brake MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 6 of 1164

HOW TO USE THIS MANUAL/FUNDAMENTAL PROCEDURES

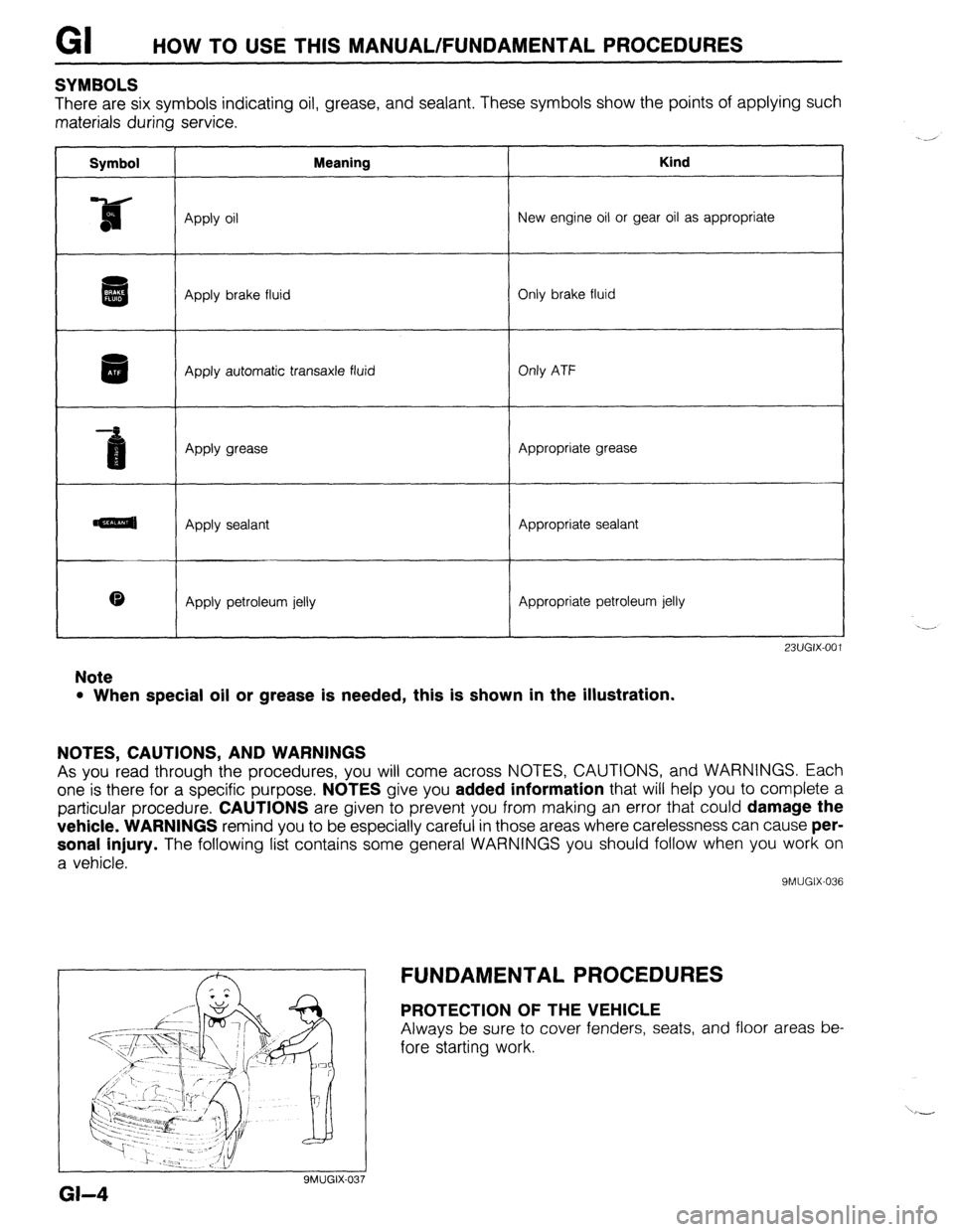

SYMBOLS

There are six symbols indicating oil, grease, and sealant. These symbols show the points of applying such

materials during service.

Symbol Meaning Kind

Apply oil New engine oil or gear oil as appropriate

aI i . Apply brake fluid Only brake fluid

Apply automatic transaxle fluid Only ATF

Apply grease Appropriate grease

amal Apply sealant Appropriate sealant

0 Apply petroleum jelly Appropriate petroleum jelly

23UGIX-001

Note

l When special oil or grease is needed, this is shown in the illustration.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one is there for a specific purpose.

NOTES give you added information that will help you to complete a

particular procedure.

CAUTIONS are given to prevent you from making an error that could damage the

vehicle. WARNINGS

remind you to be especially careful in those areas where carelessness can cause per-

sonal injury.

The following list contains some general WARNINGS you should follow when you work on

a vehicle.

9MUGIX-036

SMUGIX-037

a-4 FUNDAMENTAL PROCEDURES

PROTECTION OF THE VEHICLE

Always be sure to cover fenders, seats, and floor areas be-

fore starting work.

