oil type MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 239 of 1164

OUTLINE, TROUBLESHOOTING GUIDE D

OUTLINE

SPECIFICATIONS

Engine

Item

--

Lubrication system

Type

011 pump

Relief pressure kPa (kg/cm2, psi)

_~__

Type Oil filter

Relief pressure differential kPa (kg/cm2, psi)

Oil pressure switch activation pressure

kPa (kg/cm’, psi)

Total (dry engine)

liters (US qt, Imp qt)

Oil capacity Oil pan liters (US qt, Imp qt)

Oil filter liter (US qt, Imp qt)

Engine oil

Above -25OC (-13’F)

Viscosity number

Below 0% (32OF) BP SOHC BP DOHC

B6 SOHC

Force-fed type

Trochoid gear

343-441 (3.5-4.5, 50-64) m I, Full-flow, paper element

78-l 18 (0.8-l .2, 1 l-i 7)

25 (0.25, 3.6)

3.4 (3.6, 3.0) 4.0 (4.2, 3.5)

3.0 (3.2, 2.6) 3.6 (3.8, 3.2)

0.17 (0.18, 0.15)

API service SG Energy ConservingII (ECII) Only

SAE low-30

SAE 5W-30

23UODX-005

TROUBLESHOOTING GUIDE

Problem

Engine hard starting

Excessive oil

consumption

Oil pressure drop

Warming lamp

illuminates while

engine is running Possible Cause

Improper engine oil

Insufficient engine oil

Oil working up or down

011 leakage

Insufficient oil

Oil leakage

Worn and/or damaged oil pump gear

Worn plunger (inside oil pump) or weak spring

Clogged oil strainer

Excessive main bearing or connecting rod bearing

clearance

Oil pressure drop

Malfunction of oil pressure switch

Malfunction of electrical system Remedy

Replace

Add oil

Refer to Section B

Repair

Add oil

Repair

Replace

Replace

Clean

Refer to Section B

As described above

Refer to Section T

Refer to Section T Page

D- 7

D- 7

-

D- 7

-

D-13, 14

D-13, 14

-

-

23UODX-015

D-5

Page 241 of 1164

ENGINE OIL, OIL FILTER D

b

I

03UODX-00

ONODX-01

r

03UODX-011

ENGINE OIL

INSPECTION

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temperature and

stop it.

3. Wait for five minutes.

4. Remove the oil level gauge and check the oil level and con-

dition.

5. Add or replace oil as necessary.

Note

l The distance between the L and F marks on the level

gauge represents 0.8 liter (0.85 US qt, 0.70 Imp qt).

REPLACEMENT

Warning

l Be careful when draining; the oil is hot.

1. Warm up the engine to normal operating temperature and

stop it.

2. Remove the oil filler cap and the oil pan drain plug.

3. Drain the oil into a suitable container.

4. Install a new gasket and the drain plug.

Tightening torque:

29-41 N,m (3.0-4.2 m-kg, 22-30 ft-lb)

5. Refill the engine with the specified type and amount of en-

gine oil.

6. Refit the oil filler cap.

7. Run the engine and check for leaks.

8. Check the oil level and add oil if necessary.

Oil pan capacity

B6 SOHC

BP SOHC and DOHC

liters (US qt, Imp qt)

3.0 (3.2, 2.6)

3.6G.843.2)

w

03UODX-011

D-7

Page 246 of 1164

OIL PAN

I 03UODX.02

05UOBX.20

1

05UODX-021

56 SOHC

03UODX-02

3P s

03UODX-02!

