check oil MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 20 of 1164

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 35 of 1164

ENGINE TUNE-UP PROCEDURE Bl

ENGINE TUNE-UP PROCEDURE

PREPARATION

-.

SST

drive belt tension

m :

I 1 2311081-058

- 03UOBX-20

---

OSUOBX-OC

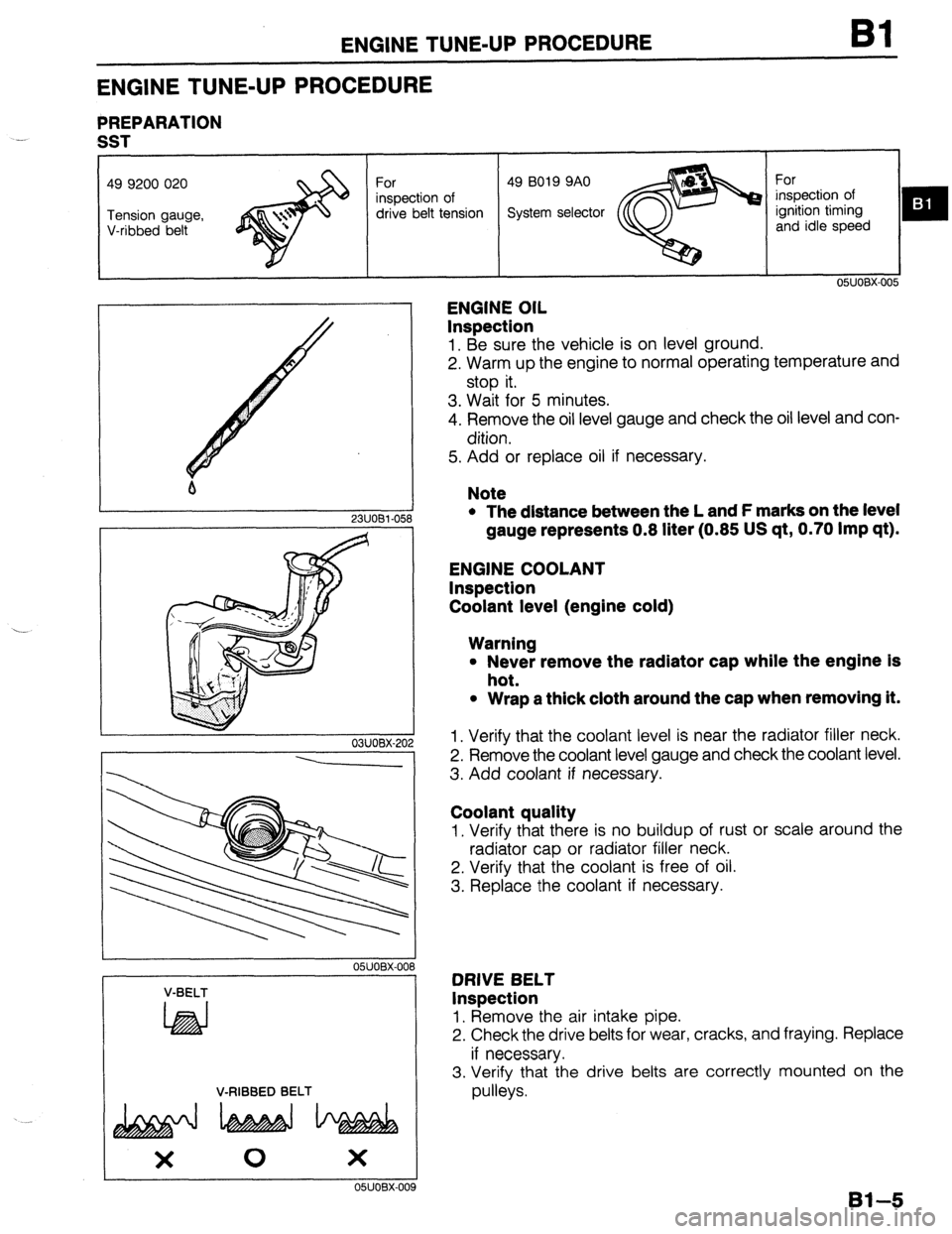

V-BELT

LhEd

V-RIBBED BELT

OSJOBX-00

ENGINE OIL

Inspection

1. Be sure the vehicle is on level ground.

2. Warm up the engine to normal operating temperature and

stop it.

3. Wait for 5 minutes.

4. Remove the oil level gauge and check the oil level and con-

dition.

5. Add or replace oil if necessary.

Note

l The distance between the L and F marks on the level

gauge represents 0.8 liter (0.85 US qt, 0.70 Imp qt).

ENGINE COOLANT

Inspection

Coolant level (engine cold)

Warning

l Never remove the radiator cap while the engine is

hot.

l Wrap a thick cloth around the cap when removing it.

1. Verify that the coolant level is near the radiator filler neck.

2. Remove the coolant level gauge and check the coolant level.

3. Add coolant if necessary.

Coolant quality

1. Verify that there is no buildup of rust or scale around the

radiator cap or radiator filler neck.

2. Verify that the coolant is free of oil.

3. Replace the coolant if necessary.

DRIVE BELT

Inspection

1, Remove the air intake pipe.

2. Check the drive belts for wear, cracks, and fraying. Replace

if necessary.

3. Verify that the drive belts are correctly mounted on the

pulleys.

