MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 531 of 1164

TRANSAXLE Jl

Assembly note

Oil seal (Speedometer gear cace)

1. Install the new oil seal with a suitable pipe.

Pipe diameter: 15mm (0.591 in)

23UOJ I-00

03UOJl-IO

03UOJl-IO!

03UOJ1.10

Roll pin (Speedometer driven gear assembly)

1. Install the new roll pin as shown in the figure.

Oil seal (Differential)

Caution

l Apply transaxle oil to the outer circumference of the

oil seal.

1. Install the new oil seal with the SST.

Adjust shim and bearing outer race (Secondary shaft

gear)

Caution

l Use adjust shim(s) selected during bearing preload

adjustment.

l Apply transaxle oil to the bearing outer race.

1. Install the adjust shim(s) and the bearing outer race with

a suitable pipe.

Adjust shim and bearing outer race (Differential)

Caution

l Use adjust shim(s) selected during bearing preload

adjustment.

l Apply transaxle oil to the bearing outer race.

1, Install the adjust shim(s) and the bearing outer race with

a suitable pipe.

Jl-41

Page 532 of 1164

Jl TRANSAXLE

03UOJl-10

-

23UOJl.01

Adjust shim (Primary shaft gear)

Caution

l Use adjust shim(s) selected during bearing preload

adjustment.

1. Apply transaxle oil to the adjust shim(s) and install it.

Funnel and bearing outer race

Caution

l Apply transaxle oil to the bearing outer race.

1. Install the funnel and the bearing outer race.

Oil seal (Primary shaft gear)

Caution

* Apply transaxle oil to outer circumference of the oil

seal.

1. install the new oil seal with a suitable pipe.

Oil seal (Change rod)

Caution

l Apply transaxle oil to the oil seal lip.

1. Install the oil seal.

Boot and change rod assembly

Caution

l Install the boot with the air bleed downward as

shown in the figure.

1. Slide the boot onto the change rod assembly.

2. Install the change rod assembly into the clutch housing.

-,

Jl-42

Page 533 of 1164

TRANSAXLE Jl

MEMO

Jl-43

Page 534 of 1164

Jl TRANSAXLE

Sth/Reverse Gear and Housing Parts

1. Assemble in the order shown in the figure, referrina to Assembly Note.

@ 2Q-

(2.0. -25

-2.5, 14-W)

PACKING.

0

-d-25 ._-..

,.-

-- -- --.

,152)

r I ew-am (13-21, 94-152) cl.9

ROLL PIN: NEW

N.m (m-kg, it-lb)

fill w ‘. 1

u.wJJl-11

51-44

Page 535 of 1164

TRANSAXLE Jl

1. Control rod

2. Control end

3. lstl2nd shift fork

4. Control lever

5. Interlock sleeve

6.3rd/4th shift fork

7. Clutch hub

8. Synchronizer key

9. Clutch hub sleeve

10. Synchronizer spring

11. Clutch housing

12. Differential assembly

13. Secondary shaft gear assembly

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-45

14. Primary shaft gear assembly

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . , . page J 1-45

15. Spring

16. Steel ball

17. Shift fork and shift rod assembly

Assembly Note.. . . . . . . . . . . , . . . . . . . . . , . . , page J 1-45

18. Crank lever assembly

Assembly Note. . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-46

19. Crank lever shaft

Assembly Note.. . . . . . . . . . . , , . . . . . . . . . . . . page Jl -46

20. Pin

21. 5th shift rod end

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page 31-46

22. 5th shift rod

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page J 1-46

23. Reverse idler gear

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-46

24. Reverse idler shaft

Assembly Note... . . . . . . . . . . . . . . . . . . . . . . . page Jl -46

25 Magnet

26. Transaxle case assembly

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl -47

27. Neutral switch

28. Back-up light switch

29. Lock bolt and washer

30. Secondary 5th gear

31. Gear sleeve

32. 5th gear

33. Synchronizer ring (5th)

34. Clutch hub assembly (5th)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

35. 5th shift fork

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

36. Stop plate

37. Locknut (Secondary shaft)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page Jl-47

38. Locknut (Primary shaft)

Assembly Note.. . . . . . . . . . . . . . . . . . . . . . . . . page J 1-47

39. Rear cover

13UOJl-005

Assembly note

Primary shaft gear assembly and secondary shaft gear

assembly

1. Install the primary shaft gear assembly and the secondary

shaft gear assembly together.

03UOJl-115 Shift fork and shift rod assembly

1. Shift to 2nd gear and position the shift fork and shift rod

assembly as shown.