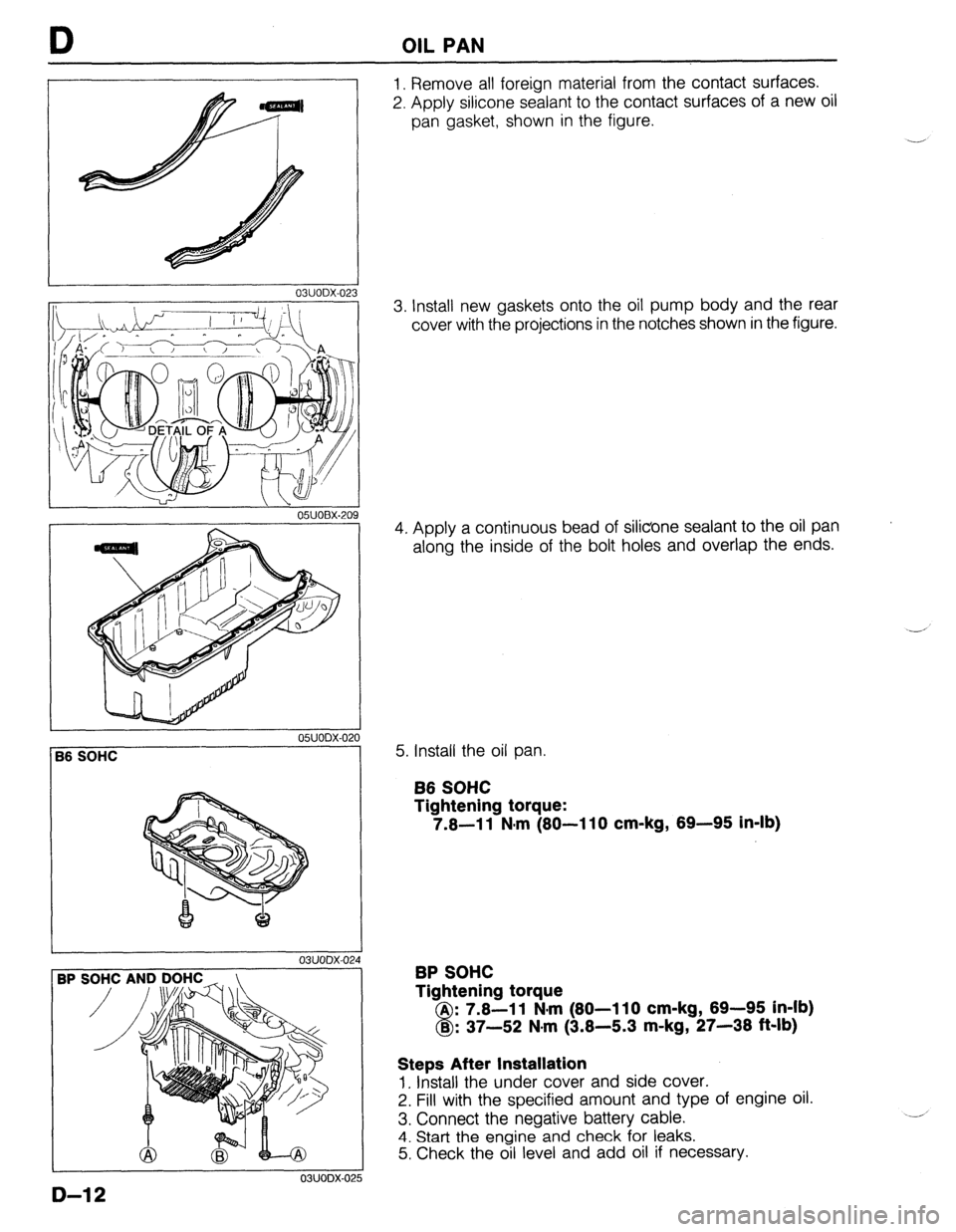

1. Remove all foreign material from the contact surfaces.

2. Apply silicone sealant to the contact surfaces of a new oil

pan gasket, shown in the figure.

3. Install new gaskets onto the oil pump body and the rear

cover with the projections in the notches shown in the figure.

4. Apply a continuous bead of silicone sealant to the oil pan

along the inside of the bolt holes and overlap the ends.

