torque MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 5 of 1164

HOW TO USE THIS MANUAL GI

HOW TO USE THIS MANUAL

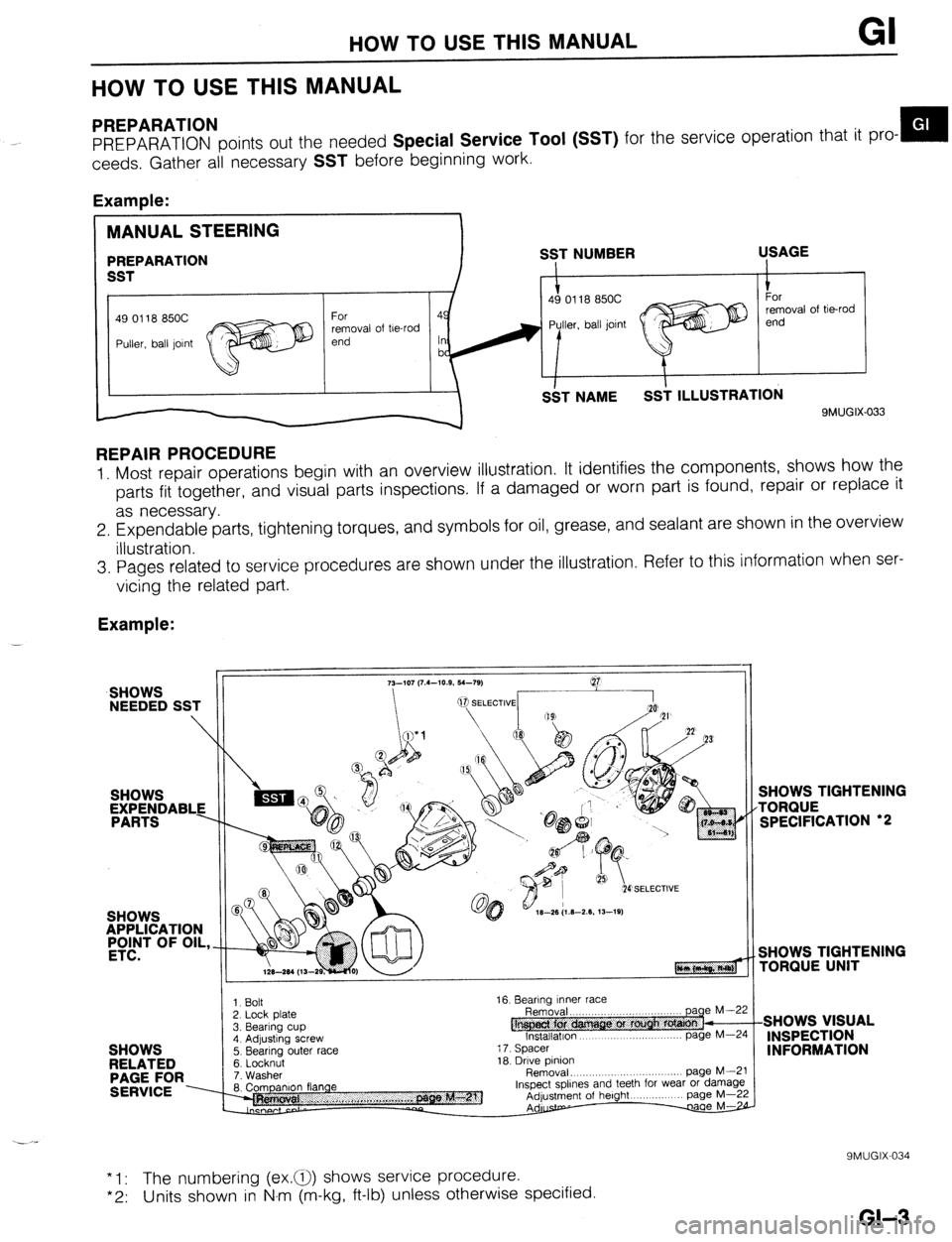

PREPARATION

PREPARATION points out the needed Special Service Tool (SST) for the service operation that it pro- m

ceeds. Gather all necessary

SST before beginning work.

Example:

49 0118 850C

removal of be-rod

9MUGIX-033

REPAIR PROCEDURE

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration.

3. Pages related to service procedures are shown under the illustration. Refer to this information when ser-

vicing the related part.

Example:

SHOWS

NEEDED SST

SHOWS

APPLICATION

#T OF OIL,

SHOWS

RELATED

PAGE FOR

SERVICE ----

3. Bearing cup 1. Bolt

2. Lock Dlate

4. Adjusting screw

5. Bearing outer race

6. Locknut

7. Washer

8. Companion flange 16. Bearing Inner race

@ Removal. ,,,..,,,..

lnstallatlon page

page M--5 M-Z

i 7. Spacer

18. Drive pinion

Removal, .,,, ,.,, .,......... page M--i

Inspect spllnes and teeth for wear or damagl

Adjustment of height page M-2

Adurstp- w

SHOWS TIGHTENING

TORQUE

SPECIFICATION ‘2

SHOWS TIGHTENING

rORQlJE UNIT

SHOWS VISUAL

INSPECTION

INFORMATION

* 1: The numbering (ex.a) shows service procedure.

*2: Units shown in N.m (m-kg, ft-lb) unless otherwise specified.

9MUGIX-034

GI-3

Page 8 of 1164

GI FUNDAMENTAL PROCEDURES

9MUGIX-04t 3

9MUGIX-041

9MUGIX.004

I

Depending on location:

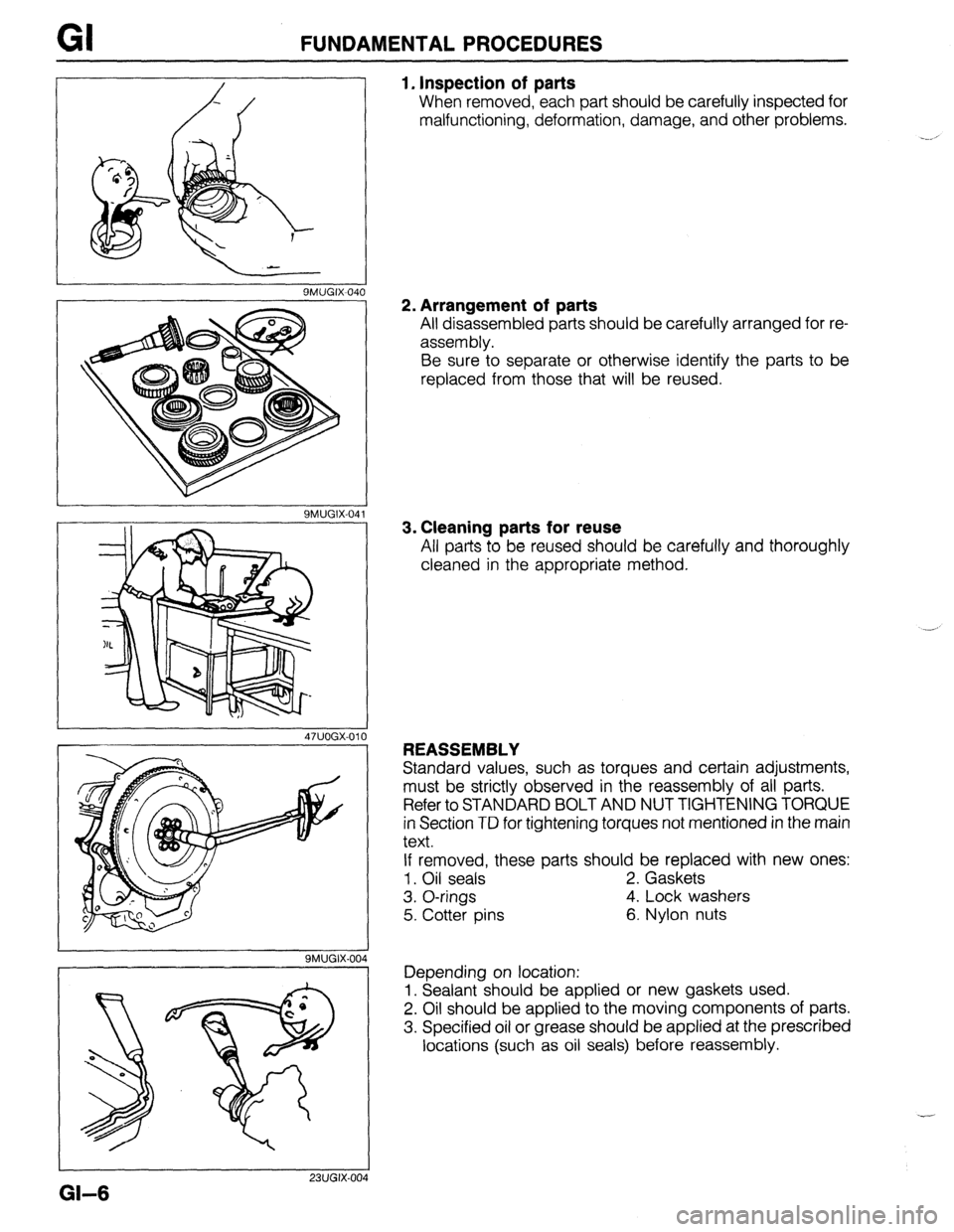

1. Inspection of parts

When removed, each part should be carefully inspected for

malfunctioning, deformation, damage, and other problems.

2. Arrangement of parts

All disassembled parts should be carefully arranged for re-

assembly.

Be sure to separate or otherwise identify the parts to be

replaced from those that will be reused.

3. Cleaning parts for reuse

All parts to be reused should be carefully and thoroughly

cleaned in the appropriate method.

REASSEMBLY

Standard values, such as torques and certain adjustments,

must be strictly observed in the reassembly of all parts.

Refer to STANDARD BOLT AND NUT TIGHTENING TORQUE

in Section TD for tightening torques not mentioned in the main

text.

If removed, these parts should be replaced with new ones:

1. Oil seals 2. Gaskets

3. O-rings 4. Lock washers

5. Cotter pins 6. Nylon nuts

1. Sealant should be applied or new gaskets used.

2. Oil should be applied to the moving components of parts.

3. Specified oil or grease should be applied at the prescribed

locations (such as oil seals) before reassembly.

