brake MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 165 of 1164

REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

J”“DC-” I I

1. Fuel hose

3. Brake vacuum hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

4. Vacuum hose (Purge control)

2. Heater hose

Removal Note . . . . . . . . . . . . . , . . . . . . . . . . . .

05UOBX-078

0311082-052

. . . . .

below 5. Vacuum hose (Cruise control)

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

82-33

Page 173 of 1164

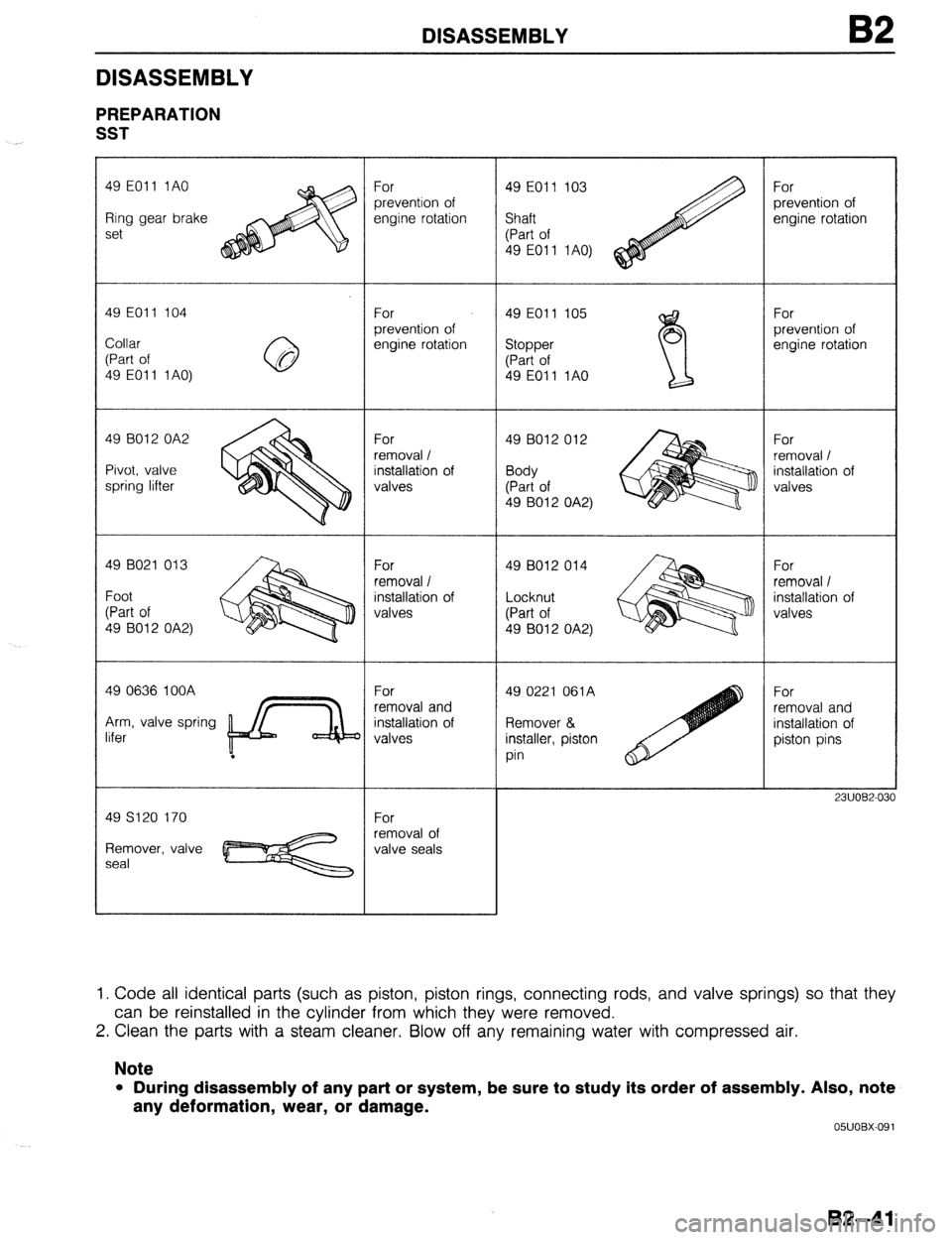

DISASSEMBLY B2

DISASSEMBLY

PREPARATION

SST

._

49 EOll 1AO

Ring gear brake

set

49 EOll 104

Collar

(Part of

49 EOI 1 1 AO)

49 8012 OA2

Pivot, valve

spring lifter

49 B021 013

Foot

(Part of

49 B012 OA2)

49 0636 IOOA

Arm, valve spring

lifer

.

Remover, valve

seal For

prevention of

engine rotation

For

prevention of

engine rotation

For

removal /

installation of

valves

For

removal /

installation of

valves

For

removal and

installation of

valves

For

removal of

valve seals 49 EOll 103

Shaft

(Part of

49 EOll 1AO)

49 EOll 105 49 EOll 105

Stopper Stopper 0

(Part of (Part of

49 E011 1AO 49 E011 1AO

w

49 B012 012

Body

(Part of

49 8012 OA2)

49 8012 014

Locknut

(Part of

49 8012 OA2)

49 0221 061A

Remover &

installer, piston

pin For

prevention of

engine rotation

For

prevention of

engine rotation

For

removal /

installation of

valves

For

removal /

installation of

valves

For

removal and

installation of

piston pins

2311082.03

1. Code all identical parts (such as piston, piston rings, connecting rods, and valve springs) so that they

can be reinstalled in the cylinder from which they were removed.

2. Clean the parts with a steam cleaner. Blow off any remaining water with compressed air.

Note

l During disassembly of any part or system, be sure to study its order of assembly. Also, note

any deformation, wear, or damage.

