belt MAZDA PROTEGE 1992 Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 138 of 1164

B2 ENGINE TUNE-UP PROCEDURE

ALTERNATOR DRIVE BELT

2311082-00

P/S OIL PUMP

DRIVE BELT

-

A/C AND P/S OIL

PUMP DRIVE BELT

23UOB2-001

1

23UOB2-00

23UOB2-OC

3. Check the drive belt deflection by applying moderate pres-

sure (98 N,

10 kg, 22 lb) midway between the pulleys.

Note

l Measure the belt deflection between the specified

pulleys.

l A belt is considered “New” if it has been used on

a running engine for less than five minutes.

Set the deflection specified below accordingly.

l Check the belt deflectlon when the engine is cold,

or at least 30 minutes after the engine has stopped.

Deflectlon

Drive belt

Alternator

P/S, PAS + A/C New Used

8.0-9.0 9.0-10.0

(0.31-0.35) (0.35-0.39)

8.0-9.0 9.0-I 0.0

(0.31-0.35) (0.35-0.39) mm (in)

Limit

12.5

(0.49)

11.5

(0.45)

4. If the deflection is not within specification, adjust it.

5. Install the air intake pipe.

Drive belt tension check

Note

l Belt tension can be checked in place of belt

deflection.

l Belt tension can be measured between any two

pulleys.

1. Removal the air intake pipe.

2. Using the

SST, check the belt tension.

_-

Tenslon

N (kg, lb)

Drive belt

Alternator New

383-461 Used

304-383 Limit

167

(39-47, 85.8-103.4) (31-39, 68.2-85.8) (17, 37)

P/S, P/S + AIC 491-589 422-491 245

(5040, 110-132) (43-50,95-l 10) (25, 55)

3. If the tension is not within specification, adjust it.

4. Install the air intake pipe.

Adjustment

Cautlon

l If a new belt is used, adjust the belt deflection at

the midpoint of new belt specification.

l A belt is considered “New” If it has been used on

a runnlng engine for less than five minutes.

1. Alternator belt

(1) Loosen the alternator mounting bolt @ and adjusting

lock bolt @.

(2) Lever the alternator outward and apply tension to the

belt.

(3) Tighten adjusting lock bolt @I.

82-6

Page 139 of 1164

ENGINE TUNE-UP PROCEDURE 92

23UOB2-OC

DRIVE PULLEY

I I

2311082.010

HLA

I Problem

1. Noise when engine is started immedi-

ately after oil is changed.

2. Noise when engine is started after set-

tina aporox. one dav.

3. Noise when engine is started after

cranking for 3 seconds or more.

4. Noise when engine is started after

new HLA is installed.

5. Noise continues more than 10 minutes

6. Noise occurs durning idle after high-

“”

