lock MAZDA PROTEGE 1992 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 88 of 1164

Bl INSPECTION / REPAIR

r

BP SPHC

I /

._~~ ~_ ’

--

23UOB1-06(

1

I 2-l

_I_

23UOBl-074

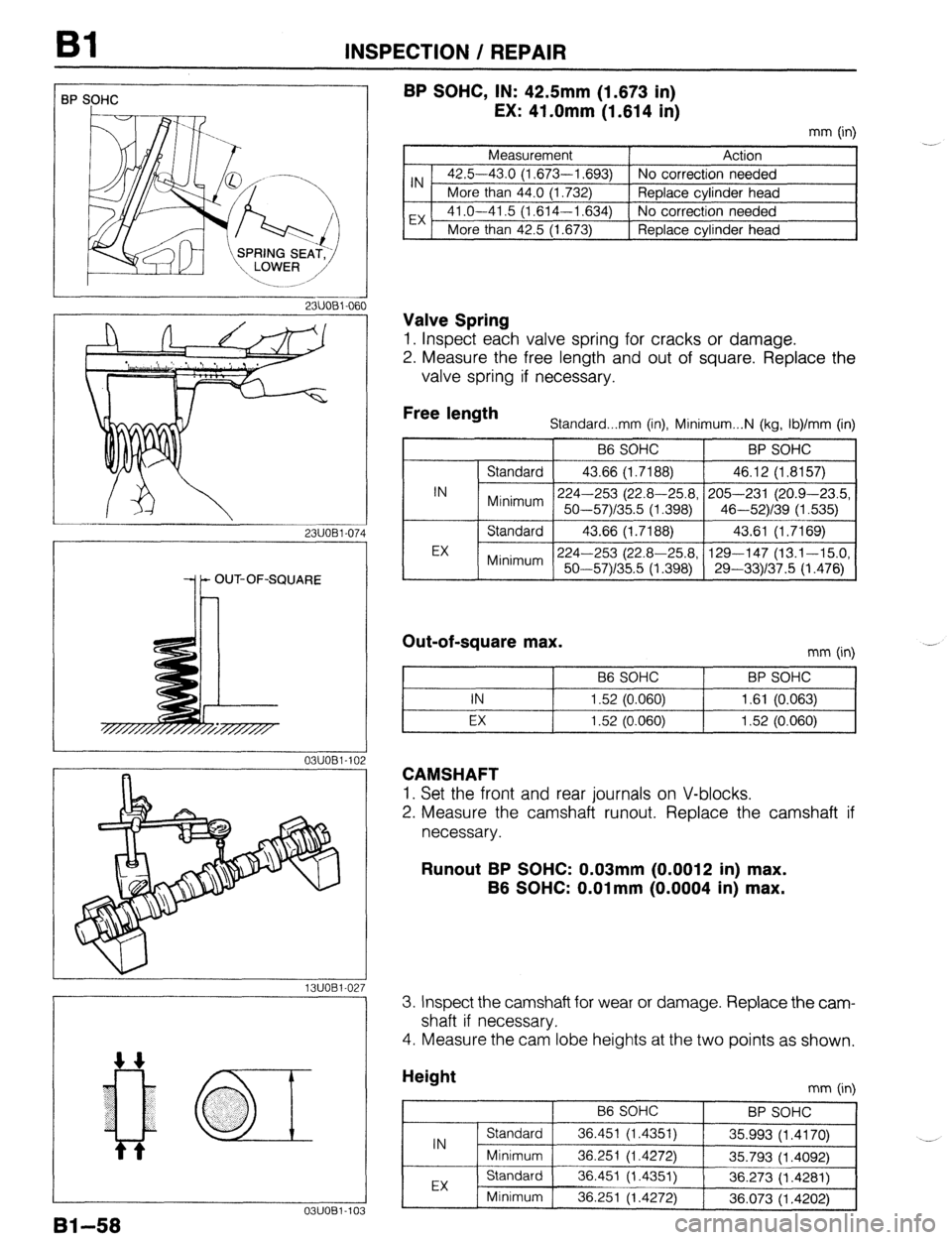

lt- OUT-OF-SQUARE

BP SOHC, IN: 42.5mm (1.673 in)

EX: 41 .Omm ‘(1.614 ii)

mm (in)

Measurement Action

IN . 42.5-43.0 (1,673-l ,693) No correction needed

More than 44.0 (1.732) Replace cylinder head

EX 41 .O-41.5 (1,614-l ,634) No correction needed

More than 42.5 (1.673) Replace cylinder head

Valve Spring

1. Inspect each valve spring for cracks or damage.

2. Measure the free length and out of square. Replace the

valve spring if necessary.

Free length

Standard...mm (in), Minimum...N (kg, Ib)/mm (in)

B6 SOHC BP SOHC

I

IN Standard 43.66 (1.7188) 46.12 (1.8157)

224-253 (22.8-25.8, 205-231 (20.9-23.5,

Minimum 50-57)/35.5 (1.398) 46-52)/39 (1.535)

EX Standard 43.66 (1.7188) 43.61 (1.7169)

224-253 (22.8-25.8, 129-147 (13.1-15.0,

Minimum 50-57Y35.5 (1.398) 29-331137.5 (1.476)

Out-of-square max. mm (in)

B6 SOHC BP SOHC I

I I IN 1.52 (0.060) 1.61 (0.063)

t I I

I I EX 1.52 (0.060) 1.52 (0.060)

CAMSHAFT

1. Set the front and rear journals on V-blocks.

2. Measure the camshaft runout. Replace the camshaft if

necessary.

Runout BP SOHC: 0.03mm (0.0012 in) max.