5. Install the oil pan.

B6 SOHC

Tightening torque:

7.6-11 N-m (80-110 cm-kg, 69-95 in-lb)

BP SOHC

Tightening torque

A : 7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

8 B : 37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

Steps After Installation

1. Install the under cover and side cover.

2. Fill with the specified amount and type of engine oil.

3. Connect the negative battery cable.

4. Start the engine and check for leaks.

5. Check the oil level and add oil if necessary.

D-12

Page 252 of 1164

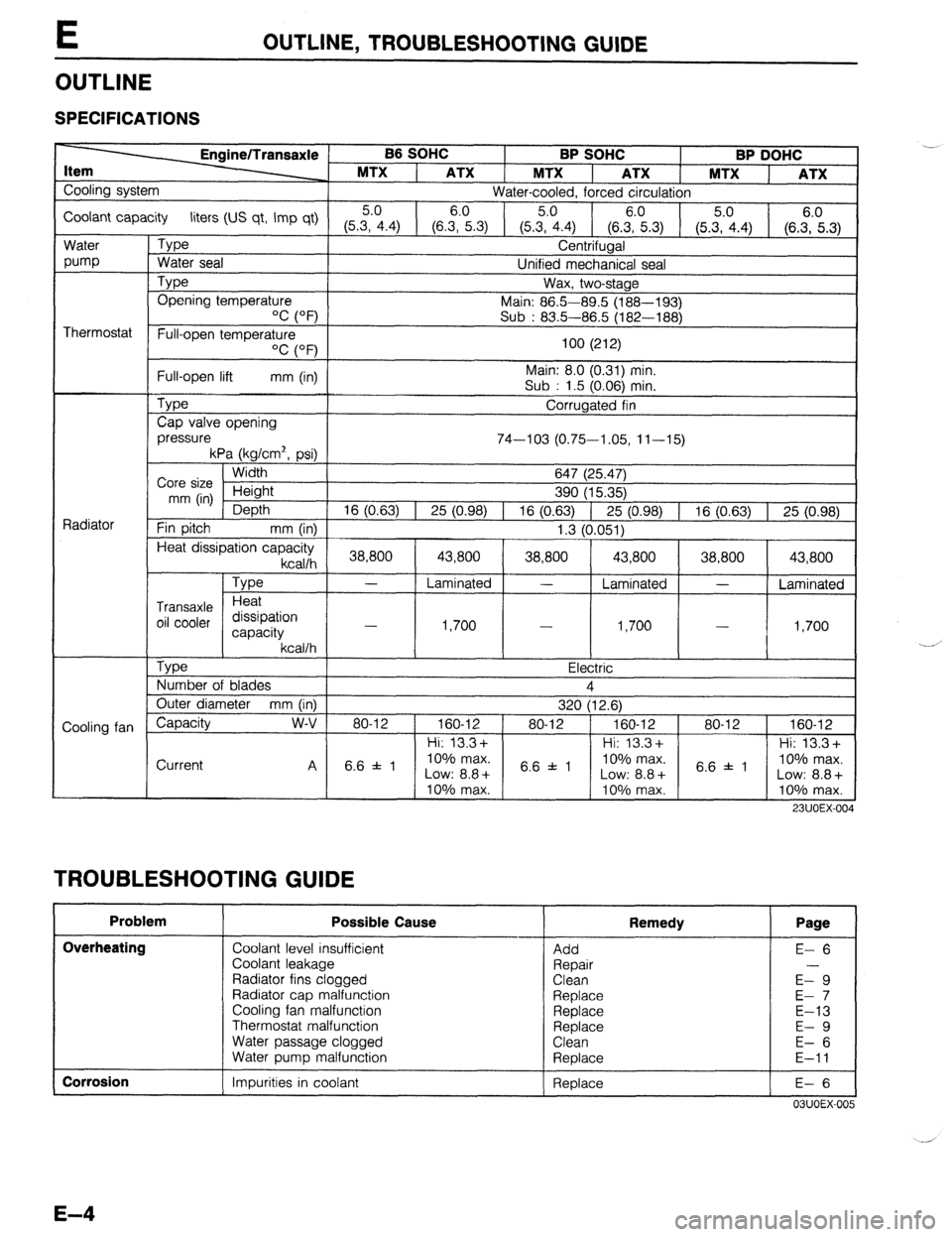

E OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

B6 SOHC

BP SOHC BP DOHC

MTX

1 ATX 1 MTX ATX 1 MTX

ATX

Cooling system

Water-cooled, forced circulation

Coolant capacity liters (US qt, Imp qt) 5.0 6.0

5.0

(5.3, 4.4) (6.3, 5.3)

