service MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 259 of 1164

WATER PUMP WATER PUMP

E

REMOVAL / INSTALLATION

Caution

l Do not disassemble the water pump. If a problem is found, replace the pump as a Unit.

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal.

B6 SOHC AND BP SOHC

83, t B6, BP SOHC

I

I

L-----------------_-- ------- -1

/ \/

19-26 (1.9-2.6, 14-19) LVVVLI. YY,

1. Timing belt 4. Water pump assembly

Service ., . . .., ,, ., . . . . . ,. ,.,. ., ,., . . ,,.... . . . . , Section Bl Inspect for cracks, damaged mounting

2. Water inlet pipe

and gasket surface, bearing condition, and leakage

3. Water bypass pipe and O-ring 5. Water pump gasket

E-l 1

Page 260 of 1164

BP DOHC

L 7.8-11 N-m (60-110 cm-kg, 69-95 in-lb)

E WATER PUMP

157-167

I

(W-17, 116-123) I

I

/

I

I

I

---N-w------

---------------

----_---_

-I

N.m (m-kg, ft-lb) 1

^^, *--., ^^^

1. Timing belt

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5. Water pump assembly

B2

2. Water inlet pipe and gasket Inspect for cracks, damaged mounting

3. Water bypass pipe and O-ring surface, bearing condition, and leakage

4. Oil dip stick pipe bracket 6. Water pump gasket

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to page E-6.)

2. Connect the negative battery cable,

3. Start the engine and check for leaks.

03UOEX-018

E-12

Page 268 of 1164

F INDEX

DlSTRhUTOR

SERVICE, SECTION G INHIBITOR SWITCH (ATX)