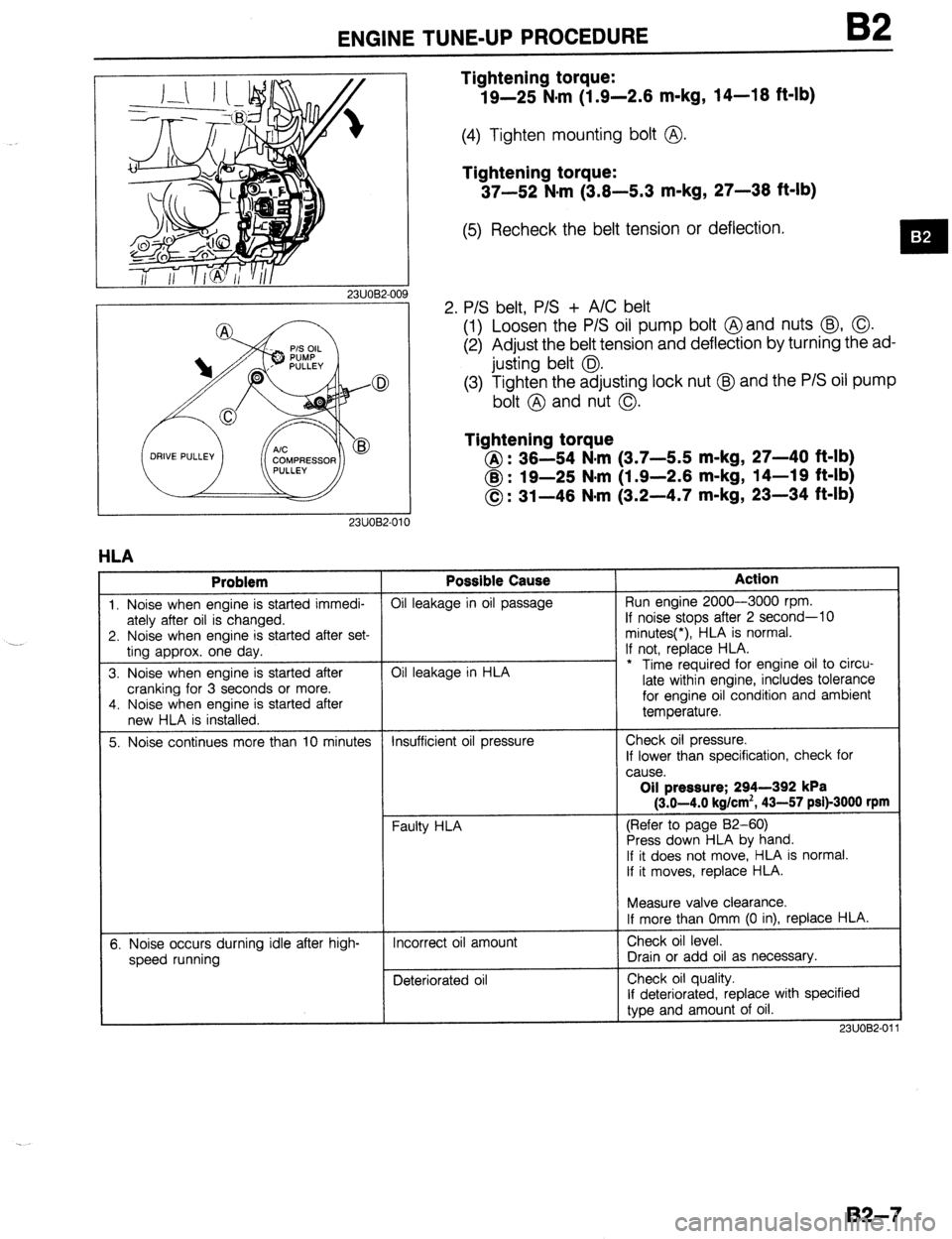

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-16 ft-lb)

(4) Tighten mounting bolt @.

Tightening torque:

37-52 N#rn (3.6-5.3 m-kg, 27-36 ft-lb)

(5) Recheck the belt tension or deflection.

2. P/S belt, P/S + A/C belt

(1) Loosen the P/S oil pump bolt @and nuts @, 0.

(2) Adjust the belt tension and deflection by turning the ad-

justing belt 0.

(3) Tighten the adjusting lock nut @J and the P/S oil pump

bolt @ and nut 0.

Tightening torque

@: 36-54 N-m (3.7-5.5 m-kg, 27-40 ft-lb)

@ : 19-25 N*m (1.9-2.6 m-kg, 14-19 ft-lb)

0: 31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb) Possible Cause

Oil leakage in oil passage

Oil leakage in HLA

Insufficient oil pressure

Faulty HLA

Incorrect oil amount

Deteriorated oil Action Run engine 2000-3000 rpm.

If noise stops after 2 second-10

minutes(*), HLA is normal.

If not, replace HLA.

* Time required for engine oil to circu-

late within engine, includes tolerance

for engine oil condition and ambient

temperature.

Check oil pressure.

If lower than specification, check for

cause. Oil pressure; 294-392 kPa

(3.0-4.0 kg/cm’, 43-57 psi)-3000 rpm

(Refer to page 82-60)

Press down HLA by hand.

If it does not move, HLA is normal.

If it moves, replace HLA.

Measure valve clearance.