05UOBX-091

B2-41

Page 198 of 1164

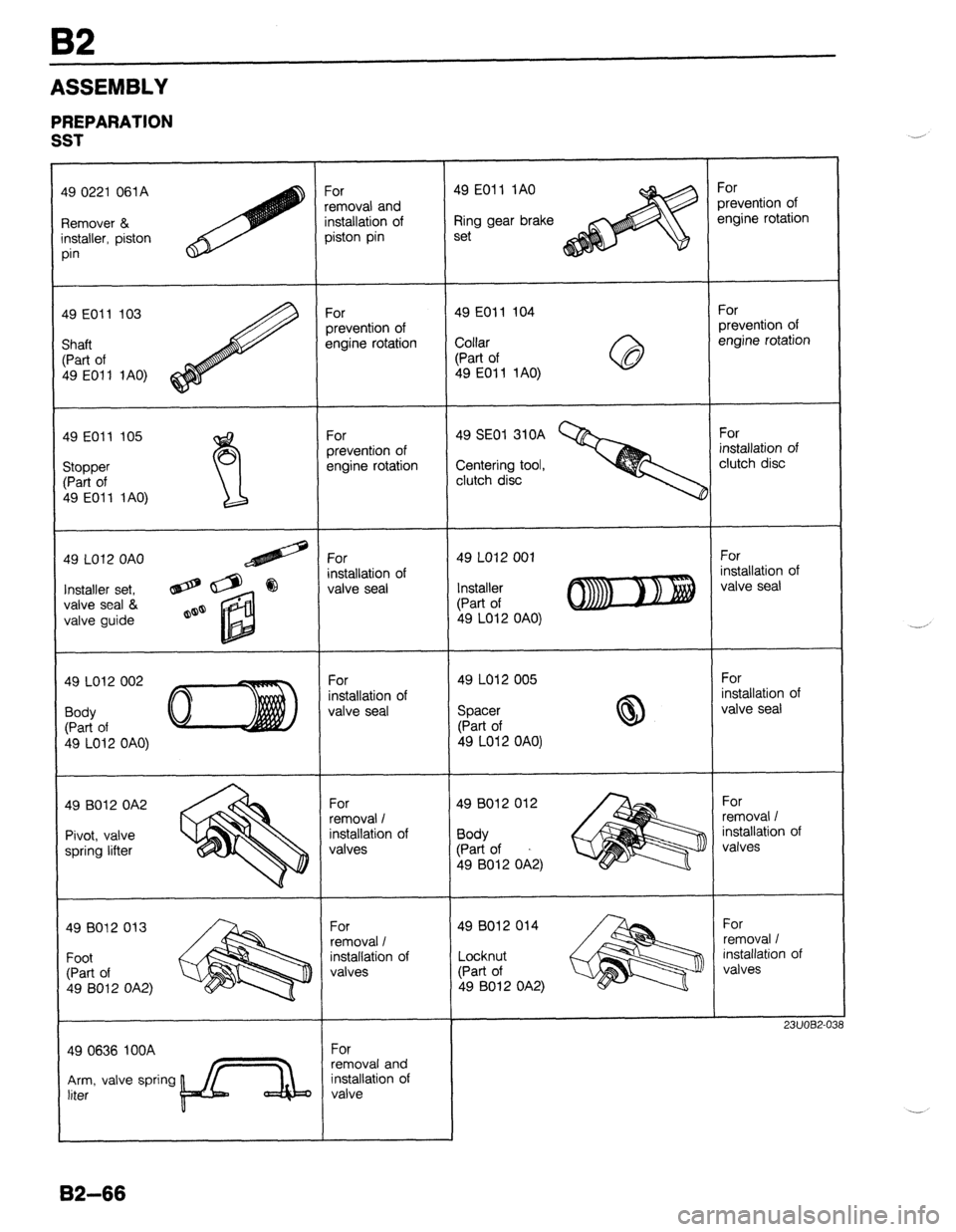

B2

ASSEMBLY

PREPARATION

SST

For

xevention of

sngine rotation For

removal and

installation of

piston pin 49 EOII IA0

Ring gear brake

set 49 0221 061A

Remover &

installer, piston

pin

For

prevention of

engine rotation For

prevention of

engine rotation 49 EOll 104

Collar

(Part of

49 EOl 1 1 AO) 49 E011 103

Shaft

(Part of

49 E011 iA0)

For

installation of

clutch disc For

prevention of

engine rotation 49 EOll 105 49 EOll 105

49 SE01 310A

Centering tool,

clutch disc Stopper Stopper

(Part of (Part of

49 EOI 1 1 AO) 49 EOI 1 1 AO)

49 LO12 OAO

For

nstallation of

valve seal For

installation of

valve seal 49 LO12 001

Installer set, @@ @

valve seal &

valve guide a@ Installer

(Part of

49 LO12 OAO)

49 LO12 005

Spacer

(Part of

49 LO12 OAO) For

installation of

valve seal For

installation of

valve seal 49 LO12 002

Body

(Part of

b9 LO12 OAO)

For

removal I

installation of

valves 49 B012 012

Body

(Part of

49 9012 OA2) For

removal /

installation of

valves 49 8012 OA2

Pivot, valve

spring lifter

For

removal I

‘nstallation of

valves For

removal I

installation of

valves 49 B012 014

-ocknut

:Part of

49 B012 OA2) 49 8012 013

Foot

(Part of

49 8012 OA2)

23UOEi2-0:

For

removal and

installation of

valve 49 0636 IOOA

Arm, valve spring

liter

82-66

Page 231 of 1164

INSTALLATION

Step 4

I. Connect the hoses shown in the figure.

Caution Speedometer cable

1. Install the speedometer cable.

Exhaust pipe

1. Install the exhaust pipe and a gasket; then loosely tighten

the lock nuts.