I

23lJGIX.004

GI-6

Page 12 of 1164

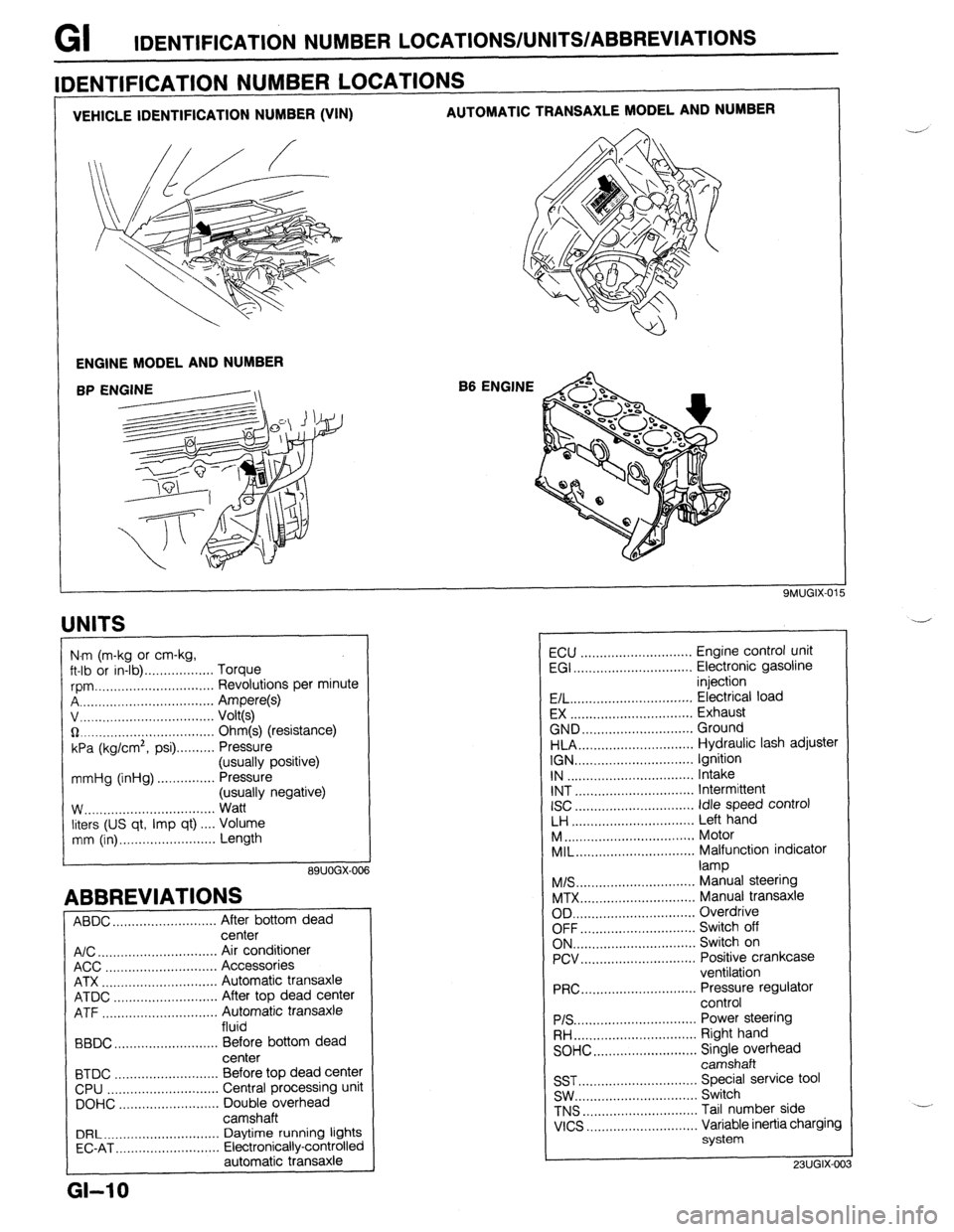

GI IDENTIFICATION NUMBER LOCATIONS/UNITS/ABBREVlATlONS

VEHICLE IDENTIFICATION NUMBER (VIN) AUTOMATIC TRANSAXLE MODEL AND NUMBER

ENGINE MODEL AND NUMBER

B6 ENGINE

IDENTIFICATION NUMBER LOCATIONS

UNITS

I

N.m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . . . . . . . . . . . . . . Torque

rpm ._..,,,.............,.......... Revolutions per minute

A . . . . . . . . . . . . . . . . . Ampere(s)

v, . . . . . . . . . . . . . .

Volt(s)

$2 _....._..,......................... Ohm(s) (resistance)

kPa (kg/cm2,

psi) . . . . . . . . . . Pressure

(usually positive)

mmHg (inHg) . . . . . . . . . . . . . . . Pressure

(usually negative)

W.. . . . . . . . . . . .

Watt

liters (US qt, Imp qt) ,... Volume

mm (in) ..,......,...,........... Length

89UOGX-00

ABBREVIATIONS

ABDC . . . . . . . . . . . . . . . . . . . . .

After bottom dead

center

A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air conditioner

ACC ..,.,...... 3 . . . . . . . . . . . . . . . . . Accessories

ATX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transaxle

ATDC ..,,...,...,............... After top dead center

ATF . . . . . . . . . . . . . . . . . Automatic transaxle

fluid

BBDC ,,..,.......,...,......,... Before bottom dead

center

BTDC .,......,...............,.. Before top dead center

CPU ..,,.......,...,..........,.. Central processing unit

DOHC ..,...,..,............,,.. Double overhead

camshaft

DRL ____.......................... Daytime running lights

EC-AT .,_.......,............,,.. Electronically-controlled

automatic transaxle

L

GI-10

ECU ............................. Engine control unit

EGI ............................... Electronic gasoline

injection

E/L.. .............................. Electrical load

EX ................................ Exhaust

GND.. ........................... Ground

HLA.. ............................ Hydraulic lash adjuster

IGN ............................... Ignition

IN ................................. Intake

INT ............................... Intermittent

ISC

............................... idle speed control

LH ................................ Left hand

M..

................................ Motor

MIL..

............................. Malfunction indicator

lamp

M/S..

............................. Manual steering

MTX.. ............................ Manual transaxle

OD ................................ Overdrive

OFF.. ............................ Switch off

ON.. .............................. Switch on

PCV.. ............................ Positive crankcase

ventilation

PRC..

............................ Pressure regulator

control

PIS ................................ Power steering

RH..

.............................. Right hand

SOHC.. .........................

