lock MAZDA PROTEGE 1992 Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 69 of 1164

DISASSEMBLY Bl

I I

49 LO11 010

Centering tool

(Part of

49 LO1 1 OAO) For

removal I

installation of

piston pins 49 LO11 011

Holder

(Part of

49 LO1 1 OAO) For

removal I

installation of

piston pins

49 HO11 OOlA

Support block

head For

removal /

installation of

piston pins

1. Code all identical parts (such as piston, piston rings, connecting rods, and valve springs) so that they

can be reinstalled in the cylinder from which they were removed.

2. Clean the parts with a steam cleaner. Blow off any remaining water with compressed air.

Note

l During disassembly of any part or system, be sure to study its order of assembly. Also, note

any deformation, wear, or damage.

05UOBX-091

81-39

Page 71 of 1164

DISASSEMBLY Bl

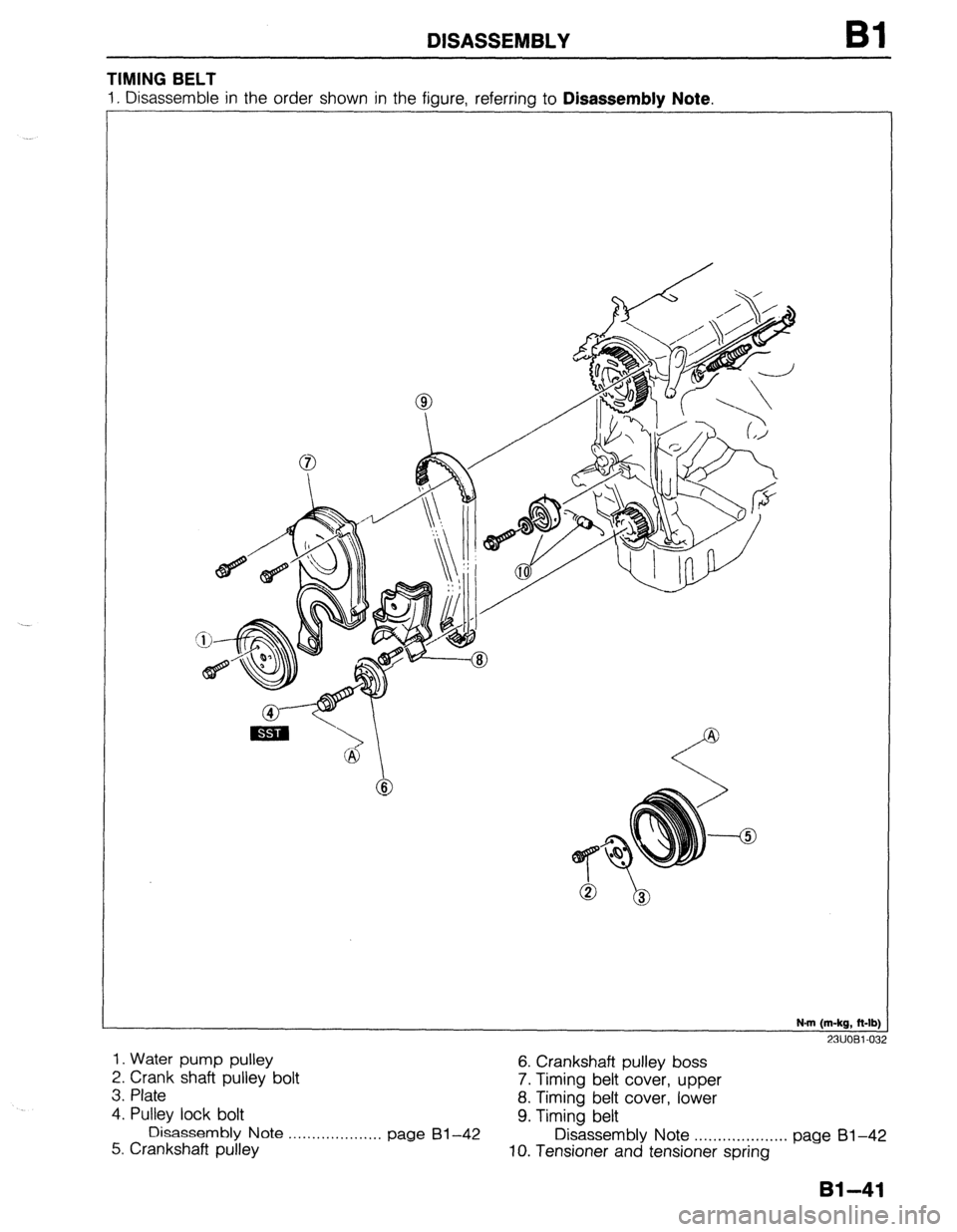

TIMING BELT

23UOBl-032

1. Water pump pulley

2. Crank shaft pulley bolt 6. Crankshaft pulley boss

3. Plate 7. Timing belt cover, upper

4. Pulley lock bolt 8. Timing belt cover, lower

9. Timing belt

Disassembly

Note . . . . . . . . . . . . . . . . . . . . page Bl-42

Disassembly

Note . . . . . . . . . . . . . . . . . . . . page

81-42

5. Crankshaft pulley

10. Tensioner and tensioner spring

Bl-41

Page 72 of 1164

DISASSEMBLY

23UOBl-067

; MARKS

MARKS