2. Loosely tighten the bracket bolts.

3. Tighten the lock nuts.

Tightening torque:

31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

4. Tighten the bracket bolts.

Tightening torque:

37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

VACUUM HOSE

(CRUISE CONTROL) BRAKE, VACUUM HOSE 1 VACUUM HOSE

(PURGE CONTROL)

HEATER HOSE

FUE’L HOSE

03UOB2-14

B2-9:

Page 281 of 1164

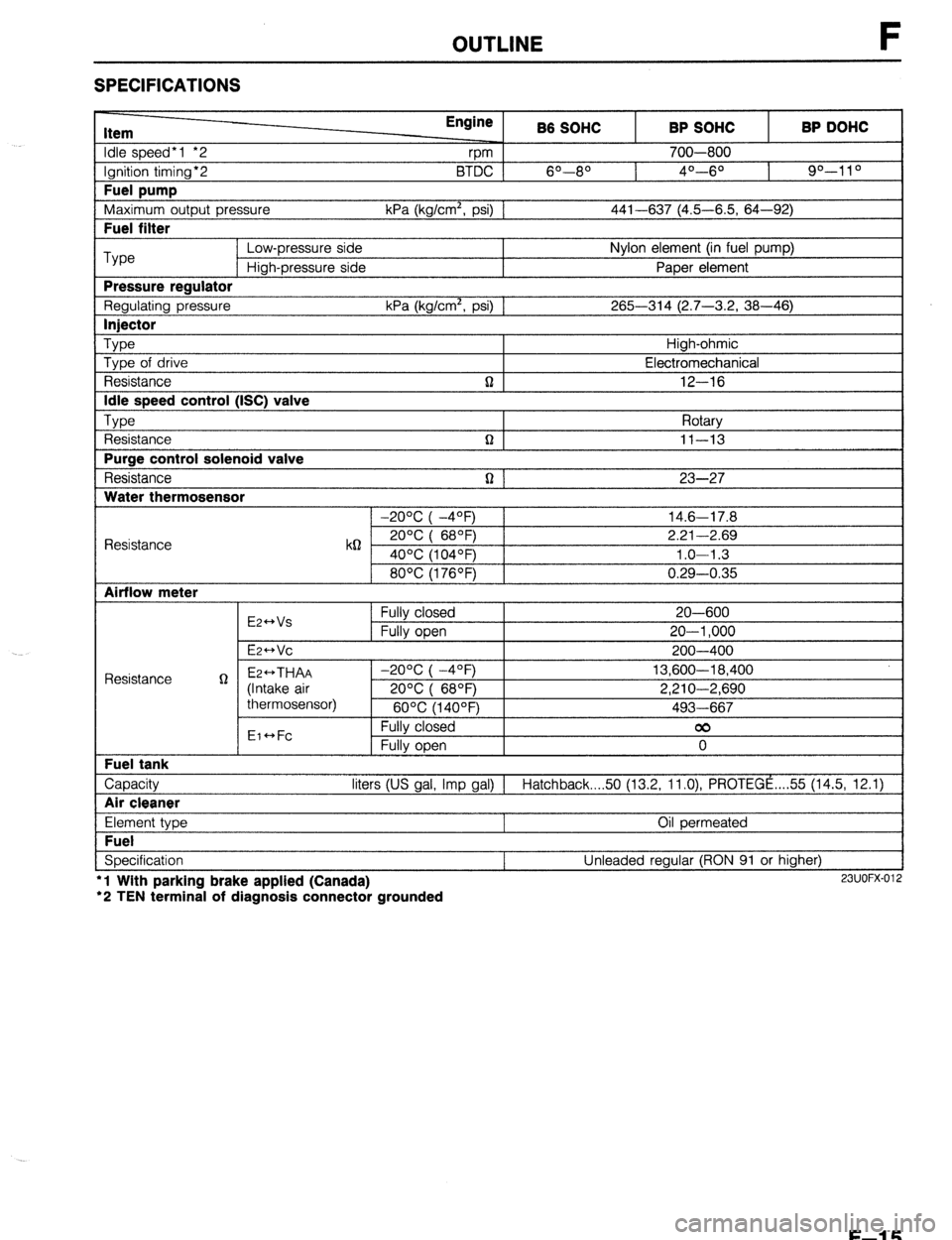

OUTLINE F

SPECIFICATIONS

Item

Idle speed*1 *2

Ignition timing*2

Fuel pump

Maximum outout Dressure Engine

rpm B6 SOHC

6O--80 BTDC 1

kPa (ka/cm’. osi1 1 BP SOHC

700-800

4O---6O BP DOHC

90-l 1 O

441-637 (4.5-6.5. 64-92) I

I Fuel filter I

Type Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element

Pressure reaulator

Regulating pressure kPa (kg/cm’, psi) 1 265-314 (2.7-3.2, 38-46)