z;;kiprhead

SST ............................... Special service tool

SW.. .............................. Switch

TNS

.............................. Tail number side

VICS

............................. Variable inertia charging

system

23UGIX-00

Page 32 of 1164

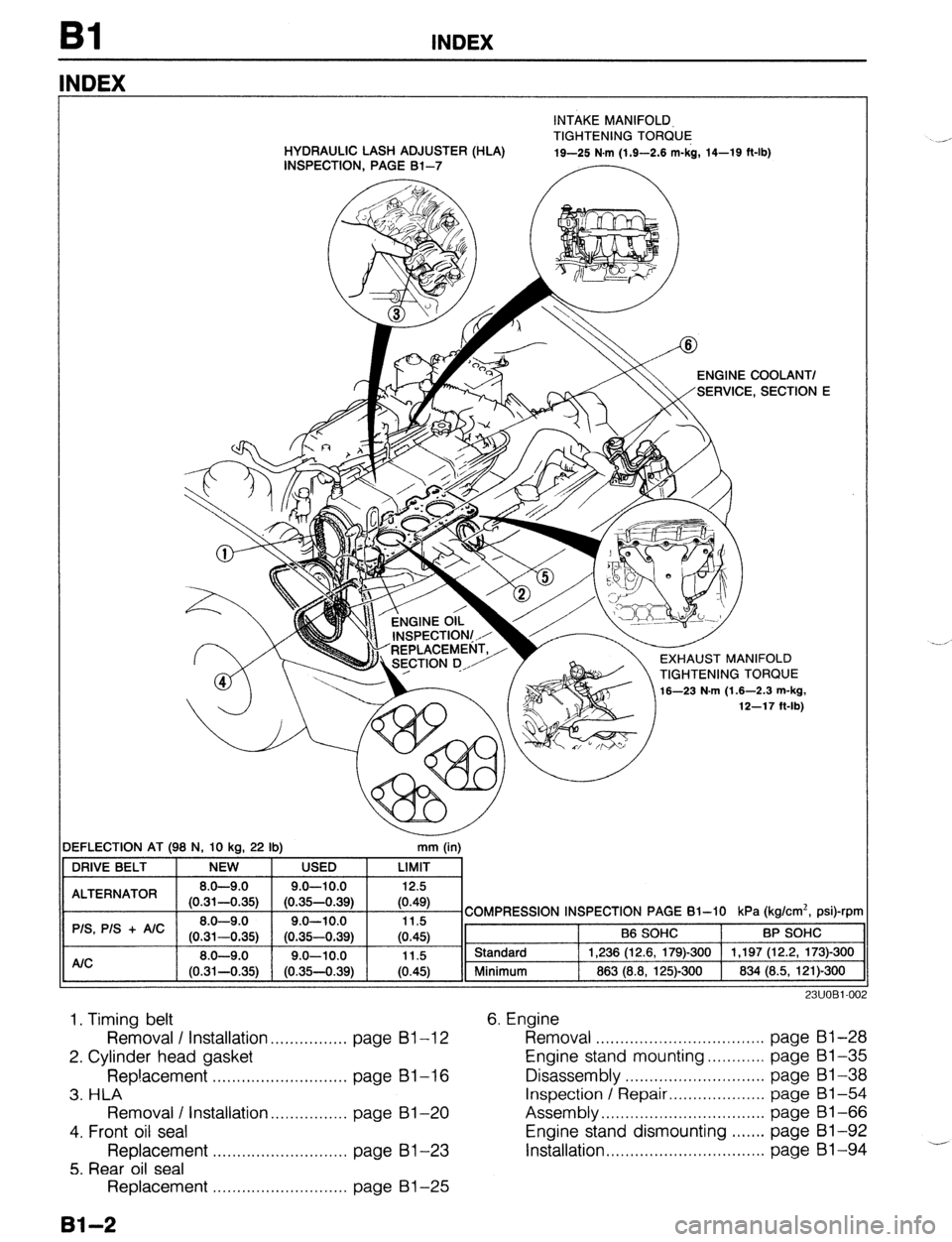

INDEX

NDEX

INTAKE MANIFOLD,

TIGHTENING TORQUE

.-’ HYDRAULIC LASH ADJUSTER (HLA)

INSPECTION, PAGE Bl-7 19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

DEFLECTION AT (98 N, 10 kc

19

22 lb)

r “Y7 ENGINE COOLANT/

SECTION

EXHAUST MANIFOLD

TIGHTENING TORQUE

16-23 N.m (1.6-2.3 m-kg,

12-17 ft-lb

mm (in)

11 DRIVE BELT NEW USED LIMIT

COMPRESSION INSPECTION PAGE 61-10 kPa (kg/cm*, psi)-rpm

y-1, Sta,,dar‘-j , ,238;;;;;;$))-3(J() , ,,97;;2~;;&)0

883 (8.8, 125)-300 834 (8.5, 121)-300 II A/C 8.0-9.

(0.31-0.35) I (0.35-0.39) I (0.45) 11 Minimum

-

E

1. Timing belt

23UOBl-00:

Removal / installation . . . . . . . . . . . . . . . . page 61-l 2

2. Cylinder head gasket

Rep!acement . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl-16

3. HLA

Removal / Installation . . . . . . . . . . . . . . . page 81-20

4. Front oil seal

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . page Bl -23

5. Rear oil seal Removal ................................... 6. Engine

page Bl-28

Engine stand mounting.. .......... page 81-35

Disassembly ............................. page Bl-38

Inspection / Repair .................... page Bl-54

Assembly.. ................................ page 81-66

Engine stand dismounting.. ..... page 81-92

Installation page 81-94 .+- .................................

