MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 571 of 1164

TRANSAXLE 52

I I

13UOJ2.006

03UOJ2-114

, 03UOJ2-115

BE Tt

03UOJ2-047

03UOJ2-04 6

4. Measure the clearance between hub sleeve and shift fork.

Clearance mm (in)

I I Standard

I Maximum

I

I l&end I 0.08-0.228 (0.003-0.009~ I 0.728 (0.029) I

3rd14th 0.1 O-0.500 (0.004-0.020) 1.000 (0.039)

5thlRev. 0.15-0.458 (0.059-0.018) 0.958 (0.038)

Reverse idler gear and reverse lever

1. Inspect gear teeth for damage, wear, and cracks.

2. Measure the clearance between the reverse idler gear bush-

ing and the reverse lever.

Standard clearance:

0.1 O-0.32mm (0.004-0.013 In)

Maximum: 0.5mm (0.020 in)

Bearing

1. Inspect for damage and rough rotation.

Primary Shaft and Secondary Shaft

1. Inspect the gear contact surface for damage and wear.

2. Inspect the splines for damage and wear.

3. Inspect the gear teeth for damage, wear, and cracks.

4. Inspect the oil passage for clogging.

5. Inspect the shaft gears’ runout.

Primary shaft gear runout: 0.05mm (0.002 in)

Secondary shaft gear runout: 0.015mm (0.0006 in)

Note

l If the shaft gear is replaced, adjust the bearing

preload. (Refer to page J2-32.)

J2-23

Page 572 of 1164

J2 TRANSAXLE

4TH

3RD

23UOJ2-015

2ND 1ST

03UOJ2-049

6. Oil clearance between shaft gears and gears.

Oil Clearance

Shaft Gear Sleeve

(Outer dia.) (inner dia.) (Outer dia.) Oil 'learanCe

1st 39.445-39.470 39.500-39.525 _

(1.553-1.554) (1.555-1.556)

2nd 34.945-34.970 35.000-35.025 _

(1.376-1.377) (1.378-1.379)

3rd 35.945-35.970 36.000-36.025 0.03-0.08

_

(1.415-1.416) (1.417-1.418) (0.001-0.003)

4th 30.945-30.970 31.000-31.025 _

(1.218-1.219) (1.220-1.221)

34.000-34.025

33.945-33.970

1 5th

-

(1.339-1.340) (1.336-1.337)

/

Speedometer Driven Gear Assembly

1. Inspect the teeth for damage and wear.

2. inspect the O-ring for damage and wear. mm (in)

_......

52-24

Page 573 of 1164

TRANSAXLE J2

MEMO

52-25

Page 574 of 1164

J2 TRANSAXLE

ASSEMBLY

Precaution

1. All O-rings and gaskets must be replaced with the new ones included in the overhaul kit.

2. The bearing outer race and bearing inner race must be replaced as a unit.

3. Before assembly, make sure all parts are completely clean.

4. Assemble the parts within 10 minutes after applying sealant, Allow all sealant to cure at least 30 minutes

after assembly before filling the transaxle with transaxle oil.

Primary Shaft Assembly and Secondary Shaft Assembly

1. Assemble in the order shown in the figure, referring to Assembly Note.

1

1

OIL GROOVE

(FOUR PLACESj==z

L

J2-26

Page 575 of 1164

TRANSAXLE J2

1. Clutch hub

Assembly Note ,......................... page J2-27

2. Synchronizer key

3. Clutch hub sleeve

4. Synchronizer spring

5. Clutch hub

Assembly Note ,......................... page J2-27

6. Synchronizer key

7. Clutch hub sleeve (reverse gear)

8. Synchronizer spring

9. Primary shaft

10. Bearing inner race

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-28

11. 3rd gear

Assembly Note.. . . . . . . . . . . . . . . . . . . . page J2-28

12. Synchronizer ring (3rd)

Assembly Note.. . . . . . . . . . . . . . . . . . . page J2-28

13. Clutch hub assembly (3rd14th)

Assembly Note.. . . . . . . . . . . . . . . . . . . . page J2-28

14. Retaining ring

15. Synchronizer ring (4th)

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-28

16. 4th gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . .

page J2-28

17. Bearing inner race

Assembly Note.. . . . . . . . . . . . . . . . . . page J2-28

18. Secondary shaft

19. Bearing inner race

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . page J2-29 20. 1st gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-29

21. Synchronizer ring (1 st)

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . .

page J2-29

22. Clutch hub assembly (IstMnd)

Assembly Note ,,..........,............. page J2-29

23. Retaining ring

24. Synchronizer ring (2nd)

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-29

25.2nd gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-29

26. Secondary 3rd gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . .

page J2-29

27. Retaining ring

28. Secondary 4th gear

Assembly Note ,.,............,....,..... page J2-30

29. Bearing inner race

Assembly Note. . . . . . . . . . . . . . . . . . page J2-30

30. Control rod

31. Control lever

32. Roll pin

33. lst/2nd shift fork

34. Control end

35. Roll pin

36. Interlock sleeve

Assembly Note.. . . . . . . . . . . . . . . . page J2-30

37. 3rd/4th shift fork

03UOJ2 051

___-__ 03UOJ2-11

Assembly note

Clutch hub

Note

l Synchronizer key dimensions are as follows.

mm (in)

(l-1

12) 1\3>

_--

1stMnd 19 (0.7480) 4.25 (0.1673) -5.00 (0.1969)

3rdl4th

SthlRev. 17 (0.6693) 4.25 (0.1673) 5.00 (0.1969)

1. Install the synchronizer key springs in the clutch hub with

the hooks in the grooves to hold the three synchronizer keys

in place.

