sensor MAZDA PROTEGE 1992 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 435 of 1164

CONTROL SYSTEM F

03UOFX-22

RESISTANCE

WI

THROTTLE VALVE

OPENING ANGLE

FULLY bPEN

03UOFX-22

03UOFX-2i

THROTTLE SENSOR

Inspection (MTX)

1. Disconnect the connector from the throttle sensor.

2. Connect an ohmmeter to the throttle sensor.

3. Insert a feeler gauge between the throttle stop screw and

the stop lever and check the continuity between terminals.

Feeler gauge Continuity between terminals

IDL - E

1 POW * E

O.lmm (0.004 in)

1 .Omm (0.039 in)

Wide-open throttle Yes

No

No No

No

Yes

Inspection (ATX)

1. Disconnect the connector from the throttle sensor.

2. Connect an ohmmeter between the throttle sensor termi-

nals E and IDL.

3. Insert a feeler gauge between the throttle stop screw and

the stop lever.

4. Check the continuity between terminals.

Feeler gauge

0.1 mm (0.004 in)

0.6mm (0.024 in) Continuity

Yes

No

5. Connect an ohmmeter to the throttle sensor terminal VT

and E.

6. Verify that the resistance increases lineally according to throt-

tle valve opening angle.

Throttle valve condition Resistance (W)

Fully closed Below 1

Fully open Approx. 5

Adjustment (MTX)

1. Disconnect the connector from the throttle sensor.

2. Connect an ohmmeter to the throttle sensor terminals IDL

and E.

3. Insert a 0.4mm (0.016 In) feeler gauge between the throt-

tle stop screw and the stop lever.

F-l 69

Page 436 of 1164

F CONTROL SYSTEM

0.7mm (0

GAUGE

1 SUOFX-10 3 03UOFX-235

03UOFX.22 5 IDL

E

03UOFX-22t 5

4. Loosen the two attaching screws.

5. Rotate the throttle sensor clockwise

approx. 30 degrees,

then rotate it back counterclockwise until the continuity

exists.

6. Replace the feeler gauge with a

0.7mm (0.027 in) gauge.

7. Verify that the continuity does not exist.

8. If it exists, repeat Steps 3 through 6. ‘-

9. Tighten the two attaching screws.

Note

l Do not move the throttle sensor from the set posi-

tion when tightening the screws.

10. Open the throttle valve fully a few times.

11. Recheck the adjustment of the throttle sensor.

Adjustment (ATX)

1. Disconnect the connector from the throttle sensor.

2. Connect an ohmmeter between the throttle sensor termi-

nals E and IDL.

3. Loosen the two attaching screws.

4. Insert a

0.25mm (0.01 in) feeler gauge between the throt-

tle stop screw and the stop lever.

5. Rotate the throttle sensor clockwise

approx. 30 degrees,

then rotate it back counterclockwise until there is continuity. i-

6. Replace the feeler gauge with a

0.4mm (0.016 in) gauge

and verify that there is no continuity.

7. If there is continuity, repeat Steps 4 through 6.

8. Tighten the two attaching screws.

Note

l Do not move the throttle sensor from the set posi-

tion when tightening the screws.

9. Open the throttle valve fully and verify that the resistance

between the throttle sensor terminals E and VT is

approx.

5 kQ.

F-l 70

Page 437 of 1164

CONTROL SYSTEM F

03UOFX-227

03UOFX-22:

03UOFX-22!