Replacement . . , . . ,.. . . . . . . . . . . . . . . . . . . . page Bl-25

81-2

Page 37 of 1164

ENGINE TUNE-UP PROCEDURE Bl

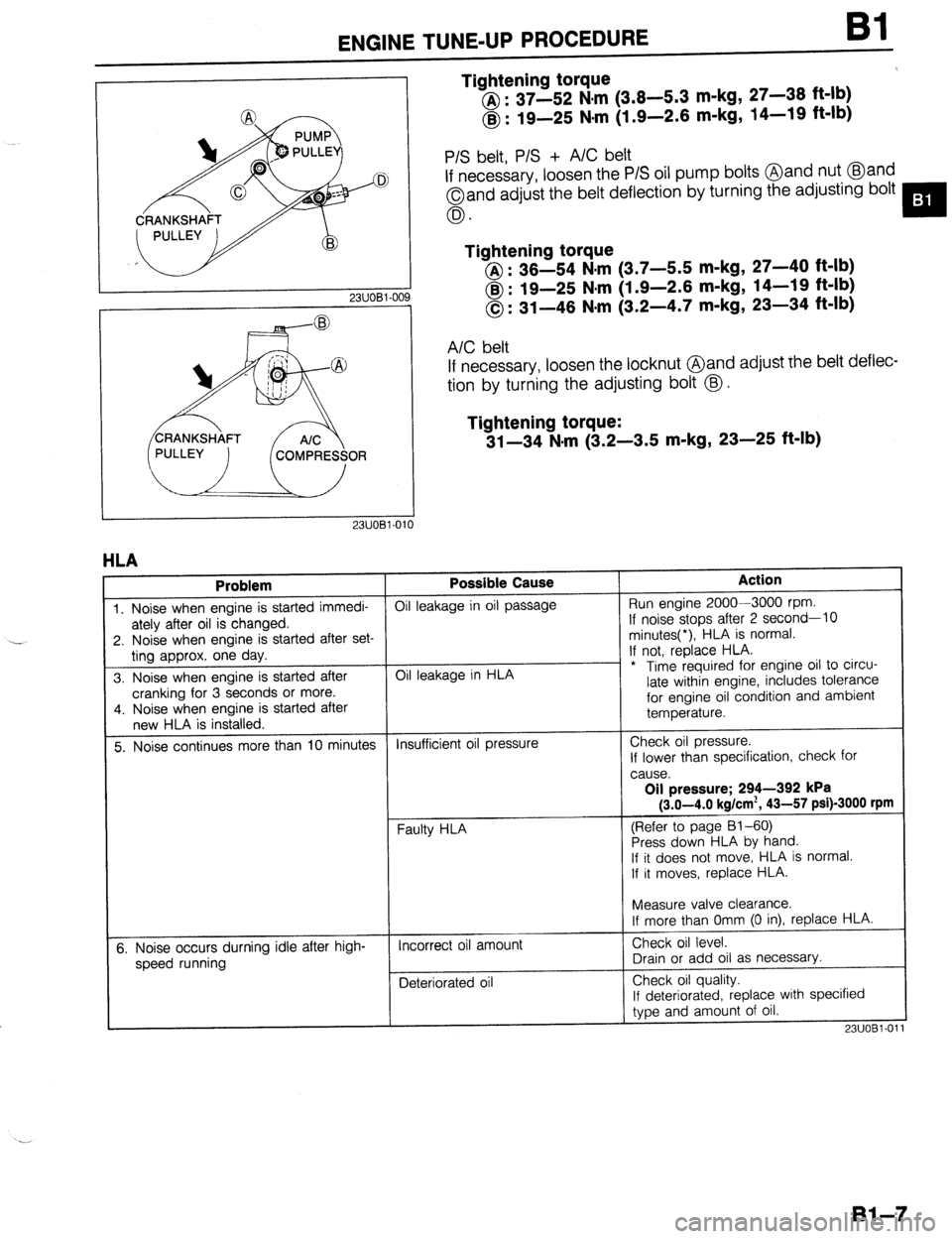

Tightening torque

@ : 37-52 N,m (3.8-5.3 m-kg, 27-38 ft-lb)

@ : 19-25 Nsm (1.9-2.6 m-kg, 14-19 ft-lb)

23UOBl-OC

P/S belt, P/S + A/C belt

If necessary, loosen the P/S oil pump bolts @and nut @and

Oand adjust the belt deflection by turning the adjusting bolt

0.

Tightening torque

@I : 36-54 N.m (3.7-5.5 m-kg, 27-40 ft-lb)

@ : 19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

0: 31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

A/C belt

If necessary, loosen the locknut @and adjust rhe belt deflec-

tion by turning the adjusting bolt @.

Tightening torque:

31-34 N-m (3.2-3.5 m-kg, 23-25 ft-lb)

1

HLA

Problem Possible Cause Action

1. Noise when engine is started immedi- Oil leakage in oil passage Run engine 2000-3000 rpm.

ately after oil is changed. If noise stops after 2 second-10

2. Noise when engine is started after set- minutes(*), HLA is normal.

ting approx. one day. If not, replace HLA.

3. Noise when engine is started after Oil leakage in HLA - * Time required for engine oil to circu-

cranking for 3 seconds or more. late within engine, includes tolerance

4. Noise when engine is started after for engine oil condition and ambient

new HLA is installed. temperature.

5. Noise continues more than 10 minutes Insufficient oil pressure Check oil pressure.

If lower than specification, check for

cause.

Oil pressure; 294-392 kPa

(3.0-4.0 kg/cm*, 43-57 psi)-3000 rpm

(Refer to page 81-60)

Press down HLA by hand.

If it does not move,. HLA is normal.

If it moves, replace HLA.

t

I

Measure valve clearance.

If more than Omm (0 in), replace HLA.

5. Noise occurs durning idle after high-

speed running Incorrect oil amount

Deteriorated oil Check oil level.

Drain or add oil as necessary.

Check oil quality.

If deteriorated, replace with specified

type and amount of oil.

