MAZDA MX-5 1994 Workshop Manual

Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 661 of 1708

N ENGINE SPEED SENSING POWER STEERING Removal Note Pressure pipe Mark the pressure pipe for reference during installation before loosening. Gartner Banana

Page 662 of 1708

ENGINE SPEED SENSING POWER STEERING N Disassembly / Inspection / Assembly 1. The following precedure is for replacement of the O-rings only. Replace the pump assembly if other repairs are necessary. 2. Disassemble in the order shown in the figure, referring to Disassembly Note. 3. Assemble in the reverse order of disassembly, referring to Assembly Note. N.m {kgfm, ftW] 1. Suction pipe 12. Cam ring ................... 2. O-ring Inspection page N-36 .............. 3. Pressure switch assembly Assembly Note page N-37 4, O-ring 13. Blade ................... 5. Connector Inspection page N-36 .............. 6. O-ring Assembly Note page N-37 7. Control valve 14. Rotor ................... Inspection ................... page N-36 Inspection page N-36 .............. 8. Spring Assembly Note page N-36 ................... Inspection page N-36 15. Side plate .................... 9. Bracket Inspection page N-36 10. Pump body rear 16. O-ring ................... w Inspection page N-36 17. O-ring 11. O-ring 18. Pin 19. Pump body front ................... Inspection page N-36 Gartner Banana

Page 663 of 1708

N ENGINE SPEED SENSING POWER STEERING Disassembly Note Oil pump Use the SSTwhen securing the oil pump in a vise, so that force is not applied to the pulley or shaft. Inspection Pump body front, rear lnspect the front and rear of the pump body for cracks and damage, and the friction surface of the rotor for wear. Replace the pump assembly if a problem is found. Cam ring, rotor, blade, side plate 1. lnspect the blade friction surface of the cam ring for wear. 2. lnspect the pump body of the rotor and side plate friction surface for wear. 3. lnspect the cam ring friction surface of the blade for -, wear. 4. lnspect clearance between the rotor and blade. Control valve, spring 1. lnspect the control valve for cracks, damage and block- age, and the friction surface for wear. 2. lnspect the spring for damage. Assembly Note Rotor Install the rotor with the indentification mark facing upward. Gartner Banana

Page 664 of 1708

ENGINE SPEED SENSING POWER STEERING N Cam ring Install the cam ring with the identification mark facing downward. Blade Install the blades into the rotor with the rounded edges facing outward. DRIVE BELT Inspection 1. Check the drive belt for wear, cracks, and fraying. Replace as necessary. 2. Verify that the drive belts are correctly mounted on the pulleys. 3. Check the drive belt deflection when the engine is cold, or at least 30 minutes after the engine has stopped. Apply moderate pressure (98 N (10 kgf, 22 Ibf)) midway between the specified pulleys. Deflection mm {in) A belt that has been on a running engine for less than five minutes. 4. If the deflection is not within specification, adjust it. Limit 11.5 (0.45) New' 8-9 {0.32-0.35) Drive belt tension check 1. Belt tension can be checked in place of belt deflection. Check the drive belt tension when the engine is cold, or at least 30 minutes after the engine has stopped. Using the SST, check the belt tension between any two pulleys. Used 9-10 {0.36-0.39) Tension N hf, Ibf) A belt that has been on a running engine for less than five minutes. .- - 2. If the tension is not within specification, adjust it. 25~0~x432 Limit 245 {25,55) New' 491-588 (50-60, 11 &I 32) Used 422490 {43--50, %--I 10) Gartner Banana

Page 665 of 1708

N ENGINE SPEED SENSING POWER STEERING Adjustment Loosen PIS oil pump bolt @ and nuts @ and 0. Adjust the belt deflection by turning adjusting bolt @I. 4 Tightening torque @: 37-53 N.m (3.7-5.5 kgf.m, 27-39 ft-lbf) @: 37-53 N-m (3.7-4.5 kgf.m, 27-39 ft4bf) 0: 19-25 N-m (1 .S2.6 kgf.m, 14-1 8 ftlbf) I 15UONX-043 Replacement 1. Loosen bolt @, nuts @ and 0, and adjusting bolt @. 2. Remove and replace the drive belt. 3. Adjust the deflection (tension). (Refer to page N-37.) Gartner Banana