*

03UOFX-231

I

SELF-W CtECXER

WOFX-15

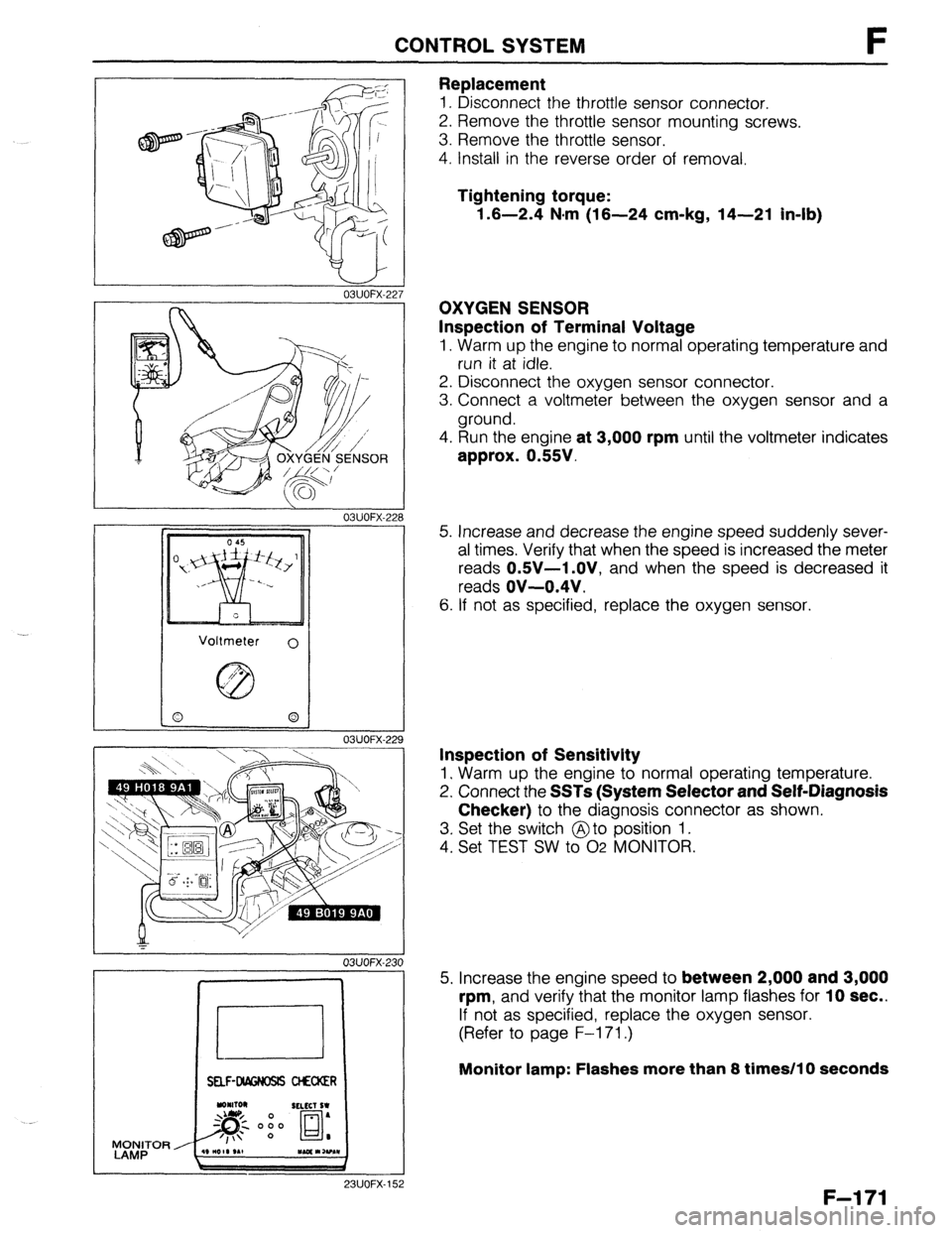

Replacement

1. Disconnect the throttle sensor connector.

2. Remove the throttle sensor mounting screws.

3. Remove the throttle sensor.

4. Install in the reverse order of removal.

Tightening torque:

1.6-2.4 N-m (16-24 cm-kg, 14-21 in-lb)