(5.35.04.4) (6.zi.3) (5.3, 4.4) (6.::.3)

Water

pump

Thermostat

Radiator

Cooling fan

L Type

Water seal Centrifugal

Unified mechanical seal

Type Opening temperature

‘C (OF’) Wax, two-stage

Main: 86.5-89.5 (188-193)

Sub : 83.5-86.5 (182-188)

Full-open temperature

OC (OF)

Full-open lift mm (in)

Type

Cap valve opening

pressure 100 (212)

Main: 8.0 (0.31) min.

Sub : 1.5 (0.06) min.

Corrugated fin

74-103 (0.75-1.05, 11-15)

kPa (kg/cm2, psi)

Width

Core size Height

mm (in)

Depth

Fin pitch

mm (in) 647 (25.47)

390 (15.35)

16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98) 1 16 (0.63) 1 25 (0.98)

1.3 (0.051)

Heat dissipation capacity

kcallh 1 38,800 [ 43,800 ( 38,800 1 43,800 1 38,800 1 43,800 1

Type

Transaxle Heat

oil cooler dissipation

capacity

kcallh

Tvoe

- Laminated - Laminated -

Laminated

1,700

I .I -?nn

- -

I,,“”

I

I - I 4 Ye,-. I,IVV 1

, a-

- Electric

Number of blades 4

Outer diameter mm (in)

320 (12.6)

Capacity w-v 80-12 1 160-12 ) 80-12 ) 160-12 1 80-12 1 160-12

1 Hi: 13.3+ 1 1 Hi: 13.3+ 1 1 Hi: 13.3+

Current

TROUBLESHOOTING GUIDE I I I I

Problem Possible Cause

Overheating

Coolant level insufficient

Coolant leakage

Radiator fins clogged

Radiator cap malfunction

Cooling fan malfunction

Thermostat malfunction

Water passage clogged

Water puma malfunction .- Remedy Page

Add

Repair

Clean

Replace

Replace

Replace

Clean

Reolace E- 6

E-9

E- 7

E-13

E- 9

E- 6

E-11

I Corrosion

1 Impurities in coolant 1 Replace

I E-6 I

03UOEX-005

Page 260 of 1164

BP DOHC

L 7.8-11 N-m (60-110 cm-kg, 69-95 in-lb)

E WATER PUMP

157-167

I

(W-17, 116-123) I

I

/

I

I

I

---N-w------

---------------

----_---_

-I

N.m (m-kg, ft-lb) 1

^^, *--., ^^^

1. Timing belt

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5. Water pump assembly

B2

2. Water inlet pipe and gasket Inspect for cracks, damaged mounting

3. Water bypass pipe and O-ring surface, bearing condition, and leakage

4. Oil dip stick pipe bracket 6. Water pump gasket

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to page E-6.)

