MAZDA MX-5 1994 Workshop Manual

Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 671 of 1708

BRAKE SYSTEM TROUBLESHOOTING GUIDE Problem Poor braking Brakes pull to one side Brakes do not release Pedal goes too far (Too much pedal stroke) Abnormal noise or vibra- tion durlng braking Possible cause Leakage of brake fluid Air in lines Worn pad Brake fluid, grease, oil, or water on pad Hardening of pad surface or poor contact Malfunction of disc brake piston Malfunction of master cylinder Malfunction of power brake unit Malfunction of check valve (vacuum hose) Damaged vacuum hose Deterioration of flexible hose Malfunction of proportioning bypass valve (PBV) Worn pad Brake fluid, grease, oil, or water on pad Hardening of pad surface or poor contact Abnormal wear, distortion, or eccentricity of disc Malfunction of automatic adjuster in rear brake Looseness or deformation of dust cover mounting bolt Malfunction of disc brake piston Worn or improperly adjusted wheel bearing preload lmproper adjustment of wheel alignment Unequal tire air pressure No brake pedal play lmproper adjustment of push rod clearance Clogged master cylinder return port Pad not returning properly lmproper return of malfunction of brake caliper piston Excessive runout of disc plate lmproper adjustment of wheel bearing preload Air in system because of insufficient brake fluid lmproper adjustment of pedal play Worn pad Air in lines Worn pad Deterioration of pads Brakes do not release Foreign material or scratches on disc plate contact surface Looseness of caliper mounting bolt(s) Damage or deviation of disc contact surface Poor contact of pads Insufficient grease on sliding parts Action Repair Air bleed Replace Clean or replace Grind or replace Replace Repair or replace Repair or replace Repair or replace Replace Replace Replace Replace Clean or replace Grind or replace Repair or replace Repair Tighten or replace Repair or replace Replace or adjust Adjust Adjust Adjust Adjust Clean Repair Replace Replace Adjust or replace Add fluid and bleed air Adjust Replace Bleed air Replace Grind or replace Repair Clean Tighten Replace Repair or replace Apply grease Page - P- 7 P-25,29 P-25,29 P-25,29 P-28,32 P-11, 14 P-22 P-22 P-22 P- 7 P-23,24 P-25,29 P-25,29 P-25,29 section M - section M P-28,32 section M section R section Q P- 9 P-l2,15 - - P-28,32 section M section M P- 7 P- 9 P-25,29 P- 7 P-25,29 P-25,29 - - P-26,30 section M P-25,29 - 15UOPX-00 Gartner Banana

Page 672 of 1708

BRAKE SYSTEM P MIRROR AIR BLEEDING The brakes should be bleed whenever a brake line is dis- connected. If a hydraulic line is disconnected at the mas- ter cylinder, start at the slave cylinder farthest from the brake master cylinder, and move to the next closest slave cylinder until all four cylinders have been bled. If the disconnection point is anywhere except the master cylinder, start at the point closest to the disconnection, and move to the next farthest slave cylinder until all four cylinders have been bled. 1. On level ground jack up the vehicle and support it evenly on safety stands. 2. Remove the bleeder cap and attach a vinyl tube to the bleeder screw. 3. Place the other end of the vinyl tube in a clear container. 4. One person should depress the brake pedal a few times, and then hold it in the depressed position. 5. A second person should loosen the bleeder screw, drain out the fluid, and close the screw by using the SST. 6. Repeat steps 4 and 5 until only clean fluid is seen. The reservoir should be kept about 3/4 full during bleeding to prevent air from reentering the lines. 7. Modify the brake pipe tightening torque to allow for a torque wrench-SST combination. (Refer to section GI) "Torque Formulas". 8. Tighten the brake pipe by using SST. 9. Check for correct brake operation. 10. Verify that there is no fluid leakage. Clean away any spilled fluid with rags. 11. After bleeding the air, add brake fluid to the reservoir up to the specified level. BRAKE HYDRAULIC LINE On-vehicle Inspection Check the following and replace parts as necessary. 1. Cracks, damage, and corrosion of the brake hose 2. Damage to the brake hose threads 3. Scars, cracks, and swelling of the flexible hose 4. All lines for fluid leakage Gartner Banana