Bl--5

Page 37 of 1164

ENGINE TUNE-UP PROCEDURE Bl

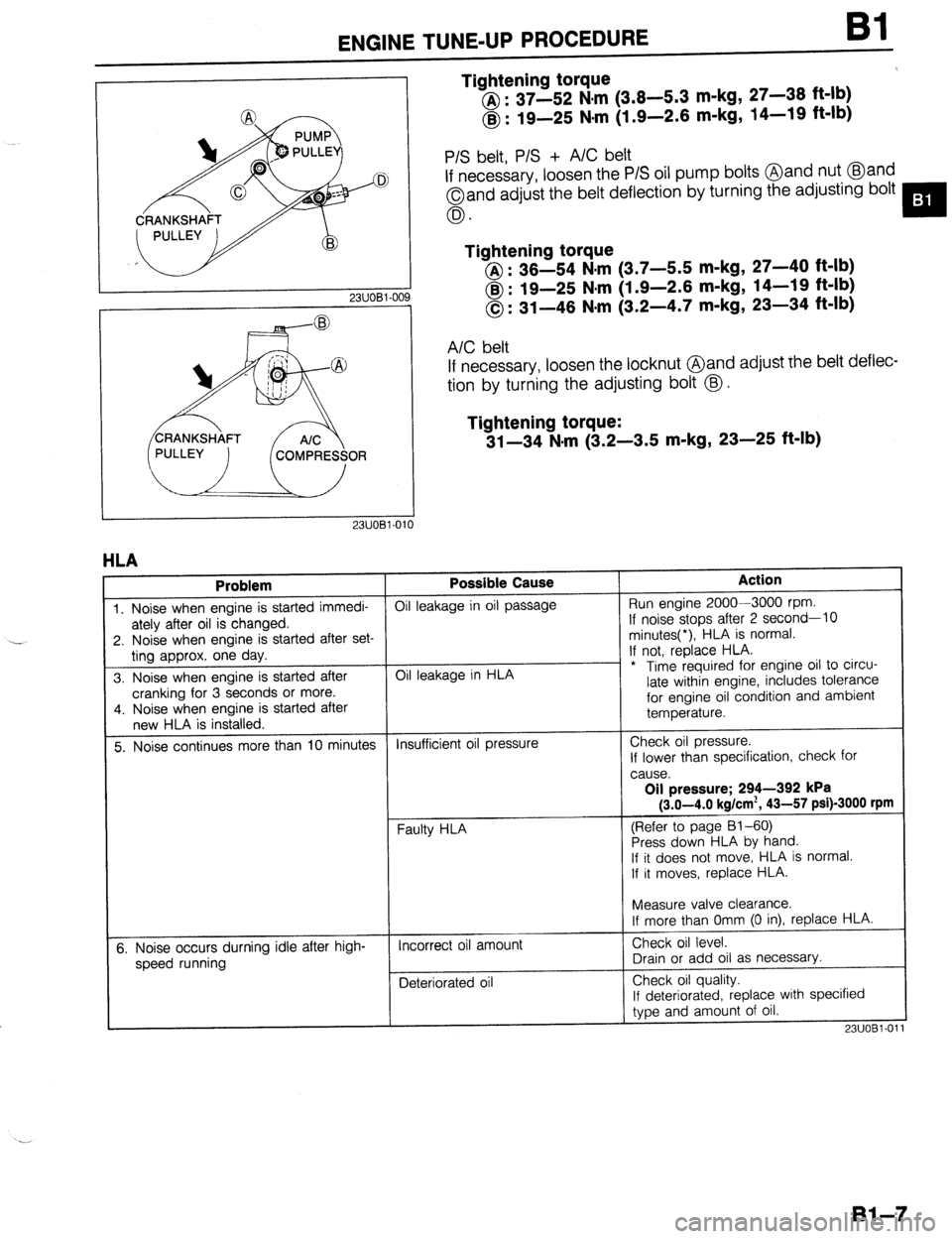

Tightening torque

@ : 37-52 N,m (3.8-5.3 m-kg, 27-38 ft-lb)

@ : 19-25 Nsm (1.9-2.6 m-kg, 14-19 ft-lb)

23UOBl-OC

P/S belt, P/S + A/C belt

If necessary, loosen the P/S oil pump bolts @and nut @and

Oand adjust the belt deflection by turning the adjusting bolt

0.

Tightening torque

@I : 36-54 N.m (3.7-5.5 m-kg, 27-40 ft-lb)

@ : 19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

0: 31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

A/C belt

If necessary, loosen the locknut @and adjust rhe belt deflec-

tion by turning the adjusting bolt @.

Tightening torque:

31-34 N-m (3.2-3.5 m-kg, 23-25 ft-lb)

1

HLA

Problem Possible Cause Action

1. Noise when engine is started immedi- Oil leakage in oil passage Run engine 2000-3000 rpm.

ately after oil is changed. If noise stops after 2 second-10

2. Noise when engine is started after set- minutes(*), HLA is normal.

ting approx. one day. If not, replace HLA.

3. Noise when engine is started after Oil leakage in HLA - * Time required for engine oil to circu-

cranking for 3 seconds or more. late within engine, includes tolerance

4. Noise when engine is started after for engine oil condition and ambient

new HLA is installed. temperature.

5. Noise continues more than 10 minutes Insufficient oil pressure Check oil pressure.

If lower than specification, check for

cause.

Oil pressure; 294-392 kPa

(3.0-4.0 kg/cm*, 43-57 psi)-3000 rpm

(Refer to page 81-60)

Press down HLA by hand.

If it does not move,. HLA is normal.

If it moves, replace HLA.

t

I

Measure valve clearance.

If more than Omm (0 in), replace HLA.

5. Noise occurs durning idle after high-

speed running Incorrect oil amount

Deteriorated oil Check oil level.

Drain or add oil as necessary.

Check oil quality.

If deteriorated, replace with specified

type and amount of oil.