03UOJ2-088

51-45

Page 536 of 1164

Jl TRANSAXLE

I I 03UOJ2-089

03UOJ2-091 3

03UOJ2-09

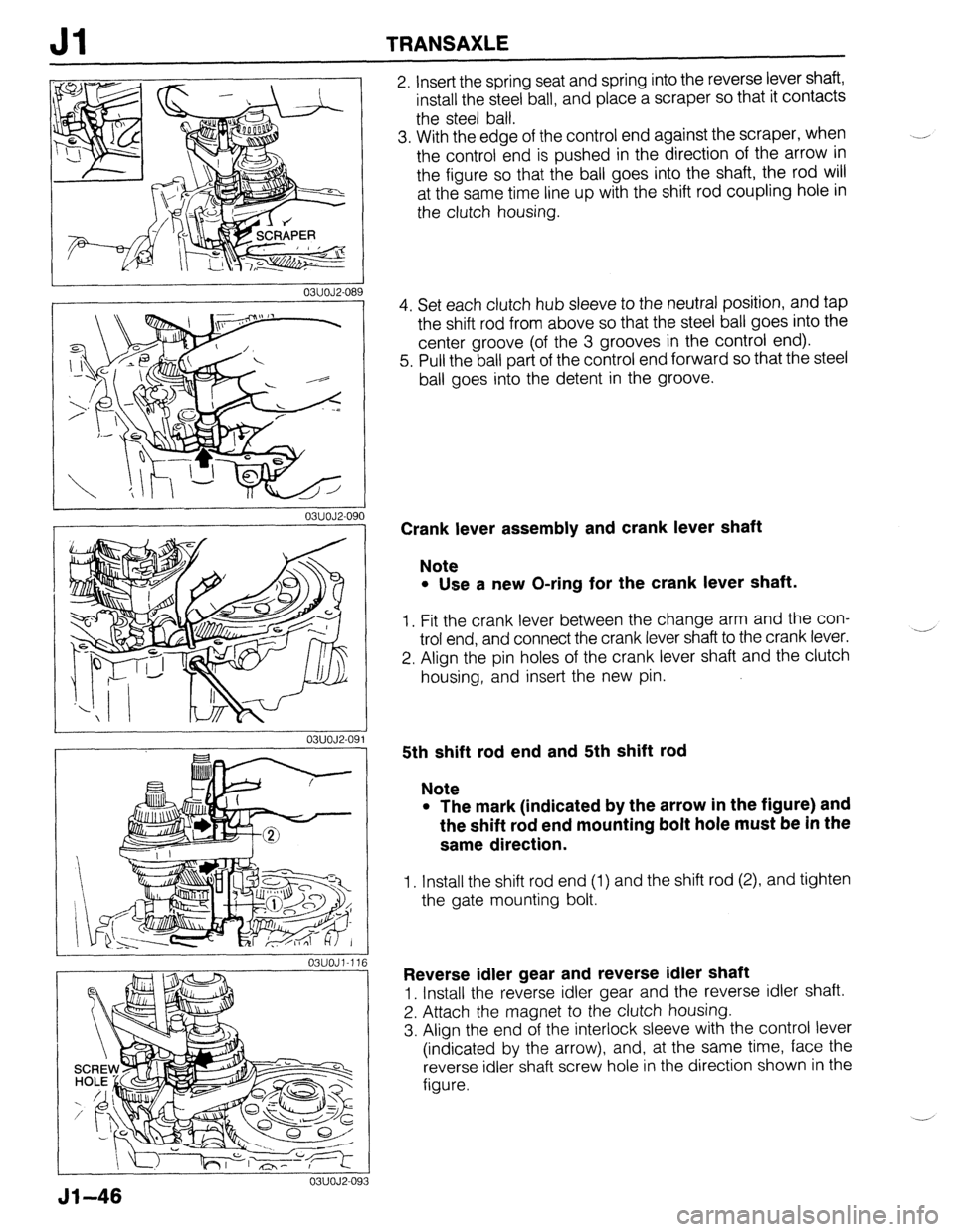

2. Insert the spring seat and spring into the reverse lever shaft,

install the steel ball, and place a scraper so that it contacts

the steel ball.

3. With the edge of the control end against the scraper, when

the control end is pushed in the direction of the arrow in

the figure so that the ball goes into the shaft, the rod will

at the same time line up with the shift rod coupling hole in

the clutch housing.

4. Set each clutch hub sleeve to the neutral position, and tap

the shift rod from above so that the steel ball goes into the

center groove (of the 3 grooves in the control end).

5. Pull the ball part of the control end forward so that the steel

ball goes into the detent in the groove.

Crank lever assembly and crank lever shaft

Note

l Use a new O-ring for the crank lever shaft.

1. Fit the crank lever between the change arm and the con-

trol end, and connect the crank lever shaft to the crank lever.