B6 SOHC: O.Olmm (0.0004 in) max.

13UOBl.02; 3. Inspect the camshaft for wear or damage. Replace the cam-

shaft if necessary.

4. Measure the cam lobe heights at the two points as shown.

0311081-103

91-58

mm (in)

Page 90 of 1164

Bl INSPECTION / REPAIR

a3

03UOBl.109

03UOBl-11t

03UOBl-111 i

3

03UOBl-112

Rocker Arm and Rocker Arm Shaft

1. Check for wear or damage to the contact surface of the rock-

er arm shaft or the rocker arm. Replace if necessary.

2. Check the oil clearance between the rocker arm and shaft,

replace if necessary.

(1) Measure the rocker arm inner diameter.

Diameter mm (in)

B6 SOHC

BP SOHC

IN 18.000-l 8.027

19.000-19.027

(0.7087-0.7097)

(0.7480-0.7491)

EX 18.000-l 8.027

19.000-19.033

(0.7087-0.7097) (0.7480-0.7493)

(2) Measure the rocker arm shaft diameter.

Diameter mm tin1

IN

EX B6 SOHC

BP SOHC ’ ’

17.959-l 7.980

18.959-18.980

(0.7070-0.7079)

(0.7464-0.7472)

17.959-l 7.980

18.959-l 8.980

(0.7070-0.7079)

(0.7464-0.7472)

(3) Subtract the shaft diameter from the rocker arm di-

ameter.

Oil clearance

IN

EX

Maximum mm (in)

B6 SOHC

BP SOHC

0.020-0.068

0.020-0.068

(0.0008-0.0027) (0.0008-0.0027)

0.020-0.068

0.020-0.074

(0.0008-0.0027) (0.0008-0.0029)

0.10 (0.004) -_

HYDRAULIC LASH ADJUSTER (HLA)

Check the HLA face for wear or damage and replace if

necessary.

Caution

l To prevent damaging the O-ring, do not remove the

HLA unless necessary.

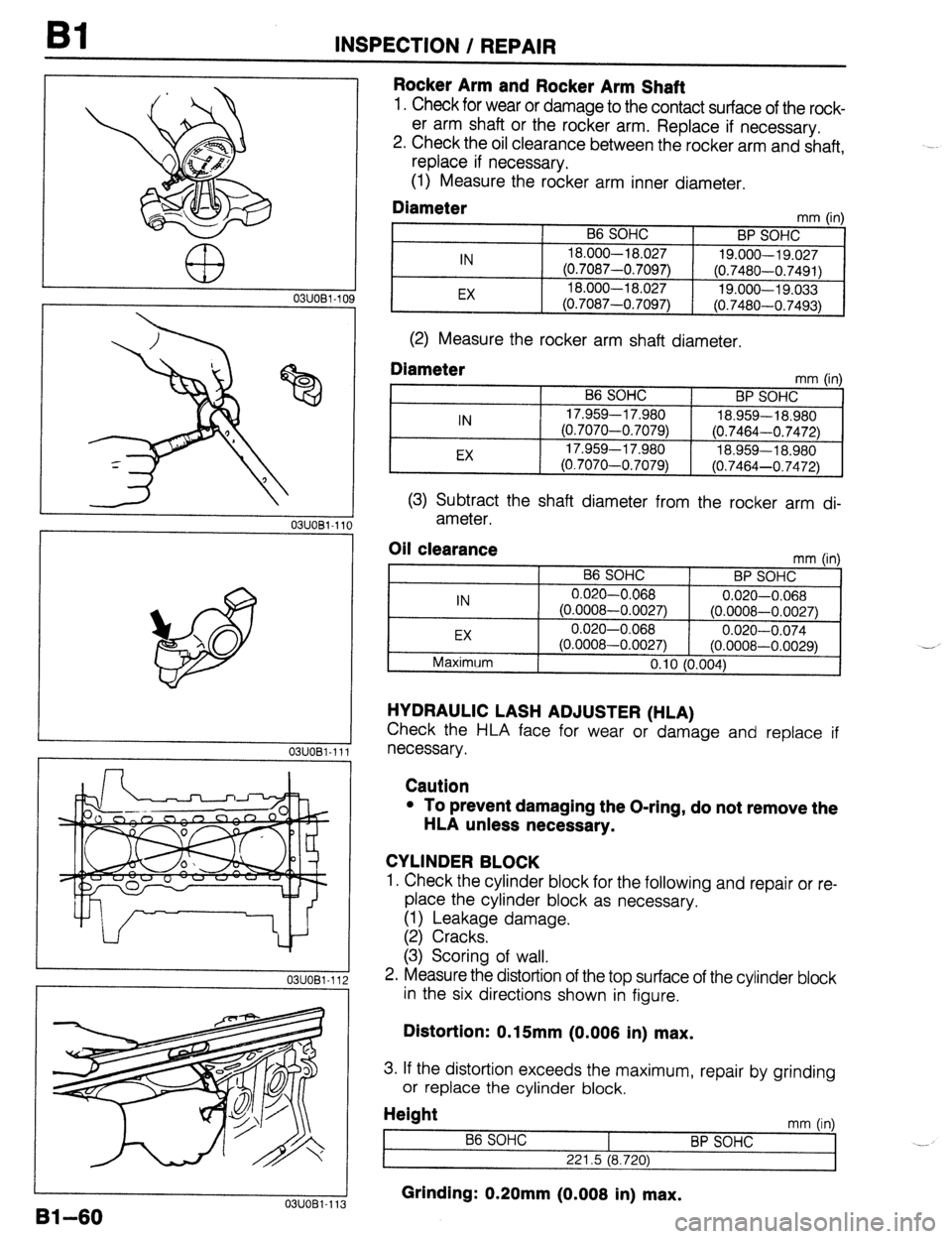

CYLINDER BLOCK

1. Check the cylinder block for the following and repair or re-

place the cylinder block as necessary.