Qe

x

25mm (1.0 in) MIN

13EOBl-0:

Disassembly Note

Pulley lock bolt

1. Hold the flywheel (MTX) or drive plate (ATX) with the SST

or equivalent.

2. Remove the pulley lock bolt.

Timing belt

1. Turn the crankshaft and align the marks.

2. Mark the timing belt rotation for proper reinstallation.

Caution

l Never forcefully twist the timing belt. Do not turn

it inside out or bend it.

l Do not allow oil or grease on the belt.

81-42

Page 75 of 1164

DISASSEMBLY Bl

23tlOBl-03

03UOBl-07

B6 SOHC

23UOBl-03

3P SOHC

Disassembly Note

Rocker arm and rocker shaft assembly

1, Loosen the rocker arm bolts in two or three steps in the or-

der shown in the figure.

2. Remove the rocker arm and rocker shaft assembly.

3. Code all rocker arms and springs so that they can be rein-

stalled in the same places from which they were removed.

Hydraulic lash adjuster (HLA)

Remove the HLA by hand.

If it is difficult, remove the HLA by using pliers.

Caution

l Do not remove the HLA unless necessary because

oil leakage will occur, if the O-ring is damaged.

Camshaft pulley

1. Hold the camshaft using a suitable wrench on the cast

hexagon.

2. Remove the camshaft pulley lock bolt.

3. Remove the camshaft pulley.

Cylinder head bolts

1. Loosen the cylinder head bolts in two or three steps in the

order shown in the figure.