Page 11 of 1164

TOWING

.-

WHEEL dOLLlES

03UGIX-00

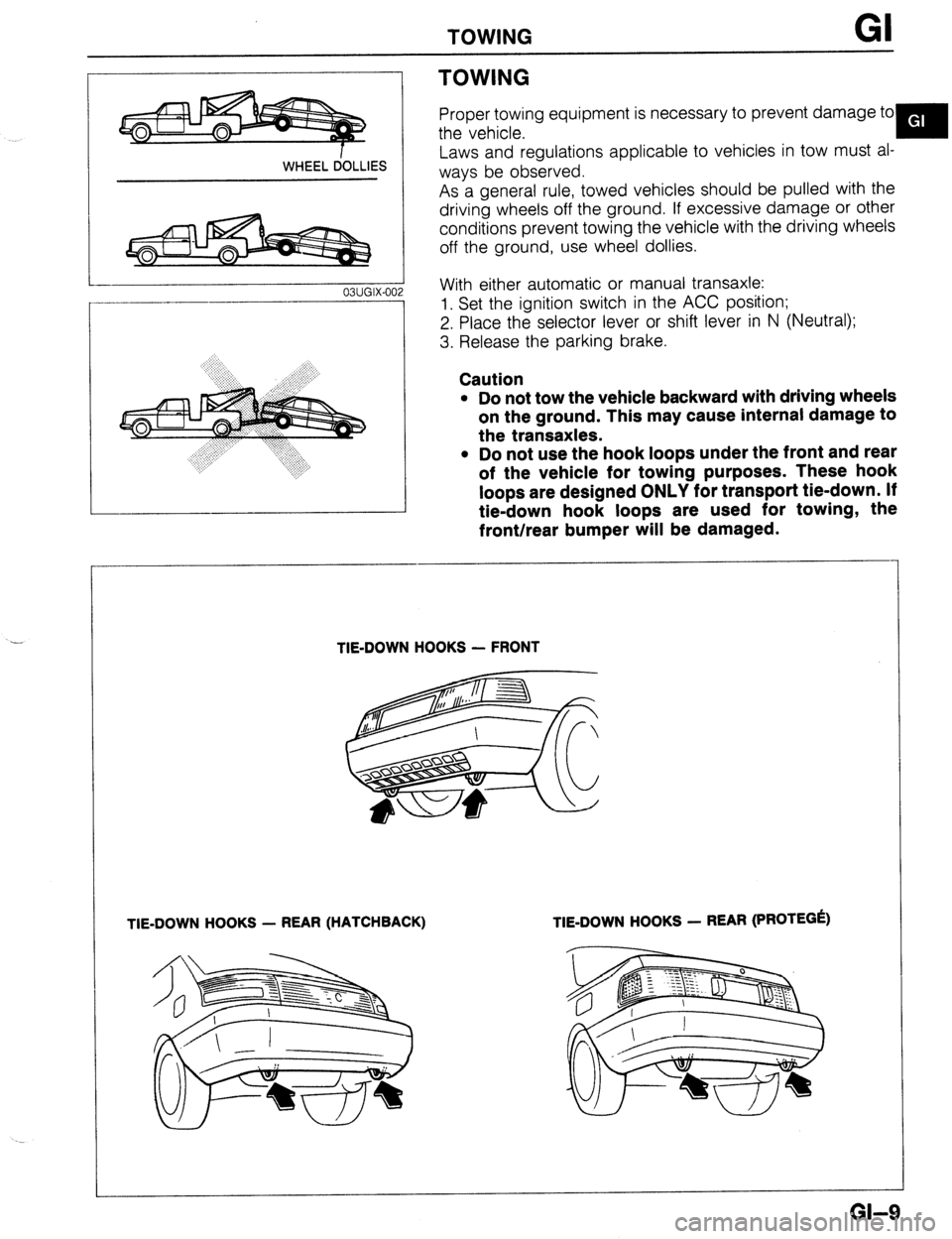

TOWING

Proper towing equipment is necessary to prevent damage to

the vehicle.

Y

Laws and regulations applicable to vehicles in tow must al-

ways be observed.

As a general rule, towed vehicles should be pulled with the

driving wheels off the ground. If excessive damage or other

conditions prevent towing the vehicle with the driving wheels

off the ground, use wheel dollies.

With either automatic or manual transaxle:

1. Set the ignition switch in the ACC position;

2. Place the selector lever or shift lever in N (Neutral);

3. Release the parking brake.

Caution

l Do not tow the vehicle backward with driving wheels

on the ground. This may cause internal damage to

the transaxles.

l Do not use the hook loops under the front and rear

of the vehicle for towing purposes. These hook

loops are designed ONLY for transport tie-down. If

tie-down hook loops are used for towing, the

front/rear bumper will be damaged.

TIE-DOWN HOOKS - FRONT

TIE-DOWN HOOKS - REAR (HATCHBACK) TIE-DOWN HOOKS - REAR (PROTEGk)