23UOBl-01

Bl-7

Page 40 of 1164

Bl COMPRESSION

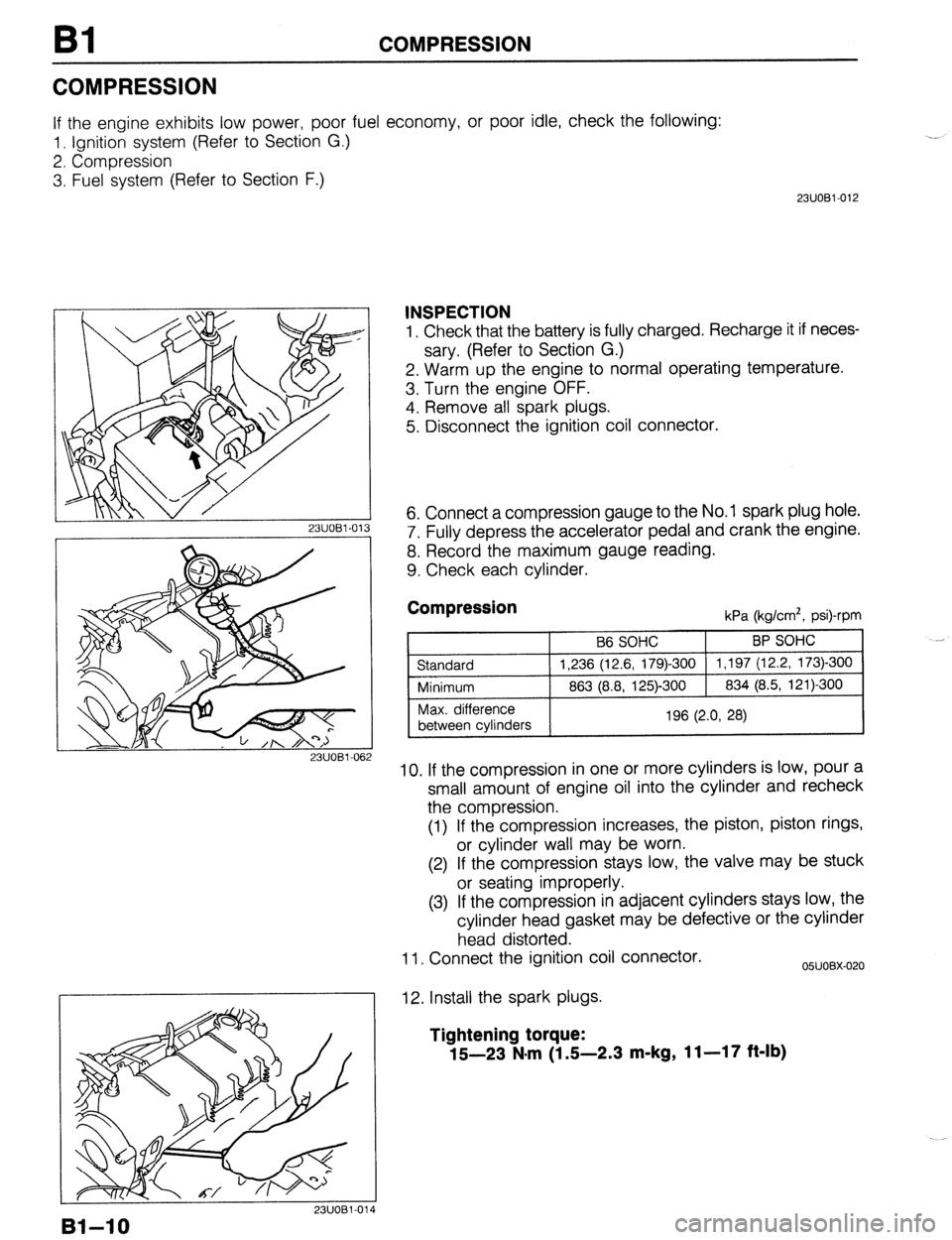

COMPRESSION

If the engine exhibits low power, poor fuel economy, or poor idle, check the following:

1. Ignition system (Refer to Section G.)

2. Compression

3. Fuel system (Refer to Section F.)

23UOBl-01

23UOBl-06

23UOBl-014 23UOBl-012

INSPECTION

1. Check that the battery is fully charged. Recharge it if neces-

sary. (Refer to Section G.)

2. Warm up the engine to normal operating temperature.

3. Turn the engine OFF.

4. Remove all spark plugs.

5. Disconnect the ignition coil connector.

6. Connect a compression gauge to the No. 1 spark plug hole.

7. Fully depress the accelerator pedal and crank the engine.

8. Record the maximum gauge reading.

9. Check each cylinder.

Compression kPa (kg/cm*, psi)-rpm

10. If the compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder and recheck

the compression.

(1) If the compression increases, the piston, piston rings,

or cylinder wall may be worn.

(2) If the compression stays low, the valve may be stuck

or seating improperly.

(3) If the compression in adjacent cylinders stays low, the

cylinder head gasket may be defective or the cylinder

head distorted.

11. Connect the ignition coil connector.

12. Install the spark plugs.

05UOBX-020

Tightening torque:

15-23 N*m (1 S-2.3 m-kg, 11-17 ft-lb)

Bl-10

Page 49 of 1164

.