2. Remove the cylinder head bolts.

Bl-45

Page 77 of 1164

DISASSEMBLY Bl

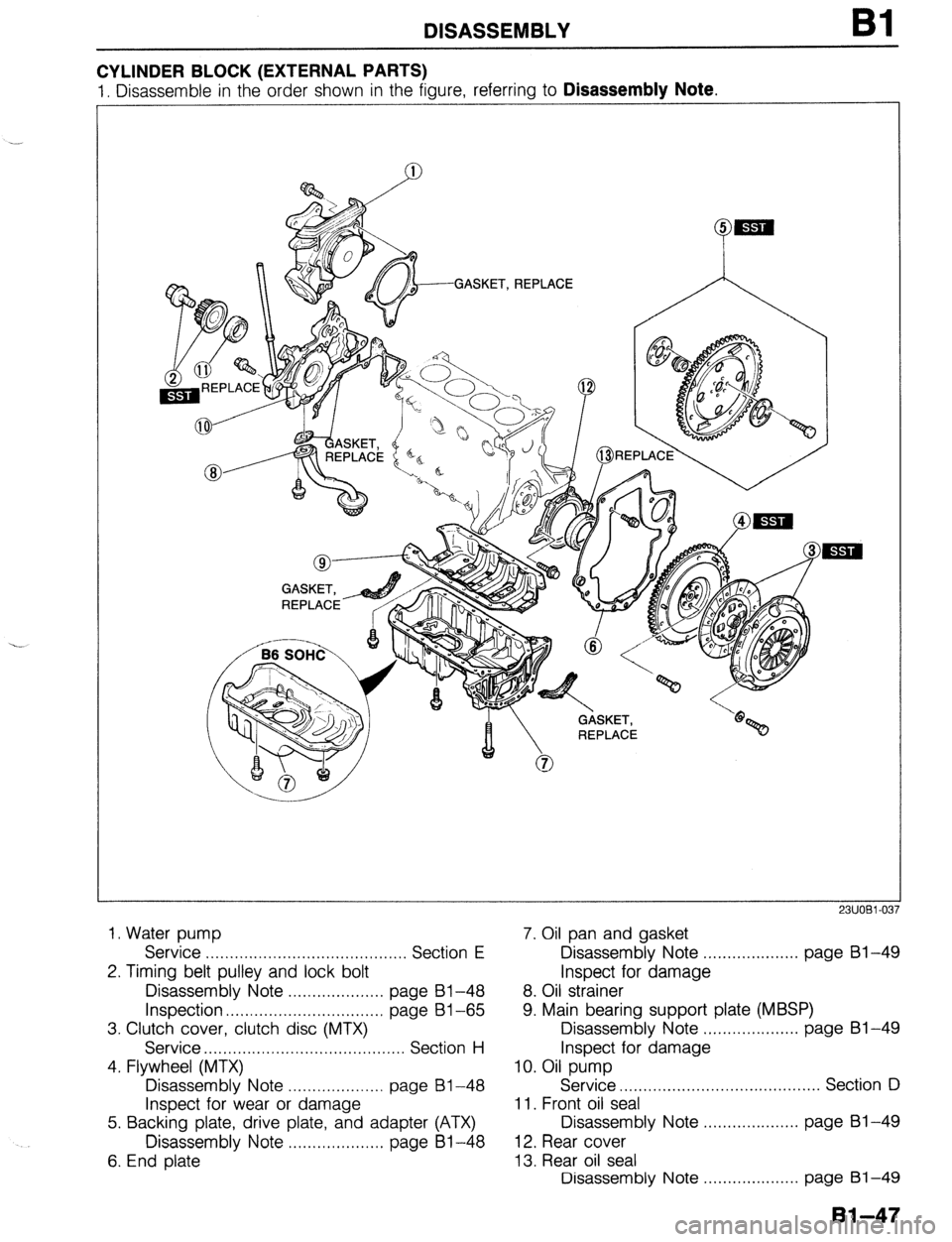

CYLINDER BLOCK (EXTERNAL PARTS)

1. Disassemble in the order shown in the fiaure, referrina to Disassembly Note.

.-.

1. Water pump

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section E

2. Timing belt pulley and lock bolt

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Bl-48

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl -65

3. Clutch cover, clutch disc (MTX)

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section H

4. Flywheel (MTX)

Disassembly Note . . . . . . . . . . . . . . . . . . . page 81-48

Inspect for wear or damage

5. Backing plate, drive plate, and adapter (ATX)

Disassembly Note ..,.....,.,........, page 81-48

6. End plate 7. Oil pan and gasket

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 81-49

Inspect for damage

8. Oil strainer

9. Main bearing support plate (MBSP)

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Bl-49

Inspect for damage

10. Oil pump

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section D

11. Front oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 81-49

12. Rear cover

13. Rear oil seal

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 81-49

Bl-47

Page 78 of 1164

Bl DISASSEMBLY

23UOBl-068

23UOBl-06!

I 2311081-070

23UOBl-071

Disassembly Note

Timing belt pulley

1. Hold the flywheel (MTX) or drive plate (ATX) with the SST

or equivalent.

2. Loosen the pulley lock bolt.

3. Remove the pulley lock bolt. -

4. Remove the timing belt pulley.

5. Remove the pulley Woodruff key.

2311081-059

Clutch cover (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Loosen the clutch cover lock bolts in two or three steps in

the order shown in the figure.

3. Remove the clutch cover.

-

Flywheel (MTX)

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel lock bolts.

