ECU MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 207 of 1164

ASSEMBLY 82

03UOB2-09

03UOB2-094

-

Caution

l Do not scratch the oil pump.

5. Cut away the portion of the gasket that projects from the

body toward the oil pan side.

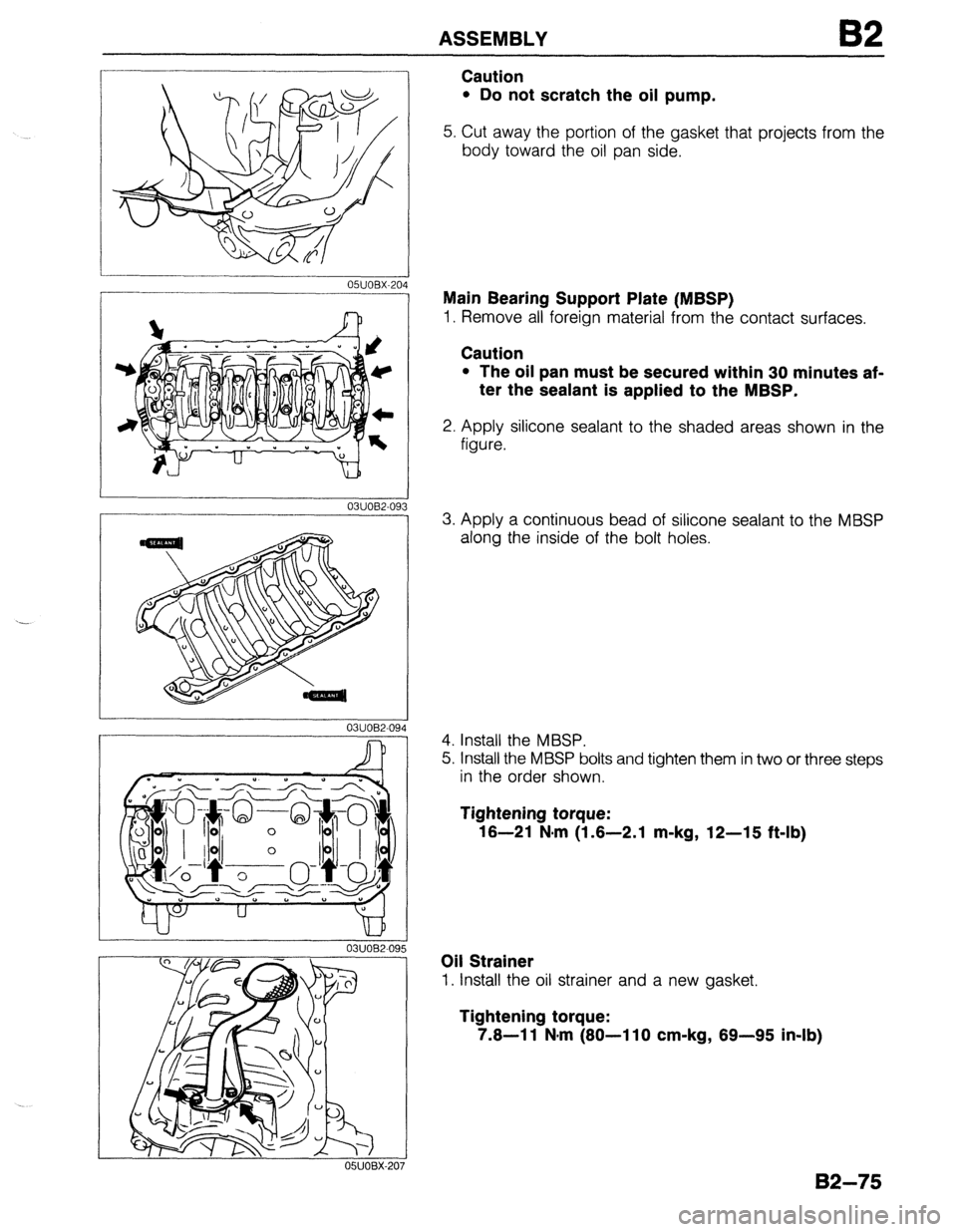

Main Bearing Support Plate (MBSP)

1. Remove all foreign material from the contact surfaces.

Caution

l The oil pan must be secured within 30 minutes af-

ter the sealant is applied to the MBSP.