ON-VEHICLE MAINTENANCE

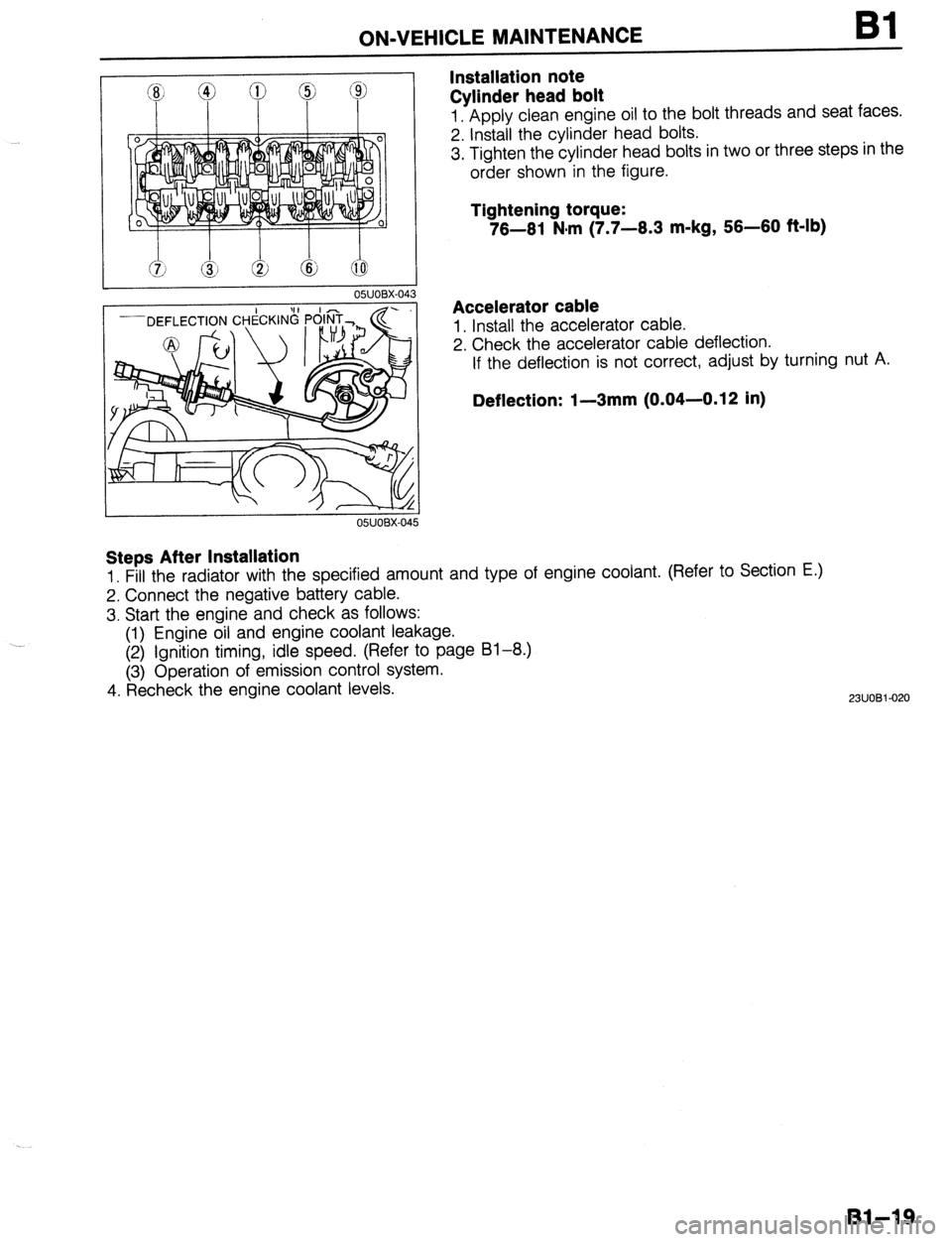

Installation note

Cylinder head bolt Bl

1. Apply clean engine oil to the bolt threads and seat faces.

2. Install the cylinder head bolts.

3. Tighten the cylinder head bolts in two or three steps in the

order shown in the figure.

Tightening torque:

76-61 N#m (7.7-6.3 m-kg, 56-60 f&lb)

Accelerator cable

1. Install the accelerator cable.

2. Check the accelerator cable deflection.

If the deflection is not correct, adjust by turning nut A.

Deflection: I-3mm (0.04-0.12 in)

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to Section E.)

2. Connect the negative battery cable.

3. Start the engine and check as follows:

(1) Engine oil and engine coolant leakage.

(2) Ignition timing, idle speed. (Refer to page 81-8.)

(3) Operation of emission control system.

4. Recheck the engine coolant levels.

2311081-020

Bl-19

Page 54 of 1164

Bl ON-VEHICLE MAINTENANCE

01 EOBX-056

23UOBi -0:

Steps After Installation

1. Lower the vehicle.

2. Connect the negative battery cable.

3. Start the engine and check the ignition timing.

(Refer to page 61-8)