If more than Omm (0 in), replace HLA.

Check oil level.

Drain or add oil as necessary.

Check oil quality.

If deteriorated, replace with specified

type and amount of oil.

2311082-01

B2-7

Page 140 of 1164

82 ENGINE TUNE-UP PROCEDURE

03UOB2-013

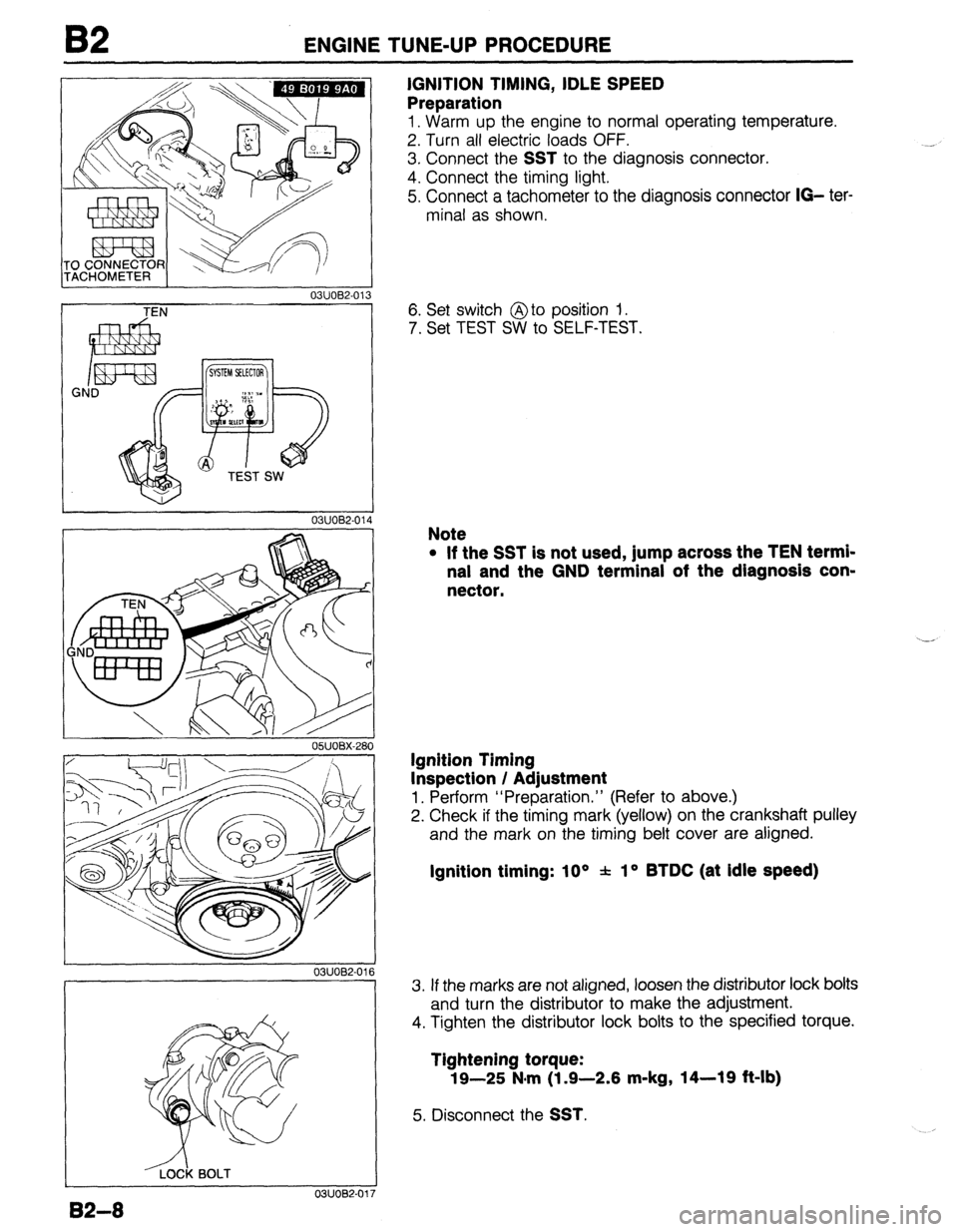

IGNITION TIMING, IDLE SPEED

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IO- ter-

minal as shown.