2. Apply silicone sealant to the shaded areas shown in the

figure.

3. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes.

4. Install the MBSP.

5. Install the MBSP bolts and tighten them in two or three steps

in the order shown.

Tightening torque:

16-21 N,m (1.6-2.1 m-kg, 12-15 ft-lb)

Oil Strainer

1. Install the oil strainer and a new gasket.

Tightening torque:

7.6-l 1 N-m (80-l 10 cm-kg, 89-95 in-lb)

B2-75

Page 216 of 1164

B2 ASSEMBLY

TIMING BELT

Torque Specifications

7.6-11 N:m

(60-l 10 cm-kg,

69-95 in-lb) \

-kg, 69-95 in-lb)

37-52

(3.8-5.3, 27-38)

157-167 (16-17, 116-123)

?.a--11 N-m

(60-110 cm-kg, 69-95 in-lb) /

12-17 (1.25-1.76, 9-13)

N-m (m-kg, ft-it

03UOB2.1

Idler

1. Install the idler.

Tightening torque:

37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

Tensioner and Tensioner Spring

1. Install the tensioner and the tensioner spring.

2. Temporarily secure the tensioner with the spring fully ex-

tended.

-’

o5uoBx-229

02-84

Page 227 of 1164

INSTALLATION B2

Step 2

Warning

l Be sure the vehicle is securely supported on Safety stands.

Torque Specifications

‘4-l 03

‘.5-10.5, 54-76)

37-52 (3.8-5.3, 27-38)

/

37-52 (3.8-5.3, 27-38)

64-89 (6.5-9.1, 47-66) 64-89 (6.5-9.1, 47-66)

N.m (m-kg, ft-II

OWOBX-21

Engine mount member (ATX)

1. Install the engine mount member.

Tightening torque:

64-89 N*m (6.5-9.1 m-kg, 47-66 ft-lb)

I I 03UOB2-130 1132-95

Page 229 of 1164

INSTALLATION

Step 3

Torque Specifications

16-23 (1.6-2.3, 12-17) 6.9-9.8 N.m (70-100 cm-kg, 61-87 in-lb)

I

m- ,,

// / 31-46 (3.2-4.7, 23-34)

ATX

Y

16-23 (1.6-2.3, 12-17) I 37-52 (3.8-5.3, 27-38) \/r-]z$/ 43-59 (4.4-6.0, 31-43)

COTTER PIN, NEW

/ 31-46 (3.2-4.7. 23-34) 42-67 (4.3-5.8, 31-42)

-_ ..------_ N.m (m-kg, R-lb)

no, Inor, 1.3

L 03UOB2 131

I 0311082-13.

Driveshaft

1. Apply grease to the end of the driveshaft.

Caution

l When installing the driveshaft, be careful not to

damage the oil seal.

l After installation, pull the front hub outward to con-

firm that the driveshaft is securely held by the clip.

2. Install the driveshaft and a new clip.

3. Install the lower arm ball-joint to the knuckle; then tighten

the lock nut.

Tightening torque:

43-59 N-m (4.4-6-O m-kg, 31-43 ft-lb)

4. Install the joint shaft.

5. Tighten the bolts in the order shown.

Tightening torque:

42-62 N-m (4.3-6.3 m-kg, 31-46 ft-lb)