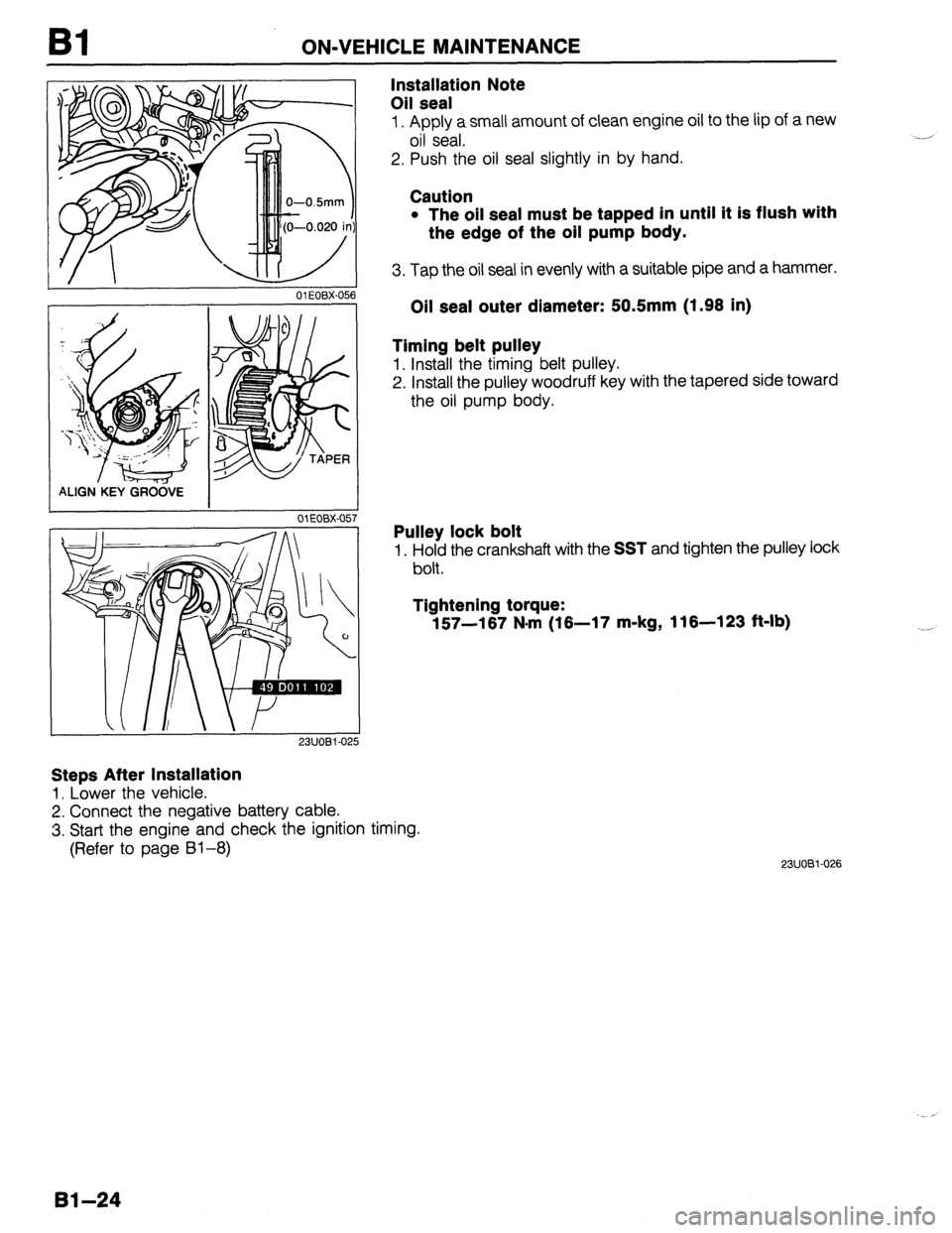

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the oil pump body.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-167 N*rn (16-17 m-kg, 116-123 ft-lb)

23UOBi-026

Bl-24

Page 81 of 1164

DISASSEMBLY Bl

23UOBl-03

05UOBX-1’ 9

23UOBl-040

03UOBl-08 5

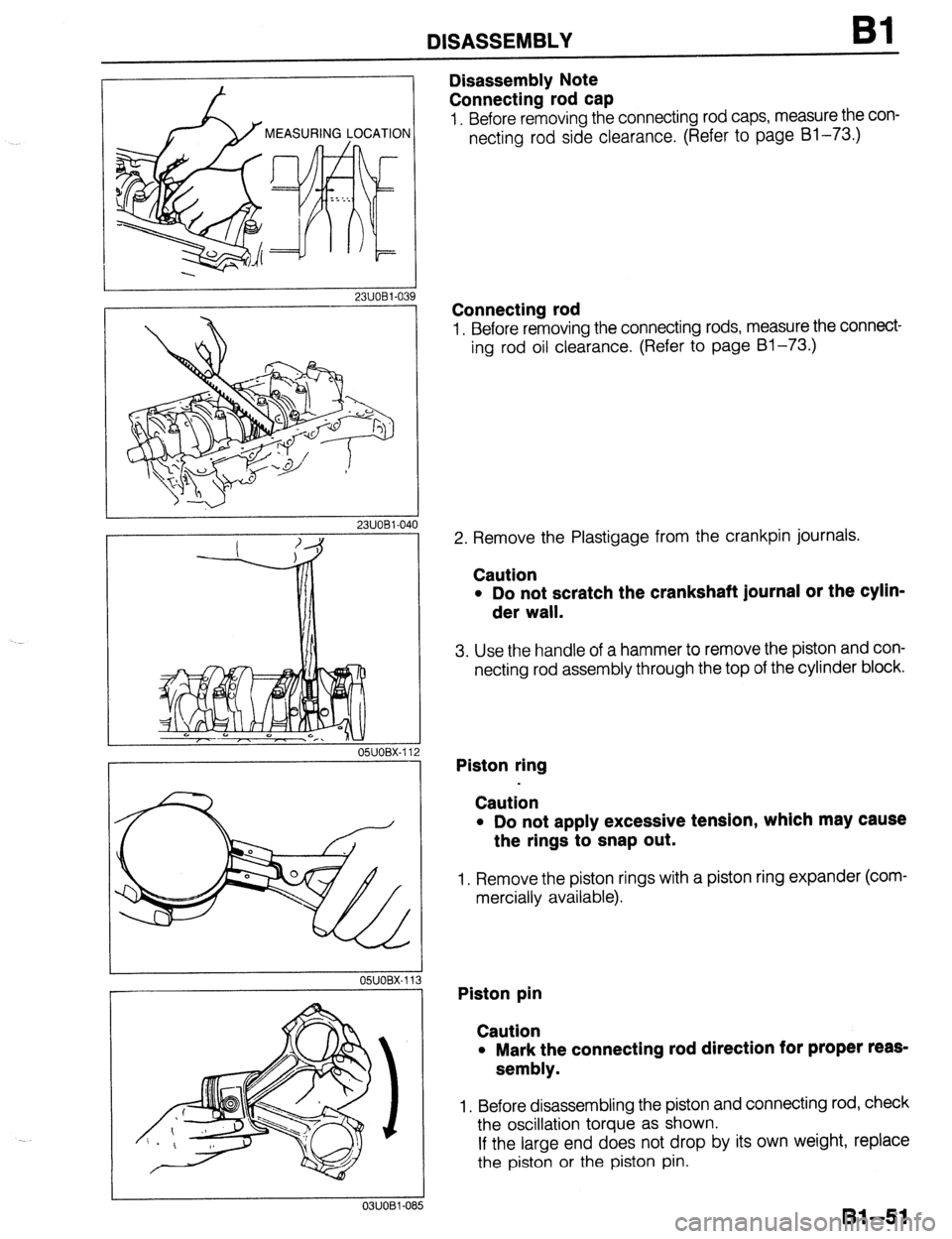

Disassembly Note

Connecting rod cap

1. Before removing the connecting rod caps, measure the con-

necting rod side clearance. (Refer to page Bl-73.)