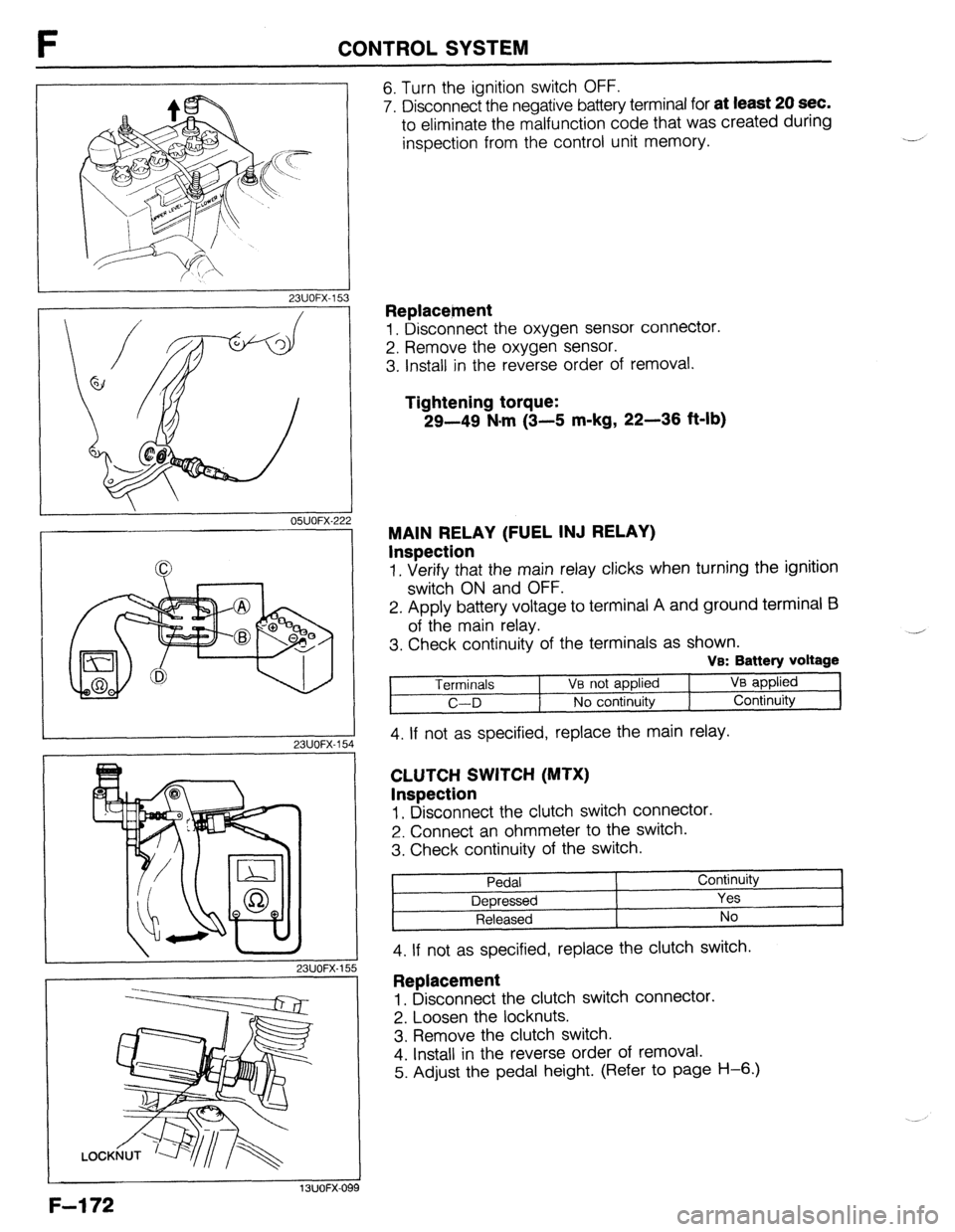

OXYGEN SENSOR

Inspection of Terminal Voltage

1. Warm up the engine to normal operating temperature and

run it at idle.

2. Disconnect the oxygen sensor connector.

3. Connect a voltmeter between the oxygen sensor and a

ground.

4. Run the engine

at 3,000 rpm until the voltmeter indicates

approx. 0.55V.

5. Increase and decrease the engine speed suddenly sever-

al times. Verify that when the speed is increased the meter

reads

OSV-1 .OV, and when the speed is decreased it

reads

OV-0.4V.

6. If not as specified, replace the oxygen sensor.

Inspection of Sensitivity

1. Warm up the engine to normal operating temperature.

2. Connect the

SSTs (System Selector and Self-Diagnosis

Checker)

to the diagnosis connector as shown.

3. Set the switch @to position 1.

4. Set TEST SW to 02 MONITOR.

5. Increase the engine speed to

between 2,000 and 3,000

rpm,

and verify that the monitor lamp flashes for 10 sec..

If not as specified, replace the oxygen sensor.

(Refer to page F-l 71.)

Monitor lamp: Flashes more than 8 times/l 0 seconds

F-l 71

Page 438 of 1164

F CONTROL SYSTEM

23UOFX-15

23UOFX-15

23UOFX-15

LOCK

4

I

13UOFX-oc

F-l 72

6. Turn the ignition switch OFF.

7. Disconnect the negative battery terminal for

at least 20 sec.

to eliminate the malfunction code that was created during

inspection from the control unit memory.

Replacetnent

1. Disconnect the oxygen sensor connector.

2. Remove the oxygen sensor.

3. Install in the reverse order of removal.

Tightening torque:

29-49 N-m (3-5 m-kg, 22-36 ft-lb)

MAIN RELAY (FUEL INJ RELAY)

Inspection

1. Verify that the main relay clicks when turning the ignition

switch ON and OFF.

2. Apply battery voltage to terminal A and ground terminal E3

of the main relay.

3. Check continuity of the terminals as shown.

VB: Battery voltage

Terminals 1 Ve not applied VB applied

C-D No continuity Continuity

4. If not as specified, replace the main relay.

CLUTCH SWITCH (MTX)

Inspection

1, Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed Yes

Released No

4. If not as specified, replace the clutch switch. ,

Replacement

1. Disconnect the clutch switch connector.

2. Loosen the locknuts.

3. Remove the clutch switch.

4. Install in the reverse order of removal.

5. Adjust the pedal height. (Refer to page H-6.)

Page 462 of 1164

\jl IGNITION SYSTEM

1.6-3.0 N.m

(16-30 cm-Fg,

14-26 in-lb)