82-97

Page 245 of 1164

OIL PAN

BPSOHCANDDOHC

D

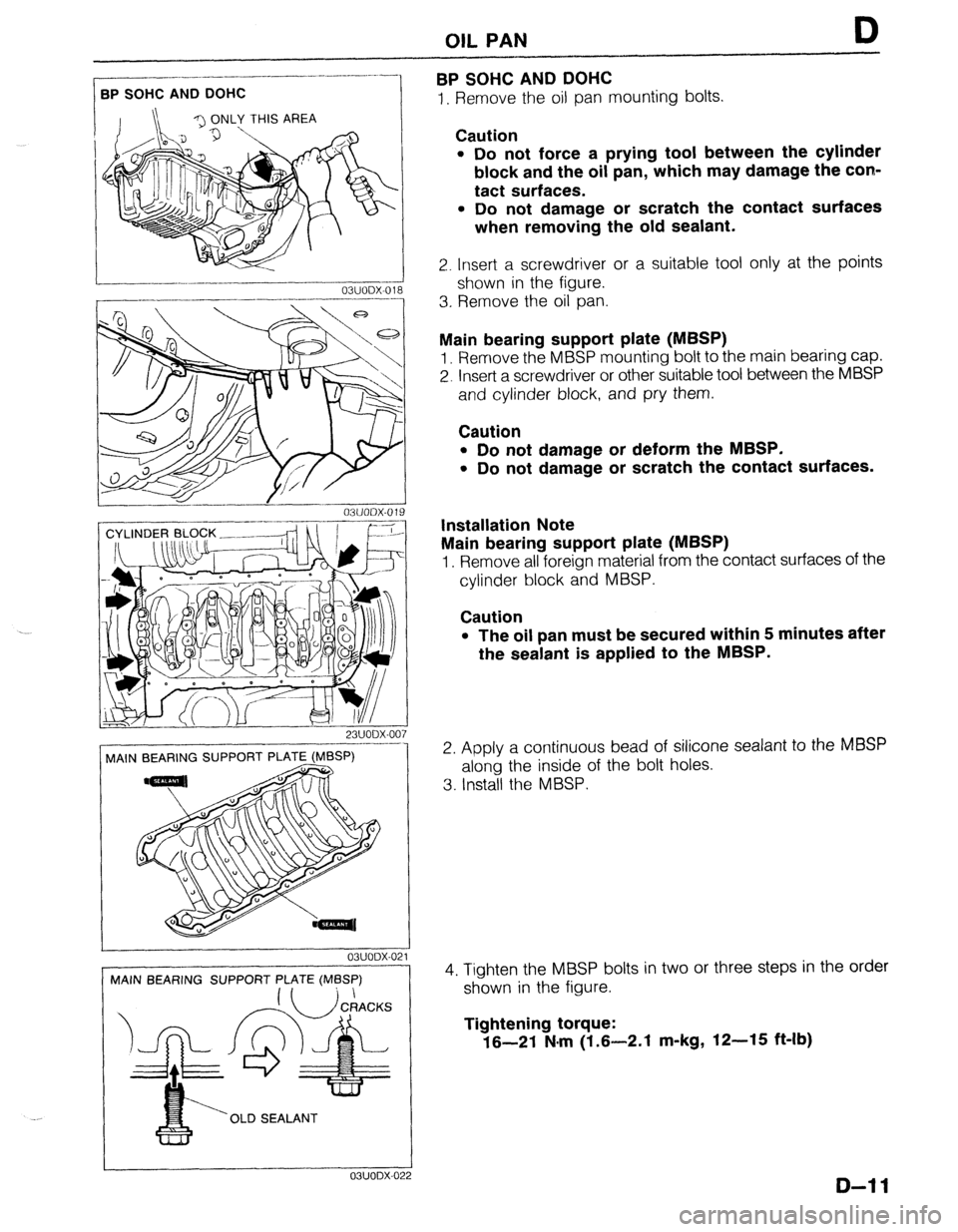

I. Remove the oil pan mounting bolts. .-_-__------- BPSOHCANDDOHC

23UODX-007

MAIN BEARING SUPPORT PLATE (MBSP)

! 03UODX-021

MAIN BEARING SUPPORT PLATE (MBSP)

‘OLD SEALANT ---1_1

OBUODX-0: !2

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Rernove the oil pan.

Main bearing support plate (MBSP)

1. Remove the MBSP mounting bolt to the main bearing cap.

2. Insert a screwdriver or other suitable tool between the MBSP

and cylinder block, and pry them.