2. Align the pin holes of the crank lever shaft and the clutch

housing, and insert the new pin. -’

5th shift rod end and 5th shift rod

Note

l The mark (indicated by the arrow in the figure) and

the shift rod end mounting bolt hole must be in the

same direction.

1. Install the shift rod end (1) and the shift rod (2), and tighten

the gate mounting bolt.

Reverse idler gear and reverse idler shaft

1. Install the reverse idler gear and the reverse idler shaft.

2. Attach the magnet to the clutch housing.

3. Align the end of the interlock sleeve with the control lever

(indicated by the arrow), and, at the same time, face the

reverse idler shaft screw hole in the direction shown in the

figure.

Jl-46

Page 537 of 1164

TRANSAXLE Jl

- 23UOJl-01

03UOJl-11

03UOJl-14

I 03UOJl-11

Transaxle case assembly

1, Apply a thin coat of sealant to the contact surfaces of the

clutch housing and transaxle case, tighten the transaxle case

installation bolts to the specified torque.

Tightening torque:

19-26 Nom (1.9-2.6 m-kg, 14-19 ft-lb)

Clutch hub assembly (6th) and 6th shlft fork

1. Install the clutch hub assembly (5th) and the 5th shift fork

together.

Locknut

1. Shift to 1 st gear.

2. Lock the primary shaft with the

SST.

3. Tighten new locknuts on the primary and secondary shafts.

Tightening torque:

126-206 N*m (13.0-21 m-kg, 94-152 ft-lb)

4. Stake the locknuts.

5. Measure the 5th gear thrust clearance with a dial indicator.

Clearance: 0.06-0.26mm (0.0024-0.0102 in)

Maximum : 0.31 mm (0.0122 in)

6. If not as specified, reassemble the transaxle.

Jl-47

Page 538 of 1164

/ cm-kg, -26-52 In-lb)

(3.8-5.3, 27-M)

Jl TRANSAXLE

INSTALLATION

1. Raise the vehicle and support it with safety stands.

2 Install in the order shown in the figure, referring to Installation Note.

3’ Add the specified amount of the specified transaxle oil. (Refer to page Jl-7.)

4: Warm up the engine and transaxle, and inspect for oil leakage and transaxle operation.

2.4-5.S N.m (30-60

9

1 8-11 N-m

o-110 cm-kg,

* h-95 In-lb)

.O,

cc.

ft-I

03UOJl-119

b)

51-48

Page 539 of 1164

TRANSAXLE Jl

1. Transaxle

Installation Note ..,......,.............. page Jl-49

2. Engine mount No.4

3. Driveshaft

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

4. Stabilizer (BP SOHC)

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

5. Tie-rod end

Installation Note ,........,..,........... page Jl-50

6. Clutch release cylinder

7. Engine mount No.2

8. Exhaust pipe

9. Engine mounting member

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-50

10. Control rod

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51 11. Extension bar

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51

1 12. Starter

13. Ground

Installation Note .,..,...,......,........ page Jl-5

14. Neutral switch connector

15. Back-up light switch connector

16. Speedometer cable

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-5

17. Battery carrier

18. Battery

19. Air hose and resonance chamber

20. Splash shield

21. Wheel and tire 1

Installation Note

Transaxle

1. Set the transaxle on a jack and lift it into place.

Install tne transaxle oorts.

Tightening torque:

64-69 N*rn (6.5-9.1 m-kg, 47-66 ft-lb)

Loosely tighten engine mount No.4 bolts.

Jl-49

Page 540 of 1164

03UOJi-12 3

03UOJl-124

L 03UOJl.126 I-

03UOJl-12

Jl TRANSAXLE

Driveshaft

Caution

l Verify that the oil seal is not damaged.

l Do not damage the oil seal

1. Insert the clip with the end-gap at the top of the groove.

2. Apply transaxle oil around the oil seal lip. Install the

driveshaft.

3. Verify that the driveshaft is correctly seated by pulling on

the shaft.

4. Connect the lower arm to the knuckle and tighten the clinch

bolt.

Tightening torque:

43-59 N-m (4.4-6.0 m-kg, 32-43 ft-lb)

Stabilizer (BP SOHC)

1. Tighten the nut until the specified amount of thread is ex-

posed at the end of the bolt.

Dimension A: 17-l 9mm (0.67-0.75 in)

Tie-rod end

1. Install the locknut.

Tightening torque:

42-57 N-m (4.3-5.6 m-kg, 31-42 ft-lb)

2. Secure the locknut with a new cotter pin.

Engine mounting member

1. Install the bolts and nuts as shown.

Tightening torque

@ : 37-52 N,m (3.6-5.3 m-kg, 27-36 ft-lb)

@I: 64-89 N-m (6.5-9.1 m-kg, 47-66 ft-lb)

51-50