TEN

03UOB2-01

I

-&k BOLT

0311082-01’

82-8

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform “Preparation.” (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: 10 * f lo BTDC (at Idle speed)

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N*m (1 .Q-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

Page 143 of 1164

ON-VEHICLE MAINTENANCE 62

ON-VEHICLE MAINTENANCE

PREPARATION

SST

49 DO11 102

Lock tool,

crankshaft

49 E011 103

Shaft

(Part of

49 EOl 1 1AO) @

49 EOI 1 104

Collar

(Part of

49 EOl 1 1AO) For

removal and

installation of

timing belt pulley

For

prevention of

engine rotation

For

prevention of

engine rotation 49 EOll IA0

Ring gear brake

set

49 EOll 105

Stopper

0

(Part of

49 EOI 1

1AO) w

49 SE01 310A

Centering tool,

clutch disc For

prevention of

engine rotation

For

prevention of

engine rotation

For

installation of

clutch disc

2311082-0‘

02-I 1

Page 144 of 1164

B2 ON-VEHICLE MAINTENANCE

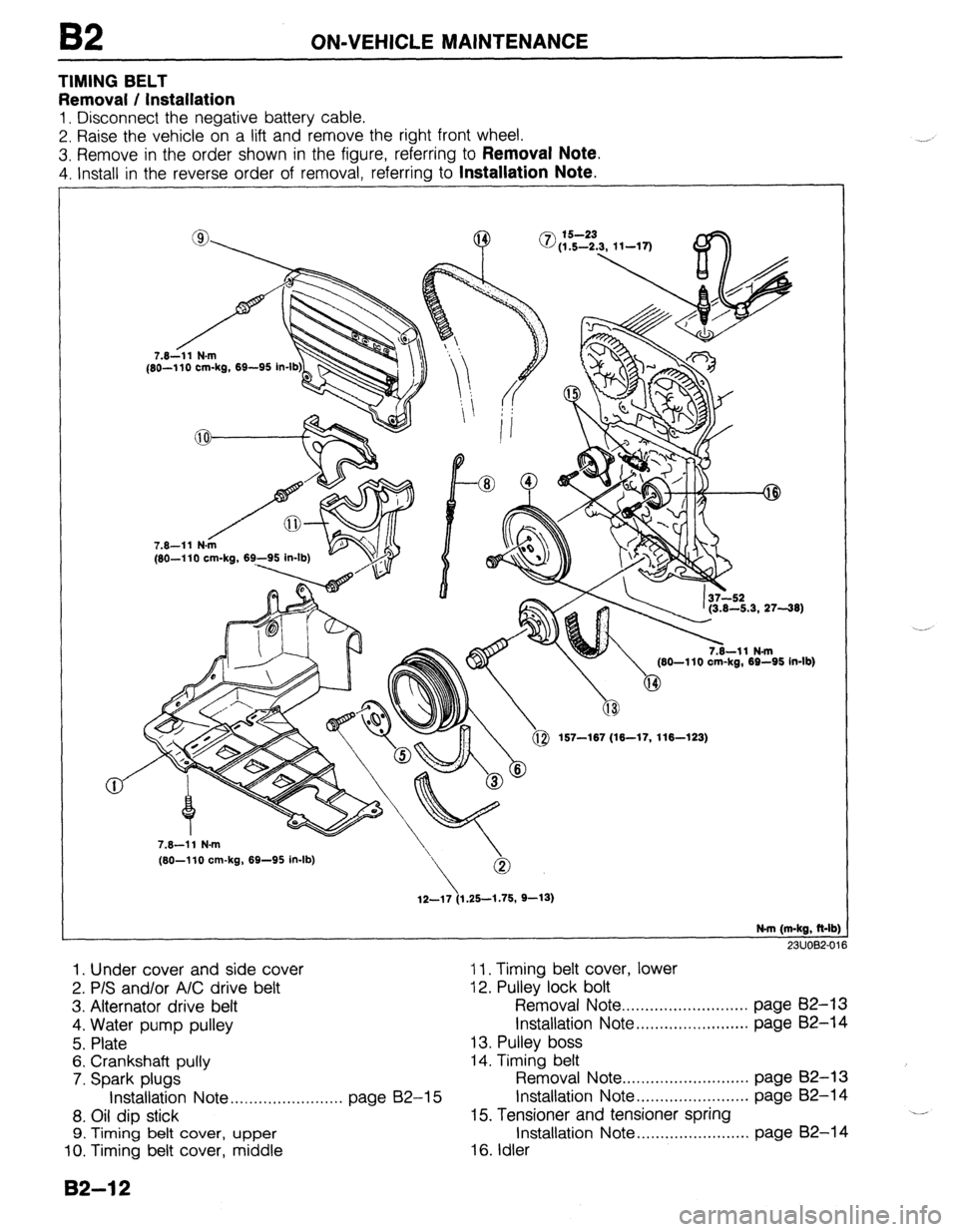

TIMING BELT

Removal / Installation

1. Disconnect the negative battery cable.

2. Raise the vehicle on a lift and remove the right front wheel.

3. Remove in the order shown in the figure, referring to

Removal Note.

4. Install in the reverse order of removal, referring to Installation Note.

/ 7.8-11 N.m

(80-l 10 Cm-kg, 69-95 in-lb

1p1\ ’ (3.8-6.3, 2738)

, (80-l 10 cm-kg, 69-95 in-lb)

167--187 (X-17, 116-123)

/ 7.8--11 N-m

(80-110 MI-kg,

7.8-11 N-m

\-

(80-110 Cm-kg, 69-95 in-lb)

12-17 (1.25-1.75, 9-13)

N-m (m-kg, &lb

23UOl32-0

1. Under cover and side cover 11. Timing belt cover, lower

2. P/S and/or A/C drive belt 12. Pulley lock bolt

3. Alternator drive belt Removal Note . . ..*..........*.*......... page 82-13