Caution

l Do not damage or deform the MBSP.

l Do not damage or scratch the contact surfaces.

Installation Note

Main bearing support plate (MBSP)

1. Remove all foreign material from the contact surfaces of the

cylinder block and MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply a continuous bead of silicone sealant to the MBSP

along the inside of the bolt holes.

3. Install the MBSP.

4. Tighten the MBSP bolts in two or three steps in the order

shown in the figure.

Tightening torque:

16-21 N.m (1.6-2.1 m-kg, 12-15 ft-lb)

D-l 1

Page 267 of 1164

F

FUEL AND EMISSION

CONTROL SYSTEM

INDEX ...........................................

OUTLINE ...................................... ;: 2

SYSTEM DIAGRAM ...................... F-

:

VACUUM HOSE ROUTING

DIAGRAM .................................

WIRING DIAGRAM ....................... F- 6

- 7

ENGINE CONTROL UNIT (ATX) ...... F- 13

SPECIFICATIONS.. ....................... F- 15

COMPONENT DESCRIPTIONS.

...... F- 16

TROUBLESHOOTING GUIDE.. ......... F- 20

ENGINE CONTROL OPERATION

CHART

..................................... F- 20

RELATIONSHIP CHART.. .............. F- 24

USING THIS SECTION .................. F- 25

DIAGNOSTIC INDEX .................... F- 27

PRECAUTION ............................. F- 29

SYMPTOM TROUBLESHOOTING .... F- 30

ENGINE TUNE-UP

.......................... F- 76

PREPARATION ............................

F- 76

BASIC INSPECTION ..................... F- 78

ADJUSTMENT .............................

F- 79

SELF-DIAGNOSIS FUNCTION .......... F- 82

DESCRIPTION .............................

F- 82

PREPARATION

............................

F- 83

SERVISE CODE NUMBER.. ........... F- 83

SWITCH MONITOR FUNCTION ...... F-105

INTAKE AIR SYSTEM.. ................... F-109

COMPONENT PARTS.. ................. F-109

THROTTLE BODY ........................ F-l 12

DYNAMIC CHAMBER ................... F-l 12

INTAKE MANIFOLD ..................... F-l 13

ACCELERATOR PEDAL ................ F-l 14

ACCELERATOR CABLE ................ F-l 14

IDLE SPEED CONTROL (ISC)

SYSTEM ......................................

F-115

DESCRIPTION ............................. F-115

PREPARATION

............................ F-116

SYSTEM OPERATION.. ................. F-l 16

ISC VALVE ................................. F-116

AIR VALVE

................................. F-116

VARIABLE INERTIA CHARGING

SYSTEM (VICS) [DOHC] ................ F-l 17

DESCRIPTION ............................. F-117

SYSTEM OPERATION ................... F-l 18

SHUTTER VALVE ACTUATOR.. ...... F-l 18

SOLENOID VALVE (VICS). ............. F-118

VACUUM CHAMBER.. .................. F-119

FUELSYSTEM .............................. F-l 20

DESCRIPTION

............................. F-l 20

PRECAUTION ............................. F-121

SYSTEM OPERATION.. ................. F-121

FUEL TANK ................................

F-l 23

FUEL FILTER .............................. F-l 24 FUEL PUMP ............................... F-l 25

CIRCUIT OPENING RELAY.. .......... F-129

PRESSURE REGULATOR.. ............ F-129

INJECTOR .................................. F-l 31

PRESSURE REGULATOR

CONTROL SYSTEM.. .................... F-l 34

SOLENOID VALVE (PRESSURE

REGULATOR CONTROL). ............ F-l 35

EXHAUST SYSTEM ........................ F-l 36

COMPONENT PARTS.. ................. F-136

OUTLINE OF EMISSION

CONTROL SYSTEM.. .................... F-l 37

STRUCTURAL VIEW.. ................... F-l 37

POSITIVE CRANKCASE

VENTILATION (PCV) SYSTEM.. ..... F-138

DESCRIPTION .............................