Page 666 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . BRAKING SYSTEM INDEX ....................................... P- 2 OUTLINE ..................................... P- 4 SPEClFlCATlONS ........................... P- 4 BRAKE SYSTEM ............................. P- 5 PREPARATION ............................. P- 5 TROUBLESHOOTING GUIDE ................ P- 6 AIR BLEEDING ............................. P- 7 BRAKE HYDRAULIC LINE ................... P- 7 BRAKE FLUID .............................. P- 8 ............................. BRAKE PEDAL P- 9 MASTER CYLINDER (STANDARD) ............ P-11 MASTER CYLINDER (ABS) .................. P-14 POWER BRAKE UNIT ....................... P-20 PROPORTIONING BYPASS VALVE ........... P-23 FRONT BRAKE (DISC) ...................... P-25 CALIPER ................................... P-28 REAR BRAKE (DISC) ........................ P-29 CALIPER ................................... P-32 PARKING BRAKE SYSTEM .................... P-34 TROUBLESHOOTING GUIDE ................ P-34 PARKING BRAKE LEVER .................... P-34 PARKING BRAKE CABLE .................... P-36 ANTILOCK BRAKE SYSTEM (ABS) ............ P-37 DESCRIPTION .............................. P-37 PREPARATION ............................. P-37 TROUBLESHOOTING GUIDE ................ P-38 CIRCUIT DIAGRAM ......................... P-52 HYDRAULIC UNIT ........................... P-53 ........................ ABS CONTROL UNIT P-55 RELAYS .................................... P-56 ABS WHEEL SPEED SENSOR (FRONT) ....... P-58 ABS SENSOR ROTOR (FRONT) .............. P-59 ABS WHEEL SPEED SENSOR (REAR) ........ P-60 ABS SENSOR ROTOR (REAR) ............... P-61 25UOPX-001 Gartner Banana