4. Water pump pulley Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-14

5. Plate 13. Pulley boss

6. Crankshaft pully 14. Timing belt

7. Spark plugs Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page 62-13

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 62-15 Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-14

8. Oil dip stick 15. Tensioner and tensioner spring ..l

9. Timing belt cover, upper Installation Note ..,..................... page B2-14

10. Timing belt cover, middle 16. Idler

B2-12

Page 145 of 1164

ON-VEHICLE MAINTENANCE B2

13EOBZ00

13EOB2-009

13EOB2.Ol (

13EOB2-01;

Removal Note

Pulley lock bolt

1. Hold the pulley boss with the SST.

2. Using the SST, loosen the pulley lock bolt.

3. Remove the bolt and the pulley boss.

Timing belt

1. Install the pulley boss and pulley lock bolt.

2. Turn the crankshaft to align the timing marks.

Note

l The pin on the pulley boss must face upward.

Cautlon

l After setting the marks, do not turn the crankshaft

when removing the pulley lock bolt and pulley boss.

Note

l Mark the timing belt rotation for proper reinstal-

lation.

Caution

l Protect the tensioner with a rag before prying on it.

3. Loosen the tensioner lock bolt and, using a suitable bar,

pry the tensioner outward (arrow).

4. Tighten the lock bolt with the tensioner spring fully extended.

5. Remove the timing belt.

B2-13

Page 146 of 1164

B2 ON-VEHICLE MAINTENANCE

13EOB2-031

OWOBX-02

0311082.023

13EOB2-013

82-l 4

13EOB2-01

Installation Note

Tensioner and tensioner spring

1. Install the tensioner and the tensioner spring.

Caution

l Protect the tensioner with a rag before prying on it.

2. Using a suitable bar, pry the tensioner outward (arrow).

3. Temporarily tighten the tensioner lock bolt with the tensioner

spring fully extended.