F-l 38

PCV VALVE ................................ F-l 38

EVAPORATIVE EMISSION

CONTROL SYSTEM.. .................... F-l 39

DESCRIPTION ............................. F-l 39

SYSTEM OPERATION.. ................. F-140

SOLENOID VALVE

(PURGE CONTROL) ................... F-140

SEPARATOR ............................... F-l 40

CHECK VALVE (TWO-WAY) ........... F-140

CHECK-AND-CUT VALVE.. ............ F-141

CHARCOAL CANISTER.. ............... F-141

DECELERATION CONTROL

SYSTEM ...................................... F-l 42

DESCRIPTION ............................. F-l 42

DASHPOT .................................. F-142

FUEL CUT CONTROL SYSTEM ....... F-143

DESCRIPTION ............................. F-l 43

PREPARATION ............................ F-l 43

SYSTEM OPERATION.. ................. F-143

DECHOKE CONTROL SYSTEM.. ...... F-145

DESCRIPTION ............................. F-l 45

SYSTEM OPERATION ................... F-l 45

CONTROL SYSTEM ....................... F-l 47

PREPARATION ............................ F-147

STRUCTURAL VIEW.. ................... F-l 48

ENGINE CONTROL UNIT (ECU) ..... F-149

AIRFLOW METER (WITH INTAKE AIR

THERMOSENSOR) ..................... F-168

WATER THERMOSENSOR.. ........... F-168

THROTTLE SENSOR .................... F-l 69

OXYGEN SENSOR.. ..................... F-171

MAIN RELAY (FUEL INJ RELAY) .... F-172

CLUTCH SWITCH (MTX) ............... F-172

NEUTRAL SWITCH (MTX). ............. F-173

POWER STEERING PRESSURE

SWITCH .................................... F-173

WJOFX-001

Page 269 of 1164

INDEX F

1. Resonance duct

Inspection / Replacement.. ........ page F-l 09

2. Air cleaner element

Inspection ................................. page F- 79

Replacement.. ........................... page F-l 09

3. Airflow meter

(With intake air thermosensor)

Inspection

................................. page F-l 68

Replacement.. ........................... page F-l 09

4. Resonance chamber

Inspection I Replacement.. ........ page F-l 09

5. Throttle body

Inspection .................................

page F-l 12

Replacement.. ...........................

page F-l 09

6. Throttle sensor

inspection ................................. page F-l 69

Adjustment..

.............................. page F-l 69

Replacement.. ........................... page F-l 71

7. ISC valve

Inspection ................................. page F-l 16

Replacement..

........................... page F-l 09

8. Dashpot

Inspection ................................. page F-l 42

9. Dynamic chamber

Removal / Installation ................

page F-109

Inspection [DOHC] ................... page F-l 12

10. Air valve

Inspection

................................. page F-l 16

Removal / Installation ................ page F-109

11. Shutter valve actuator

Inspection ................................. page F-l 18

12. Vacuum chamber [DOHC]

Inspection ................................. page F-l 19

13. Intake manifold

Removal / Installation ................ page F-l 09

14. Injector

Inspection .................................

page F-l 31

Removal .................................... page F-131

Installation.. ............................... page F-l 33 15. Pressure regulator