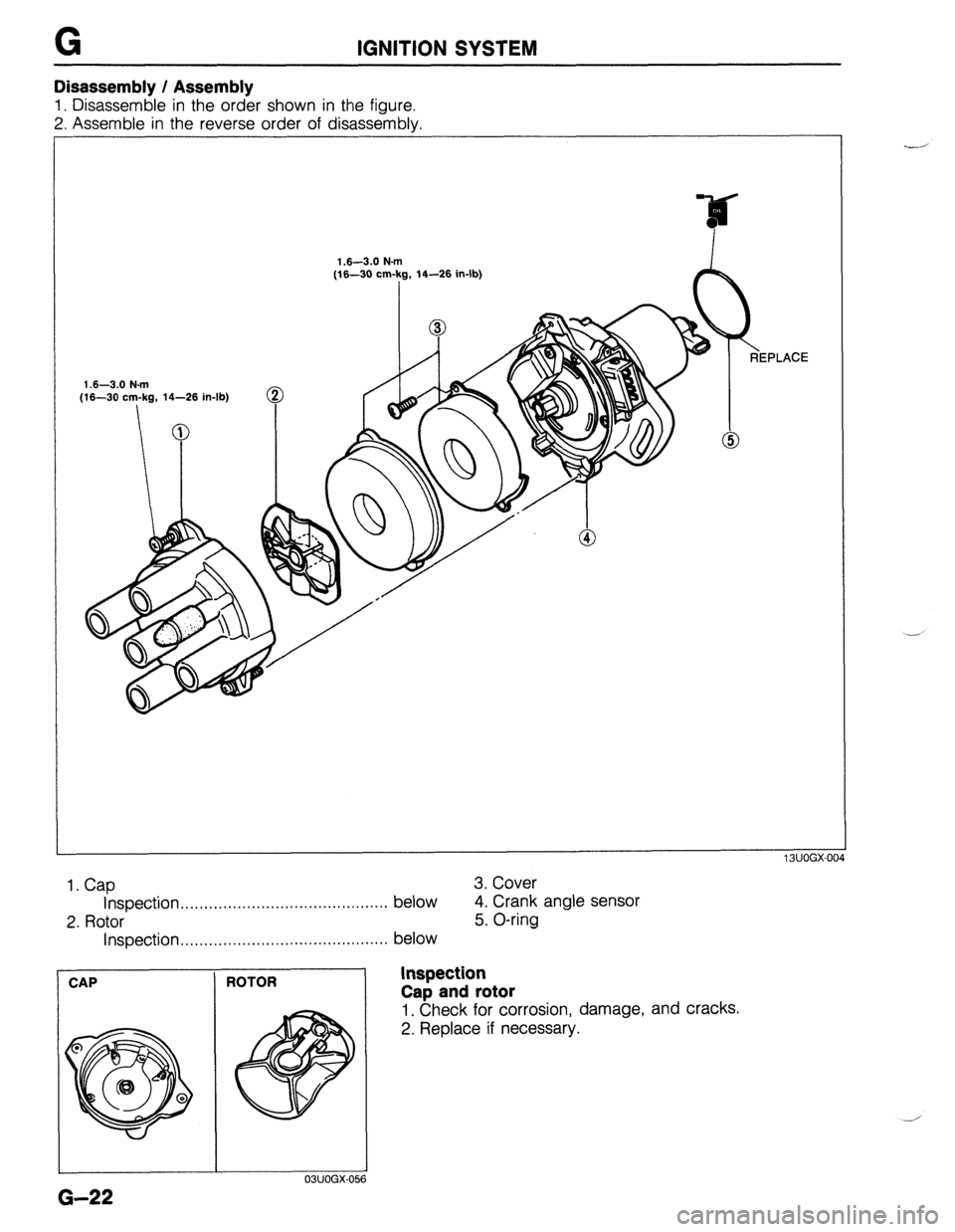

Disassembly / Assembly

1. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

1 BUOGX-00.

1. Cap

3. Cover

Inspection . . . . . . . . . . . . . . . . . . . . . . . ..*..................

below 4. Crank angle sensor

2. Rotor

5. O-ring

Inspection .,..........................................

below

CAP

G-22

I

ROTOR

I 03UOGX.051 ?