Timing belt

1. Verify that the timing belt pulley mark is aligned with the tim-

ing mark.

2. Verify that the camshaft pulley marks are aligned with the

seal plate marks.

3. Install the timing belt so that there is no looseness at the

idler side or between the camshaft pulleys.

4. Install the pulley boss and pulley lock bolt.

Caution

. Do not turn the crankshaft counterclockwise.

5. Turn the crankshaft two turns clockwise and face the pin

on the pulley boss upright.

6. Verify that the camshaft pulley marks are again aligned with

the seal plate marks.

If not aligned, remove the timing belt and repeat from ten-

sioner installation.

7. Turn the crankshaft 1 and 5/6 turns clockwise and align the

timing belt pulley mark with the tension set mark for proper

timing belt tension adjustment.

8. Using the

SST (49 DO1 1 102), loosen the pulley lock bolt

and remove the bolt and pulley boss.

Caution

l Do not turn the crankshaft. . .

9. Verify that the timing belt pulley mark is aligned with the ten-

sion set mark.

Page 147 of 1164

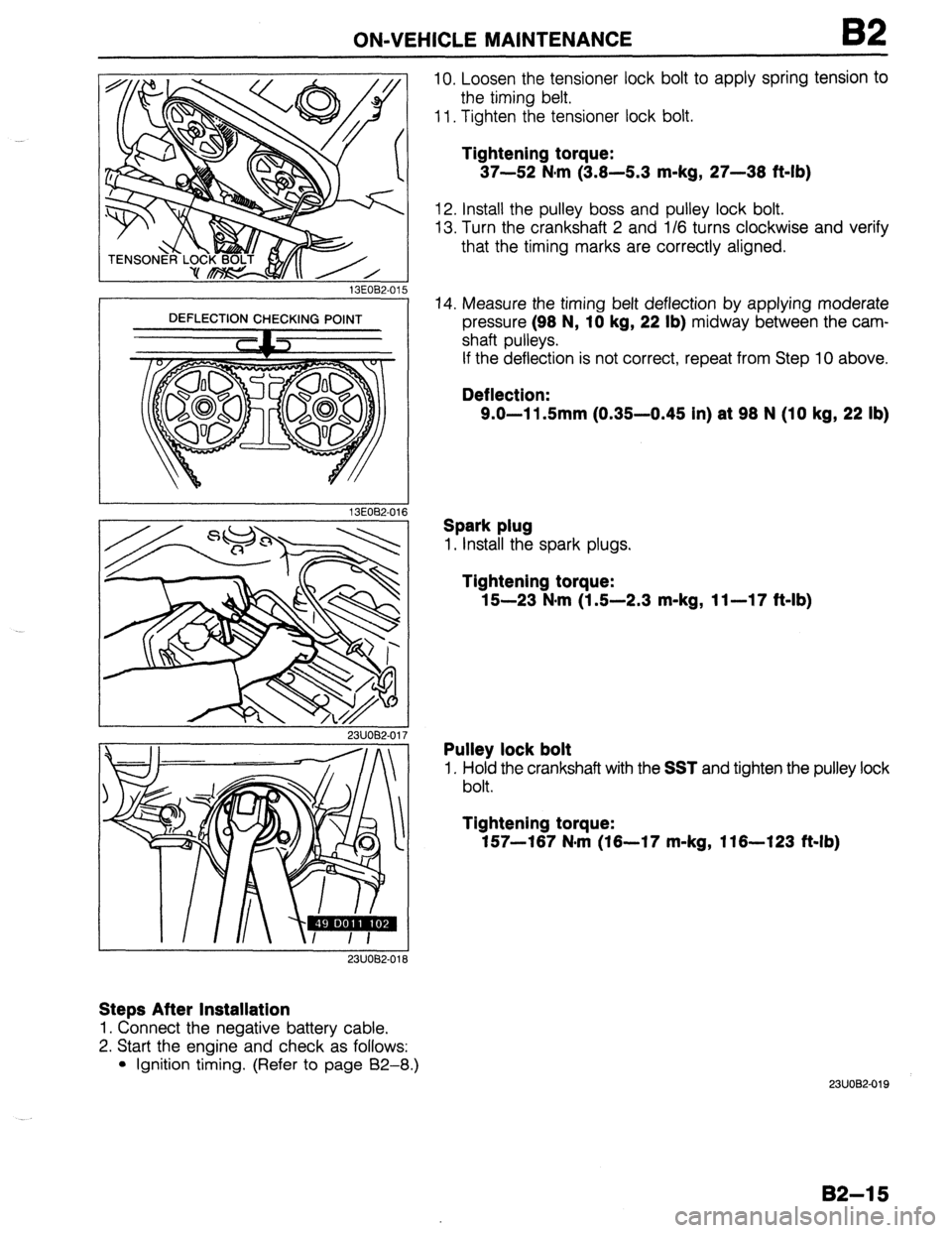

ON-VEHICLE MAINTENANCE

13EOB2-015

DEFLECTION CHECKING POINT

13EOE2-011

23UOB2-017

23UOB2-018

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page B2-8.) 10. Loosen the tensioner lock bolt to apply spring tension to

the timing belt.

11. Tighten the tensioner lock bolt.

Tightening torque:

37-52 Narn (3.8-5.3 m-kg, 27-38 ft-lb)

12. Install the pulley boss and pulley lock bolt.

13. Turn the crankshaft 2 and 116 turns clockwise and verify

that the timing marks are correctly aligned.

14. Measure the timing belt deflection by applying moderate

pressure (98 N,

10 kg, 22 lb) midway between the cam-

shaft pulleys.

If the deflection is not correct, repeat from Step 10 above.

Deflection:

9.0-11.5mm (0.35-0.45 In) at 98 N (10 kg, 22 lb)

Spark plug

1. Install the spark plugs.

Tightening torque:

15-23 Nern (1.5-2.3 m-kg, 11-17 ft-lb)

Pulley lock bolt

1, Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-187 N*rn (18-17 m-kg, 118-123 ft-lb)