I lniector I

Type Type of drive

Resistance

Idle speed control (ISC) valve

TvDe , ,

t Resistance

Purge control solenoid valve

Resistance

Water thermosensor n High-ohmic

Electromechanical

12-16

Rotarv

n I II-13 I

n 1 23-27

1 -20% I -4OFj 1 14.6-17.8

Resistance k62 2ooc i 68OF) 2.21-2.69

40°C (104OF) 1.0-l .3

80°C (176OF) 0.29-0.35

Airflow meter

E2++Vs

E2-Vc Fully closed

Fully open 20-600

20-l ,000

200-400

Capacity liters (US gal, Imp gal) 1 Hatchback 50 (13.2, ll.O), PROTEGE ,... 55 (14.5, 12.1)

I Air cleaner I

Element type

Fuel

Specification l

l Wlth parking brake applied (Canada)

‘2 TEN terminal of diagnosis connector grounded Oil permeated

Unleaded regular (RON 91 or higher) 23UOFX-012

F-l 5

Page 315 of 1164

TROUBLESHOOTING GUIDE F

12 ROUGH IDLE/ENGINE STALLS JUST AFTER STARTING

DESCRIP-

*Engine starts normally but vibrates excessively or stalls just after starting (acceleration from idle) TION

*Idle conditions are normal in the other conditions [TROUBLESHOOTING HINTS]

@ Fuel injection control system or idle speed control sys-

@ Idle speed misadjustment

tern malfunction @ Ignition timing misadjustment

*Start signal not input to ECU iTEl

-s-- 3

4

5 INSPECTION

-T- ACTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM,SELECT: I

r -SELECT SW: A

Check if ECU terminal voltages are OK

MTX...Especially 1 N

ATX... Especially 1T w page F-150

Connect System Selector to diagnosis connector

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up w page F-78

Ignition timing (BTDC)

l BP DOHC : 9”-11 o l BP SOHC : 4O--6O

l B8 : 60-80

Check continuity between throttle sensor termi-

nals IDL and E CT page F-159

MTX

Clearance between throttle

lever and stopper

MTX O.lmm (0.004 in)

1 .Omm (0.039 in)

ATX 0.1 mm (0.004 in)

0.6mm (0.024 in) Continuity

Yes

No

Yes

No

Try known good ECU and check if condition

mproves w page F-149 Yes

No

Yes

Go to next step No

Check for cause Yes

In same condition as Step 3 inspection

and apply parking brake

Check for correct idle speed w page F-80

Idle speed: 700-800 rpm

No

Adjust Yes

Go to next step No

Adjust Go to next step Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

d If OK, replace ECU w page F-149

* If not OK, check wiring between

ECU and Self-Diagnosis Checker c7 page F-151

3 If OK, go to next step

3 If not OK, adjust idle speed w page F-80

w page F-79

w page F-159

F-49

Page 327 of 1164

![MAZDA PROTEGE 1992 Owners Manual TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS] MAZDA PROTEGE 1992 Owners Manual TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS]](/img/28/57077/w960_57077-326.png)

TROUBLESHOOTING GUIDE F

9 LACK OF POWER

_-- --

L L -

ESCRIP- *Performance poor under load when throttle valve wide open

ION *Reduced maximum speed

* Idle condition normal

VtOUBLESHOOTlNG HINTS]