Page 667 of 1708

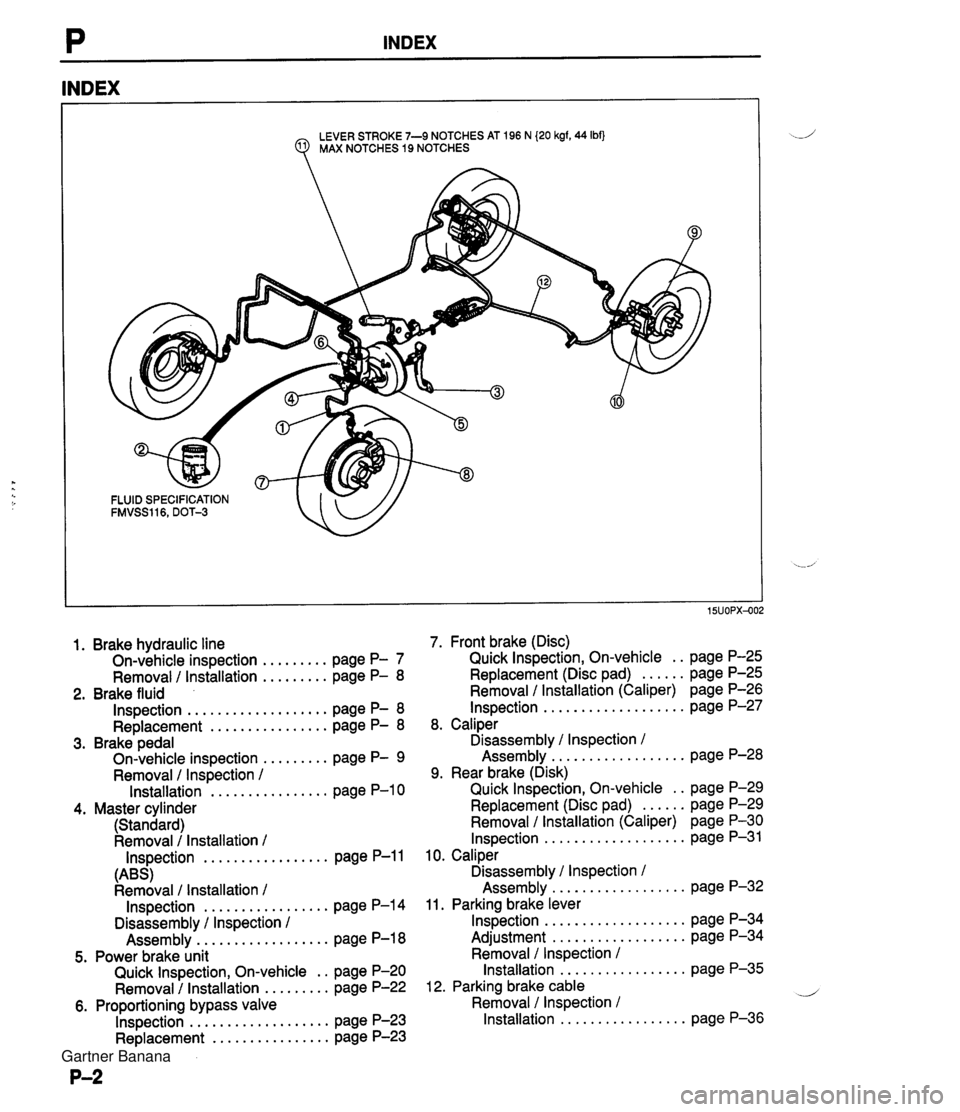

INDEX INDEX LEVER STROKE 7-9 NOTCHES AT 196 N (20 kgf, 44 IbfJ 9 MAX NOTCHES 19 NOTCHES FLUID SPECIFICATION FMVSS116, DOT-3 1. Brake hydraulic line 7. Front brake (Disc) On-vehicle inspection ......... page P- 7 Quick Inspection, On-vehicle . . page P-25 ...... Removal / Installation ......... page P- 8 Replacement (Disc pad) page P-25 2. Brake fluid Removal / Installation (Caliper) page P-26 ................... Inspection ................... page P- 8 Inspection page P-27 Replacement ................ page P- 8 8. Caliper 3. Brake pedal Disassembly / Inspection l On-vehicle inspection ......... page P- 9 Assembly .................. page P-28 Removal / Inspection / 9. Rear brake (Disk) Installation ................ page P-10 Quick Inspection, On-vehicle . . page P-29 ...... 4. Master cylinder Replacement (Disc pad) page P-29 (Standard) Removal / Installation (Caliper) page P-30 ................... Removal / Installation / Inspection page P-31 Inspection ................. page P-1 1 10. Caliper (ABS) Disassembly 1 Inspection / Removal / Installation / Assembly .................. page P-32 Inspection ................. page P-14 11. Parking brake lever ................... Disassembly / Inspection / Inspection page P-34 Assembly .................. page P-18 Adjustment .................. page P-34 5. Power brake unit Removal / Inspection / Quick Inspection, On-vehicle . . page P-20 Installation ................. page P-35 Removal / Installation ......... page P-22 12. Parking brake cable J 6. Proportioning bypass valve Removal / Inspection 1 Inspection ................... page P-23 Installation ................. page P-36 ................ Replacement page P-23 Gartner Banana

Page 668 of 1708

INDEX P ANTILOCK BRAKE SYSTEM (ABS) 1. Hydraulic unit 5. ABS sensor rotor (front) Removal / Installation ......... page P-53 Removal / Ins~ection / ................. Disassembly / Assembly ...... page P-54 Installation page P-59 2. ABS control unit 6. ABS wheel-speed sensor (rear) Removal I Installation ......... page P-55 Removal 1 Inspection I ................. 3. Relays Installation page P-60 Removal / Inspection / 7. ABS sensor rotor (rear) ......... ................. w Installation page P-56 Removal / Inspection page P-61 .................. 4. ABS wheel-speed sensor (front) Installation page P-62 Removal / Inspection / ................. Installation page P-58 Gartner Banana

Page 669 of 1708

OUTLINE OUTLINE SPECIFICATIONS Item TY ~e Specifications Suspended Pedal level ratio Maximum stroke mm (in) 4.1 : I 1 20 14.72) - -- TY ~e Bore mm (in) Pad dimensions (area x thickness) mm2 x mm {in2 x in) Tandem (with level sensor) 22.22 (0.875) -- - TY ~e Cylinder bore mm (in) Disc plate dimension (effective diame- ter x thickness) mm {in) Disc (ventilated) 51.1 (2.01) Pad dimensions (area x thickness) mm2 x mm (in2 x in) Cylinder bore mm {in) Disc plate dimensions (effective diameter x thickness) mm (in) Disc (solid) 31.75 (1.25) Size mm {in) Vacuum multiplier 21 4 (8) Proportioning bypass valve (PBV) FMVSS 11 6: DOT-3 Brake fluid Mechanical, two rear brakes Hand lever Parking brake TY Pe - Operation system Gartner Banana

Page 670 of 1708

BRAKE SYSTEM P BRAKE SYSTEM PREPARATION - SST Wrench, flare nut 49 0221 600C Expand tool, disc brake 49 8043 001 Adjust gauge 49 8043 004 Wrench, socket Gauge, oil pressure (Part of 49 U043 OAO) - 49 U043 006 Hose (Part of 49 U043 OAO) For removal and installation brake PIPS For installation of disc pads 49 F043 001 Adjust gauge For Adjustment of push rod clearance For adjustment of push rod clearance 49 0208 701 A Boot air out tool For adjustment of push rod clearance For inspection of brake fluid pressure For removal of piston seal 49 8043 003 Lock tool, turning For inspection of brake fluid pressure For adjustment of push rod clearance 49 U043 OAO Gauge set, oil pressure & - For inspection of brake fluid pressure 49 U043 005 Joint (Part of ,-, 49 U043 OAO) For inspection of brake fluid pressure Gartner Banana