03UOJ2-052

J2-27

Page 576 of 1164

J2 TRANSAXLE

I

23UOJ2-OC

W-W i

W-U

(REVERSE)

I 03UOJ2-054

(FOUR PLACES)!

23UOJ2-00

r

1

03UOJ2-O!

52-m

7

1 57

Bearing inner race (primary shaft end)

1. install the new bearing inner race with the SST.

3rd gear, synchronizer ring (3rd) and clutch hub

assembly (3rd/4th)

Note

l The size of the lst, 2nd, 3rd, and 4th synchronizer

rings are the same. Be careful when installing them.

The 2nd ring has the larger cut-out as shown in the

illustration.

l Align the synchronizer ring groove and clutch hous-

ing hub key when installing.

1, Install the 3rd gear, synchronizer ring (3rd), and clutch hub

assembly (3rd/4th) with the

SST.

Synchronizer ring (4th), 4th gear and bearing inner race

1. Install the synchronizer ring (4th), 4th gear, and bearing in-

ner race with the

SST.

2. Measure the clearance between the 3rd gear and 2nd gear.

Clearance: 0.05-0.20mm (0.002-0.008 in)

Maximum : 0.25mm (0.010 in)

Page 577 of 1164

TRANSAXLE J2

13UOJ2-006

I 03UOJ2-06f

23UOJ2.011

3. Measure the clearance between the 4th gear and bearing

inner race.

Clearance: 0.165-0.365mm (0.0065-0.0144 in)

Maximum : 0.415mm (0.0163 in)

4. If not as specified, reassemble the primary shaft assembly.

Bearing inner race (secondary shaft end)

1. Install the new bearing inner race with the SST.

1st gear, synchronizer ring (1st) and clutch hub

assembly (1 st/2nd)

Note

l Align the synchronizer ring, groove and clutch hous-

ing hub key when installing.

1. Assemble the 1 st gear, synchronizer ring (1 St), and clutch

hub assembly (lst/2nd), as shown in the figure.

2. Press the clutch hub assembly (1 st/2nd) on with the

SST.

Synchronizer ring (2nd), 2nd gear and secondary 3rd

gear

1. Install the synchronizer ring (2nd) and 2nd gear.

2. Install the secondary 3rd gear with the

SST.