GI-9

Page 20 of 1164

PRE-DELIVERY INSPECTION

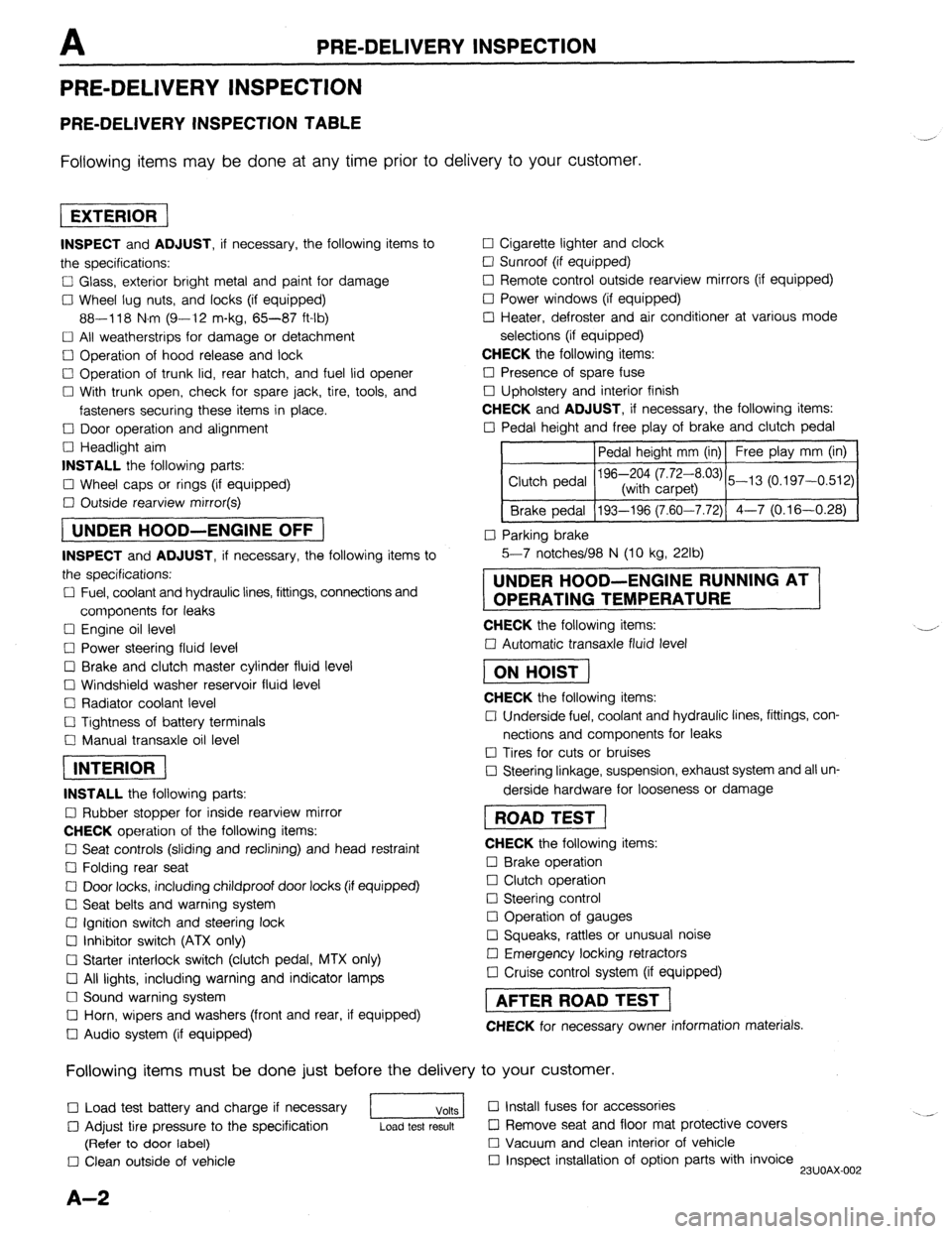

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 21 of 1164

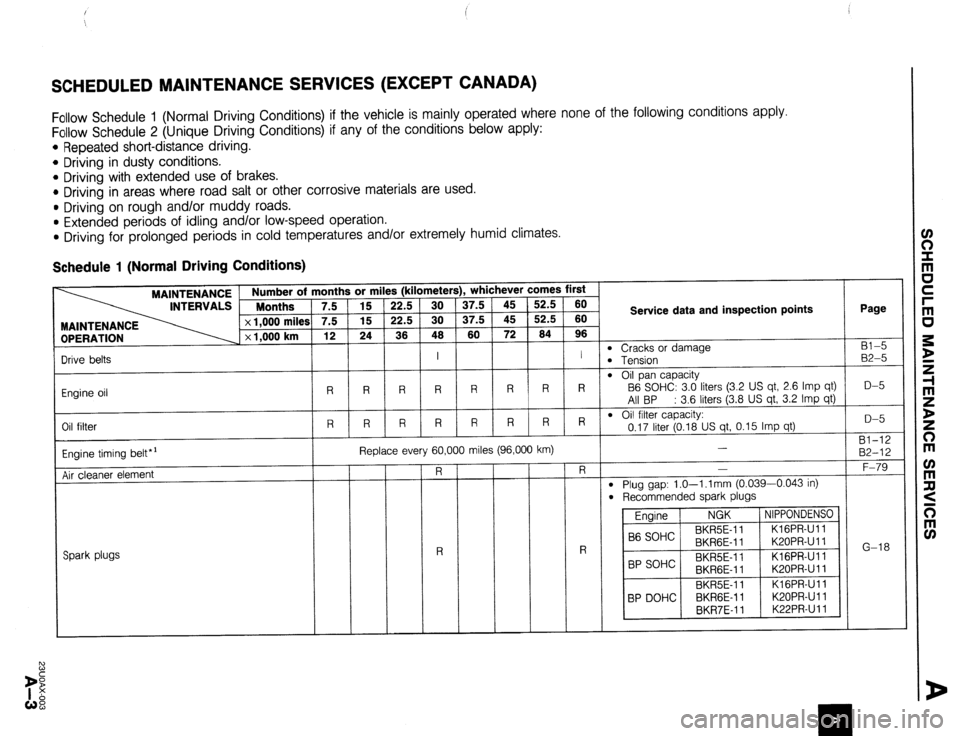

SCHEDULED MAINTENANCE SERVICES (EXCEPT CANADA)

Follow Schedule 1 (Normal Driving Conditions) if the vehicle is mainly operated where none of the following conditions apply.

Follow Schedule 2 (Unique Driving Conditions) if any of the conditions below apply:

l Repeated short-distance driving.

l Driving in dusty conditions.

* Driving with extended use of brakes.

* Driving in areas where road salt or other corrosive materials are used.

l Driving on rough and/or muddy roads.

l Extended periods of idling and/or low-speed operation.

l Driving for prolonged periods in cold temperatures and/or extremely humid climates.

Schedule 1 (Normal Driving Conditions)

Number of months or miles (kilometers), whichever comes first

Months 7.5 15 22.5 30 37.5 45 52.5 60

7.5 15 22.5 30 37.5 45 52.5 60

12 24 36 46 60 72 64 96 Service data and inspection points Page

Bl-5

B2-5

D-5

D-5

Bl-12

B2-12

F-79

G-18 MAINTENANCE

OPERATION

m Cracks or damage

B Tension

m Oil pan capacity

B6 SOHC: 3.0 liters (3.2 US qt, 2.6 Imp qt)

All BP : 3.6 liters (3.8 US qt, 3.2 Imp qt)

l Oil filter capacity:

0.17 liter (0.18 US qt, 0.15 Imp qt)

-

l Plug gap: 1.0-l .l mm (0.039-0.043 in)

l Recommended spark plugs

Engine NGK NIPPONDENSO

B6 SOHC BKR5E-11 KIGPR-Ull

BKRGE-11 K20PR-U 11

BP SOHC BKR5E-11 KlGPR-Ull

BKRGE-11 K20PR-U 11

BKR5E-11 KlGPR-Ull

BP DOHC BKRGE-11 K20PR-U 11

BKR7E-11 K22PR-Ull I I

R R R R R R R R

R R R R R R R R Drive belts

Engine oil

Oil filter

Engine timing belt*’

Air cleaner element Replace every 60,000 miles (96,000 km)