2. Connect the negative battery cable,

3. Start the engine and check for leaks.

03UOEX-018

E-12

Page 281 of 1164

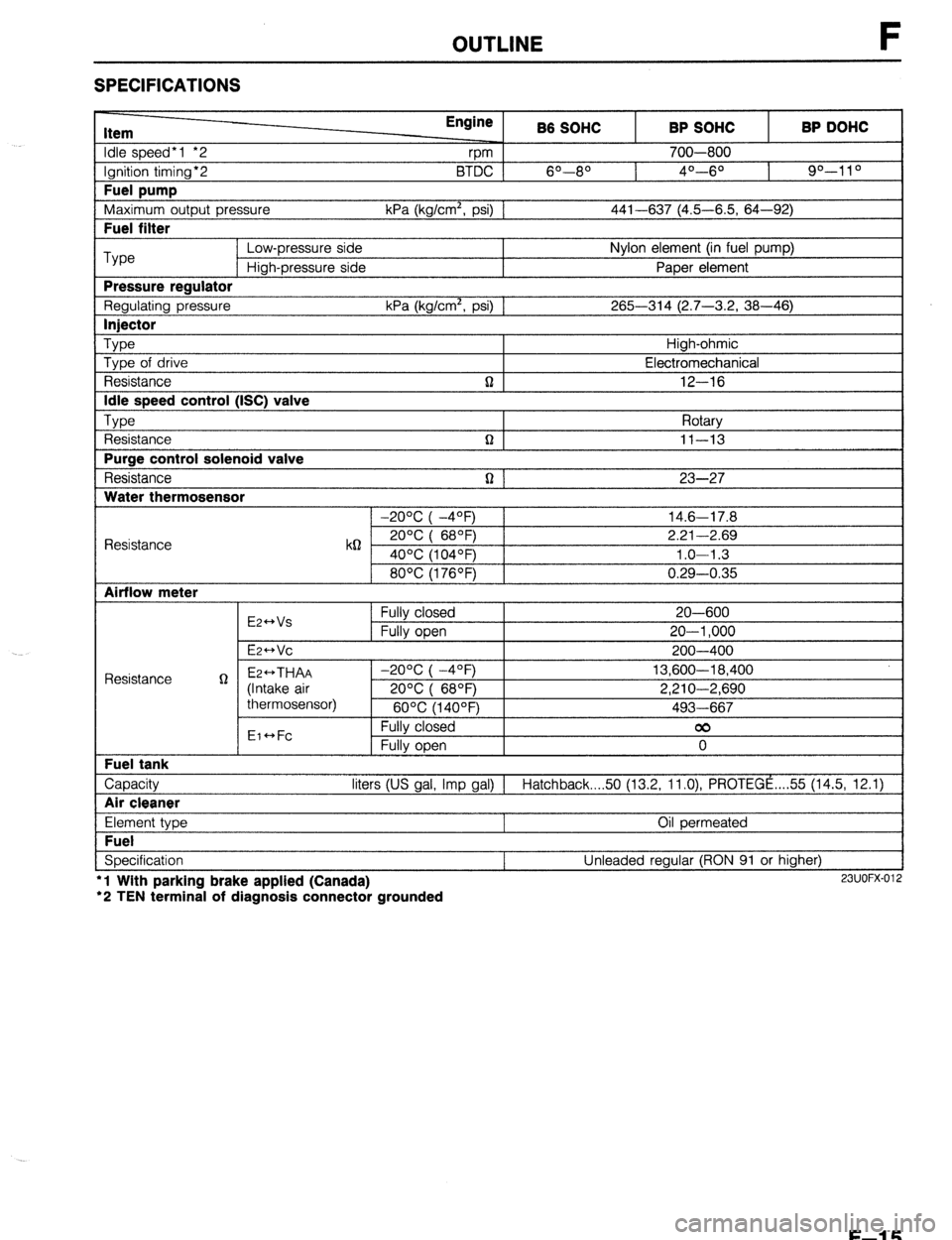

OUTLINE F

SPECIFICATIONS

Item

Idle speed*1 *2

Ignition timing*2

Fuel pump

Maximum outout Dressure Engine

rpm B6 SOHC

6O--80 BTDC 1

kPa (ka/cm’. osi1 1 BP SOHC

700-800

4O---6O BP DOHC

90-l 1 O

441-637 (4.5-6.5. 64-92) I

I Fuel filter I

Type Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element

Pressure reaulator

Regulating pressure kPa (kg/cm’, psi) 1 265-314 (2.7-3.2, 38-46)