Page 673 of 1708

P BRAKE SYSTEM Removal / Installation 1. When disconnecting the flexible hose and brake line, remove the clip after loosening the flare nut by using the SST. > 2. When connecting the flexible hose, do not over tighten or twist it. 3. Verify that the hose does not contact other parts when the vehicle bounces or when the steering wheel is turned all the way to the left or right. 4. Modify the brake pipe tightening torque to allow for a torque wrench-SST combination. (Refer to section GI) "Torque Formulas". 5. Tighten the flare nut by using the SST. Tightening torque: 13-22 N.m (1 3-2.2 kgf-m, %&-I 6 ft-lbf} 6. Bleed the air from the brake system. BRAKE FLUID Inspection Check the fluid level in the reservoir. It should be between MAX and MIN. If the fluid level is extremely low, check the brake system for leaks. J Fluid specification: FMVSS 11 6: DOT-3 Replacement 1. Follow the procedure outlined in Air Bleeding. (Refer to page P-7.) 2. Continuity air bleeding and replacing the brake fluid until only clean fluid is seen. 3. Fill the reservoir to MAX. Gartner Banana

Page 674 of 1708

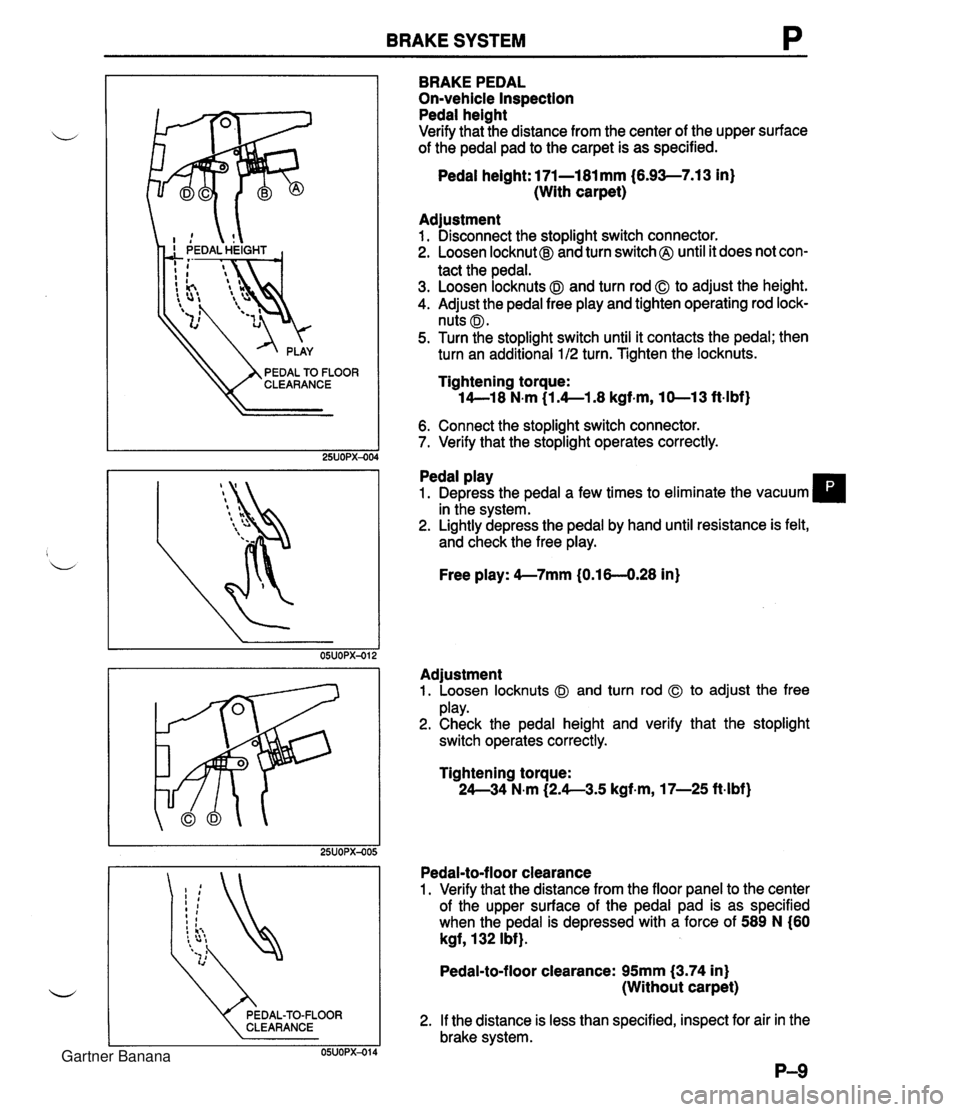