) Factors other than engine malfunction

*Clutch slipping

* ATX slipping

l Brake dragging l Low tire pressure

l Incorrect We size l Overloaded

‘, Low intake air amount @ Air/Fuel mixture too lean

l Fuel line pressure decreases l Fuel injection malfunction

@ Poor ignition

@ Low engine compression

@ Alcohol blended fuel used

l Throttle valve not open fully

*Clogged intake air system

l Low tire pressure CY Section H

CY Section K

cz7 Section P

c7 Section Q

w page F-l 14

CT= page F-l 12

Checker with ignition switch ON

w page F-83

rminal 1F voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU w page F-149

c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

Ignition timing (BTDC)

l BP DOHC : 9*-l lo l BP SOHC

: 4O-8O 4 If advances, go to next step

* If not advance, check ECU terminal

w page F-150

F-61

Page 331 of 1164

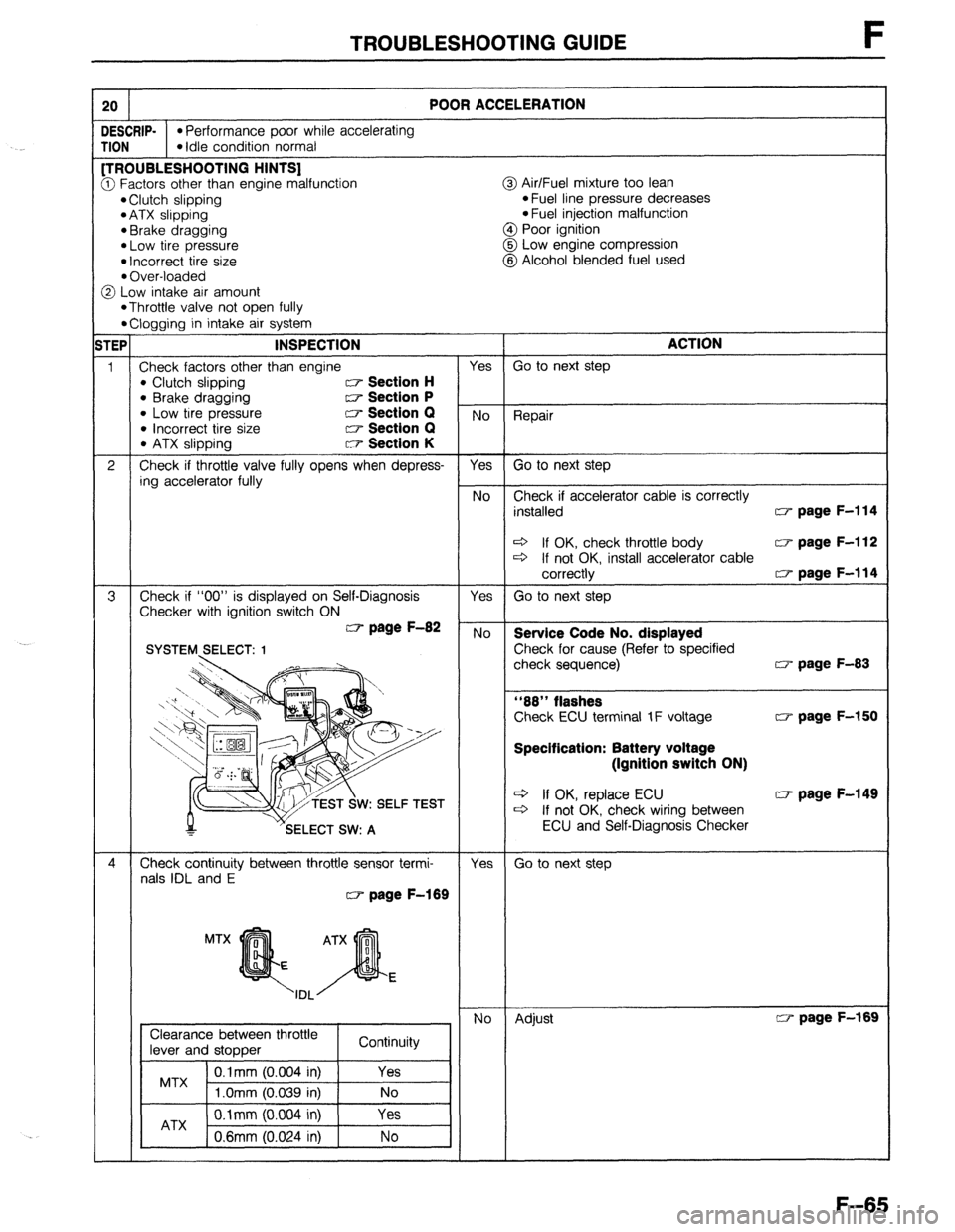

TROUBLESHOOTING GUIDE F

20 POOR ACCELERATION

DESCRIP- l Performance poor while accelerating

TION l idle condition normal [TROUBLESHOOTING HINTS)