(1) Leakage damage.

(2) Cracks.

(3) Scoring of wall.

2. Measure the distortion of the top surface of the cylinder block

in the six directions shown in figure.

Distortion: 0.15mm (0.006 in) max.

3. If the distortion exceeds the maximum, repair by grinding

or replace the cylinder block.

Height

t mm (in)

86 SOHC

BP SOHC _._

221.5 (8.720)

Grinding: 0.20mm (0.006 in) max. U3UU81-113

Page 94 of 1164

INSPECTION / REPAIR

05UOBX-1E

X

8 Y

03UOBl-21

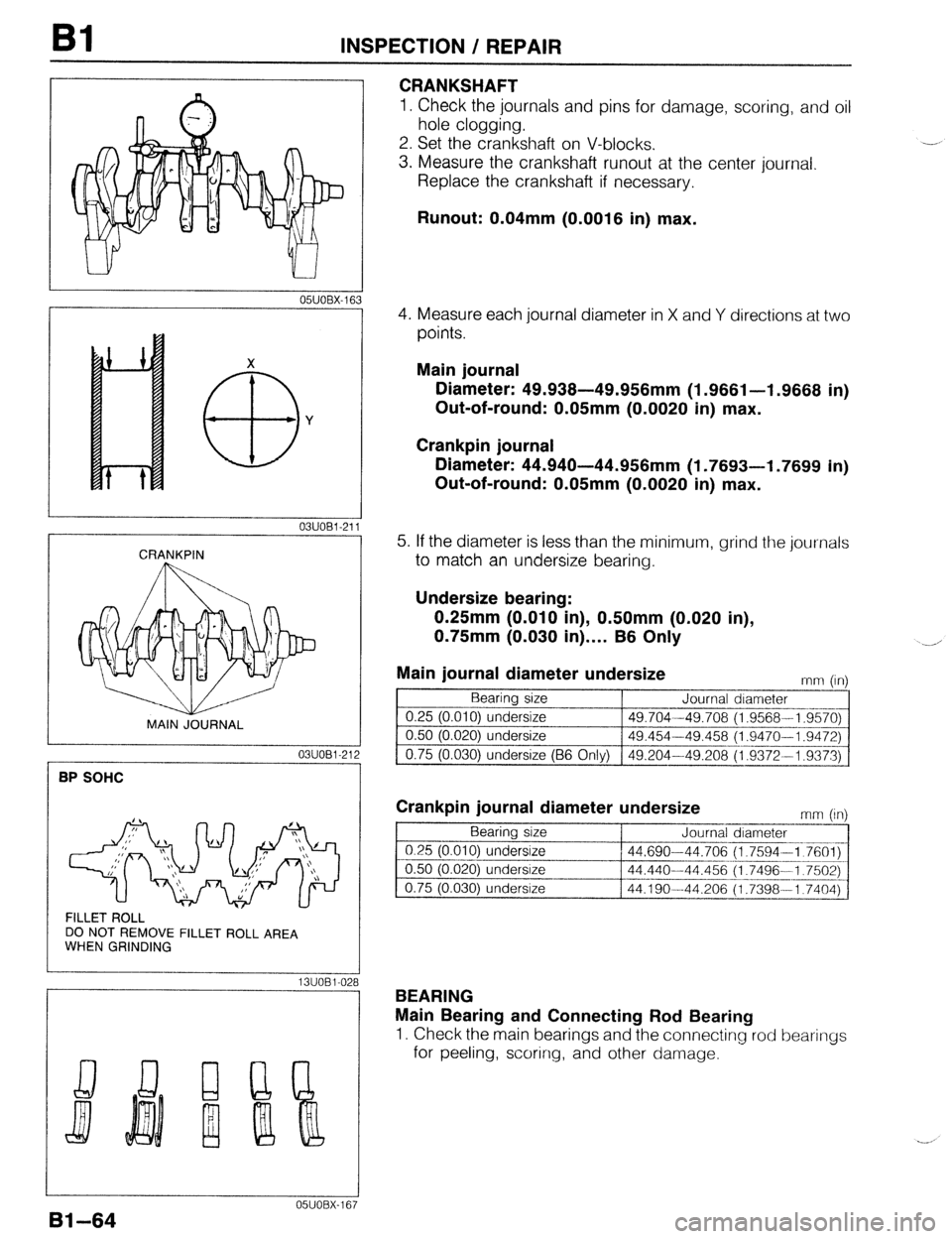

CRANKPIN

MAIN JOURNAL

03UOBl-21

BP SOHC .r -

FILLET ROLL

DO NOT REMOVE FILLET ROLL AREA

WHEN GRINDING

1311081-028

CRANKSHAFT

1. Check the journals and pins for damage, scoring, and oil

hole clogging.

2. Set the crankshaft on V-blocks.

3. Measure the crankshaft runout at the center journal.

Replace the crankshaft if necessary. -.

Runout: 0.04mm (0.0016 in) max.

4. Measure each journal diameter in X and Y directions at two

points.

Main journal

Diameter: 49.938-49.956mm (1.9661-l .9668 in)

Out-of-round: 0.05mm (0.0020 in) max.

Crankpin journal

Diameter: 44.940-44.956mm (1.7693-l .7699 in)

Out-of-round: 0.05mm (0.0020 in) max.

5. If the diameter is less than the minimum, grind the journals

to match an undersize bearing.