BRAKE SYSTEM P CLEARANCE BRAKE PEDAL On-vehicle Inspection Pedal height Verify that the distance from the center of the upper surface of the pedal pad to the carpet is as specified. Pedal height: l7l-l8l mm (6.93-7.13 in} (With carpet) Adjustment 1. Disconnect the stoplight switch connector. 2. Loosen locknut@ and turn switch @ until it does not con- tact the pedal. 3. Loosen locknuts @I and turn rod 0 to adjust the height. 4. Adjust the pedal free play and tighten operating rod lock- nuts @I. 5. Turn the stoplight switch until it contacts the pedal; then turn an additional 1 /2 turn. Tighten the locknuts. Tightening torque: 14--18 N.m (1.4--1.8 kgf-m, 10-13 ft-lbf) 6. Connect the stoplight switch connector. 7. Verify that the stoplight operates correctly. Pedal play 1. Depress the pedal a few times to eliminate the vacuum in the system. 2. Lightly depress the pedal by hand until resistance is felt, and check the free play. Free play: 4--7mm (0.16-4.28 in) Adjustment 1. Loosen locknuts @I and turn rod to adjust the free play. 2. Check the pedal height and verify that the stoplight switch operates correctly. Tightening torque: 24--34 N.m (2.4--3.5 kgf-m, 17-25 ft-lbf} Pedal-to-floor clearance 1. Verify that the distance from the floor panel to the center of the upper surface of the pedal pad is as specified when the pedal is depressed with a force of 589 N (60 kgf, 132 Ibf}. Pedal-to-floor clearance: 95mm (3.74 in} (Without carpet) 2. If the distance is less than specified, inspect for air in the brake system. Gartner Banana

