distributor MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 38 of 1164

Bl ENGINE TUNE-UP PROCEDURE

13UOBi-036

-i

OWOBX-261

13UOBl-08

LOCK BOLTS

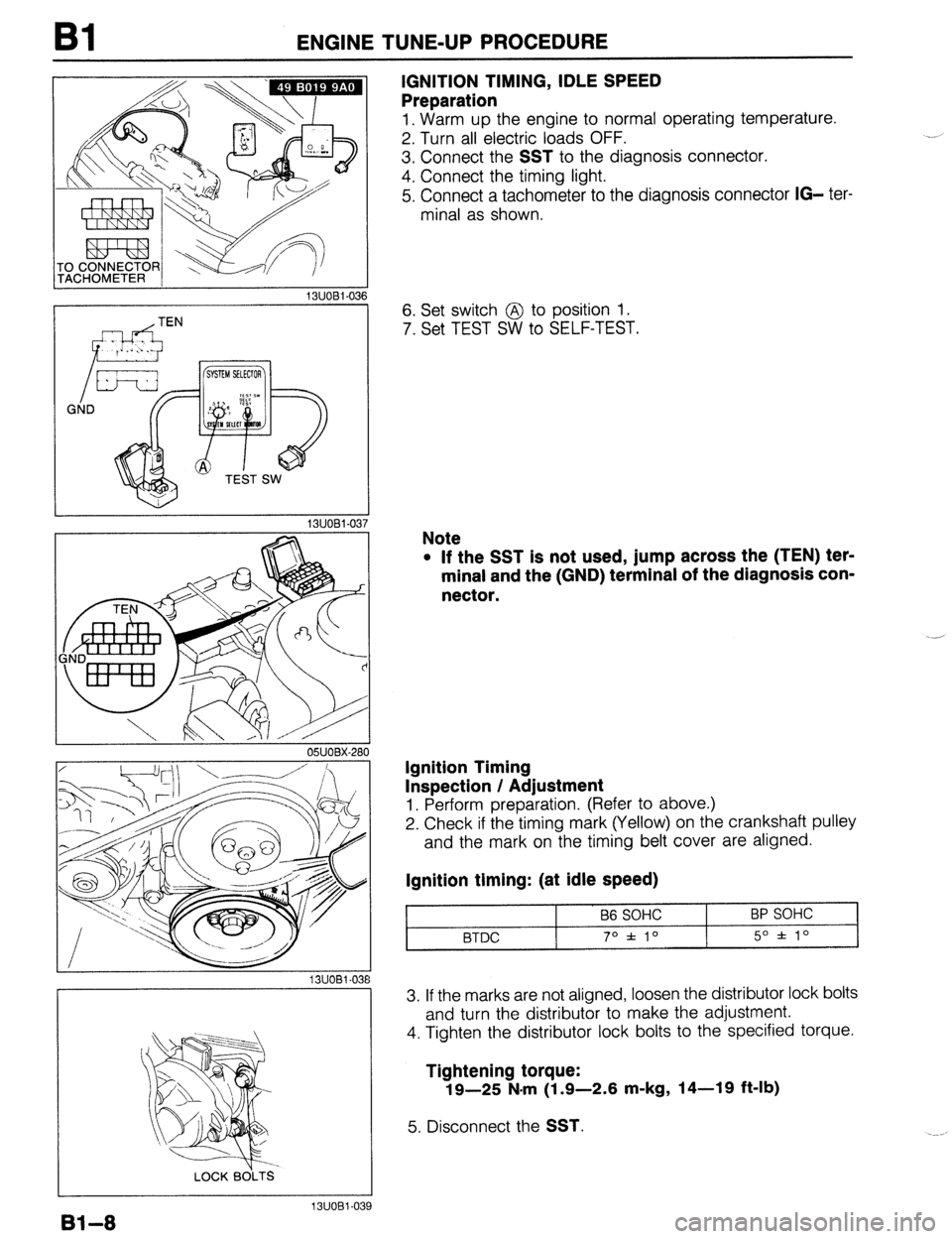

IGNITION TIMING, IDLE SPEED

Preparation

1, Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @ to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the (TEN) ter-

minal and the (GND) terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform preparation. (Refer to above.)