SERVICE, SECTION K

F-2

Page 282 of 1164

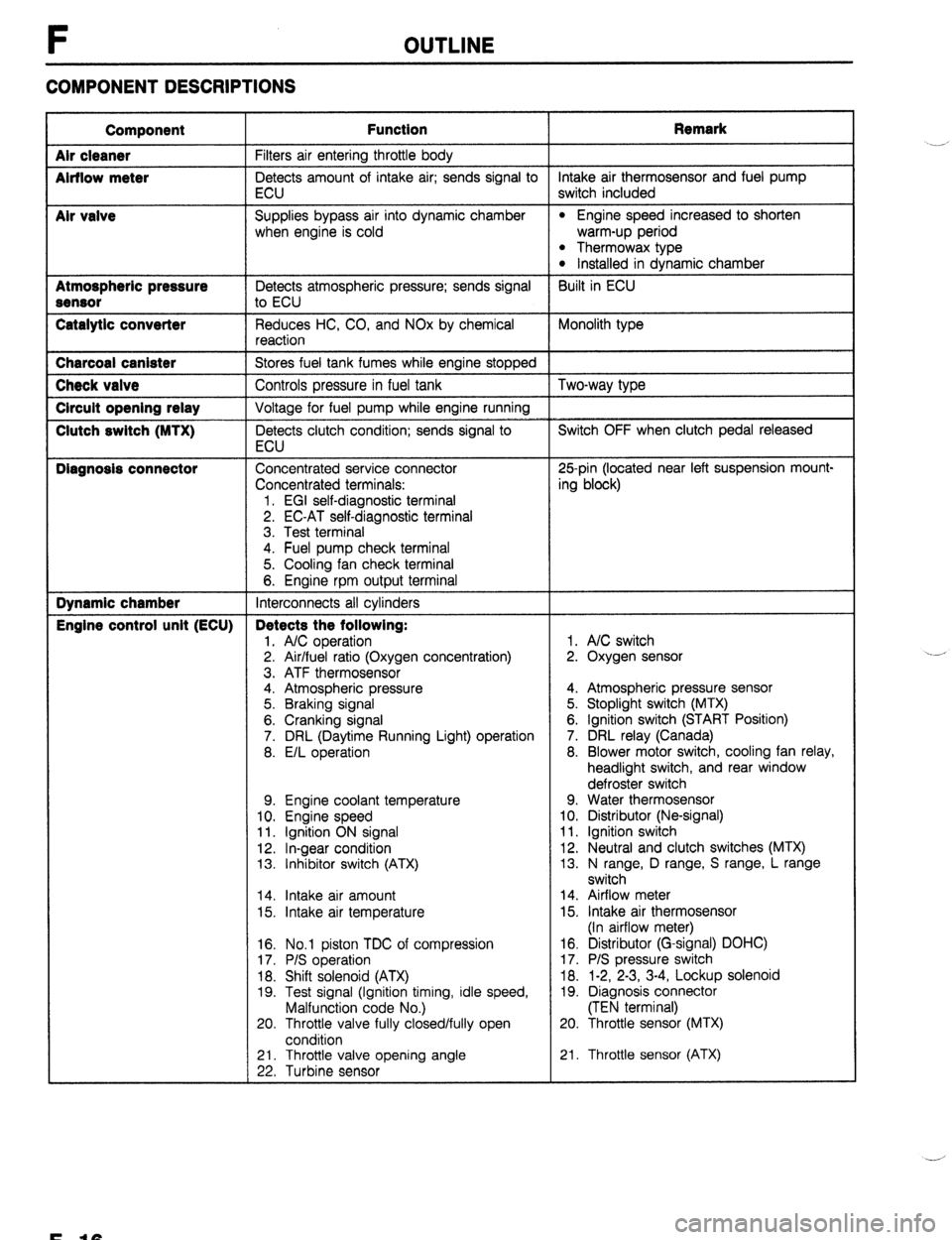

F OUTLINE

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 296 of 1164

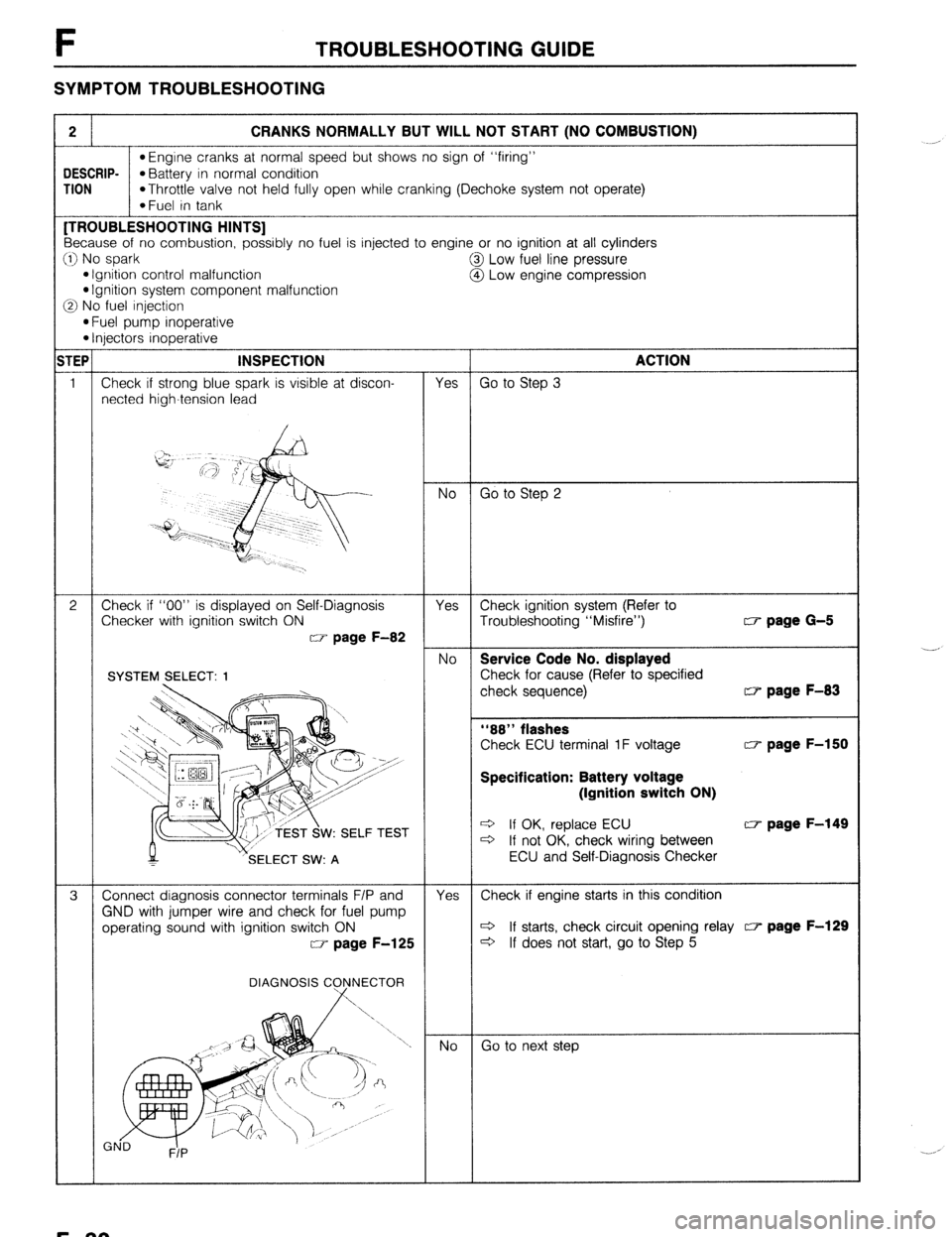

F TROUBLESHOOTING GUIDE

SYMPTOM TROUBLESHOOTING

2 CRANKS NORMALLY BUT WILL NOT START (NO COMBUSTION)

l Engine cranks at normal speed but shows no sign of “firing”

DESCRIP-

*Battery in normal condition

TION

*Throttle valve not held fully open while cranking (Dechoke system not operate)

*Fuel in tank [TROUBLESHOOTING HINTS]

Because of no combustion, possibly no fuel is injected to engine or no ignition at all cylinders

:I) No spark

@I Low fuel line pressure

l Ignition control malfunction

@ Low engine compression l Ignition system component malfunction

3 No fuel injection

l Fuel pump inoperative l Injectors inoperative

TEP INSPECTION

ACTION

1 Check if strong blue spark is visible at discon-

Yes Go to Step 3

netted high-tension lead

No Go to Step 2

2 Check if “00” is displayed on Self-Diagnosis

Yes Check ignition system (Refer to

Checker with ignition switch ON

Troubleshooting “Misfire”) w page G-5

w page F-82

No Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST e If OK, replace ECU w page F-149 c3 If not OK, check wiring between

SELECT SW: A ECU and Self-Diagnosis Checker

3 Connect diagnosis connector terminals F/P and

Yes Check if engine starts in this condition

GND with jumper wire and check for fuel pump

operating sound with ignition switch ON c3 If starts, check circuit opening relay c7 page F-129