Page 675 of 1708

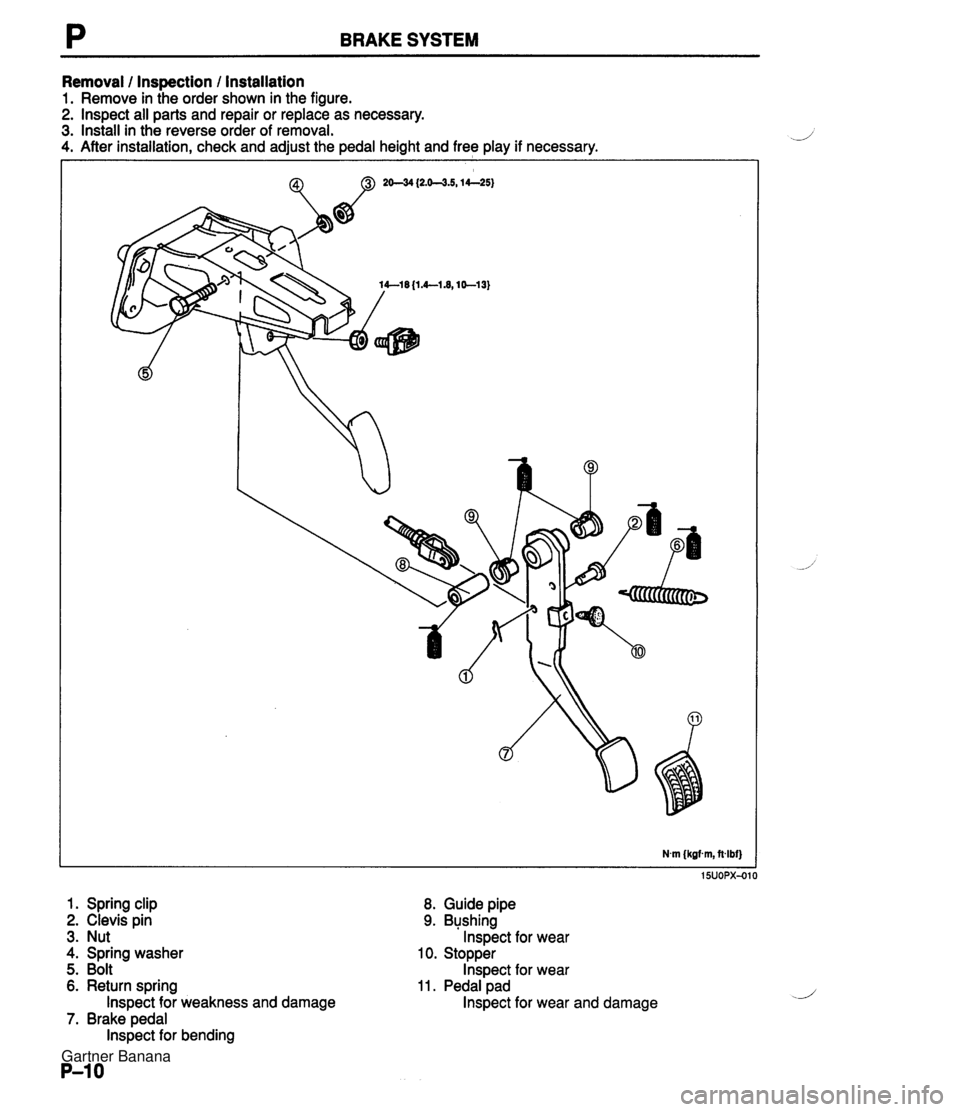

P BRAKE SYSTEM Removal l Inspection / Installation 1. Remove in the order shown in the figure. 2. lnspect all parts and repair or replace as necessary. 3. Install in the reverse order of removal. 4. After installation, check and adjust the pedal height and free play if necessary. 1. Spring clip 2. Clevis pin 3. Nut 4. Spring washer 5. Bolt 6. Return spring lnspect for weakness and damage 7. Brake pedal lnspect for bending I BUOPX-OI 8. Guide pipe 9. Bushing lnspect for wear 10. Stopper lnspect for wear 11. Pedal pad lnspect for wear and damage Gartner Banana

Page 676 of 1708

BRAKE SYSTEM P MASTER CYLINDER (STANDARD) Removal / Installation 1 lnspection 1. Remove in the order shown in the figure, referring to Removal Note. ,, 2. Install in the reverse order of removal, referring to Installation Note. 3. After installation, add brake fluid, bleed the brakes, and check for fluid leakaae. 1. Fluid level sensor connector 5. Proportioning bypass valve and bracket Inspection ................... page P-13 6. Master cylinder 2. Brake pipe Installation Note ............. page P-12 Removal Note ............... page P-12 Disassembly 1 Assembly I 3. Connector bolt Inspection ................. page P-18 4. Nut and washer Gartner Banana