REPLACE

Inspection

Cap and rotor

1. Check for corrosion, damage, and cracks.

2. Replace if necessary.

Page 669 of 1164

OUTLINE

OUTLINE

SPECIFICATIONS

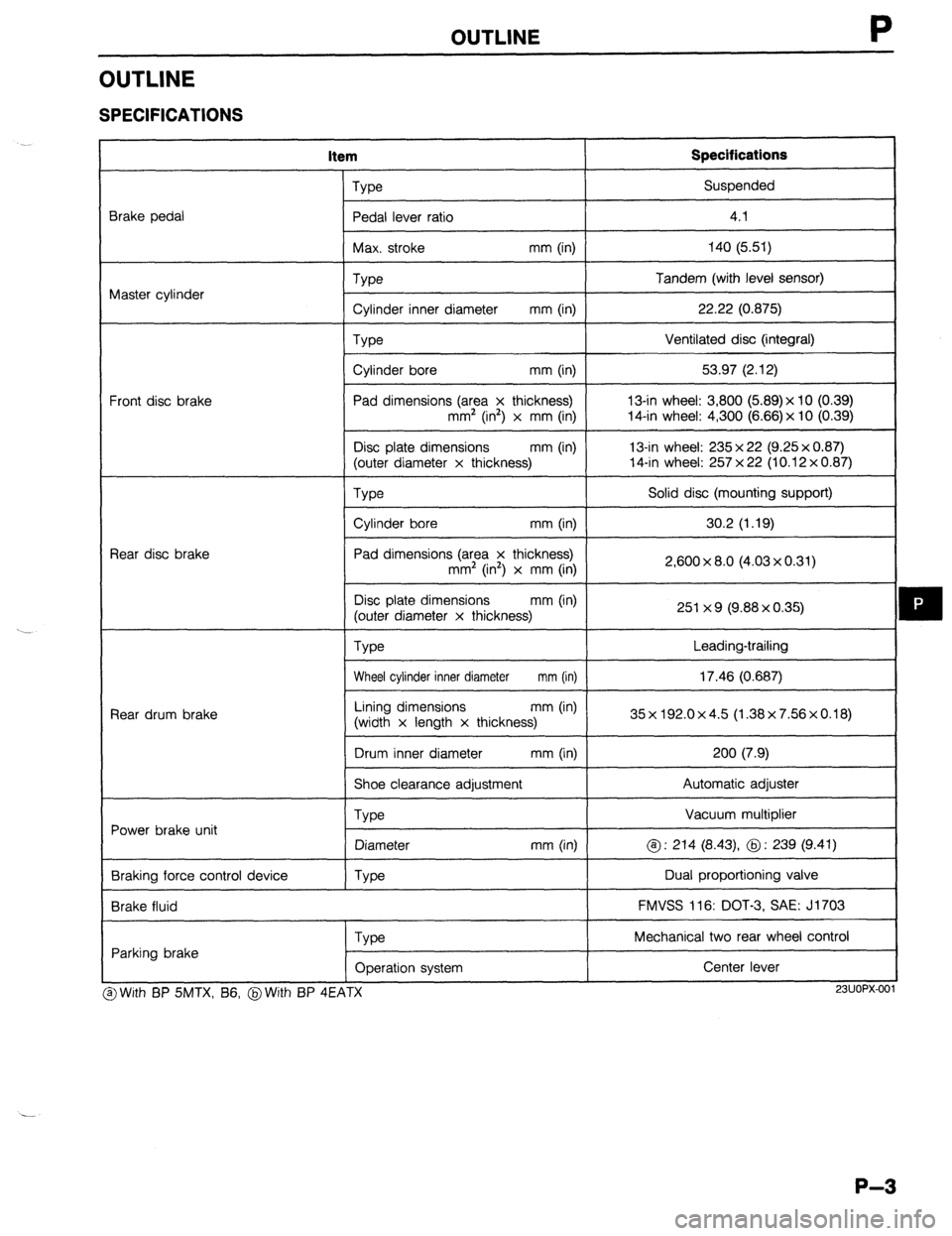

item Specifications

Brake pedal

Master cylinder

Front disc brake

Rear disc brake

Rear drum brake

Power brake unit

Braking force control device

Brake fluid Type Suspended

Pedal lever ratio

I 4.1

I

Max. stroke mm (in) 140 (5.51)

I

Type

Cylinder inner diameter mm (in)

Type

Cylinder bore mm (in)

Pad dimensions (area x thickness)

mm’ (in2) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness) Tandem (with level sensor)

22.22 (0.875)

Ventilated disc (integral)

53.97 (2.12)

13-in wheel: 3,800 (5.89)x 10 (0.39)

14-in wheel: 4,300 (6.66) x 10 (0.39)

13-in wheel: 235 x 22 (9.25 x 0.87)

14-in wheel: 257 x 22 (10.12 x 0.87)

We

I Solid disc (mounting support)

I

Cylinder bore mm (in)

I 30.2 (1.19)

I

Pad dimensions (area x thickness)

mm2 (in’) x mm (in)

Disc plate dimensions mm (in)

(outer diameter x thickness)

Type 2,600 x 8.0 (4.03 x 0.31)

251 x 9 (9.88 x 0.35)

Leading-trailing

Wheel cylinder inner diameter mm (in) 17.46 (0.687)

I

Lining dimensions mm (in)

(width x length x thickness) 35x192.0x4.5 (1.38x7.56x0.18)

I

Drum inner diameter mm (in) 200 (7.9)

I

Shoe clearance adjustment Automatic adjuster

Vacuum multiplier

@ : 214 (8.43) @ : 239 (9.41)

Dual proportioning valve

FMVSS 116: DOT-3, SAE: J1703

Type

Diameter

Type mm (in)

Parking brake

Type

Operation system Mechanical two rear wheel control

Center lever I

3 With BP SMTX, B6, @With BP 4EATX

I I

23UOPX-001

P-3

Page 678 of 1164

P CONVENTIONAL BRAKE SYSTEM

Disassembly / Assembly / Inspection

1. After removing the brake fluid, disassemble in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

Caution

l Secure the master cylinder flange in a vise when necessary.

l Replace the piston assembly, if necessary.

l Do not let foreign material enter the cylinder, and do not scratch the inside of the cylinder

or the outer surface of the piston.