Undersize bearing:

0.25mm (0.010 in), 0.50mm (0.020 in),

0.75mm (0.030 in).... B6 Only

Main journal diameter undersize

mm iin) 1. Bearing size Journal diameter

_-.---

0.25 (0.010) undersize 49.704.-49.708 (1.9568-l .9570)

---.-___

0.50 (0.020) undersize 49.454-49.458 (1.9470-l .9472)

0.75 (0.030) undersize (B6 Only) 49.204-49.208(1.9372--l .9373)

Crankpin journal diameter undersize ” ” ” 1” Bearing size Journal diameter

-_ ____~_.

0.25 (0.010) undersize 44.690-44.706

(1.7594 -1 7601) .--.._-.~.--~-.~

0.50

(0.020) underslze 44.440-44.456 (1.7496-I .7502) -- _____----.

0.75 (0.030) undersize 44.190--44.206 (1.7398---i .7404)

BEARING

Main Bearing and Connecting Rod Bearing

1. Check the main bearings and the connecting rod bearings

for peeling, scoring, and other damage.

05UOBX-167

Bl-64

Page 96 of 1164

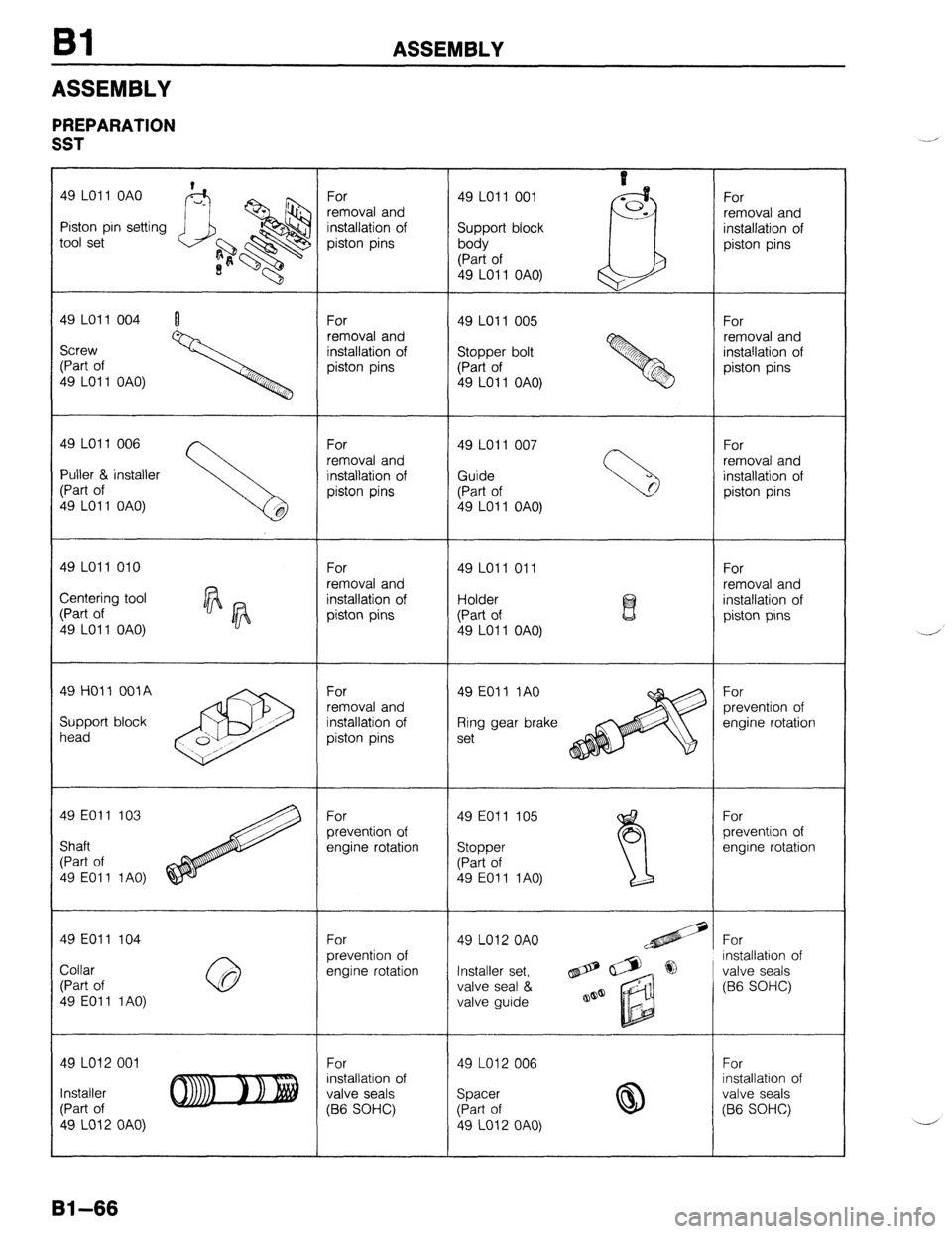

Bl ASSEMBLY

ASSEMBLY

PREPARATION

SST

49 LO1 1 OAO

Piston pin setting

tool set

49 LO1 1 004 I

Screw

(Part of

49 LO1 1 OAO)

49 LO1 1 006

Puller & installer

49 LO1 1 OAO) For

removal and

installation of

piston pins 49 LO11 001

Support block

body

(Part of

49 LO11 OAO)

49 LO1 1 005

Stopper bolt

(Part of

49 LO1 1 OAO)