w page F-125

c3 If does not start, go to Step 5

DIAGNOSIS C

Go to next step ._-,

._. ,

F-30

Page 302 of 1164

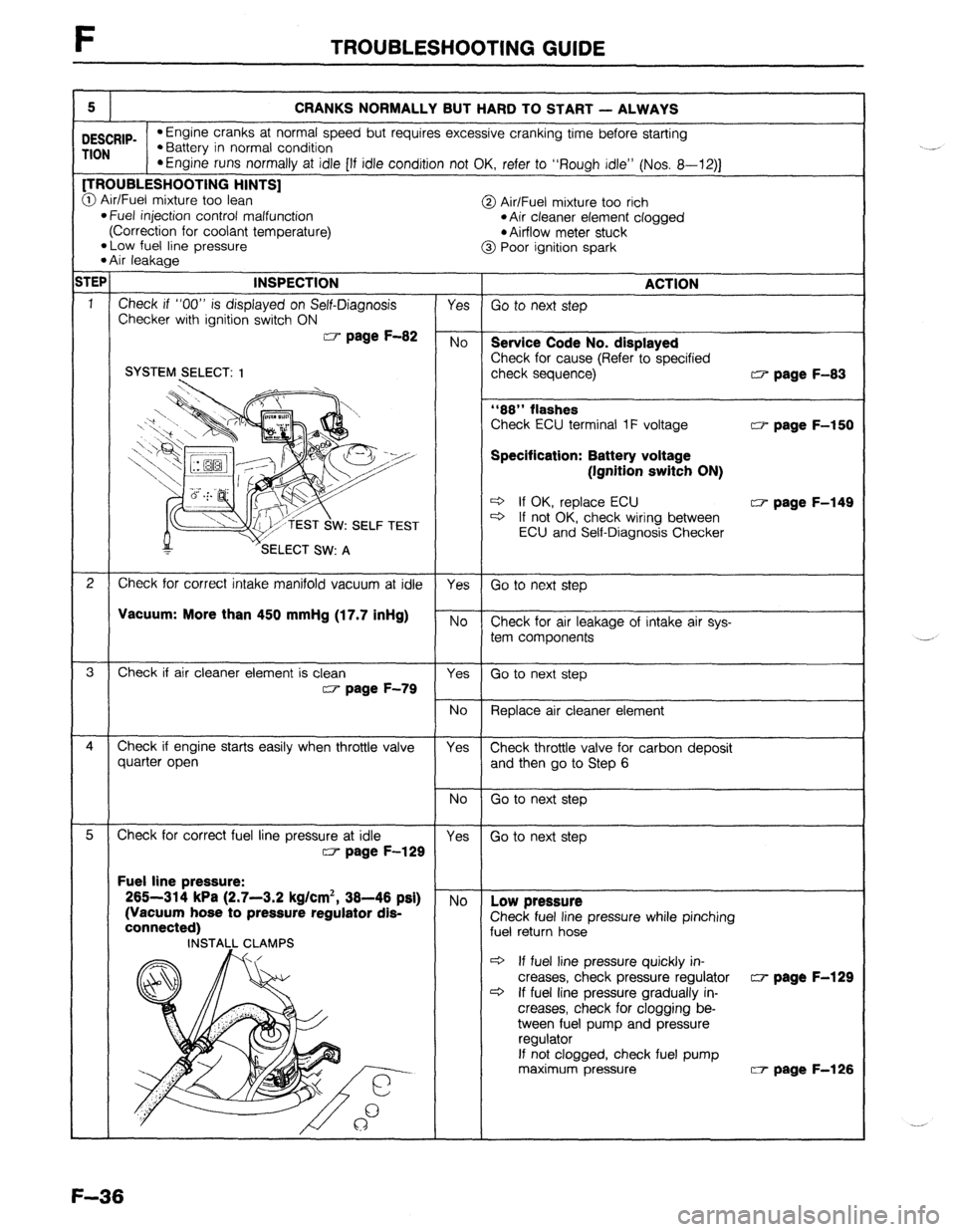

F TROUBLESHOOTING GUIDE

5

CRANKS NORMALLY BUT HARD TO START - ALWAYS

DESCRIP- l Engine cranks at normal speed but requires excessive cranking time before starting

TION l Battery in normal condition

*Engine runs normally at idle [If idle condition not OK, refer to “Rough idle” (Nos. 8-12)J [TROUBLESHOOTING HINTS]

@ Air/Fuel mixture too lean

@ Air/Fuel mixture too rich l Fuel injection control malfunction

(Correction for coolant temperature) *Air cleaner element clogged

l Airflow meter stuck

*Low fuel line pressure

l Air leakage @ Poor ignition spark

;TEP INSPECTION ACTION

1

Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with ignition switch ON W page F-82 No

Service Code No. displayed

Check for cause (Refer to specified SYSTEM SELECT: 1 check sequence) w page F-83

“88” flashes

Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignitlon switch ON)

* If OK, replace ECU w page F-149

W: SELF TEST c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

2 Check for correct intake manifold vacuum at idle

Yes Go to next step

VsCUUm: More than 450 mmHg (17.7 inHg) No Check for air leakage of intake air sys-

tem components

3 Check if air cleaner element is clean

Yes Go to next step w page F-79

No

Replace air cleaner element

4 Check if engine starts easily when throttle valve Yes Check throttle valve for carbon deposit

quarter open and then go to Step 6 Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm*, 38-46 psi)