I lniector I

Type Type of drive

Resistance

Idle speed control (ISC) valve

TvDe , ,

t Resistance

Purge control solenoid valve

Resistance

Water thermosensor n High-ohmic

Electromechanical

12-16

Rotarv

n I II-13 I

n 1 23-27

1 -20% I -4OFj 1 14.6-17.8

Resistance k62 2ooc i 68OF) 2.21-2.69

40°C (104OF) 1.0-l .3

80°C (176OF) 0.29-0.35

Airflow meter

E2++Vs

E2-Vc Fully closed

Fully open 20-600

20-l ,000

200-400

Capacity liters (US gal, Imp gal) 1 Hatchback 50 (13.2, ll.O), PROTEGE ,... 55 (14.5, 12.1)

I Air cleaner I

Element type

Fuel

Specification l

l Wlth parking brake applied (Canada)

‘2 TEN terminal of diagnosis connector grounded Oil permeated

Unleaded regular (RON 91 or higher) 23UOFX-012

F-l 5

Page 443 of 1164

OUTLINE G

OUTLINE

SPECIFICATIONS

Item EnginelTransaxle

‘-2, B6 SOHC BP SOHC BP DOHC

MTX 1 ATX MTX ( ATX

Voltage v 1 12

I

3attery

Dark current*’ Type and capacity

(20-hour rate)

mA 55D23L (60AH) 55D23L (60AH)

Max. 20.0

L\lternator

Starter

Type AC

output V-A 12-65

Regulator type Transistorized (built-in IC regulator)

Regulated voltage V 14.1-14.7

Brush length Standard 21.5 (0.846)

mm (in) Minimum 8.0 (0.315)

Drive belt deflection

New

98 N (10 kg, 22 lb)

mm (in) Used 8-Q (0.31-0.35)

Q-10 (0.35-0.39)

Type

I Direct Direct

I Coaxial

Direct Coaxial

reduction reduction I

output V-kW 12-0.95 12-0.95 12-1.4

12-0.95 12-1.4

Brush length Standard 17 (0.67) 17 (0.67) 17.5 (0.69) 17 (0.67)

17.5 (0.69)

mm (in) Minimum 11.5 (0.453) 11.5 (0.453) 10.0 (0.39) 11.5 (0.453) 10.0 (0.39)

Distributor

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded) Electronic spark advance (photo diode)

6O--8O 4O-6O Q”-1 1 o

Ignition coil

Spark plug Resistance

(at 20% [68OF]) Primary

coil winding 0.81-O.QQg

Secondary

coil winding IO-16 kg

BKR5E-11 BKR5Ell BKR5Ell

NGK

BKR6E-11 BKRGEl 1 BKRGEli

BKR7Ell

Type NIPPON-

DENSON Kl GPR-Ul l

K20PRU 11 KIGPR-Ull

K20PR-Ul l KIGPR-Ull

K20PRUll

K22PR-Ul l

I Plua aao mm (in) I 1.0-l .l (0.039-0.043)

Firing order

’ Dark current is the constant flow of current while the ignition switch is OFF.

(i.e. engine control unit, audio, etc.) l-3-4-2

23lJOGX-00

G-3

Page 469 of 1164

STARTING SYSTEM G

WEAR LIMIT

/ -- _._- .------

03UOGX-07L i

-----.