49 LO1 1 007 For

removal and

installation of

piston pins

For

removal and

installation of

piston pins

Centering tool

49 LO1 1 OAO)

49 HO11 OOlA

Support block

49 EOll 103

49 EOll 104

installation of

Collar

49 LO12 001

installation of

Page 97 of 1164

ASSEMBLY Bl

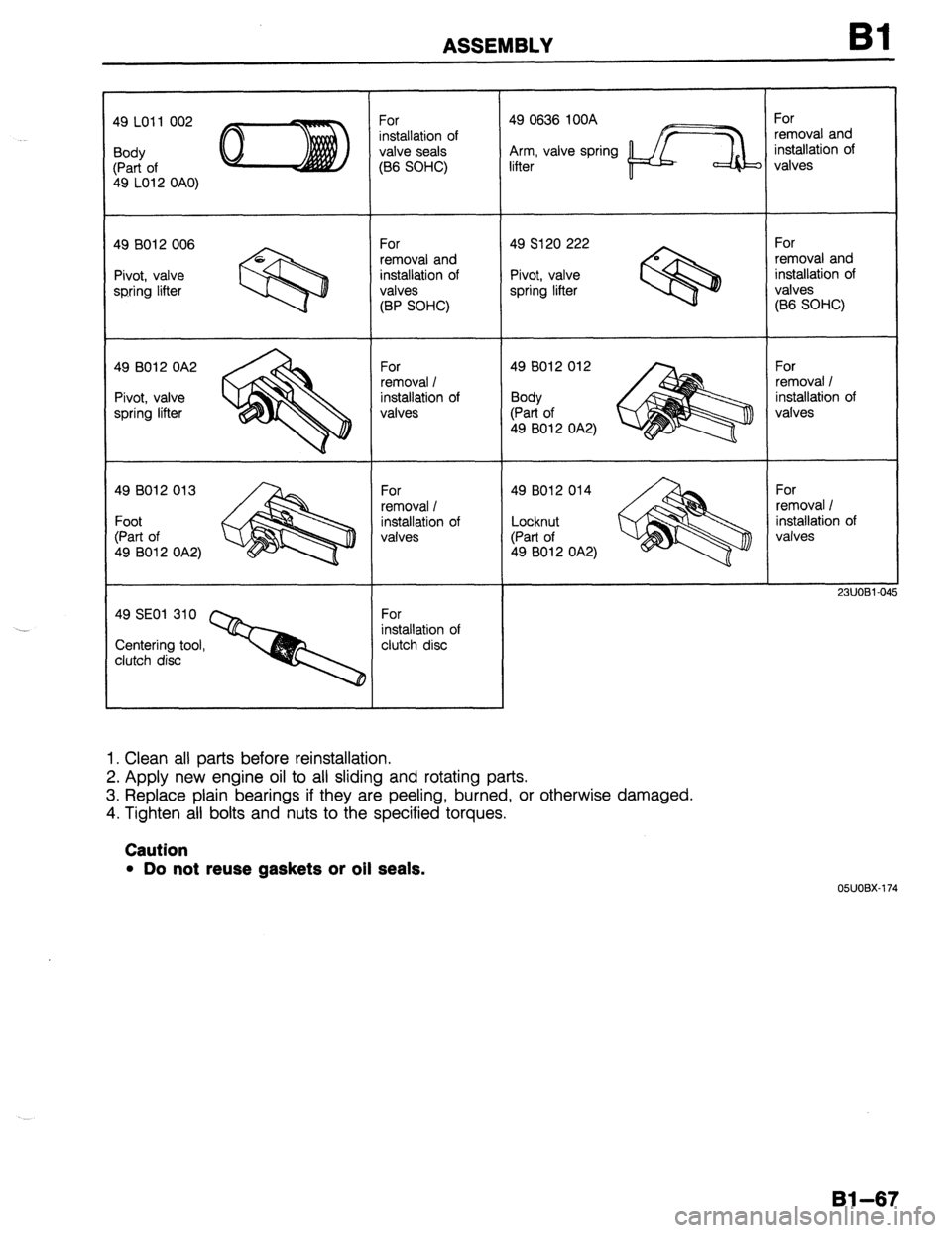

19 LO11 002

Body

:Part of

49 LO12 OAO)

49 8012 006

Pivot, valve

spring lifter

49 8012 OA2

Pivot, valve

spring lifter

49 8012 013

Foot

(Part of

49 B012 OA2)

49 SE01 310

Centering tool,

clutch disc For

installation of

valve seals

(B6 SOHC)

For

removal and

installation of

valves

(BP SOHC)

For

removal I

installation of

valves

For

removal I

installation of

valves

For

installation of

clutch disc 49 0636 1OOA

Arm, valve spring

lifter

49 s120 222

0

Pivot, valve

spring lifter

%

49 8012 012

Body

(Part of

49 8012 OA2)

49 B012 014

Locknut

(Part of

49 8012 OA2)

1. Clean all parts before reinstallation.

2. Apply new engine oil to all sliding and rotating parts.

3. Replace plain bearings if they are peeling, burned, or otherwise damaged.

4. Tighten all bolts and nuts to the specified torques.

Caution

l Do not reuse gaskets or oil seals.

