------------- 1-E8 1-E7 1-67 STOPPER,RUMP------------- 1 -C12 1-H13 STOPPERICONSOLE LID------ 2-N7 STOPPER,FILLER LID------- 1-K14 STOPPEK,GLASS------------ 2-L'3 STOPPERILINK-HOOD-------- 2-Dl2 STOPPERISOFT TOP--------- 2-L12 STOPPER,LIPPEP-BACK WINDO 2-El2 STRAINER,INNER----------- 1 -K8 STRAINER,OJL-------- ----- 1-18 1-J8 1-144 STRAP ,ALTERNATOR--------- 1 -M6 STRIKER-- ------ ----- ---- - 2-C10 2- J7 STRIKER(L),LOCK-TOP------ 2- J12 STRIKEK(R),LOCK-TOP------ 2- J1.2 STRIKER,LID---..---------- 2-M4 STRUT,BAND--------------- 1 -n7 STUD--------------------- 1-E3 1 -E4 STUD,EX. MANIFOLD------- -- 1-E3 STUD,HEX-HYD. UHJT------- 1 -MI5 SUN VISOR(L)-----------..- 2-F16 SUN v~so~(~)------------- 2-Fl6 §UPPORT(L),MOUNTING------ 1-F11 1-613 SUPPOHT(R),MOUNTING------ 1-F11 1-G13 SUPPORT,C€NTER----------- 1 -G9 SUPPORT,DRUH------------- 1 -D8 SUPPORT.OIL PIPE--------- 1-L7 SUPPURTER,ACTUATOR------- 1-K9 SUPPORTER,FORK----------- 1-C6 ..- - . - - - - --.- - - CAT. AUNA04 - 03 2-~12 SWITCH(R),CLUSTER-------- 2-El3 SWITCH,BACK UP LAMP------ 2-N12 SWITCH,Cl.UTCH------------ 1-L14 SWITCH ,CLUTCH CUT-------- 1 -HI4 SWITCHICOMBINATION------- SWJTCH,DOOR-------------- 2.-F13 2-113 SWITCHIFAN-HEATER CONTROL 2-Ell SWITCH,IGNITION---------- 2-C3 SWITCH,INHIBITOR--------- 2-C13 SWITCH,LEVEL-WASHER TANK- 2-El5 SWITCH,MAIN-------------- 2-El3 SWITCHIOIL PRESSURE------ 2-N12 SWITCH,OVER DRIVE CONTROL 1-616 SWITCH,PARKING LAMPe----- 1-Dl6 SWITCH,POWER WINDOW------ 2-N7 SWITCH,RMT.MIRROR--------- 2-El3 SWITCH,RR.DEF.----------- 2-El3 SWITCH,STOP-LAMP--------- 1-Dl5 1-M14 1-N14 2-Fi5 TANK,WASHEH-FRONT-------- 2-C15 2-El5 TAPE,EDGE PROTECTOR-CTR-- Z-K12 TAPE,PROTECTOR-STOPPER--- 2-El0 TAPE,SEAL-RAIN RAIL------ 2-El2 TENSIONER,T.BELT--------- 1 -C4 TERMINAL SET------------- 1-D7 THERMOSTAT SET----------- 1 -D5 THERMOSTAT,COOLIHG UNIT-- 2-Mll TIMER & BUZZER----------- TIRE ---..- ----------..----- 2-013 TOOL SET----------------- 1-L13 2-Dl6 TRA~,ASH----------------- 2-D7 TRAY,BATTER~--------.----- 1-17 TRAYIREAR PACKAGE-------- 2-L15 TRIMIL),'A'PILLAR-------- 2-K15 TRIM(L1,DOOR------------- 2-61 0 2-HlO TRIM(L1,FRONT SIDE------- 2-l.15 TRIMCL) ,UUARTER---------- 2-116 TRIM(L),SEAT BACK-------- 2-CY 2-D9 TRIM(L1,SEAT CUSHION----- 2-NO TRIM(L),TRUNK SIDE------- 2-M15 TRIM(R),'A'PILLAR-------- 2-K15 TRIM(R),DOOR------------- 2-F10 2-61 0 TRIM(R),FRONT SIDE------- 2-L15 TRIM(R),OUARTER---------- 2-116 TRIMCR) ,SEAT BACK----.---- 2-M8 TRIM(K),SEAT CUSHION----- 2-KO TKIH,FRONT HEADER------ -- 2-K15 TRIM,TRUNK END--------- -- 2-MIS TUBE,FILLER---------TuBE,FILLER------------..---TuBE,FILLER------------..-TuBE,FILLER------------..-- I -D8 TUBE,HEAD LAMP----------- 2-C4 TUBEIOIL FILTER-UPPER-- -- 1-00 TU3E,SILJCOq------------- 1-J3 TUBE,VACUUH-------------- 1 -F4 1-17 1-L4 TUNER 8 DEC.:,COHB.