23UOJ2-011

J2-29

Page 578 of 1164

J2 TRANSAXLE

03UOJ2-06 3

r

03UOJ2-068 ‘4

03UOJ2-06

03UOJ2-Of

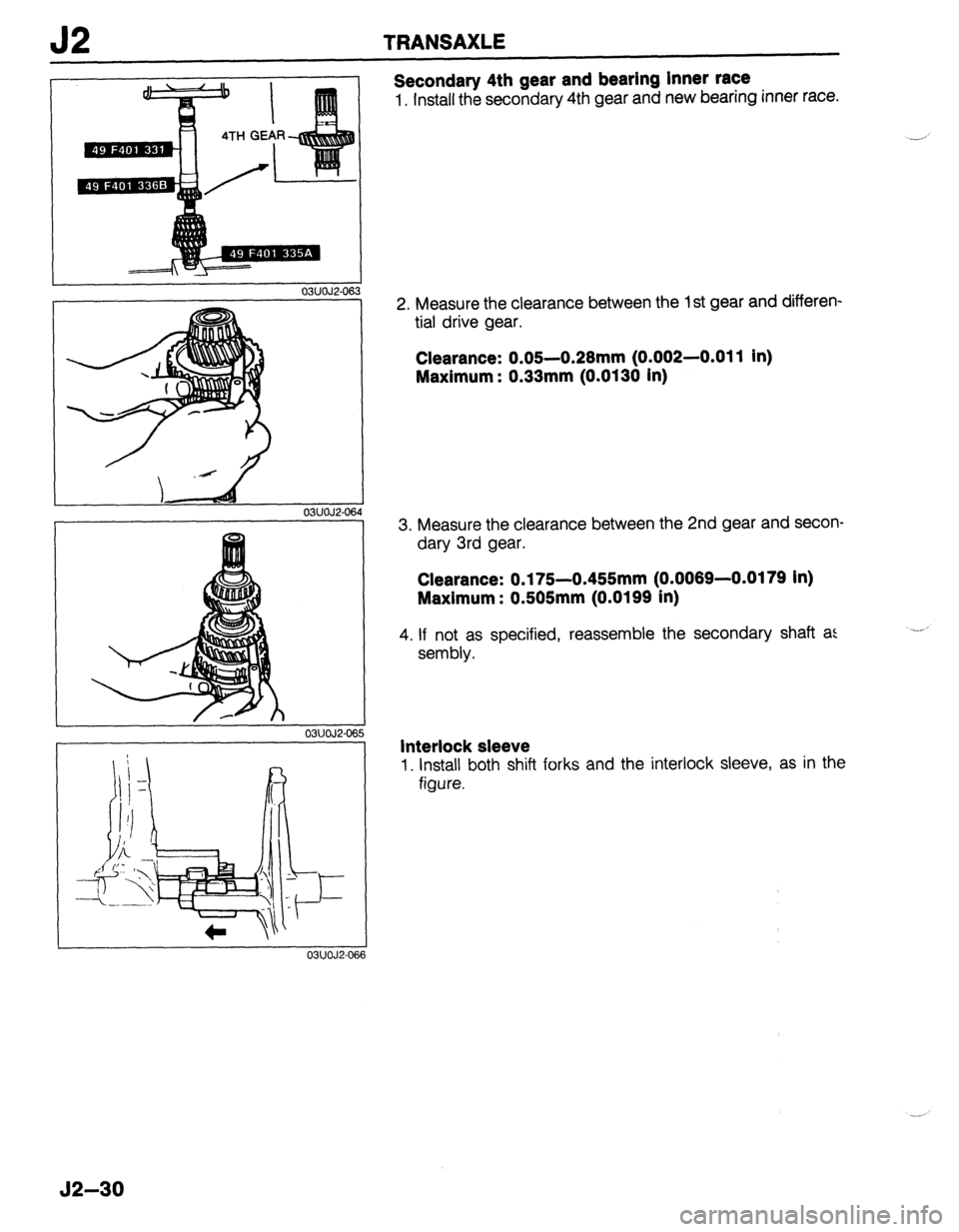

Secondary 4th gear and bearing Inner race

1. Install the secondary 4th gear and new bearing inner race.

2. Measure the clearance between the 1 st gear and differen-

tial drive gear.

Clearance: 0.05-0.28mm (0.002-0.011 In)

Maximum: 0.33mm (0.0130 in)

3. Measure the clearance between the 2nd gear and secon-

dary 3rd gear.

Clearance: 0.175-0.455mm (0.0089-0.0179 in)

Maximum: 0.505mm (0.0199 in)

4. If not as specified, reassemble the secondary shaft at

sembly. -’

Interlock sleeve

1. Install both shift forks and the interlock sleeve, as in the

figure.

J2-30

Page 579 of 1164

TRANSAXLE J2

Clutch Housing and Transaxle Case Components

1. Select the adjust shim(s), referring to Bearing Preload Adjustment.

2. Assemble in the order shown in the figure, referring to Assembly Note.

3. Verify that the bearing preload is satisfied after assembly, referring to Bearing Preload.

-s

APPLY SPECIFIED OIL TO INDIVIDUAL PARTS EXCEPT SWITCHES

&II N.m (SO-110 cm-kg, SO-95 In-lb)

20-29

P-3,

@NEW=

O-RING, I

14-22) 11

R N.m (120-160 cm-kg,

104-l 39 in-lb)

A

=SELECTlVE ROLL PIN NE

(120-140 cm-kg,

SELECTIVE 20-29 (2-3, 14-22)

N.m (m-kg,

??I 1

1. Change rod 16. Oil seal

2. Joint

3. Oil passage

4. Back-up light switch

5. Oil seal

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-35

6. Adjust shim(s)

Bearing preload adjustment . . . . . page J2-32

Bearing preload . . . . . . . . . . . . . . . . . . . . . . . . page J2-36

7. Bearing outer race

8. Adjust shims

Bearing preload adjustment . . . . . page J2-32

Bearing preload . . . . . . . . . . . . . . . . . . . . . . . . page J2-36

9. Diaphragm springs

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-35 Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page J2-35

17. Gear case

18. Driven gear

19. Speedometer driven gear assembly

20. Bleeder

21. Bleeder cover assembly

22. Oil seal

23. Selector

24. Reverse gate

25. Spring

26. Boot

Assembly Note ,.,....................... page J2-35

27. Change rod assembly

28. Roll pin

10. Bearing outer races

11. Neutral switch and gasket

12. Drain plug and washer

13. Reverse lever

14. Reverse lever shaft

15. Bearing outer race 29. Change arm

30. Guide plate

31, Funnel

32. Bearing outer race

33. Oil seal

34. Bearing outer race

J2-31

Page 580 of 1164

TRANSAXLE

Bearing preload adjustment

Adjust the bearing preload by selecting adjust shim(s).

SST

TRANSAXLE CASE

CUTER RACES

PRIMARY SHAFT ASSEMBLY

iECONDARY SHAFT

rSSEMBLY

CLUTCH HOUSIN

SST USAGE

83U07A-03