Page 677 of 1708

P BRAKE SYSTEM ADJUSTING BOLT I ADJUSTING BOLT ' CKNUT Removal note Brake pipe Caution . Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off lm- mediately. 1. Modify the brake pipe tightening torque to allow for use of a torque wrench-SST combination. (Refer to section GI) "Torque Formulas'' 2. Disconnect/connect the brake pipe fromlto the master . . cylinder by using the SST. 3. Tighten the brake pipe by using the SST. Tightening torque: 13-22 N-m (1.3-2.2 kgfem, 9.4--16 ft-lbf) Installation note Master cylinder 1. Measure the clearance between the push rod of the power brake unit and the piston of the master cylinder. (1) Place the SST atop the master cylinder. Turn the adjusting bolt until it bottoms in the piston. i (2) Apply 66.7 kPa (500 mmHg, 19.7 inHg} vacuum to the power brake unit with a vacuum pump. (3) Invert the SST used in step 1, and place it on the power brake unit. (4) Measure the clearance between the end of the adjusting bolt and the push rod of the power brake unit. If it is not Omm (0 in}, loosen the push rod locknut and turn the push rod to make the adjustment. Gartner Banana

Page 678 of 1708

BRAKE SYSTEM CLEARANCE JSH ROD 2. By making'the above adjustment, the clearance between . the push rod and piston (after installation of the brake mas- ter cylinder and the power brake unit) will be as shown in the table below. - Clearance When vacuum applied to unit is approx. 0.1 -4.4mm 66.7 kPa (500 mmHg, 19.7 inHg) (0.004--0.016 in) Inspection Fluid level sensor connec 1. Disconnect the sensor connector. 2. Connect an ohmmeter to the connector. 3. Starting with the fluid level above the MIN mark on the reservoir, verify that there is no continuity. 4. Remove the brake fluid and verify continuity when the level is below the MIN mark. 5. Replace the sensor if necessary. Gartner Banana

Page 679 of 1708

BRAKE SYSTEM MASTER CYLINDER (ABS) Removal / Installation / lnspection 1. Remove in the order shown in the figure, referring to Removal Note. 2. Install in the reverse order of removal, referring to Installation Note. 3. After installation, add brake fluid, bleed air, and check for fluid leakage. Caution Brake fluid will damage painted surfaces. If it does get on a painted surface, wipe it off immedi- Fluid level sensor connector 5. Proportioning bypass valve and bracket Inspection ................... page P-17 6. Master cylinder Brake pipe Installation Note ............. page P-15 Removal Note ............... page P-15 Disassembly 1 Assembly 1 Connector bolt Inspection ................. page P-18 Nut and washer Gartner Banana

Page 680 of 1708

BRAKE SYSTEM P I I TOUCHING 1 T~~H,IN~ I ADJUSTING NUT 97GOPX-O Removal note Brake pipe Cautlon Brake fluid will damage painted surfaces. If brake fluid does get on a painted surface, wipe it off im- mediately. 1. Modify the brake pipe tightening torque to allow for use of a torque wrench-SST combination. (Refer to section GI) "Torque Formulas" 2. Disconnect~connect the brake pipe fromlto the master cylinder by using the SST. 3. Tighten the brake pipe by using the SST. Tightening torque: 13--22 N-m (1 3-2.2 kgf-m, 9.4--16 ft-lbf) Installation note Master cylinder Inspect the push rod clearance as follows. 1. Turn the nut of the SST clockwise to fully retract the SST gauge rod. Attach the SST to the power brake unit. Tightening torque: 9.8-15.7 N.m (1 .&I .6 kgf.m, 7.2-11.6 ft4bf) 2. Apply 66.7 kPa (500 mmHg, 19.7 inHg) vacuum using a vacuum pump. 3. Turn the adjusting nut of the SST counterclockwise until the gauge rod just contacts the push rod end of the power brake unit. Push lightly on the end of the gauge rod to be sure it is seated. Verify that there is no gap between the adjusting nut and SST body. Gartner Banana