------- 2-M13 VALVE,CONTROL------------ 1-00 VALVE,CONTROL BACK UP---- VALVE,E,G.R. ..----------a- 1 -K8 1-L4 VALVE,EXHAUST------------ 1-N3 VALVE,EXPAHSION---------- 2-Ml VALVE,FUEL VAPOR.-------- 1-11 VALVE,IDLE AIR CONTPOL--- 1-K4 VALVE,INLET-.------------- VALVE,MANUAL----------..-- 1-N3 1-00 VAL,VE,MODIFIER----------- 1 .H8 VALVE,NON RETURN--------- 1-11 VALVE,OIL JET------------ 1-H3 VALVE,ONE WAY------------ 1-E8 1-K8 VALVEjORIFICE CHECK------ VALVE,P.B.---------------- 1-Ha 1-11 1-Ki VALVE,P.C.V.------------- 1 -F3 VALVE,REDUCING----------- 1 -18 VALVE,REGULATOR---------- 1 -GB VALVE,RELIEF------..------ 2-Kl VALVE,SHIFT 3-4---------- 1-U8 VALVEISOLENOID----------- 1-L4 2-Hl VALVE,SOLENOID N01------- 1-K8 VALVE,ST. GEAR----------- 1-N1 YALVE,THREE WAY---------- 1-L4 2-Nl VALVE,THROTTLE----------- 1-Ha VALVE,THROTTLE BACK-UP--- 1-H8 VALVE,l-2 REDUCING------- 1-18 VALVE,l-2 SHIFT---------- 1-G8 VALVE,2-3 SHIFT---------- 1 -G8 VALVE,3-4 SHIFT-COAST---- 1 -K8 WASHER------------------- 1 -F9 1-H1 1-H1 1-11 1-K1 1-L1 1 -Ml 2- J1 2-L3 WASHER SET--------------- 2-Ll 1-E7 WASHER,DISHED------------ 1 -KB WASHER,FASTEN€k-RAIN PAIL 2-El WASHER,FRONT CLUTCH------ 1-E9 WASHER,HOOKmA'----------- 2-1.1 WASHER,HOOK'A'LIB'------- 2-K1 WASHERIHYD. UNIT--------- 1-Hl WASHER,LID OPENER-------- 1-K14 WASHER,LOCK-PUMP FILTER-- 1-H14 WASHERIPLAIN------------- 1-C8 1-H9 1-J7 1-N7 WASHERIPLAIN CYL. HEAD--- 1-E3 WASHER,PLAIN-FRAME------- 1-C14 WASHERISETTING----------- 2-J9 MASHER,STOP-------------- 1-F12 WASHER,THRUST-----------• 1-F6 1-Gh 1-16 WASHER,THRUST LOCK-OVER T 1-H6 1-16 WASHER,THRUST-REVERSE IDL 1-H6 WASHEW,TOOTHED----------- 2- J15 WASHER WAVE-CHANGE C0NT.C 1-L6 WASHER. A' DECK LOCK------ 2-112 WASHERIB',DECK LOCK------ 2- J12 WEATHERSTRIP N0.1-------- 2-El0 WEATHERSTRIP N0.2-------- ?-El0 WEATHERSTRIP(L1---------- 2-K9 WEATHERSTRIP(L1,DOOR----- 2-K9 2-L9 UEATHERSTRIP(L),OUT/---- 2-El0 WEATHERSTRIP(R)---------- 2-K9 WEATHERSTRIP(R),DOOR------ 2-K9 WEATHERSTRIPCR) ,OUT, ------ 2-El0 WEATHERSTRIP, BONNET-REAii- 2-K4 WEATHERSTRIP,D.TOP-REAR-- 2-K12 WEATHEWSTRIP,LID---me---- 2 -H4 WEDGE,DOOR-FRONT--------- 2-Dl0 WEIGHT,DISC WHEEL-ALUMI-- :-HI3 WEIGHTIDISC WHEEL-STEEL-- 1-L:3 1-M13 WIRING~INJECTOR---------- 2-114 WREHCH,HUB NUT----------- 2-Dl6 WRENCHIWHEEL CAP--------- 2-Dl6 WTHSTP NO.l(L),LINK------ 2-Gl2 WTHST? tiO.l(R) ,LINK------ 2-612 WTHSTP H0.2CL) ,LINK------ 2-01 2 WTHSTP NO.?(R),LINK------ 2-812 WTHSTP NU.3(L),LINK------ 2-612 WTHSTP H0.3(K),LINK------ 2-612 WTHST?(L),CAB SIDE------- 2-H12 WTHFiP(L),ROOF PANEL----- 2-K12 WTH'TP(R),CAB SIDE------- 2-H12 WT'iSTP(R),ROOF PANEL----- 2-K12 G'IHSTP,FROHT HEADER------ 2-612 YOKE------------.-------- 1 -E7 1-67 YOKE SETISUPPORT-ST. GEAR 1-L12 YOKE,DTFFEREHTIAL-------- 1-Jl1 Gartner Banana