Inspection ................................. page F-l 29

Replacement ............................. page F-l 30

16. Solenoid valve (Pressure regulator control)

[BP1

Inspection ................................. page F-l 35

17. Solenoid valve (VICS) [DOHC]

Inspection ................................. page F-l 18

18. Charcoal canister

Inspection ................................. page F-l 41

19. Solenoid valve (Purge control)

Inspection ................................. page F-l 40

20. Circuit opening relay

Inspection ................................. page F-l 29

Replacement ............................. page F-l 29

21. Engine control unit (ECU)

Removal / Installation ................ page F-l 49

Inspection ................................. page F-149

22. Clutch switch (MTX)

Inspection ................................. page F-l 72

Replacement.. ........................... page F-l 72

23. PCV valve

Inspection ................................. page F-l 38

24. Water thermosensor

Removal / Inspection /

Installation ............................... page F-l 68

25. Fuel filter (High-pressure side)

Replacement.. ........................... page F-l 24

26. Main relay (FUEL INJ relay)

Inspection ................................. page F-l 72

27. Neutral switch (MTX)

inspection ................................. page F-l 73

Replacement.. ........................... page F-l 73

28. Oxygen sensor

Inspection ................................. page F-l 71

Replacement ............................. page F-l 72

29. Power steering pressure switch

Inspection ................................. page F-l 73

Replacement.. ........................... page F-l 73

23UOFX-002

F-3

Page 279 of 1164

OUTLINE F

ENGINE CONTROL UNIT (ATX)

The engine control unit (ECU) is united with the EC-AT control unit for simplification of the system.

PREVIOUS

I

EC-AT CONTROL UNIT

OUTPUT DEVICES

ENGINE CONTROL

I I MALFUNCTION DISPLAY FUNCTION

I

L- ------ -------- ----__ __J

NEW ENGINE/EC-AT CONTROL UNIT

-----------m--e-

I

1

1

4

I I

OUTPUT

*

h

T I

NPUT SIGNALS I )c

I ENGINE CONTROL

‘I

FAIL-SAFE FUNCTION

NPUT SIGNALS I EC-AT CONTROL

I DEVICE!

OUTPUT DEVICE:

23UOFX-01

Signals input to the combined engine/EC-AT control unit are classified into engine and EC-AT control signals within the unit.

The operation of the engine control and EC-AT control are unchanged from the previous model.