I

Spark plugs

Page 22 of 1164

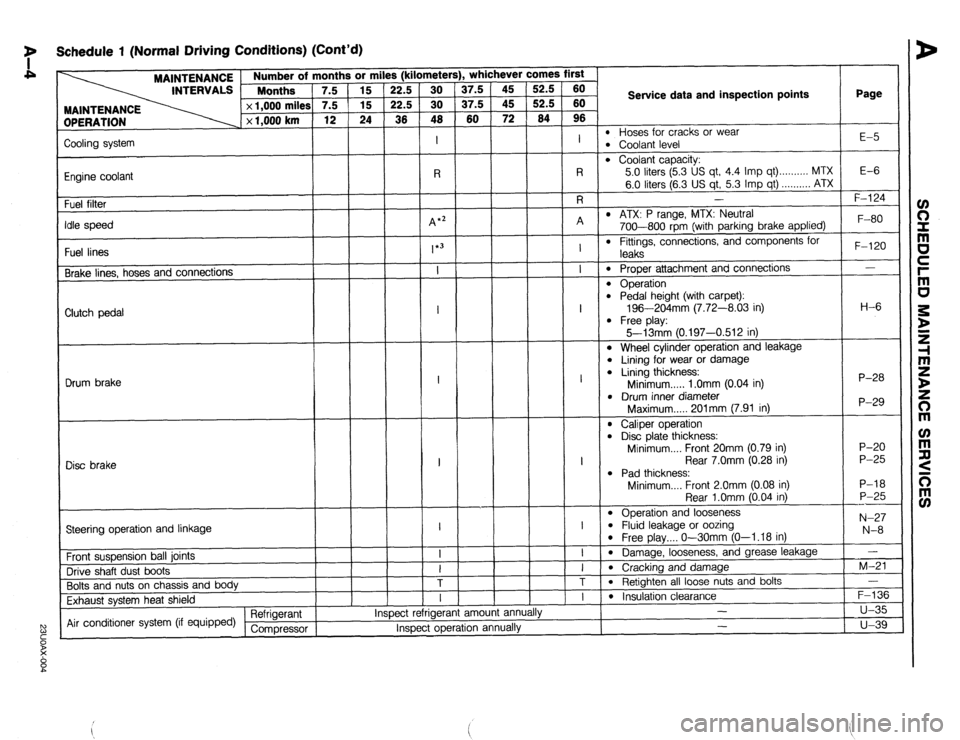

7 Schedule 1 (Normal Driving Conditions) (Cont’d)

MAINTENANCE

INTERVALS 1 ::::“’ rths ’ 7.5

DPERATION x 1,000 miles

x 1,000 km 3r mi

15

15

24

1

Page

l- . whichever comes first s (kilometer!

37.5

37.5

60 52.5

52.5

64 60

60

96

I

l-7

Service data and inspection points

l Hoses for cracks or wear l Coolant level E-5

Zooling system

Engine coolant

Fuel filter

‘die speed

Fuel lines

Brake lines, hoses and connections

l Coolant capacity:

5.0 liters (5.3 US qt, 4.4 Imp qt) . . . . . . . . . . MTX

6.0 liters (6.3 US qt, 5.3 Imp qt) . . . . . . . . . . ATX

I E-6 -

F-l 24

l ATX: P range, MTX: Neutral

700-800 rpm (with parking brake applied)

l Fittings, connections, and components for F-80

F-120

-

H-6

P-28

P-29

P-20

P-25

P-18

P-25

---

N-27

N-8

-

M-21

-

F-136

u-35

u-39 leaks

0 Proper attachment and connections

l Operation l Pedal height (with carpet):

196-204mm (7.72-8.03 in)

l Free play:

5--13mm 10.197-0.512 in) Clutch pedal

l Wheel cylinder operation and leakage

l Lining for wear or damage l Lining thickness:

Minimum . . . . . 1 .Omm (0.04 in)

l Drum inner diameter

Maximum..... 201mm (7.91 in) Drum brake

l Caliper operation l Disc plate thickness:

Minimum.... Front 20mm (0.79 in)

Rear 7.0mm (0.28 in)

l Pad thickness:

Minimum.... Front 2.0mm (0.08 in)

Rear l.Omm (0.04 in)

l Operation and looseness l Fluid leakage or oozing l Free play.... O-30mm (O-l .18 in)

l Damage, looseness, and grease leakage

l Cracking and damage

l Retighten all loose nuts and bolts I

1

Disc brake

I

---l-T

Steering operation and linkage

Front suspension ball joints

Drive shaft dust boots

Bolts and nuts on chassis and body

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor am01 anni I

l Insulation clearance

- ,.

Inspect rerrlgerar

Inspect operation annually -

Page 24 of 1164

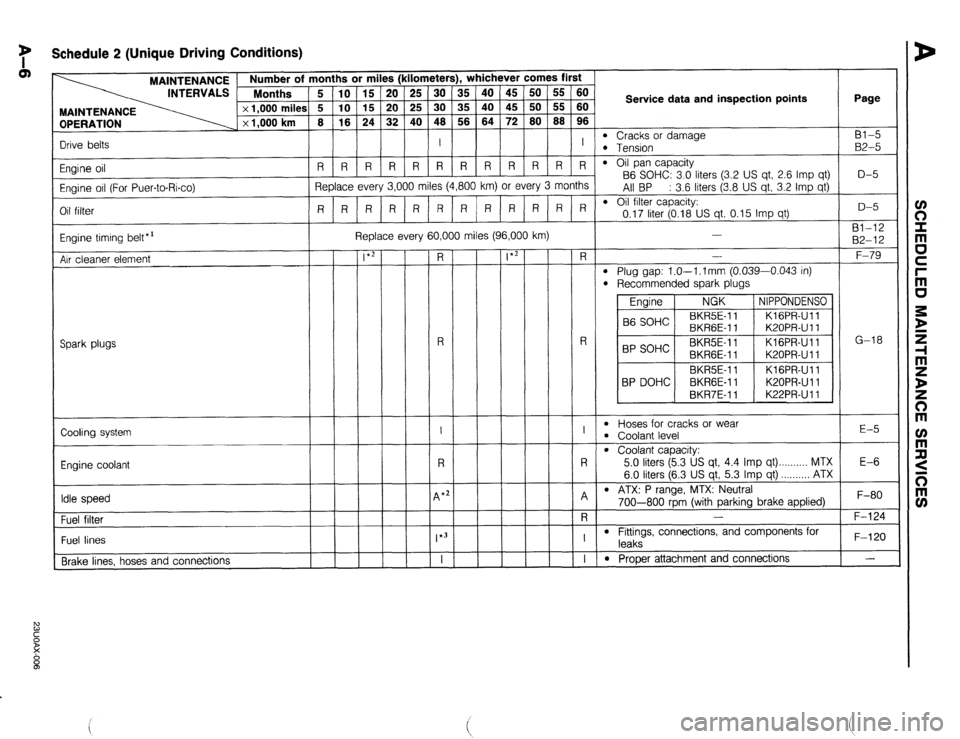

y Schedule 2 (Unique Driving Conditions)