(Vacuum hose to pressure regulator dis-

pressure while pinching

c3 If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

c3 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and pressure

If not clogged, check fuel pump

maximum pressure W- page F-126

F-36

Page 308 of 1164

![MAZDA PROTEGE 1992 Owners Manual F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D MAZDA PROTEGE 1992 Owners Manual F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D](/img/28/57077/w960_57077-307.png)

F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D Air/Fuel mixture too lean @ Incorrect idle speed

l Air leakage l Idle speed misadjustment l Fuel injection control malfunction l Idle speed control malfunction

*Low fuel line pressure @ One or more spark plugs not firing

3 One or more injectors clogged or not operating @ Low engine compression

3 Low intake air amount @ Airflow meter stuck INSPECTION

1

1

2

3

4

5

6

- Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM2ELECT: 1

M v’SELECT SW: A TEST

Check if ECU terminal voltages are OK

MTX...Especially 2D, 20 and 2Q

ATX... Especially 2B, 2E and 3D CT page F-150

Disconnect high-tension lead at idle and check if

engine speed decreases equally at each cylinder

Check for injector operating sound at idle

Check if battery voltage exists at injector connec-

tor (W/R) wire

Check if strong blue spark is visible at discon-

nected high-tension lead

, Yes No Service Code No. displayed

Check for cause (Refer to specified

:heck sequence) “88” flashes

Check ECU terminal IF voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

3 If OK, replace ECU w page F-149 3 If not OK, check wiring between

ECU and Self-Diaanosis Checker Yes

Go to next step No

Check for cause Yes

Go to Step 8 No

Go to next step

Go to Step 6

Go to Step 5 Yes

No

Yes

No

Yes

No I-

30 to next step w page F-83

0 page F-151

Check if injector resistance is OK c7 page F-131

Resistance: Approx. 12-l 852

c3 If OK, check wiring between ECU

and injector

c3 If not OK, replace injector w page F-131