I

3 For

removal and

installation of

valves

For

removal and

installation of

valves

(B6 SOHC)

For

removal I

installation of

valves

For

removal I

installation of

valves

23UOBl-0,

05UOBX-174

Bl-67

Page 98 of 1164

Bl ASSEMBLY

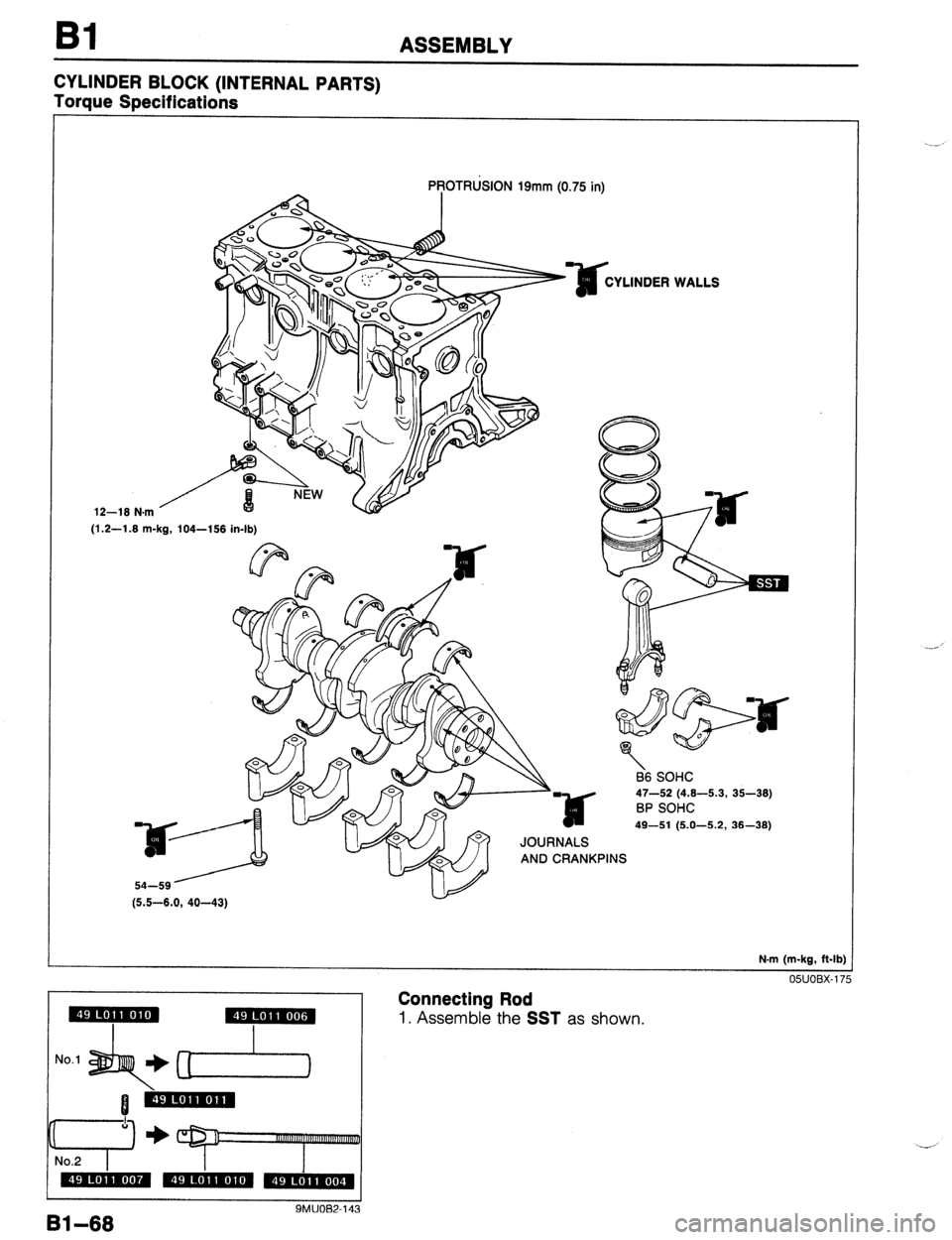

CYLINDER BLOCK (INTERNAL PARTS)

Torque SPecifications

12-18 N.m PROTRLklON 19mm (0.75 in)

YLINDER

(1.2-1.8 m-kg, 104-158 in-lb)

JOURNALS

AND CRANKPINS

(5.5-8.0, 40-43) WALLS

66 SOHC

47-52 (4.8-5.3, 35-38)

BP SOHC

49-51 (5.0-5.2, 36-38)

N.m (m-kg, ft-lb)