OPERATION

Drive belts MAINTENANCE / Number of months or miles (kilometers), whichever comes first

INTERVALS Months

5 IO 15 20 25 30 35 40 45 50 55 60

x 1,000 milea i 5 10 15 20 25 30 35 40 45 50 55 60

x 1,000 km 8 16 24 32 40 48 56 64 72

80 88 96

I I Service data and inspection points Page

l Cracks or damage Bl-5 l Tension B2-5

l Oil pan capacity

B6 SOHC: 3.0 liters (3.2 US qt, 2.6 Imp qt)

All BP : 3.6 liters (3.8 US qt, 3.2 Imp qt)

l Oil filter capacity: D-5

I I I I I I I I I I I

RRRRRRR R R R R R

Replace every 3,000 miles (4,800 km) or every 3 months

R R R R R RRRRRRR

0.17 liter (0.18 US qt, 0.15 Imp qt) Engine oil

Engine oil (For Puer-to-Rico)

Oil filter D-5

81-12

82-12

F-79

G-18 Replace every 60,000 miles (96,000 km)

Engine timing belt*’

Air cleaner element -

-

-

-

-

-

-

-

- -

-

-

-

-

-

-

-

-

FL

-

R

-

I

-

R

-

4 *;

-

-

*3

T

- -

-

-

-

-

-

-

-

- -

-

-

-

-

-

-

-

-

*2 -

-

-

-

-

-

-

-

- - R -

l Plug gap: l.O--l.lmm (0.039-0.043 in)

l Recommended spark plugs

Engine NGK NIPPONDENSO

B6 SOHC BKR5E-11

KlGPR-Ull

BKRGE-I 1 K20PR-U 11

BP SOHC BKR5E-I 1 KlGPR-Ull

BKRGE-11 K20PR-U 11

BKRSE-I 1 Kl GPR-Ul 1

BP DOHC BKRGE-11 K20PRUll

BKR7E-11 K22PR-U 11 R

Spark plugs

I

l Hoses for cracks or wear l Coolant level E-5

Cooling system

R

l Coolant capacity:

5.0 liters (5.3 US qt, 4.4 Imp qt) MTX

6.0 liters (6.3 US qt, 5.3 Imp qt) ...,,,,,. ATX

l ATX: P range, MTX: Neutral E-6

Engine coolant

A

-

R

-

I

-

I Idle speed , F-80

F-124 / 700-800 rbrn (with parkina brake applied) -

- -

- , , I .I

-

Fuel filter

l Fittings, connections, and components for

leaks

l Prooer attachment and connections F-120

- Fuel lines

Brake lines. hoses and connections

Page 25 of 1164

I

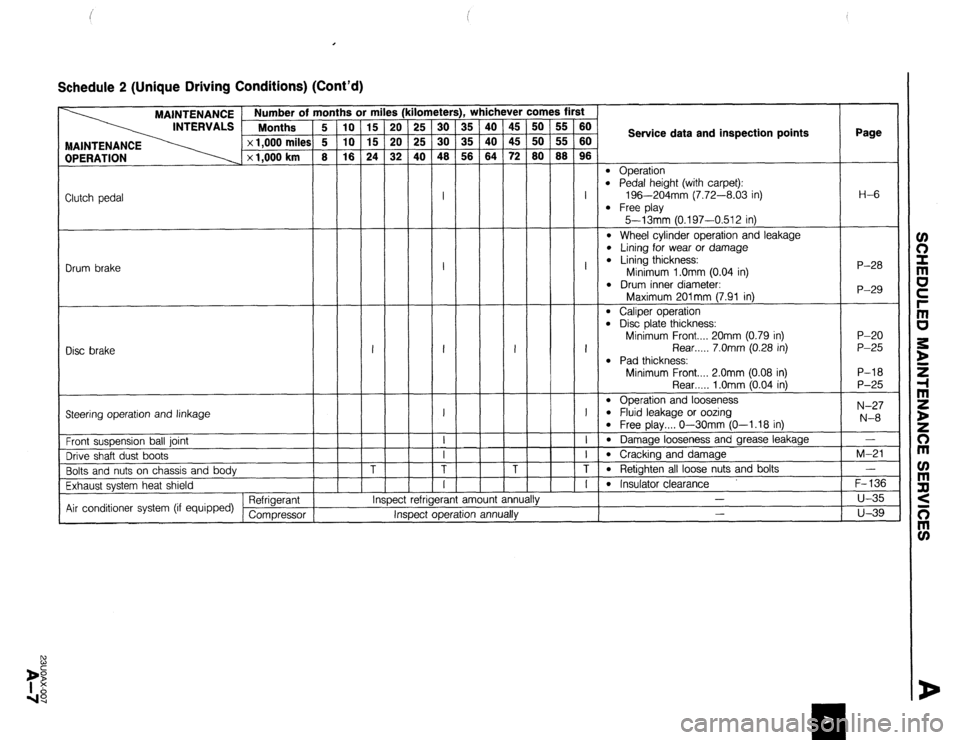

Schedule 2 (Unique Driving Conditions) (Cont’d)

(kil

I :

I :