23UOBl-01

Bl-7

Page 38 of 1164

Bl ENGINE TUNE-UP PROCEDURE

13UOBi-036

-i

OWOBX-261

13UOBl-08

LOCK BOLTS

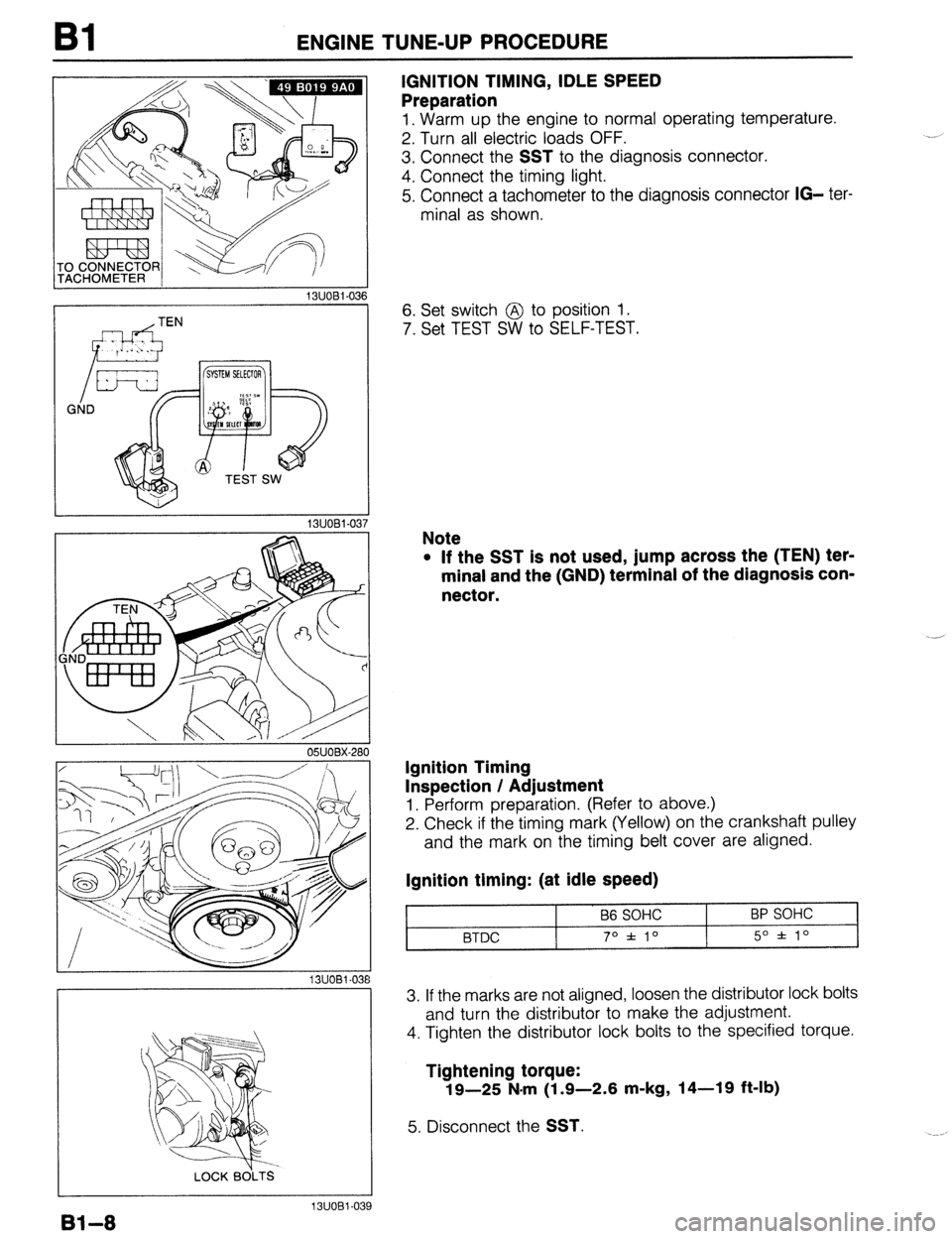

IGNITION TIMING, IDLE SPEED

Preparation

1, Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @ to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the (TEN) ter-

minal and the (GND) terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform preparation. (Refer to above.)

2. Check if the timing mark (Yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: (at idle speed)

B6 SOHC

BTDC 70 f 10 BP SOHC

5O f lo

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

Bl-8

13UOBl-039

Page 40 of 1164

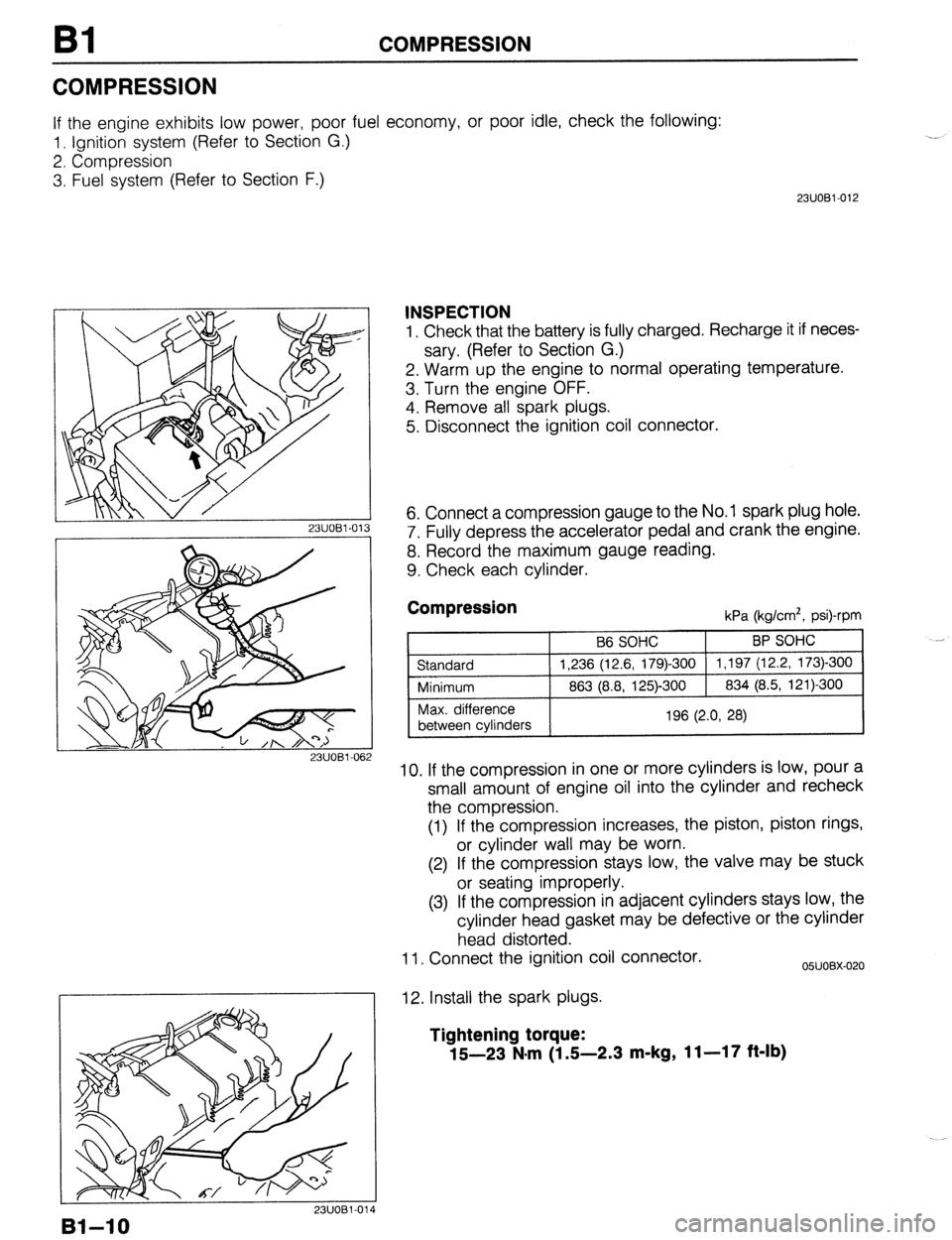

Bl COMPRESSION

COMPRESSION

If the engine exhibits low power, poor fuel economy, or poor idle, check the following:

1. Ignition system (Refer to Section G.)

2. Compression

3. Fuel system (Refer to Section F.)

23UOBl-01

23UOBl-06

23UOBl-014 23UOBl-012

INSPECTION

1. Check that the battery is fully charged. Recharge it if neces-

sary. (Refer to Section G.)

2. Warm up the engine to normal operating temperature.

3. Turn the engine OFF.

4. Remove all spark plugs.

5. Disconnect the ignition coil connector.

6. Connect a compression gauge to the No. 1 spark plug hole.

7. Fully depress the accelerator pedal and crank the engine.

8. Record the maximum gauge reading.

9. Check each cylinder.

Compression kPa (kg/cm*, psi)-rpm

10. If the compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder and recheck

the compression.