23UOB2-019

82-l 5

Page 149 of 1164

ON-VEHICLE MAINTENANCE B2

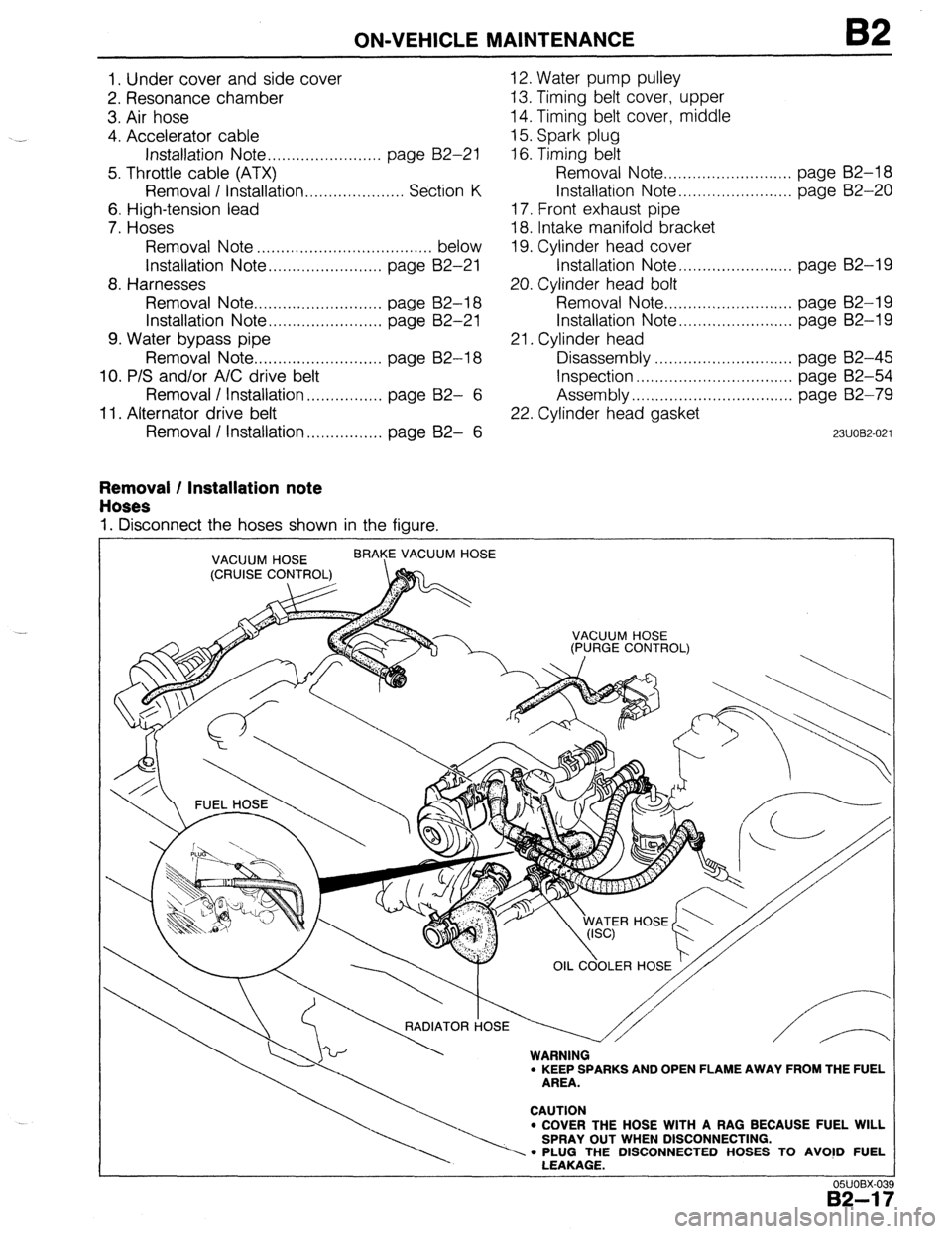

1. Under cover and side cover

2. Resonance chamber

3. Air hose

4. Accelerator cable

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-21

5. Throttle cable (ATX)

Removal I Installation . . . . . . . . . . . . . . . . . . . . . Section K

6. High-tension lead

7. Hoses

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . below

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 82-21

8. Harnesses

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-18

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 82-21

9. Water bypass pipe

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-18

10. P/S and/or A/C drive belt

Removal / Installation . . . . . . . . . . . . . . . . page B2- 6

11. Alternator drive belt

Removal / Installation . . . . . . . . . . . . . . . . page B2- 6 12. Water pump pulley

13. Timing belt cover, upper

14. Timing belt cover, middle

15. Spark plug

16. Timing belt

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page 82-l 8

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-20

17. Front exhaust pipe

18. Intake manifold bracket

19. Cylinder head cover

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page 82-19

20. Cylinder head bolt

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-19

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page B2-19

21. Cylinder head

Disassembly . . . . . . . . . . . , . . . . . . . . . . . . . page B2-45

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page B2-54

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 82-79

22. Cylinder head gasket

23UOB2-021

Removal / Installation note

Hoses

1. Disconnect the hoses shown in the figure.

VACUUM HOSE BRAYE VACUUM HOSE

‘-;:I::------. CAUT’oN

l COVER THE HOSE WITH A RAG BECAUSE FUEL WILL

SPRAY OUT WHEN DISCONNECTING.

- PLUG THE DISCONNECTED HOSES TO AVO!D FUEL

LEAKAGE.

OWOBX-03

82-l i

Page 150 of 1164

B2 ON-VEHICLE MAINTENANCE

Harnesses

1, Disconnect the harness connectors shown in the figure.

.~

DISTRBUTOR

GRqUND

B2-18

Water bypass pipe

1. Remove the transaxle installation bolt as shown in the figure.

2. Remove the exhaust manifold nut as shown in the figure.

3. Remove the water bypass pipe from the cylinder head as-

sembly.

Timing belt

Note

l Remove all spark plugs for easier rotation of the

crankshaft.

1. Turn the crankshaft and align the marks.