’ 1 iii ichever comes first lometers), Y

25 30 35

25 30 35

40 48 58

I

45

45

72 50

50

80

-

-

I

I

I

I

I

T

I

,

40

iii

i5i

-

-

-

-

-

-

-

-

-

I

-

-

T -

-

-

- -

1 nspec L :t rerngeranr amount annually

Inspect operation annually m

rs

E

24

-

-

-

I

-

-

-

T

-

T fn

iiF

is

w

-

-

-

-

-

-

-

-

- iii

iii

,s

-

I

-

I

-

I

-

I

T

I-

r

T

-

T7

Service data and inspection points Page l

Operation l Pedal height (with carpet):

196-204mm (7.72-8.03 in) l

Free play

5-13mm (0.197-0.512 in) l

Wheel cylinder operation and leakage l Lining for wear or damage l Lining thickness:

Minimum l.Omm (0.04 in) l

Drum inner diameter: H-6

Clutch pedal

P-28

P-29 Drum brake

Maximum 201mm (7.91 in) l

Caliper operation l Disc plate thickness:

Minimum Front.... 20mm (0.79 in)

Rear . . . . . 7.0mm (0.28 in) l

Pad thickness:

Minimum Front.... 2.0mm (0.08 in)

Rear . . . . . 1 .Omm (0.04 in) l

Operation and looseness l Fluid leakage or oozing l Free play.... O-30mm (O-l.18 in) l

Damage looseness and grease leakage l

Cracking and damage l

Retighten all loose nuts and bolts l

Insulator clearance

-

- P-20

P-25

P-18

P-25

N-27

N-8 Disc brake

Steering operation and linkage

Front suspension ball joint

Drive shaft dust boots

Bolts and nuts on chassis and body

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor -

M-21

-

F-136

u-35

u-39

Page 27 of 1164

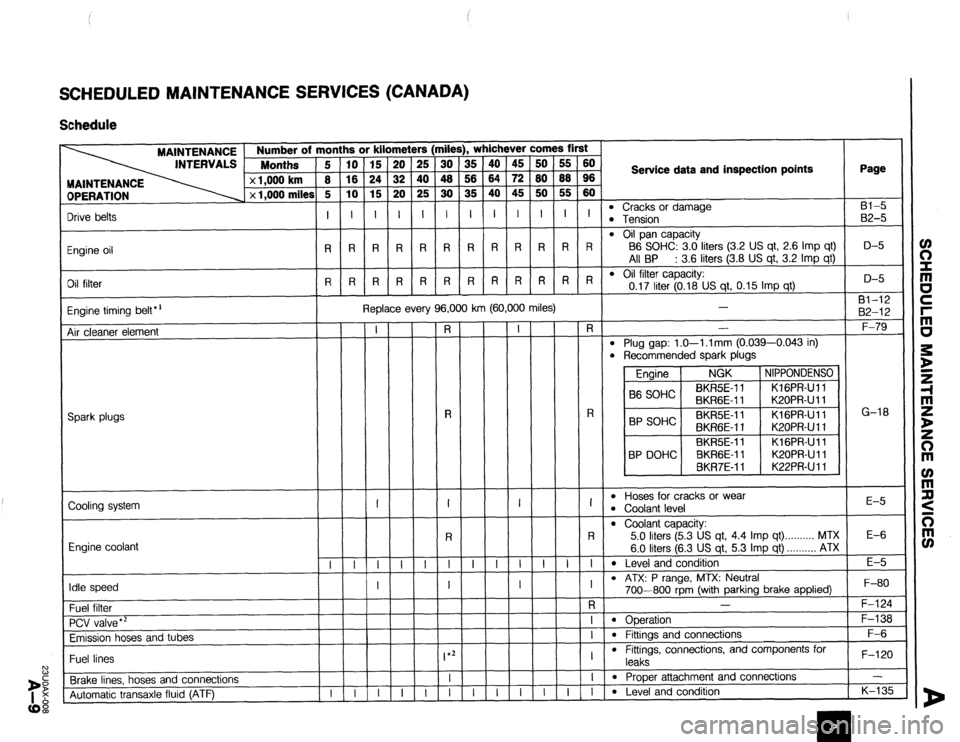

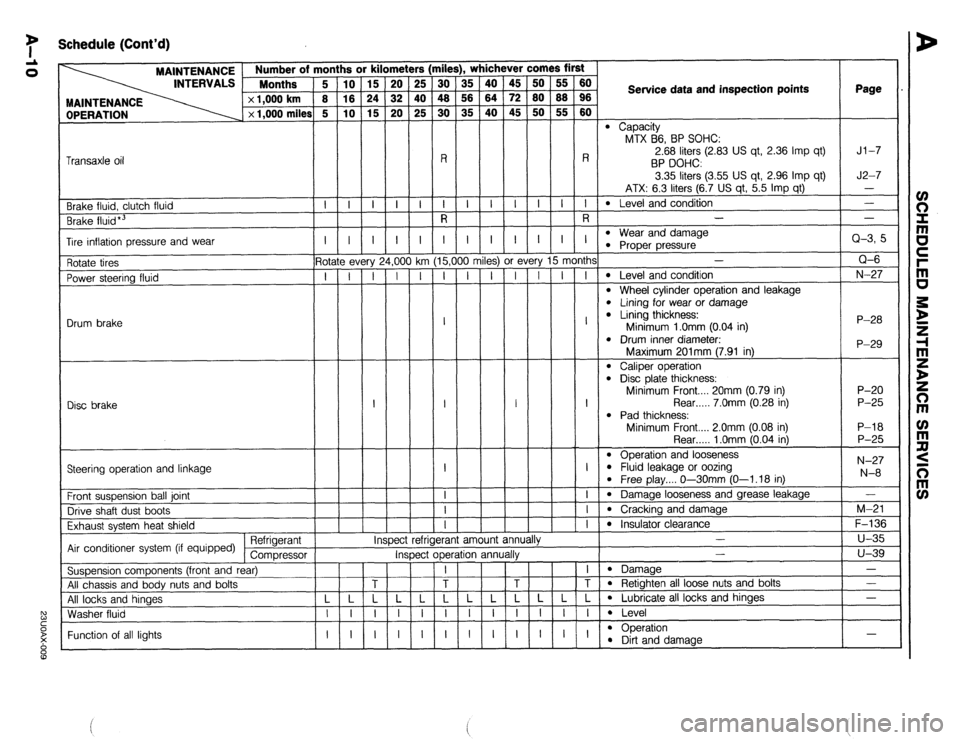

SCHEDULED MAINTENANCE SERVICES (CANADA)