3. Remove the flywheel.

4. Remove the

SST or equivalent.

Backing plate, drive plate, and adapter (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

4. Remove the

SST or equivalent.

Bl-48

Page 79 of 1164

DISASSEMBLY Bl

0311081-08

PROTECT PUMP w

BODY WITH RAG

OTECT REAR COVER 0

Oil pan

B6 SOHC

1. Remove the oil pan mounting bolts.

2. Insert a screwdriver or a suitable tool between the MBSP

and oil pan, and pry them.

Caution

l Do not insert the prying tool between the MBSP and

cylinder block.

l Do not damage or scratch the contact surfaces.

BP SOHC

1. Remove the oil pan mounting bolts.

Caution

l Do not force a prying tool between the cylinder

block and the oil pan, which may damage the con-

tact surfaces.

l Do not damage or scratch the contact surfaces

when removing the old sealant.

2. Insert a screwdriver or a suitable tool only at the points

shown in the figure.

3. Remove the oil pan.

Main bearing support plate (MBSP)

1. Remove the MBSP mounting bolts to the main bearing cap.

2. Insert a screwdriver or a suitable tool between the MBSP

and cylinder block, and pry them.

Caution

l Do not damage or scratch the contact surfaces

when removing old sealant.

Front oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

Rear oil seal

1. Remove the oil seal with a screwdriver protected with a rag.

Bl-49

Page 80 of 1164

Bl DISASSEMBLY

CYLINDER BLOCK (INTERNAL PARTS)

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

1. Connecting rod cap

7. Main bearing cap

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 81-51

Disassembly Note . . . . . . . . . . . . . . . . . . . . page

81-52

2. Connecting rod

8. Crankshaft

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Bl-51

Disassembly Note . . . . . . . . . . . . . . . . . . . . page 81-53

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-63

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page

Bl-64

3. Connecting rod bearing

9. Main bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . page Bl-64 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page

Bl-64

4. Piston ring

10. Thrust bearing

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Bl-51 11. Oil filter joint

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page

Bl-62 12. Oil jet

5. Piston pin

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-61

Disassembly Note . . . . . . . . . . . . . . . . . . . . page Bl-51 13. Cylinder block

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-63

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-60 ‘-”