F-l 3

Page 282 of 1164

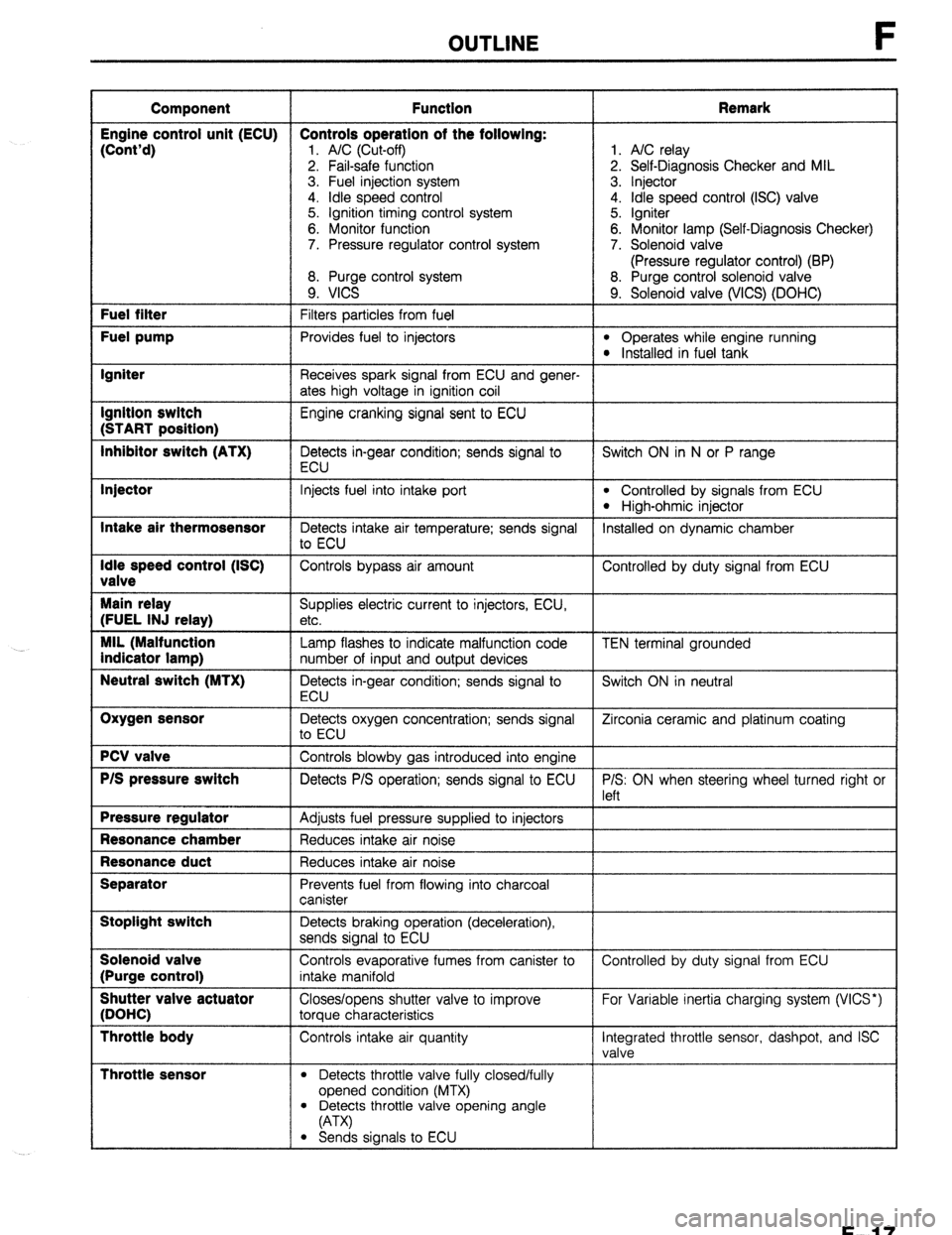

F OUTLINE

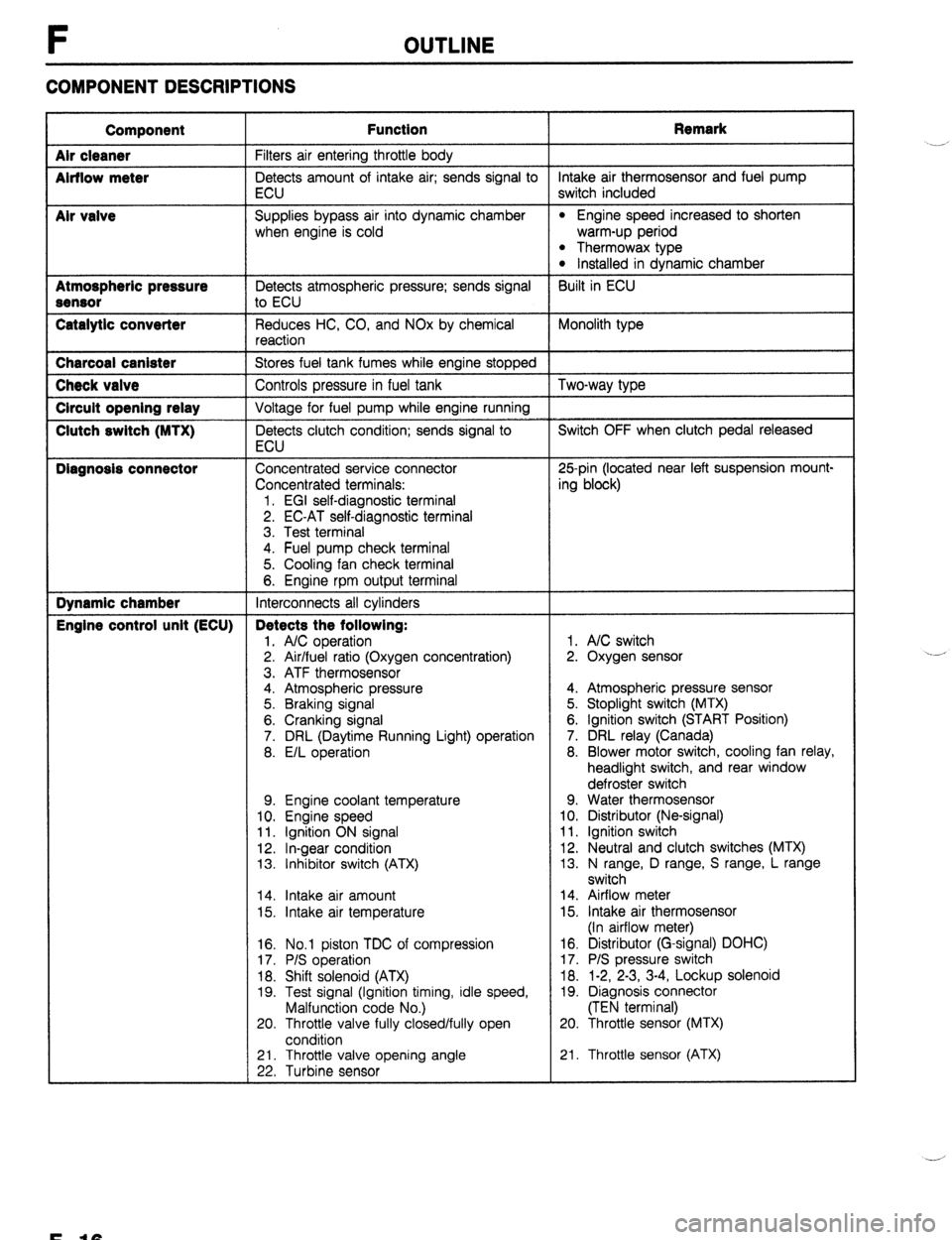

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 283 of 1164

OUTLINE

Component Function Remark

Engine control unit (ECU) Controls operation of the following:

(Cont’d)

1. A/C (Cut-off) 1. A/C relay

2. Fail-safe function 2. Self-Diagnosis Checker and MIL

3. Fuel injection system 3. Injector

4. idle speed control 4. Idle speed control (ISC) valve

5. Ignition timing control system 5. Igniter

6. Monitor function 6. Monitor lamp (Self-Diagnosis Checker)

7. Pressure regulator control system 7. Solenoid valve

(Pressure regulator control) (BP)

8. Purge control system 8. Purge control solenoid valve

9. VICS 9. Solenoid valve (WCS) (DOHC) Fuel filter

Filters particles from fuel Fuel pump

Provides fuel to injectors l Operates while engine running l Installed in fuel tank Igniter

Receives spark signal from ECU and gener-

ates high voltage in ignition coil Ignition switch

Engine cranking signal sent to ECU (START position)

Inhibitor switch (ATX)

Detects in-gear condition; sends signal to Switch ON in N or P range

ECU Injector

Intake air thermosensor

Idle speed control (ISC)

valve

Main relay

(FUEL INJ relay)

MIL (Malfunction

indicator lamp)

Neutral switch (MTX)

Oxygen sensor

PCV valve

P/S pressure switch

Pressure regulator

Resonance chamber

Resonance duct

Separator