Schedule

2 1,000 km

x 1,000 mile! Number of months or kilometers (miles), whichever comes first

Months 5 10 15 20 25 30 35 40 45 50 55 60

8 16 24

32 40 40 56 64 72 80 88 96

s 5 10 15 20 25 30 35 40 45 50 55 60

I I I Service data and inspection points Page

MAINTENANCE

OPERATION

l Cracks or damage Bl-5 l Tension 82-5

l Oil pan capacity

B6 SOHC: 3.0 liters (3.2 US qt, 2.6 Imp qt)

All BP : 3.6 liters (3.8 US qt, 3.2 Imp qt)

l Oil filter capacity: D-5

0.17 liter (0.18 US qt, 0.15 Imp qt) Drive belts I I I I I I I I I I I I

Engine oil RRRRRRR R R R R R

Oil filter R R R R R R R R R R R R D-5

81-12

82-12

F-79 Replace every 96,000 km (60,000 miles)

Engine timing belt*’

Air cleaner element

T

-

-

I

-

-i

-

I

-

-

-

-

-

-i-

- -

R -

-

-

-

T

-

-

-

-

-

-

-7

- -

-

-

-

T

-

-

-

-

-

-

T

- -r

-

-

I

-

T

-

I

-

-

-

-

-

-i

-

-

-

-

-

T

-

-

-

-

-

-

T

- -

-

-

-

T

-

-

-

-

-

-

T

- i?-

-

R

-

I

-

R

-i

-

I

F

T

T

-

I

-i

-i

-

-

-

-

-

T

-

-

-

-

-

-

-i

- -

l Plug gap: 1.0-l .l mm (0.039-0.043 in)

l Recommended spark plugs .-

Engine NGK NIPPONDENSO

86 SOHC BKR5E-11 KlGPR-Ull

BKRGE-11 K20PR-U 11

BP SOHC BKR5E-11 KlGPR-Ull

BKRGE-11 K20PR-U

11

BKRSE-11 KlGPR-Ull

BP DOHC BKRGE-11 K20PR-U 11

BKR7E-11 K22PRU 11 G-18

R

-

I

-

R

-i- Spark plugs -

-

-

-

I

-

-

E-5

Cooling system l Hoses for cracks or wear

l Coolant level

0 Coolant capacity: 5.0

liters (5.3 US qt, 4.4 imp qt) ..,.,..,,. MTX

6.0 liters (6.3 US qt, 5.3 Imp qt) . . . . . . . . . . ATX

l Level and condition

l ATX: P range, MTX: Neutral

700-800 rpm (with parking brake applied) E-6

Engine coolant

E-5

F-80

F-124 I

- I

Idle speed

Fuel filter

PCV valve *’

Emission hoses and tubes

Fuel lines

Brake lines, hoses and connections

Automatic transaxle fluid (ATF) -

-

-

I *2

l Operation - F-138

F-6 -

-

- -

-

-

l Fittings and connections

l Fittings, connections, and components for

leaks

l Proper attachment and connections

l Level and conditinn F-l 20 - K-l 35

I I

- I

- I

Page 28 of 1164

7 Schedule (Cont’d)

rile

iii

48

30

-

R

I

R !rs

25

40

25

-

-i- , whichever comes first

OPERATION MAINTENANCE Number of m

INTERVALS Months

x 1,000 km

x 1,000 miles

ii

is

G

-

i-

-

-

I

5-

T

-

-

-

-

-

-

- ii

z

ro

-

I-

-

-

I

- 45

72

45

-

-i-

-

-

I

-

ry 15 month:

I I I

A

t

A

j

milt Service data and inspection points Page

l Capacity

MTX B6, BP SOHC:

2.68 liters (2.83 US qt, 2.36 Imp qt)

BP DOHC

3.35 liters (3.55 US qt, 2.96 Imp qt)

ATX: 6.3 liters (6.7 US qt, 5.5 Imp qt)

l Level and condition

- Jl-7

J2-7

- Transaxle oil

l Wear and damaae -i- -i- -i- -

Brake fluid, clutch fluid

Brake fluid*3 -

Q-3, 5

Q-6

N-27

P-28

P-29 I I

- I

1,oo

-i

-

-

-

-

-

-

- I

G

T

-

-

-

-

-

-

- I

15,(

I Tire inflation pressure and wear l Proper pressure-

-

l Level and condition

l Wheel cylinder operation and leakage l Lining for wear or damage l Lining thickness:

Minimum 1 .Omm (0.04 in)

l Drum inner diameter. 3s) or f

I I

I

:t r

- Rotate tires

Power steering fluid

Drum brake ? every

I I

Disc brake I I

Maximum 201mm (7.91 in)

l Caliper operation l Disd plate thickness:

Minimum Front.... 20mm (0.79 in)

Rear . . . . . 7.0mm (0.28 in)

l Pad thickness:

Minimum Front.... 2.0mm (0.08 in) P-20

P-25

P-l 8

P-25

N-27

N-8 Rear . . . . . 1 .Omm (0.04 in)

l Operation and looseness l Fluid leakage or oozina

l Free play.... O--3OmmjO-1.18 in)

l Damage looseness and grease leakage

l Cracking and damage

l Insulator clearawp .-v

-

Steering operation and linkage

I

-i-

-I-

-i- Front suspension ball joint

Drive shaft dust boots

Exhaust system heat shield

Air conditioner system (if equipped) Refrigerant

Compressor

Suspension components (front and rear)