6. Piston

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-62

Bl-50

Page 81 of 1164

DISASSEMBLY Bl

23UOBl-03

05UOBX-1’ 9

23UOBl-040

03UOBl-08 5

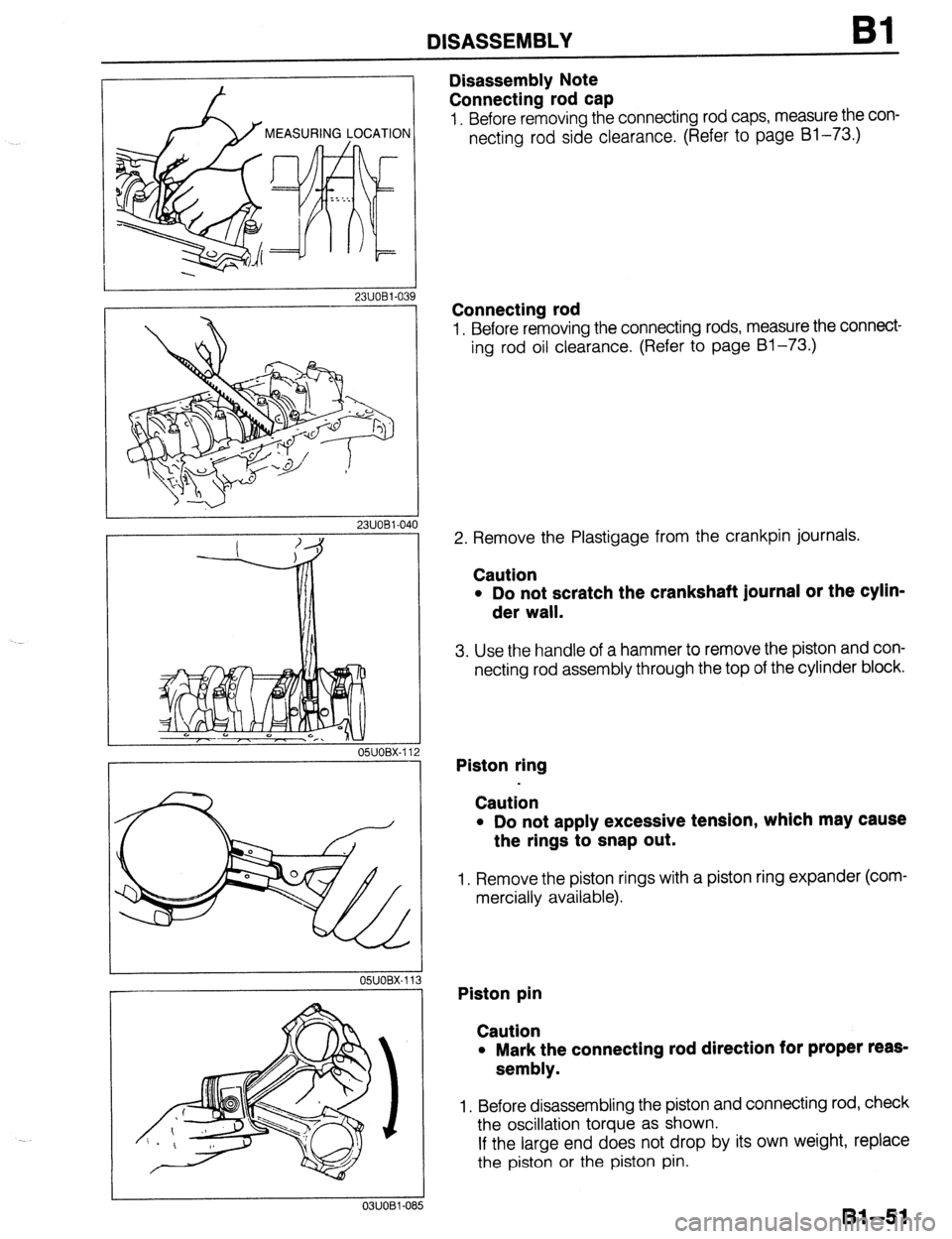

Disassembly Note

Connecting rod cap

1. Before removing the connecting rod caps, measure the con-

necting rod side clearance. (Refer to page Bl-73.)

Connecting rod

1. Before removing the connecting rods, measure the connect-

ing rod oil clearance. (Refer to page Bl-73.)

2. Remove the Plastigage from the crankpin journals.

Caution

l Do not scratch the crankshaft journal or the cylin-

der wall.

3. Use the handle of a hammer to remove the piston and con-

necting rod assembly through the top of the cylinder block.

Piston ring

Caution

l Do not apply excessive tension, which may cause

the rings to snap out.

1. Remove the piston rings with a piston ring expander (com-

mercially available).

Piston pin

Caution

l Mark the connecting rod direction for proper reas-

sembly.

1. Before disassembling the piston and connecting rod, check

the oscillation torque as shown.

If the large end does not drop by its own weight, replace

the piston or the piston pin.