i

03UOGX 076

03UOGX-07

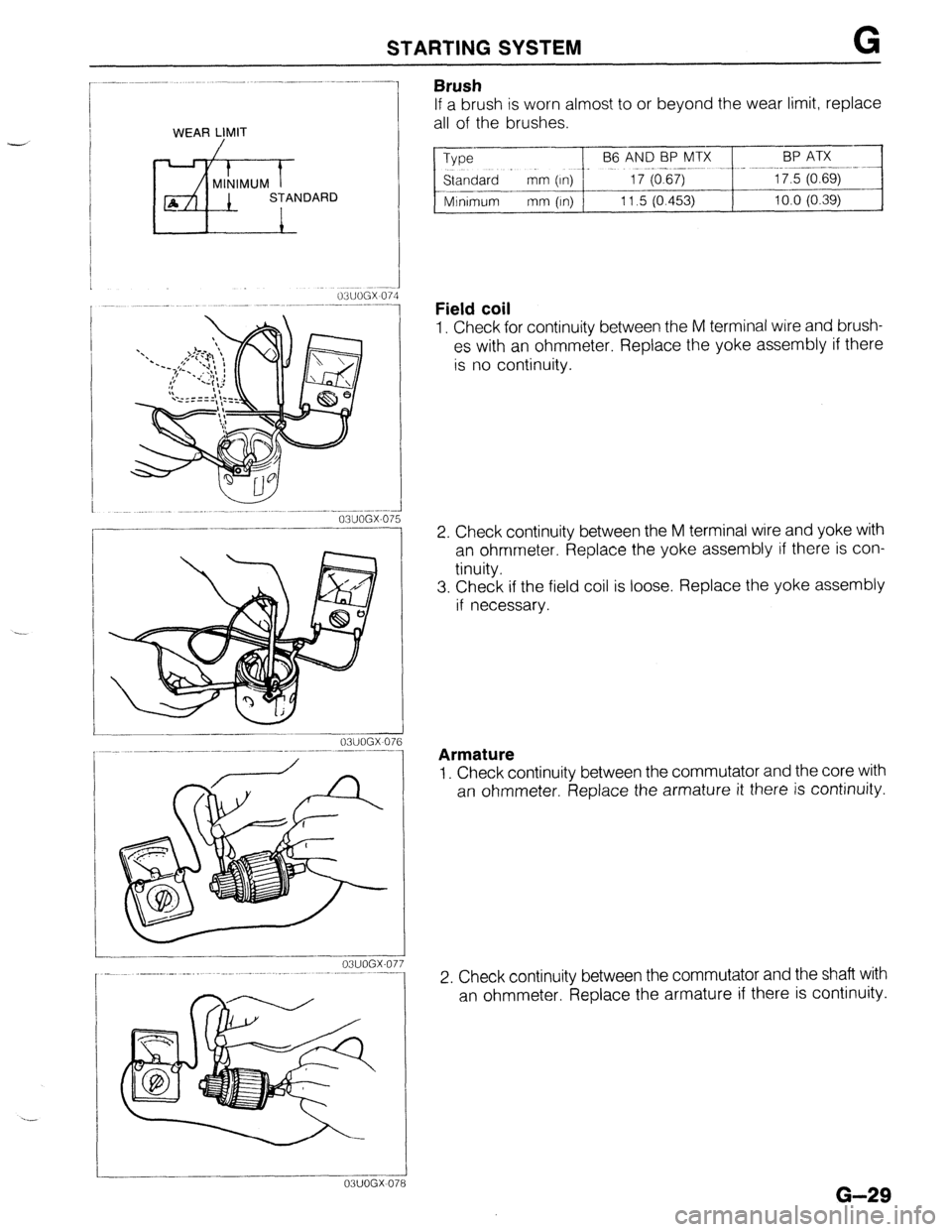

Brush

If a brush is worn almost to or beyond the wear limit, replace

all of the brushes.

Type

--pFeE?~Ix _~~_ -.~+~~zE~~:

Standard - mm (In) 1

--.-

Minimum mm (In) 11.5 (0.453) 10.0 (0.39)

Field coil

1. Check for continuity between the M terminal wire and brush-

es with an ohmmeter. Replace the yoke assembly if there

is no continuity.

2. Check continuity between the M terminal wire and yoke with

an ohmmeter. Replace the yoke assembly if there is con-

tinuity.

3. Check if the field coil is loose. Replace the yoke assembly

if necessary.

Armature

1. Check continuity between the commutator and the core with

an ohmmeter. Replace the armature it there is continuity.