Check wiring between ECU and injector

Go to next step

Check high-tension lead w page G-17

Q If OK, check distributor cap and

rotor w page G-22

c3 If not OK, replace high-tension lead

F-42

Page 314 of 1164

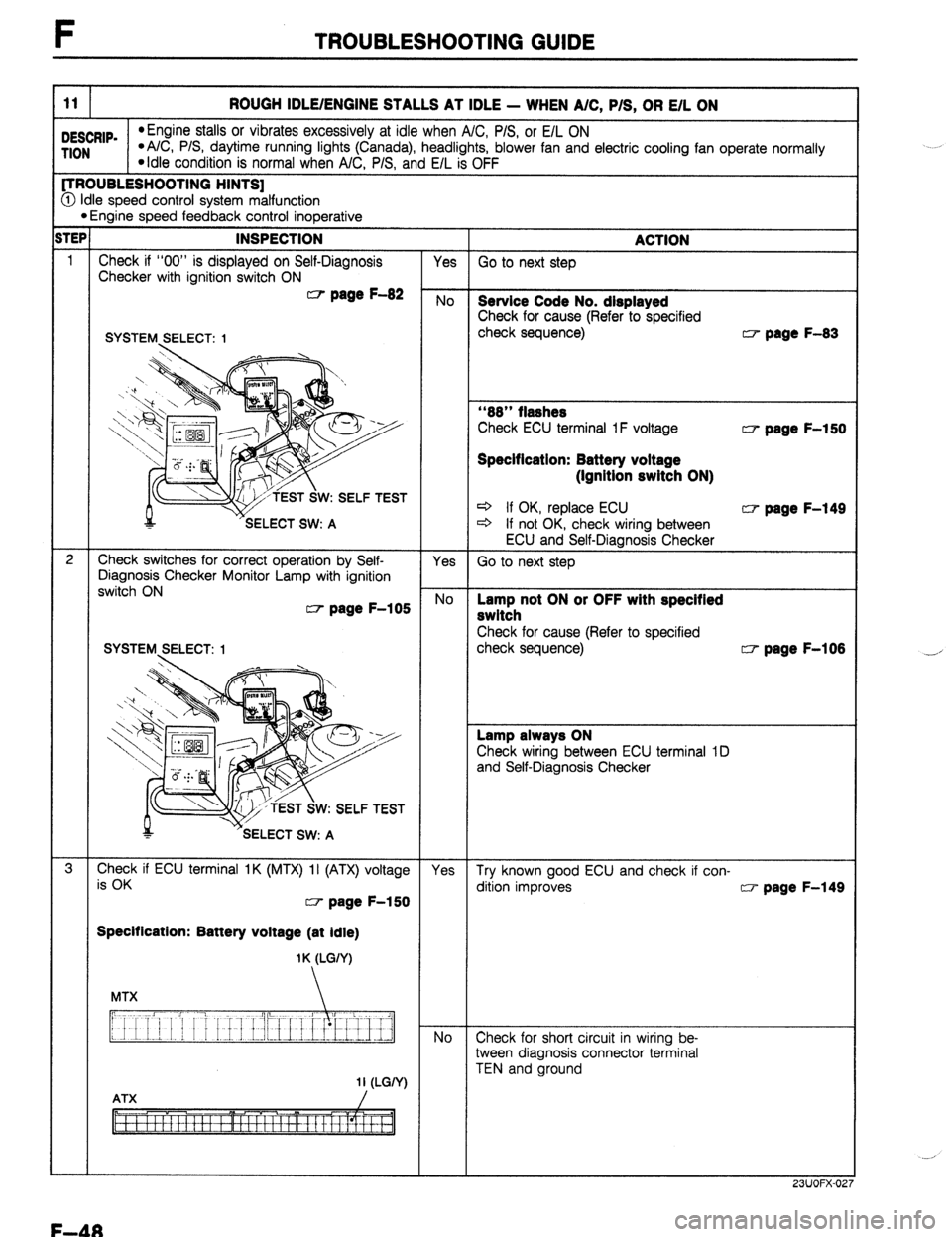

F TROUBLESHOOTING GUIDE

11 ROUGH IDLE/ENGINE STALLS AT IDLE - WHEN A/C, P/S, OR E/L ON

DESCRIP.

*Engine stalls or vibrates excessively at idle when A/C, P/S, or E/L ON TION *A/C, P/S, daytime running lights (Canada), headlights, blower fan and electric cooling fan operate normally

*Idle condition is normal when A/C, P/S, and E/L is OFF (TROUBLESHOOTING HINTS]

@ Idle speed control system malfunction l Engine speed feedback control inoperative ;TEP INSPECTION

ACTION

1

Check if “00” is displayed on Self-Diagnosis Yes

Checker with ignition switch ON Go to next step W page F-82 No

Service Code No. displayed

Check for cause (Refer to specified

SYSTEM SELECT: 1 check sequence) w page F-83

“88” flashes

W:SELFTEST

Check ECU terminal 1 F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

* If OK, replace ECU w page F-149

c3 If not OK, check wiring between

ECU and Self-Diagnosis Checker

2 Check switches for correct operation by Self-

Yes

Diagnosis Checker Monitor Lamp with ignition Go to next step

switch ON CT page F-105

No Lamp not ON or OFF with specltied

switch

Check for cause (Refer to specified

check sequence) w page F-108

Lamp always ON

Check wiring between ECU terminal ID

and Self-Diagnosis Checker

W:SELFTEST

3

EhFKk if ECU terminal IK (MTX) II (ATX) voltage

Yes Try known good ECU and check if con-

dition improves w page F-150 w page F-149

Specification: Battery voltage (at Idle)

1 K (LGIY)

No

Check for short circuit in wiring be-

tween diagnosis connector terminal

TEN and ground

23UOFX-02

-’

F-48

Page 315 of 1164

TROUBLESHOOTING GUIDE F

12 ROUGH IDLE/ENGINE STALLS JUST AFTER STARTING

DESCRIP-

*Engine starts normally but vibrates excessively or stalls just after starting (acceleration from idle) TION