All chassis and body nuts and bolts

All locks and hinaes

Washer fluid -

M-21

F-136

u-35

u-39

-

- IY efrigerant amount ann

*. I# mspec

Inspect operation annualry -

l Damaae

l Retighten all loose nuts and bolts

l Lubricate all locks and hinges

l Level

l ODeration - Function of all lights l !%t and damage -

Page 33 of 1164

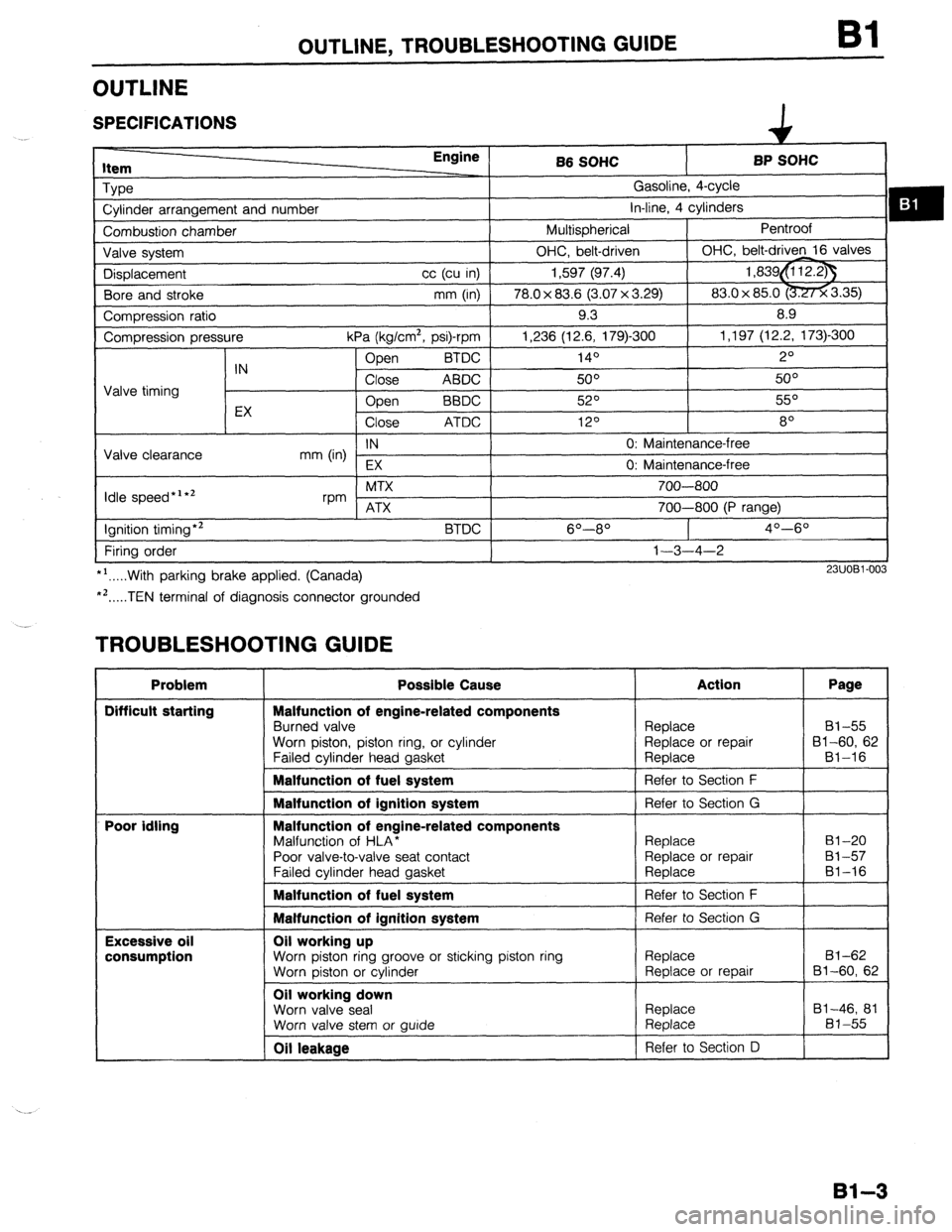

OUTLINE, TROUBLESHOOTING GUIDE Bl

OUTLINE

SPECIFICATIONS

item Engine

Type

Cylinder arrangement and number

Combustion chamber

Valve system

Displacement cc (cu in)

Bore and stroke mm (in)

Compression ratio

Compression pressure

kPa (kg/cm2, psi)-rpm

Open BTDC

IN

Close ABDC

Valve timing

EX Open

BBDC

Close ATDC

IN

Valve clearance

mm (in)

EX

Idle speed*‘*’ MTX

rpm ATX

Ignition timing*2

BTDC

Firing order

*‘.....With parking brake applied. (Canada)

*‘.....TEN terminal of diagnosis connector grounded B6 SOHC BP SOHC

Gasoline, 4-cycle

in-line, 4 cylinders

Multispherical Pentroof

OHC, belt-driven OHC, belt-driven 16 valves

1,597 (97.4) 1,839&i 12.23

78.0 x 83.6 (3.07 x 3.29) 83.0x 85.0 -3.35)

9.3 8.9

1,236 (12.6, 179)300 1,197 (12.2, 173)-300

140 2O

50° 5o”

52O 55O

120 8

0: Maintenance-free

0: Maintenance-free

700-800

700-800 (P range)

6O----8O 4O--6O

1-3-4-2

23UOBl-003

TROUBLESHOOTING GUIDE

Problem

Difficult starting

Poor idling

Excessive oil

consumption Possible Cause

Malfunction of engine-related components

Burned valve

Worn piston, piston ring, or cylinder

Failed cvlinder head aasket Action Page

Replace 81-55

Replace or repair 81-60, 62

Reolace Bl-16

Malfunction of fuel system

1 Refer to Section F

I

Malfunction of ignition system

Malfunction of engine-related components

Malfunction of HLA*

Poor valve-to-valve seat contact

Failed cvlinder head aasket Refer to Section G

Replace

Replace or repair

Reolace 81-20

81-57

81-16

Malfunction of fuel system 1 Refer to Section F

I

Malfunction of ignition system Refer to Section G

Oil working up

Worn piston ring groove or sticking piston ring

Worn piston or cylinder

Oil working down

Worn valve seal

Worn valve stem or wide Replace

Replace or repair

Replace

Replace 81-62

Bl-60, 62

81-46, 81

81-55

Oil leakage Refer to Section D

81-3