REP1 .ACE

0.98-1.47 (10-15, 8.7-13.0)

o R,NG ,,,dcE @.96-2.45 (20-25, 17.4-21.7)

- 3

N.m (cm-kg, in-lb)

1. Reservoir cap assembly 5. Bushing 9. Primary piston assembly

2. Float 6. Stopper screw 10. Secondary piston assembly

3. Screw 7. Fluid level sensor 11. Master cylinder body

4. Reservoir 8. Snap ring

P-12

Page 737 of 1164

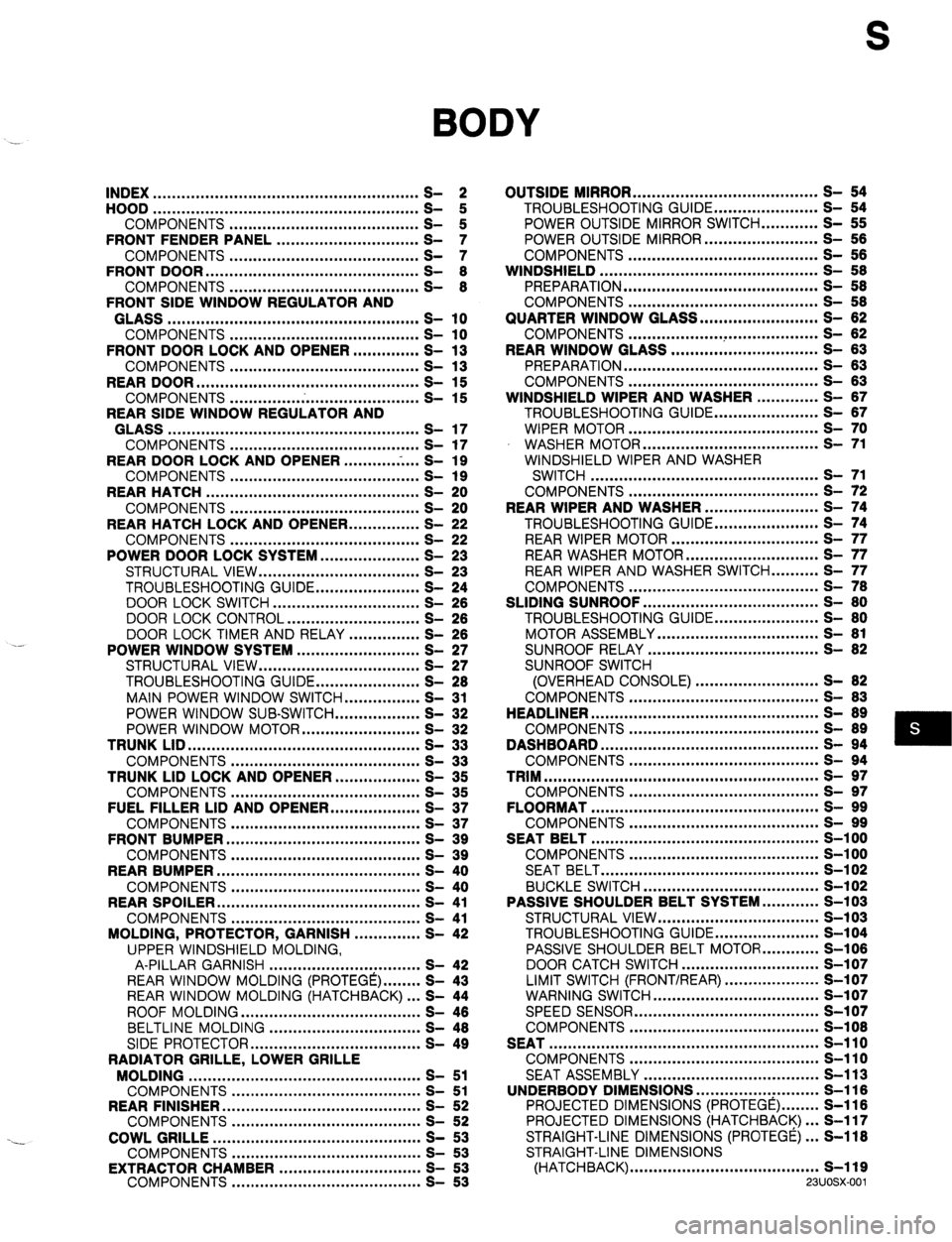

S

BODY

INDEX ........................................................ 2

HOOD ........................................................