*Idle conditions are normal in the other conditions [TROUBLESHOOTING HINTS]

@ Fuel injection control system or idle speed control sys-

@ Idle speed misadjustment

tern malfunction @ Ignition timing misadjustment

*Start signal not input to ECU iTEl

-s-- 3

4

5 INSPECTION

-T- ACTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM,SELECT: I

r -SELECT SW: A

Check if ECU terminal voltages are OK

MTX...Especially 1 N

ATX... Especially 1T w page F-150

Connect System Selector to diagnosis connector

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up w page F-78

Ignition timing (BTDC)

l BP DOHC : 9”-11 o l BP SOHC : 4O--6O

l B8 : 60-80

Check continuity between throttle sensor termi-

nals IDL and E CT page F-159

MTX

Clearance between throttle

lever and stopper

MTX O.lmm (0.004 in)

1 .Omm (0.039 in)

ATX 0.1 mm (0.004 in)

0.6mm (0.024 in) Continuity

Yes

No

Yes

No

Try known good ECU and check if condition

mproves w page F-149 Yes

No

Yes

Go to next step No

Check for cause Yes

In same condition as Step 3 inspection

and apply parking brake

Check for correct idle speed w page F-80

Idle speed: 700-800 rpm

No

Adjust Yes

Go to next step No

Adjust Go to next step Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

d If OK, replace ECU w page F-149

* If not OK, check wiring between

ECU and Self-Diagnosis Checker c7 page F-151

3 If OK, go to next step

3 If not OK, adjust idle speed w page F-80

w page F-79

w page F-159

F-49

Page 318 of 1164

![MAZDA PROTEGE 1992 Owners Manual F TROUBLESHOOTING GUIDE

14 IDLE MOVES UP AND DOWN/IDLE HUNTING

DESCRIP-

*Engine speeds up and down periodically at idle

TION

[TROUBLESHOOTING HINTS]

@ idle switch (built in throttle sensor) OFF MAZDA PROTEGE 1992 Owners Manual F TROUBLESHOOTING GUIDE

14 IDLE MOVES UP AND DOWN/IDLE HUNTING

DESCRIP-

*Engine speeds up and down periodically at idle

TION

[TROUBLESHOOTING HINTS]

@ idle switch (built in throttle sensor) OFF](/img/28/57077/w960_57077-317.png)

F TROUBLESHOOTING GUIDE

14 IDLE MOVES UP AND DOWN/IDLE HUNTING

DESCRIP-

*Engine speeds up and down periodically at idle

TION

[TROUBLESHOOTING HINTS]

@ idle switch (built in throttle sensor) OFF at idle

@ Air leakage

@ Fuel injection amount inconstant

spoor contact point inside airflow meter

@ Poor ignition

iTEP INSPECTION

1 Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON

CT page F-82

SYSTEM SELECT: 1

ACTION

Yes Go to next step

No

Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

,,;9 Check ECU terminal 1F voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST + If OK, replace ECU KIT page F-149

ELECT SW: A + If not OK, check wiring between

ECU and Self-Diagnosis Checker

2 Check for correct intake manifold vacuum at idle Yes Go to next step

Intake manifold vacuum:

More than 450 mmHg (17.7 inHg)

No Low vacuum

Check for air leakage at intake air

system

3 Check if air cleaner element is clean Yes Go to next step

w page F-79

No Replace air cleaner element

4

Disconnect high-tension lead at idle and check if Yes Go to next step

engine speed decreases equally at each cylinder

No Go to Step 9

5 Check if ECU terminal voltages are OK Yes Go to next step

w page F-150

No Check for cause KII page F-151

6

Connect System Selector to diagnosis connector Yes Go to next step

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up

w page F-79

Ignition timing (BTDC)

l BP DOHC : 9”-11 o l BP SOHC : 4O-8” l B6 : 6O--8O No Adjust ignition timing r-7 page F-79

TEST SWITCH . .

F-52