05UOBX-171

Connecting Rod

1. Assemble the SST as shown.

9MUOW143

Page 99 of 1164

ASSEMBLY Bl

I-

r

I 03UOBl-12

A NO.1

M

9MUOB2-14 I ‘NDENTIFICATION MARK

03UOBl-02

I

23UOBl-04

05UOBX.179

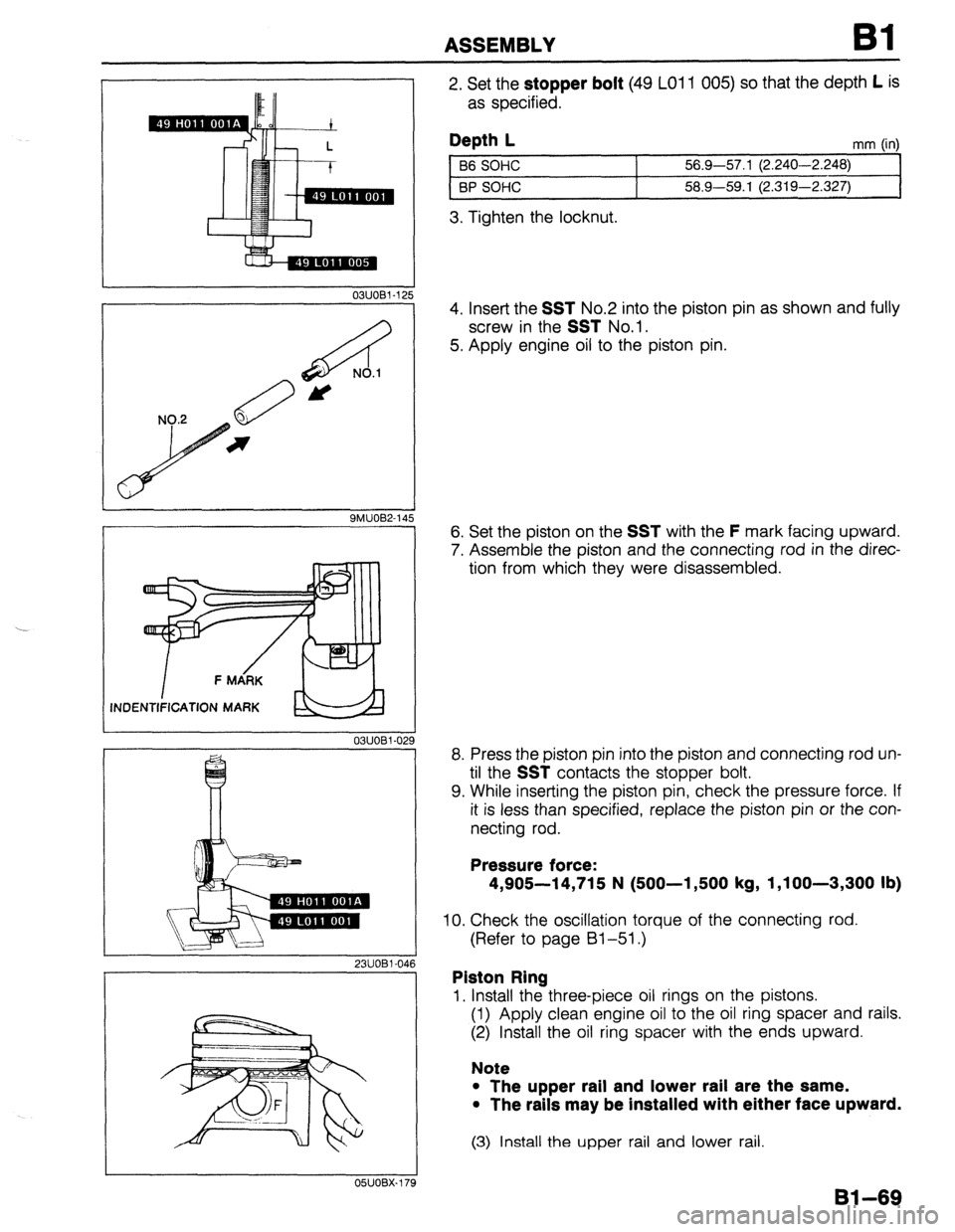

2. Set the stopper bolt (49 LO1 1 005) so that the depth L is

as specified.

Depth L

B6 SOHC

BP SOHC mm (in)

I 56.9-57.1 (2.240-2.248)

58.9-59.1 (2.319-2.327)

3. Tighten the locknut.

4. Insert the

SST No.2 into the piston pin as shown and fully

screw in the

SST No.1.

5. Apply engine oil to the piston pin.

6. Set the piston on the

SST with the F mark facing upward.

7. Assemble the piston and the connecting rod in the direc-

tion from which they were disassembled.

8. Press the piston pin into the piston and connecting rod un-

til the SST contacts the stopper bolt.

9. While inserting the piston pin, check the pressure force. If

it is less than specified, replace the piston pin or the con-

necting rod.

Pressure force:

4,905-14,715 N (500-l ,500 kg, 1 ,lOO-3,300 lb)

10. Check the oscillation torque of the connecting rod.

(Refer to page Bl-51.)

Piston Ring 1,

Install the three-piece oil rings on the pistons.

(1) Apply clean engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer with the ends upward.

Note

l The upper rail and lower rail are the same.

l The rails may be installed with either face upward. (3) Install the upper rail and lower rail

Bl-69

Page 101 of 1164

ASSEMBLY

f

05UOW18

THRUST BEARING

OYJOBX-18

05UOBX-18

23UOBl-04

OWOBX-181

Crankshaft

1. Before installing the crankshaft, inspect the main bearing

oil clearances as follows.

Oil clearance inspection

(1) Remove all foreign material and oil from the journals and

bearings.

Caution

l Install the grooved upper main bearings in the cyl-

inder block.

l Install the thrust bearings with the oil groove fac-

ing the crankshaft.

(2) Install the upper main bearings and thrust bearings.

(3) Set the crankshaft in the cylinder block.

Caution

l Do not rotate the crankshaft when measurlng the

oil clearances.

(4) Position Plastigage atop the journals in the axial di-

rection.

(5) Install the lower main bearings and the main bearing

caps according to the cap number and + mark.

(6) Tighten the main bearing cap bolts in two or three steps

in the order shown in the figure.

Tightening torque:

54-59 N-m (5.5-6.0 m-kg, 40-43 ft-lb)

(7) Remove the main bearing caps, and measure the P lasti-

gage at each journal at the widest point for the smallest

clearance and at the narrowest point for the largest

clearance.

(8) If the oil clearance exceeds specification, grind the

crankshaft and use undersize main bearings.

(Refer to page Bl-64.)

Oil clearance: 0.016-0.036mm (0.0007-0.0014 in)

Maximum: O.lOmm (0.004 in)

2. Apply a liberal amount of clean engine oil to the main bear-

ings, thrust bearings and main journals.

3. Install the crankshaft and the main bearing caps accord-

ing to the cap number and + mark.