2. Check continuity between the commutator and the shaft with

an ohmmeter. Replace the armature if there is continuity.

G-29

Page 475 of 1164

OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

-

-

Item

Clutch control Engine/Transaxle B6 SOHC BP SOHC BP DOHC

F!Wl-R GBM-R Hvdraulic

Clutch cover

Clutch disc Type

Set load Diaphragm spring

N

(kg, lb) 1 3,630 (370, 814) 1 3,826 (390, 858) 1 3,846 (392, 862)

30 17.48)

200 (7.87) 215 (8.46) Outer diameter mm (in)

Inner diameter mm (in)

Pressure plate

side mm (in)

Thickness

Flywheel side

mm lit-d

1! , I

130 (5.12) ’ ’

150 i5.91 j

3.5 (0.138) 3.8 (0.150)

3.5 (0.138)

Type Suspended

Clutch pedal

Master cylinder

Release cylinder

Clutch fluid Pedal ratio 6.55

Full stroke mm (in) 135 (5.32)

Height (With carpet)

mm (in) 196-204 (7.72-8.03)

Inner diameter mm (in) 15.87 (0.625)

Inner diameter

mm (in) 19.05 (0.750)

SAE J1703 or FMVSS116 DOT-3

23UOHX-003

TROUBLESHOOTING GUIDE Problem Possible Cause Remedy Page

Slipping

Clutch disc facing worn excessively Replace H-15, 17

Clutch disc facing surface hardened or oil on surface Repair or replace H-15

Pressure plate damaged Repair or replace H-15

Diaphragm spring damaged or weakened Replace H-15

Insufficient clutch pedal play Adjust H- 5

Clutch pedal sticking Repair or replace H- 6

Flywheel damaged Repair or replace H-15, 17 Faulty disen-

Excessive runout or damaged clutch disc Replace H-15, 17 gagement Clutch disc splines rusted or worn Remove rust or replace H-15

Oil on facing Repair or replace H-15

Diaphragm spring weakened Replace H-15

Excessive clutch pedal play Adjust H- 5

Insufficient clutch fluid

Add fluid H- 3

Leakage of clutch fluid Locate and repair or -

replace Clutch vibrates

Oil on facing Repair or replace H-15 when accelerating Torsion rubbers weakened Replace H-15

Clutch disc facing hardened or damaged Repair or replace H-15

Clutch disc facing rivets loose Replace H-15

Pressure plate damaged or excessive runout Replace H-15

Flywheel surface hardened or damaged Repair or replace H-15

Loose or worn engine mount Tighten or replace - Clutch pedal

Pedal shaft not properly lubricated Lubricate or replace H- 6 sticking

Abnormal noise

Clutch release bearing damaged Replace H-15, 17

Poor lubrication of release bearing sleeve Lubricate or replace H-15

Torsion rubbers weakened Replace H-15

Excessive crankshaft end play Repair Refer to Section E

Pilot bearing worn or damaged Replace H-15, 18

Worn pivot points of release fork Repair or replace H-15

^^. .^. I~, ^r

H-3

Page 656 of 1164

ENGINE SPEED SENSING POWER STEERING

i

93GONX-02t

93GONX-02 ‘8

93GONX-029

I I

93GONX-030

N-32

Disassembly note

Oil pipe

Caution

l After disconnecting the pipes, use a plug or adhe-

sive type tape to seal each port to prevent the en-

try of foreign materials.

Tie rod

1. Use the SST to remove the tie rod.

Caution

l To avoid scratching the rack, secure the rack in a

vise protected with brass pads or cloth.

Locknut

1, Use the SST to remove the locknut.

Housing cover

1. Use a drill @1.5mm (0.06 in)) to make a recessed area (ap-

prox. 1.5mm (0.06 in)) at the punch-crimped part of the

threaded part.

Caution

l if the drill diameter and/or the depth of the recess

are excessive, the threads will be too loose when

the plug is reused.

Plug

1. Use the SST to remove the plug.