(1) If the compression increases, the piston, piston rings,

or cylinder wall may be worn.

(2) If the compression stays low, the valve may be stuck

or seating improperly.

(3) If the compression in adjacent cylinders stays low, the

cylinder head gasket may be defective or the cylinder

head distorted.

11. Connect the ignition coil connector.

12. Install the spark plugs.

05UOBX-020

Tightening torque:

15-23 N*m (1 S-2.3 m-kg, 11-17 ft-lb)

Bl-10

Page 44 of 1164

Bl ON-VEHICLE MAINTENANCE

13EOBl-023

MARKS

13EOBl-02, 4

I

03UOBl-02

98 N

(10 kg, 22 lb)

13EOBl-02 15

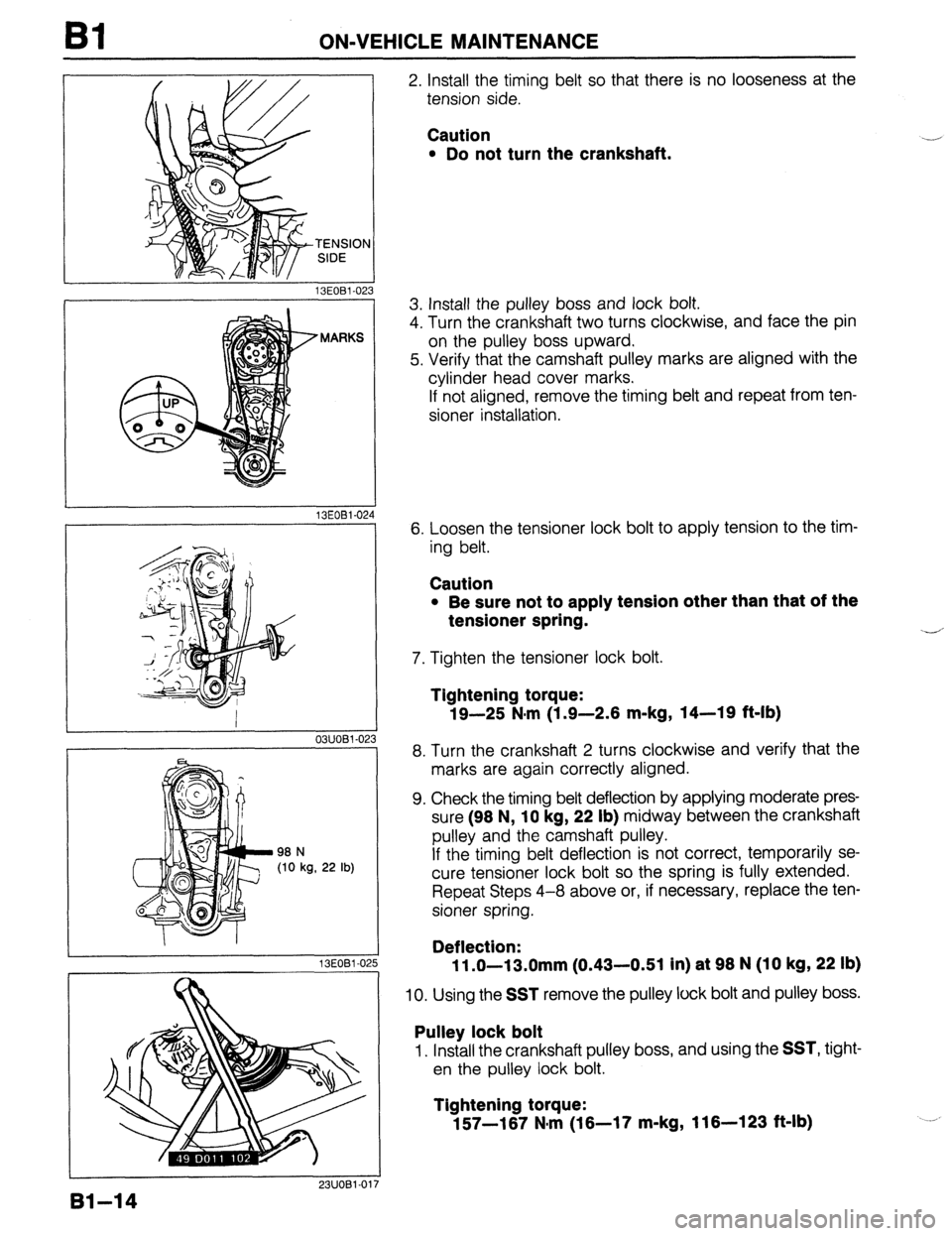

2. Install the timing belt so that there is no looseness at the

tension side.

Caution

l Do not turn the crankshaft. .-

3. Install the pulley boss and lock bolt.

4. Turn the crankshaft two turns clockwise, and face the pin

on the pulley boss upward.

5. Verify that the camshaft pulley marks are aligned with the

cylinder head cover marks.

If not aligned, remove the timing belt and repeat from ten-

sioner installation.

6. Loosen the tensioner lock bolt to apply tension to the tim-

ing belt.

Caution

l Be sure not to apply tension other than that of the

tensioner spring.

7. Tighten the tensioner lock bolt.

--

Tightening torque:

19-25 N,m (1.9-2.6 m-kg, 14-19 ft-lb)

8. Turn the crankshaft 2 turns clockwise and verify that the

marks are again correctly aligned.

9. Check the timing belt deflection by applying moderate pres-

sure (96 N,

10 kg, 22 lb) midway between the crankshaft

pulley and the camshaft pulley.

If the timing belt deflection is not correct, temporarily se-

cure tensioner lock bolt so the spring is fully extended.

Repeat Steps 4-8 above or, if necessary, replace the ten-

sioner spring.

Deflection:

11 .O-13.0mm (0.43-0.51 in) at 96 N (10 kg, 22 lb)

10. Using the SST remove the pulley lock bolt and pulley boss.

Pulley lock bolt

1. Install the crankshaft pulley boss, and using the SST, tight-

en the pulley lock bolt.

Tightening torque:

157-167 N,m (16-17 m-kg, 116-123 ft-lb)

91-14

Page 49 of 1164

.