61-71

Page 104 of 1164

Bl ASSEMBLY

CYLINDER BLOCK (EXTERNAL PARTS)

Torque Specifications

19-25

(1.9-2.6, 14-19)

GASKET, NEW

OIL SEAL,

NEW

7.6-11 N.m

(60-l 10 cm-kg,

69-95 in-lb)

GASKET, NE

16-21 (1.6-2.1, 12--15)-j

R

A -22% / 7.6-11 N.m

(60-110 cm-kg, 69-95 in-lb) 6-103 w

,..6-10.6,

71-76) 16-26

(1.6-2.7, 13-20)

7.6-11 N-m

(60-110 cm-kg, 69-95 in-lb)

N.m (m-kg, R-lb)

Bl-74

OWOBX-201 0

Rear Cover

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be pressed in until it is flush with

the edge of the rear cover.

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 1OOmm (3.94 in)

4. Apply silicone sealant to the shaded area shown in the

figure.

Page 105 of 1164

ASSEMBLY Bl

OWOBX-20

23UOBl-049

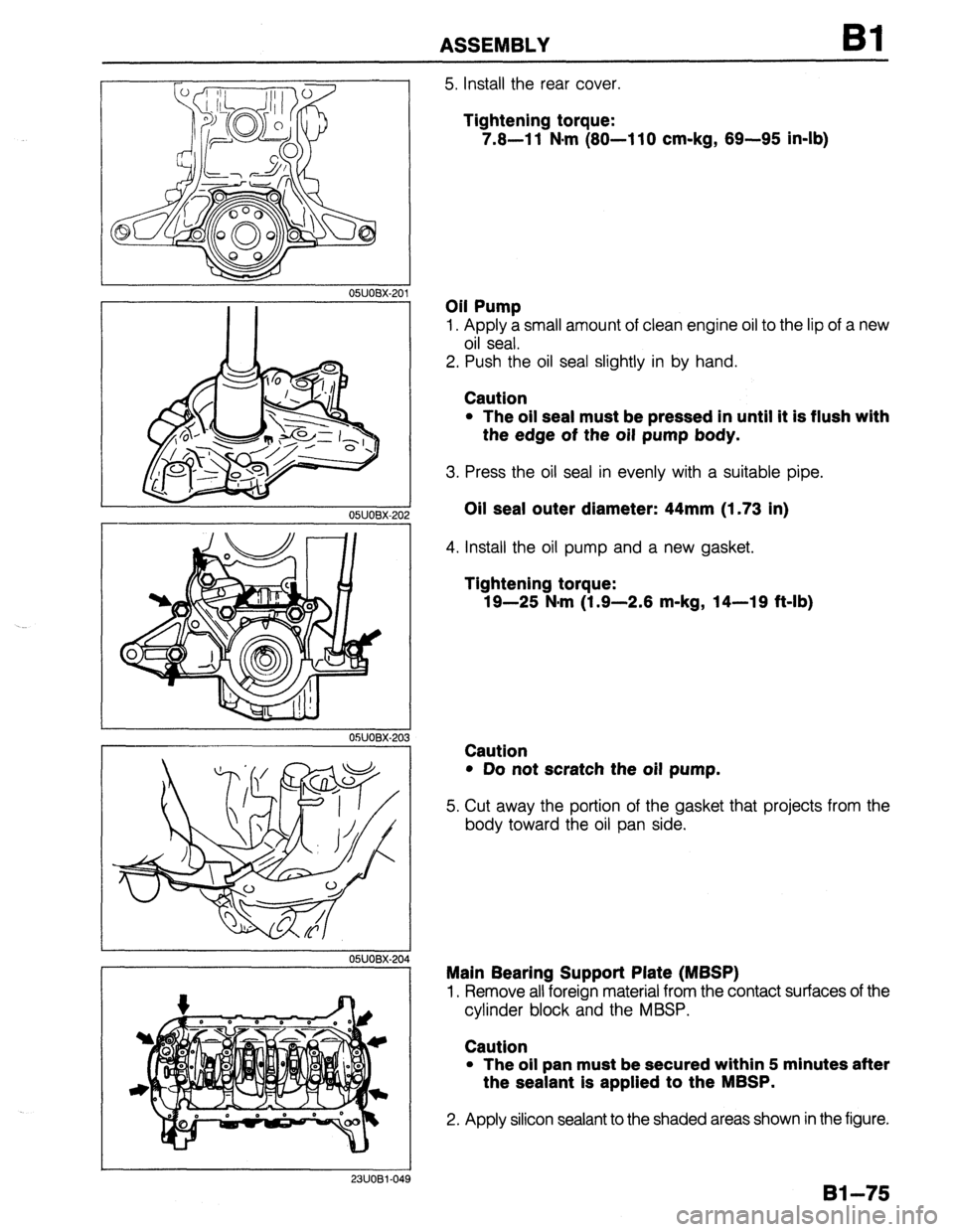

5. Install the rear cover.

Tightening torque:

7.8-l 1 N*m (80-l 10 cm-kg, 89-95 in-lb)

Oil Pump

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be pressed in until it is flush with

the edge of the oil pump body.

3. Press the oil seal in evenly with a suitable pipe.

Oil seal outer diameter: 44mm (1.73 in)

4. Install the oil pump and a new gasket.

Tightening torque:

19-25 N-m (1.9-2.8 m-kg, 14-19 ft-lb)

Caution

l Do not scratch the oil pump.

5. Cut away the portion of the gasket that projects from the

body toward the oil pan side.

Main Bearing Support Plate (MBSP)

1, Remove all foreign material from the contact surfaces of the

cylinder block and the MBSP.

Caution

l The oil pan must be secured within 5 minutes after

the sealant is applied to the MBSP.

2. Apply silicon sealant to the shaded areas shown in the figure.

81-75