COMPONENTS ........................................ t

FRONT FENDER PANEL .............................. ;I

COMPONENTS ........................................ S- ::

FRONT DOOR ............................................. S- 8

COMPONENTS ........................................ S- 8

FRONT SIDE WINDOW REGULATOR AND

GLASS ..................................................... s- 10

COMPONENTS ........................................ s- 10

FRONT DOOR LOCK AND OPENER .............. S- 13

COMPONENTS ........................................ s- 13

REAR DOOR ............................................... s- 15

COMPONENTS ........................................ s- 15

REAR SIDE WINDOW REGULATOR AND

GLASS ..................................................... s- 17

COMPONENTS ........................................ s- 17

REAR DOOR LOCK AND OPENER ...........

.-. ...

S- 19

COMPONENTS ........................................ s- 19

REAR HATCH ............................................. s- 20

COMPONENTS ........................................ s- 20

REAR HATCH LOCK AND OPENER.. .............

S- 22

COMPONENTS ........................................ s- 22

POWER DOOR LOCK SYSTEM.. ................... S- 23

STRUCTURAL VIEW .................................. S- 23

TROUBLESHOOTING GUIDE ...................... S- 24

DOOR LOCK SWITCH ............................... S- 28

DOOR LOCK CONTROL ............................ S- 26

DOOR LOCK TIMER AND RELAY ............... S- 26

POWER WINDOW SYSTEM .......................... S- 27

STRUCTURAL VIEW .................................. S- 27

TROUBLESHOOTING GUIDE.. .................... S- 28

MAIN POWER WINDOW SWITCH.. .............. S- 31

POWER WINDOW SUB-SWITCH.. ................ S- 32

POWER WINDOW MOTOR ......................... S- 32

TRUNK LID .................................................

s- 33

COMPONENTS ........................................ s- 33

TRUNK LID LOCK AND OPENER.. ................ S- 35

COMPONENTS ........................................ s- 35

FUEL FILLER LID AND OPENER ................... S- 37

COMPONENTS ........................................ s- 37

FRONT BUMPER ......................................... s- 39

COMPONENTS ........................................ s- 39

REAR BUMPER ........................................... s- 40

COMPONENTS ........................................ s- 40

REAR SPOILER ........................................... s- 41

COMPONENTS ........................................ s- 41

MOLDING, PROTECTOR, GARNISH .............. S- 42

UPPER WINDSHIELD MOLDING,

A-PILLAR GARNISH ................................ S- 42

REAR WINDOW MOLDING (PROTEGE) ........ S- 43

REAR WINDOW MOLDING (HATCHBACK) ... S- 44

ROOF MOLDING ...................................... S- 46

BELTLINE MOLDING ................................ S- 48

SIDE PROTECTOR.. .................................. S- 49

RADIATOR GRILLE, LOWER GRILLE

MOLDING ................................................. s- 51

COMPONENTS ........................................ S- 51

REAR FINISHER.. ........................................

S- 52

COMPONENTS ........................................ S- 52

COWL GRILLE ............................................ s- 53

COMPONENTS ........................................ s- 53

EXTRACTOR CHAMBER ..............................