Connecting rod

1. Before removing the connecting rods, measure the connect-

ing rod oil clearance. (Refer to page Bl-73.)

2. Remove the Plastigage from the crankpin journals.

Caution

l Do not scratch the crankshaft journal or the cylin-

der wall.

3. Use the handle of a hammer to remove the piston and con-

necting rod assembly through the top of the cylinder block.

Piston ring

Caution

l Do not apply excessive tension, which may cause

the rings to snap out.

1. Remove the piston rings with a piston ring expander (com-

mercially available).

Piston pin

Caution

l Mark the connecting rod direction for proper reas-

sembly.

1. Before disassembling the piston and connecting rod, check

the oscillation torque as shown.

If the large end does not drop by its own weight, replace

the piston or the piston pin.

81-51

Page 84 of 1164

Bl INSPECTION / REPAIR

INSPECTION / REPAIR

PREPARATION

SST

49 LO12 OAO)

Remover and

03UOBi-08

1. Clean all parts, being sure to remove all gasket fragments, dirt, oil or grease, carbon, moisture residue,

and other foreign materials.

2. Inspection and repairs must be performed in the order specified. .__a

Caution

l Do not damage the joints or friction surfaces of aluminum alloy components (such as the cyl-

inder head or pistons).

81-54

03UOBl-090 05UOBX-119

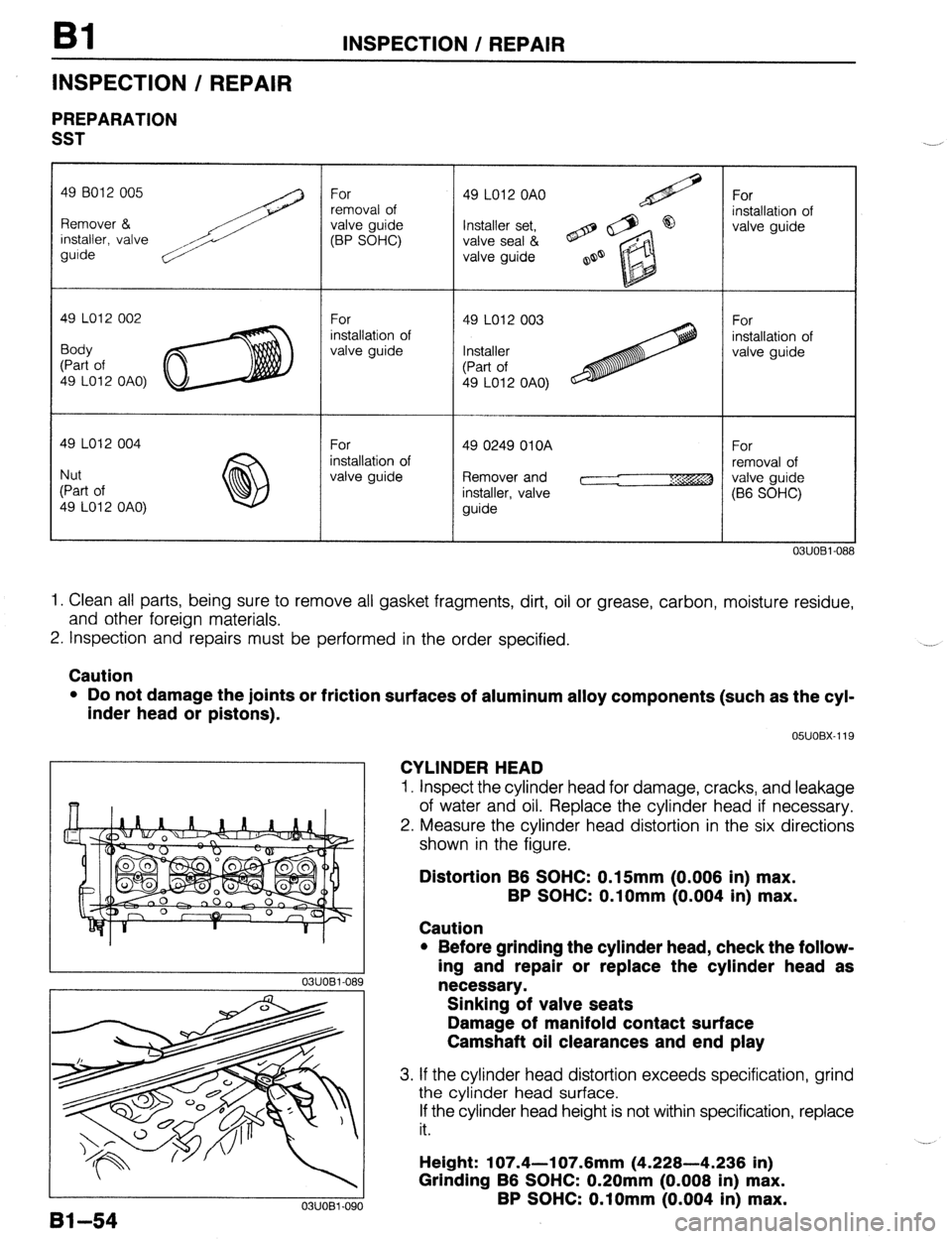

CYLINDER HEAD

1. Inspect the cylinder head for damage, cracks, and leakage

of water and oil. Replace the cylinder head if necessary.

2. Measure the cylinder head distortion in the six directions

shown in the figure.

Distortion B6 SOHC: 0.15mm (0.006 in) max.

BP SOHC: O.lOmm (0.004 in) max.

Caution

l Before grinding the cylinder head, check the follow-

ing and repair or replace the cylinder head as

necessary.

Sinking of valve seats

Damage of manifold contact surface

Camshaft oil clearances and end play

3. If the cylinder head distortion exceeds specification, grind

the cylinder head surface.