Stoplight switch

Solenoid valve

(Purge control)

Shutter valve actuator

(DOHC)

Throttle body

Throttle sensor

Injects fuel into intake port l Controlled by signals from ECU

l High-ohmic injector

Detects intake air temperature; sends signal Installed on dynamic chamber

to ECU

Controls bypass air amount Controlled by duty signal from ECU

Supplies electric current to injectors, ECU,

etc.

Lamp flashes to indicate malfunction code

number of input and output devices

Detects in-gear condition; sends signal to

ECU

Detects oxygen concentration; sends signal

to ECU

Controls blowby gas introduced into engine

Detects P/S operation; sends signal to ECU

Adjusts fuel pressure supplied to injectors

Reduces intake air noise

Reduces intake air noise

Prevents fuel from flowing into charcoal

canister

Detects braking operation (deceleration),

sends signal to ECU

Controls evaporative fumes from canister to

intake manifold

Closes/opens shutter valve to improve

torque characteristics

Controls intake air quantity

l Detects throttle valve fully closed/fully

opened condition (MTX) TEN terminal grounded

Switch ON in neutral

Zirconia ceramic and platinum coating

P/S: ON when steering wheel turned right or

left

Controlled by duty signal from ECU

For Variable inertia charging system (VICS*)

Integrated throttle sensor, dashpot, and ISC

valve

l Detects throttle valve opening angle

(A-W

l Sends signals to ECU

F-l 7