COMPONENTS ........................................ g-

- ;; OUTSIDE MIRROR ....................................... s- 54

TROUBLESHOOTING GUIDE.. .................... S- 54

POWER OUTSIDE MIRROR SWITCH ............ S- 55

POWER OUTSIDE MIRROR.. ...................... S- 56

COMPONENTS ........................................ s- 66

WINDSHIELD .............................................. S- 58

PREPARATION ......................................... S- 58

COMPONENTS ........................................ S- 58

QUARTER WINDOW GLASS ......................... S- 62

COMPONENTS .................. ..T ................... S- 82

REAR WINDOW GLASS ............................... S- 63

PREPARATION ......................................... S- 63

COMPONENTS ........................................ S- 63

WINDSHIELD WIPER AND WASHER ............. S- 87

TROUBLESHOOTING GUIDE.. .................... S- 67

WIPER MOTOR ........................................ s- 70

WASHER MOTOR ..................................... s- 71

WINDSHIELD WIPER AND WASHER

SWITCH ................................................ s- 71

COMPONENTS ........................................ S- 72

REAR WIPER AND WASHER ........................ S- 74

TROUBLESHOOTING GUIDE.. .................... S- 74

REAR WIPER MOTOR ............................... s- 77

REAR WASHER MOTOR ............................ s- 77

REAR WIPER AND WASHER SWITCH.. ........ S- 77

COMPONENTS ........................................ S- 78

SLIDING SUNROOF ..................................... S- 80

TROUBLESHOOTING GUIDE.. .................... S- 80

MOTOR ASSEMBLY .................................. S- 81

SUNROOF RELAY .................................... S- 82

SUNROOF SWITCH

(OVERHEAD CONSOLE) .......................... S- 82

COMPONENTS ........................................ S- 83

HEADLINER ................................................ S- 89

COMPONENTS ........................................ S- 89

DASHBOARD .............................................. s- 94

COMPONENTS ........................................ s- 94

TRIM .......................................................... s- 97

COMPONENTS ........................................ s- 97

FLOORMAT ................................................ s- 99

COMPONENTS ........................................ s- 99

SEAT BELT ................................................ S-l 00

COMPONENTS ........................................ S-l 00

SEAT BELT .............................................. S-l 02

BUCKLE SWITCH ..................................... s-102

PASSIVE SHOULDER BELT SYSTEM.. .......... S-103

STRUCTURAL VIEW .................................. s-103

TROUBLESHOOTING GUIDE.. .................... S-104

PASSIVE SHOULDER BELT MOTOR.. .......... S-106

DOOR CATCH SWITCH ............................. S-l 07

LIMIT SWITCH (FRONT/REAR)

WARNING SWITCH ....................................................... z-:X;

-

SPEED SENSOR ....................................... s-i 07

COMPONENTS ........................................ S-l 08

SEAT ......................................................... s-110

COMPONENTS ........................................ s-110

SEAT ASSEMBLY ..................................... S-l 13

UNDERBODY DIMENSIONS .............. ..: ......... S-116

PROJECTED DIMENSIONS (PROTEGE) ........ S-116

PROJECTED DIMENSIONS (HATCHBACK). .. S-117

STRAIGHT-LINE DIMENSIONS (PROTEGE). .. S-118

STRAIGHT-LINE DIMENSIONS

(HATCHBACK) ........................................ s-119

23UOSX.001

Page 740 of 1164

S INDEX

1. Headliner

Components .............................

page S- 89 Components ............................. page S-l 10

2. Dashboard Seat assembly ..........................

page S-l 13

Components

............................. page S- 94 8. Underbody dimensions

3. Trim

Projected djmensions

Components

............................. page S- 97 (PROTEGE). ............................

page S-l 16

4. Floormat

Projected dimensions

Components ............................. page

S- 99 (Hatchback) ............................

page S-l 17

5. Seat belt

Straight-line, dimensions

Components ............................. page S-i 00 (PROTEGE). ............................ page

S-l 18

Seat belt ...................................

page S-102 Straight-line dimensions

Buckle switch.. .......................... page

S-102 (Hatchback) ............................

page S-l 19

6. Passive shoulder belt system

Structural view.. ........................

page S-103

Troubleshooting guide.. ............ page S-l 04

Passive shoulder belt motor..

... page S-l 06

Door catch switch..

................... page S-l 07

Limit switch.. ............................. page S-107

Warning switch

......................... page S-l 07

Speed sensor ........................... page

S-l 07

Components .............................

page S-l 08

s-4

Page 842 of 1164

PASSIVE SHOULDER BELT SYSTEM

Passive shoulder belt stays in rearward position

Cl ___

Disconnect passive shoulder belt control unit and door NG

catch switch connector; check for continuity between c Broken harness (Passive shoulder belt control unit -

terminal-wires (L/O or L/Y) of above connectors Door catch switch) OK

Reconnect door catch switch connector; check for con- NG Defective door catch switch (Refer to Inspection;

tinuity of terminal-wire (L/O or L/Y) of door catch switch 2 page S-107) or broken harness (Door catch switch -

connector to ground when door open Ground)

I OK

Check for no continuity of terminal-wire (Y/L or L/B) of NGs Short circuit (Passive shoulder belt control unit - Front

passive shoulder belt control unit connector to ground limit switch) or defective front limit switch

1

(Refer to Inspection; page S-107) OK

Check for continuity between terminal-wires (L/G, BR or NG

Y/G, W/B) of above connector and passive shoulder belt _ Repair harness (Passive shoulder belt control unit -

motor connector Passive shoulder belt motor)

L

1 OK

I

Check passive shoulder belt motor

(Refer to page S-106) NG

_ Replace passive shoulder belt

- (Refer to Removal/Installation; page S-l 08) OK

L Replace passive shoulder belt control unit

(Refer to Removal/Installation; page S-l 08) i-.. ”

OBUOSX-I 96 Passive shoulder belt moves to forward position

when door is opened while vehicle is running at

more than 10 km/h (6.2 mph)

J

NG

Check speed sensor (Refer t = Replace speedometer (Refer to Section T) OK

Replace passive shoulder belt control unit (Refer to

Removalilnstallation; page S-l 08)

03uosx-197

I 23UOSX-03

PASSIVE SHOULDER BELT MOTOR

Inspection

1, Disconnect the passive shoulder belt connector.

2. Connect battery voltage to terminal (a) and ground termi-

nal (b). Verify that the motor rotates in the forward direction

(release).

3. Reverse the above connection, and check that the motor

rotates in the rearward direction (lock).

4. If not as specified, replace the passive shoulder belt. Caution

l Do not operate the motor for an extended time.

S-l 06