If the cylinder head height is not within specification, replace

it.

Height: 107.4-l 07.6mm (4.228-4.236 in)

Grinding B6 SOHC: 0.20mm (0.008 in) max.

BP SOHC: O.lOmm (0.004 in) max.

Page 90 of 1164

Bl INSPECTION / REPAIR

a3

03UOBl.109

03UOBl-11t

03UOBl-111 i

3

03UOBl-112

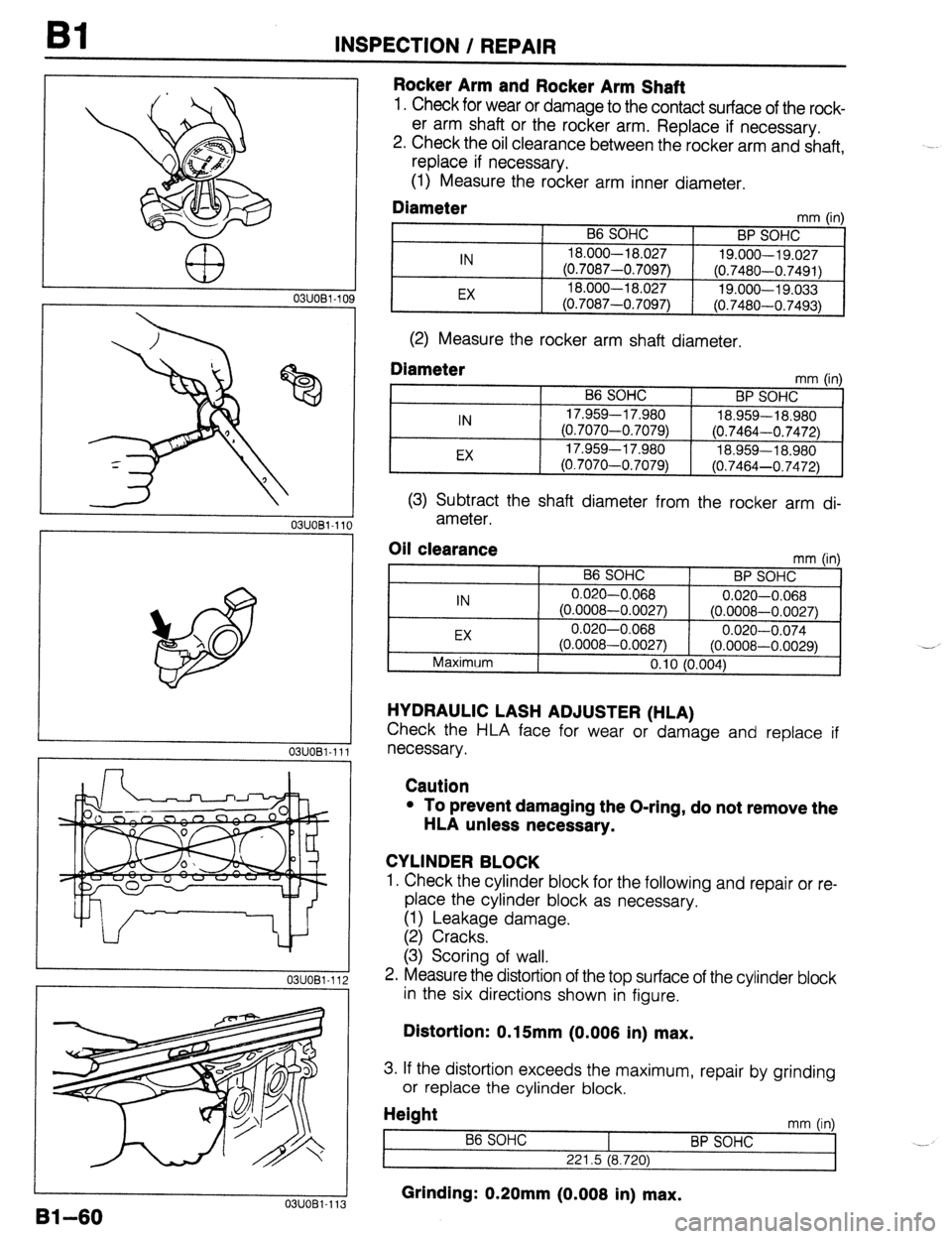

Rocker Arm and Rocker Arm Shaft

1. Check for wear or damage to the contact surface of the rock-

er arm shaft or the rocker arm. Replace if necessary.

2. Check the oil clearance between the rocker arm and shaft,

replace if necessary.

(1) Measure the rocker arm inner diameter.

Diameter mm (in)

B6 SOHC

BP SOHC

IN 18.000-l 8.027

19.000-19.027

(0.7087-0.7097)

(0.7480-0.7491)

EX 18.000-l 8.027

19.000-19.033

(0.7087-0.7097) (0.7480-0.7493)

(2) Measure the rocker arm shaft diameter.

Diameter mm tin1

IN

EX B6 SOHC

BP SOHC ’ ’

17.959-l 7.980

18.959-18.980

(0.7070-0.7079)

(0.7464-0.7472)

17.959-l 7.980

18.959-l 8.980

(0.7070-0.7079)

(0.7464-0.7472)

(3) Subtract the shaft diameter from the rocker arm di-

ameter.

Oil clearance

IN

EX

Maximum mm (in)

B6 SOHC

BP SOHC

0.020-0.068

0.020-0.068

(0.0008-0.0027) (0.0008-0.0027)

0.020-0.068

0.020-0.074

(0.0008-0.0027) (0.0008-0.0029)

0.10 (0.004) -_

HYDRAULIC LASH ADJUSTER (HLA)

Check the HLA face for wear or damage and replace if

necessary.

Caution

l To prevent damaging the O-ring, do not remove the

HLA unless necessary.

CYLINDER BLOCK

1. Check the cylinder block for the following and repair or re-

place the cylinder block as necessary.