ON-VEHICLE MAINTENANCE

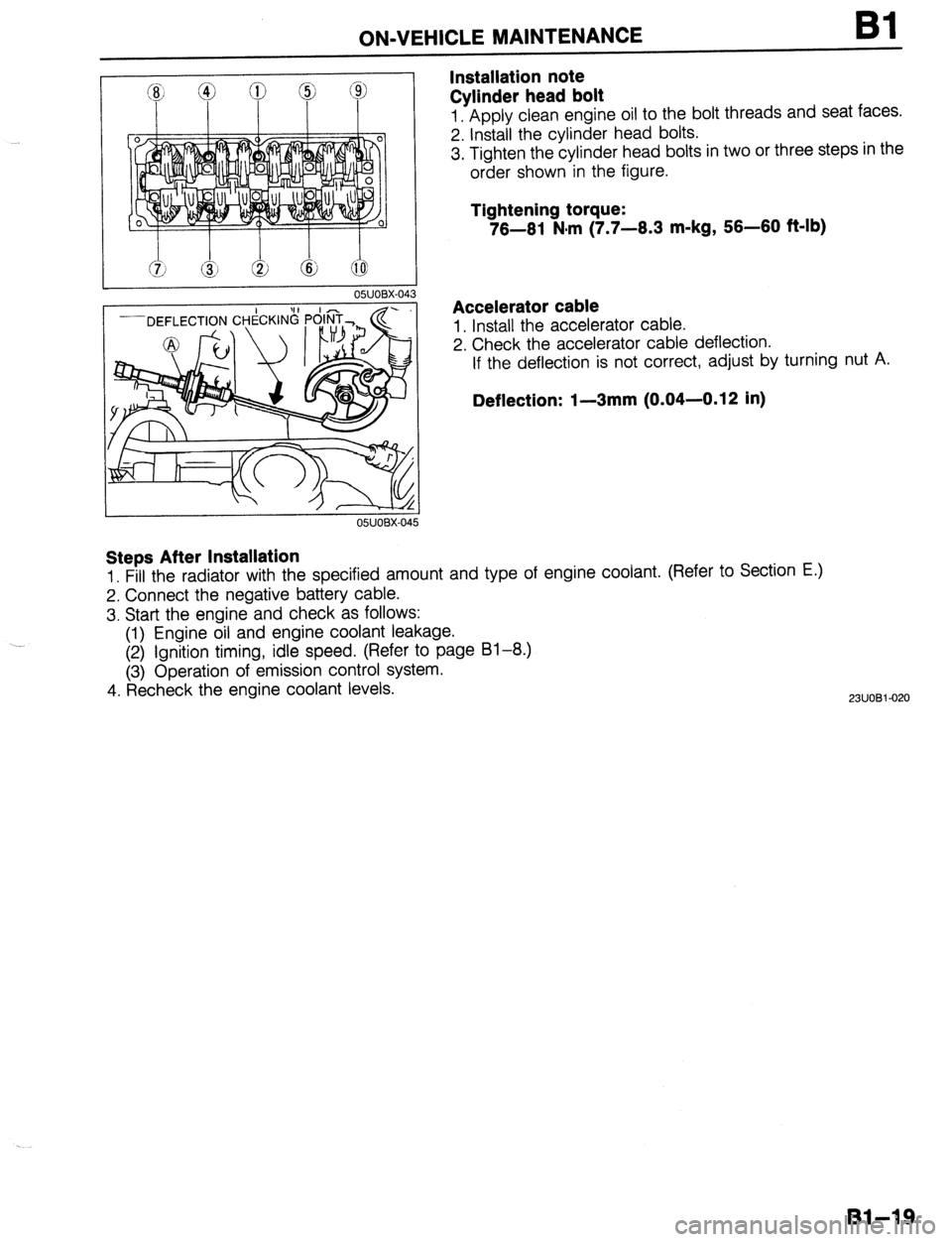

Installation note

Cylinder head bolt Bl

1. Apply clean engine oil to the bolt threads and seat faces.

2. Install the cylinder head bolts.

3. Tighten the cylinder head bolts in two or three steps in the

order shown in the figure.

Tightening torque:

76-61 N#m (7.7-6.3 m-kg, 56-60 f&lb)

Accelerator cable

1. Install the accelerator cable.

2. Check the accelerator cable deflection.

If the deflection is not correct, adjust by turning nut A.

Deflection: I-3mm (0.04-0.12 in)

Steps After Installation

1. Fill the radiator with the specified amount and type of engine coolant. (Refer to Section E.)

2. Connect the negative battery cable.

3. Start the engine and check as follows:

(1) Engine oil and engine coolant leakage.

(2) Ignition timing, idle speed. (Refer to page 81-8.)

(3) Operation of emission control system.

4. Recheck the engine coolant levels.

2311081-020

Bl-19

Page 52 of 1164

Bl ON-VEHICLE MAINTENANCE

8 e

93UOlA.08

EX

03UOBl-035

HEAD COVER

)

23UOBl-023

Steps After Installation

1, Connect the negative battery cable.

2. Start the engine and fully warm up.

3. Verify that there is no tappet noise. 2. Install the rocker arm and rocker shaft assembly.

Caution

l The bolts must be tightened gradually and in the or-

der shown in the figure.

Tightening torque:

22-28 N-m (2.2-2.9 m-kg, 18-21 ft-lb)

BP SOHC

1. Assemble the rocker arm and rocker shaft assembly as

shown in the figure.

Caution

l Face the rocker shaft identification mark upward.

l The installation bolt holes are different for the ex-

haust and intake sides.

Identification mark

IN . . . . . . . . . . White

EX . . . . . . . . . . . Blue

2. Install the rocker arm and rocker shaft assembly.

3. Tighten the rocker arm bolts in two or three steps in the or-

der shown in the figure.

Tightening torque:

22-28 Nsrn (2.2-2.9 m-kg, 16-21 ft-lb)

Cylinder head cover

1. Install the cylinder head cover.

Tightening torque

Bolt @:

4.9-8.8 N-m (50-90 cmikg, 43-78 in-lb)

Bolt @:

7.8-l 1 Nnrn (80-l 10 cm-kg, 69-95 in-lb)

Caution

l If the head cover gasket is reused, apply sealant in

the groove as shown.

03UOBl-038

.-

Bl-22