3 Factors other than engine malfunction @ Air/Fuel mixture too lean

*Clutch slipping l Fuel line pressure decreases l ATX slipping l Fuel injection malfunction

l Brake dragging @ Poor ignition l Low tire pressure

@ Low engine compression

l Incorrect tire size @ Alcohol blended fuel used l Over-loaded

3 Low intake arr amount

*Throttle valve not open fully

*Clogging in intake air system

Check factors other than engine CT Section H

c7 Section

P

ing accelerator fully w page F-l 14

w page F-l 12

Checker with ignition switch ON w page F-83

rminal 1 F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST c3 If OK, replace ECU w page F-149 r;3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

Clearance between throttle

lever and stopper

0.1 mm (0.004 in)

l.Omm (0.039 in)

O.lmm (0.004 in)

0.6mm (0.024 in)

Page 341 of 1164

![MAZDA PROTEGE 1992 Owners Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati MAZDA PROTEGE 1992 Owners Manual TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operati](/img/28/57077/w960_57077-340.png)

TROUBLESHOOTING GUIDE F

26 POOR FUEL ECONOMY

DESCRIP-

l Fuel economy unsatisfactory TION

[TROUBLESHOOTING HINTS]

While fuel consumption is drastically increased by city driving, short-run operation, stop and go driving, extended winter

warm-up periods, etc., as opposed to “trip” mileage, an attempt should be made to determine these factors when con-

fronted with “poor mileage” conditions. However, since the operator is not always at fault, the following is offered.

@II Operator depressing accelerator more than usual due to

@ Air/Fuel mixture too rich

low engine power

l Poor ignition *High fuel line pressure

@ Alcohol blended fuel used

*Low intake air amount

l Electronic spark advance control system malfunction @ High vehicle load l Low tire pressure

*Clutch slipping/ATX slipping l Incorrect tire size l Exhaust component restricted l Brake dragging ;TEP

INSPECTION ACTION

1

Check factors other than engine Yes

Go to next step

l Low tire pressure = Section Q 9 Unrecommended tire srze v Section Q l Clutch slipping w Section H l Brake dragging No

0 Section P Repair

l Exhaust component restricted cz= page F-136

2

Check if air hoses are connected correctly - Yes

Go to next step CI page F-109

No

Repair 3

Check if “00” IS displayed on Self-Diagnosis

Yes

Checker with ignition switch ON Go to next step W page F-82 No

SYSTEM SELECT: 1 Service Code No. displayed Check for cause (Refer to specified

check sequence) w page F-63

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU CT= page F-149 e If not OK, check wiring between

ECU and Self-Diagnosis Checker 4

Check for correct intake manifold vacuum at idle

Yes Go to next step Vacuum: More than 450 mmHg (17.7 inHg) No

Check for air leakage at intake air sys-

tem components 5

Check if air cleaner element is clean Yes

Go to next step CT= page F-79

No

Replace air cleaner element

F-75

Page 346 of 1164

F ENGINE TUNE-UP

23UOFX-046 Note

l When the parking brake is not applied, the idle

speed for ATX model (Canada) is approx. 800 rpm. Idle Speed

1. Perform “Preparation”. (Refer to page F-79.)

2. Apply parking brake.

3. Check that the idle speed is within specification.

Idle speed (Neutral or P range): 700-800 rpm

Caution

l Check the idle speed without the electric cooling

fan operating.

4. If not within the specification, adjust the idle by turning the

air adjusting screw.

5. Disconnect the SST.

F-80