81-51

Page 86 of 1164

Bl INSPECTION / REPAIR

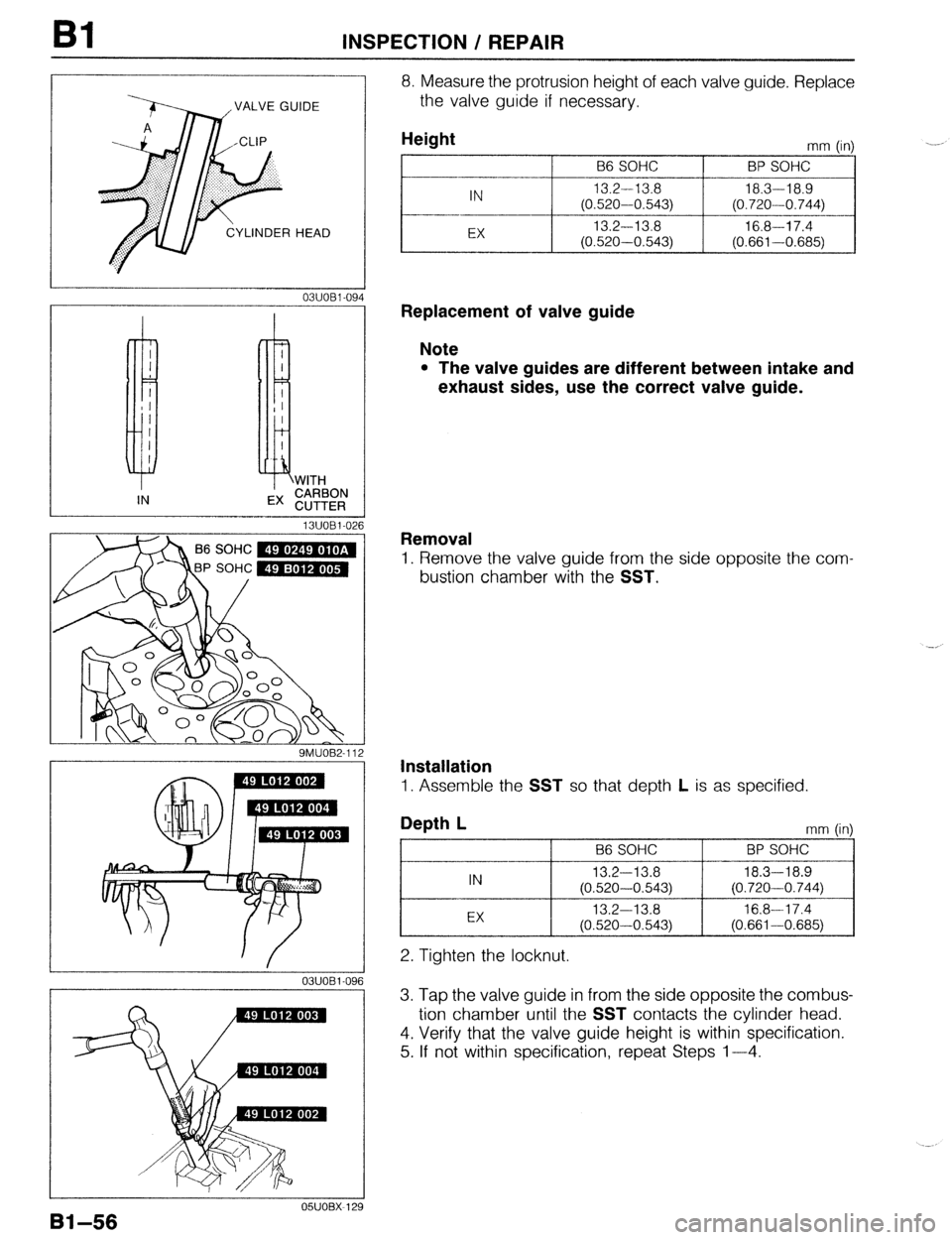

VALVE GUIDE

8. Measure the protrusion height of each valve guide. Replace

the valve guide if necessary.

13UOBl-026

P SOHC m

9MUOB2-112

OSUOBX-12’

Bi-56

Height

B6 SOHC mm (in)

BP SOHC

I

IN 13.2-13.8 18.3-i 8.9

(0.520-0.543)

(0.720-0.744)

-.. --

EX 13.2-13.8 16.8-17.4

(0.520-0.543) (0.661-0.685)

Replacement of valve guide

Note

l The valve guides are different between intake and

exhaust sides, use the correct valve guide.

Removal

1. Remove the valve guide from the side opposite the com-

bustion chamber with the SST.

Installation

1. Assemble the SST so that depth L is as specified.

Depth L

mm (in)

I B6 SOHC

I BP SOHC

I

IN 13.2-13.8 18.3-l 8.9

(0.520-0.543) (0.720-0.744)

EX 13.2-13.8 16.8-17.4

(0.520-0.543) (0.661-0.685)

2. Tighten the locknut.

3. Tap the valve guide in from the side opposite the combus-

tion chamber until the SST contacts the cylinder head.

4. Verify that the valve guide height is within specification.

5. If not within specification, repeat Steps l-4.