(1) Leakage damage.

(2) Cracks.

(3) Scoring of wall.

2. Measure the distortion of the top surface of the cylinder block

in the six directions shown in figure.

Distortion: 0.15mm (0.006 in) max.

3. If the distortion exceeds the maximum, repair by grinding

or replace the cylinder block.

Height

t mm (in)

86 SOHC

BP SOHC _._

221.5 (8.720)

Grinding: 0.20mm (0.006 in) max. U3UU81-113

Page 91 of 1164

INSPECTION / REPAIR Bl

.-J-

03UOBl-11

05UOBX-1:

OWOBX-15 4

il

2

3

_I

5

OWOBX-15:

03UOBl-11:

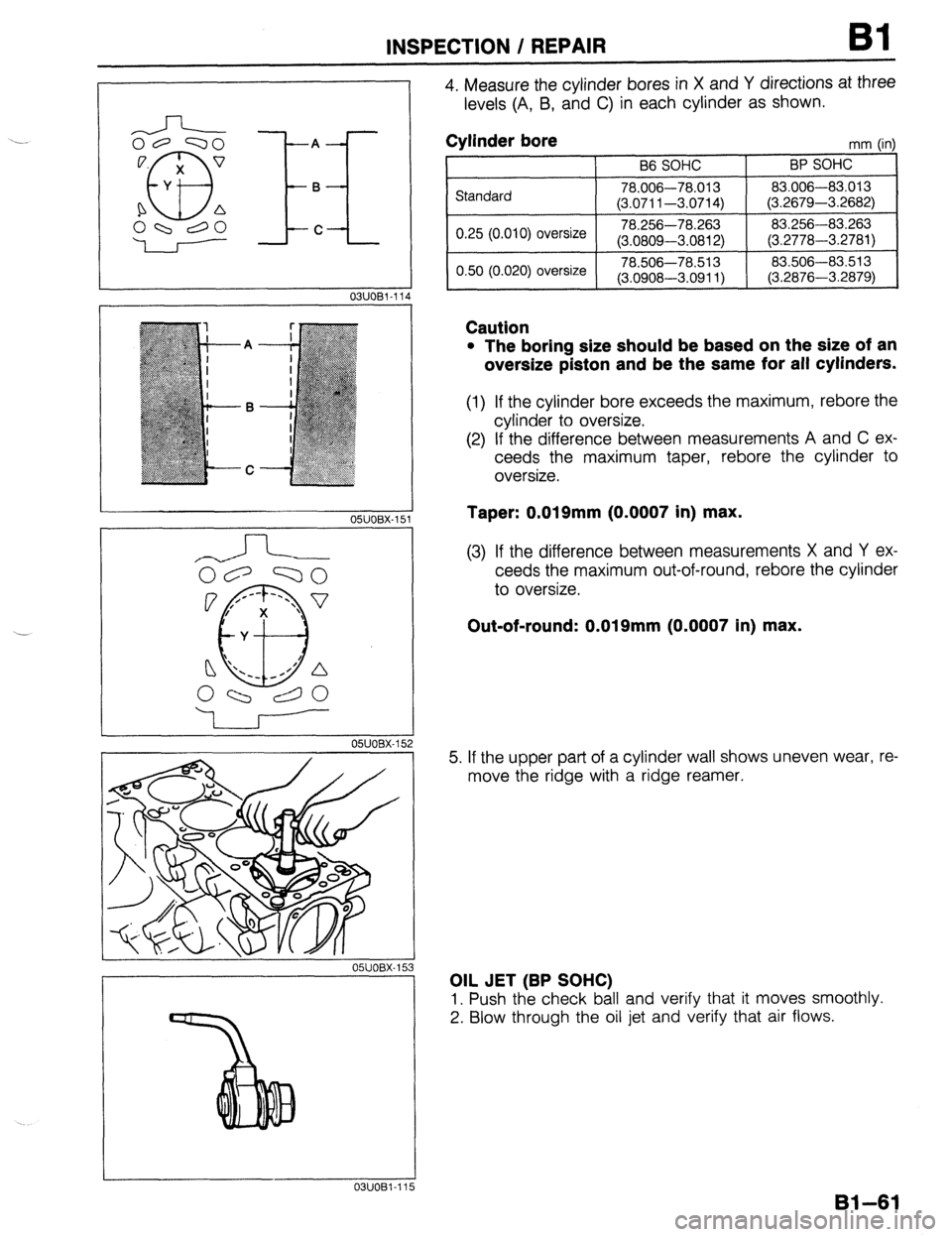

4. Measure the cylinder bores in X and Y directions at three

levels (A, B, and C) in each cylinder as shown.

Cylinder bore mm h-d

I I B6 SOHC I BP SOHC ’ ‘I

,r jtanciard 1 78.006-78.013 1 83.006-83.013

(3.0711-3.0714) (3.2679-3.2682)

0.25 (0.010) oversize 78.256-78.263 83.256-83.263

(3.0809-3.0812) (3.2778-3.2781)

I 0.50 (0.020) oversize 78.506-78.513 83.506-83.513

(3.0908-3.0911) (3.2876-3.2879)

I

Caution

l The boring size should be based on the size of an

oversize piston and be the same for all cylinders.

(1) If the cylinder bore exceeds the maximum, rebore the

cylinder to oversize.

(2) If the difference between measurements A and C ex-

ceeds the maximum taper, rebore the cylinder to

oversize.

Taper: 0.019mm (0.0007 in) max.

(3) If the difference between measurements X and Y ex-

ceeds the maximum out-of-round, rebore the cylinder

to oversize.

Out-of-round: 0.019mm (0.0007 in) max.

5. If the upper part of a cylinder wall shows uneven wear, re-

move the ridge with a ridge reamer.

OIL JET (BP SOHC)

1. Push the check ball and verify that it moves smoothly.

2. Blow through the oil jet and verify that air flows.

81-61