2. Check if the timing mark (Yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: (at idle speed)

B6 SOHC

BTDC 70 f 10 BP SOHC

5O f lo

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

Bl-8

13UOBl-039

Page 48 of 1164

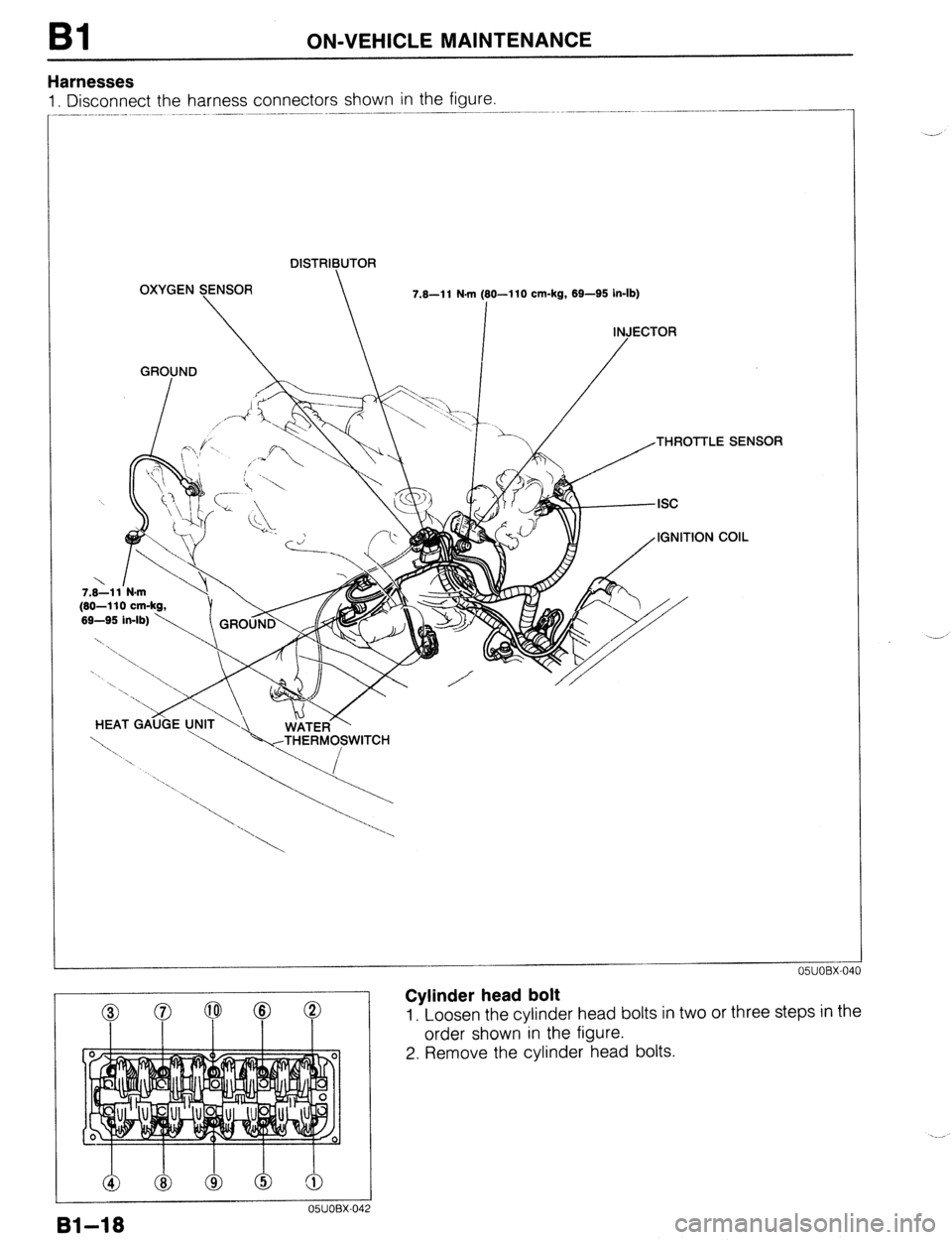

Bl ON-VEHICLE MAINTENANCE

Harnesses

1. Disconnect the harness connectors shown in the figure.

DISTRIBUTOR

OXYGEN SENSOR

7.8-l 1 N.m (80-I 10 cm-kg, 69-95 in-lb)

I

INJECTOR

GROUND

/

7.8-11 N-m

(80-110 cm-kg,

HEAT GAijijE

Cylinder head bolt

1, Loosen the cylinder head bolts in two or three steps in the

order shown in the figure.

2. Remove the cylinder head bolts.

Page 70 of 1164

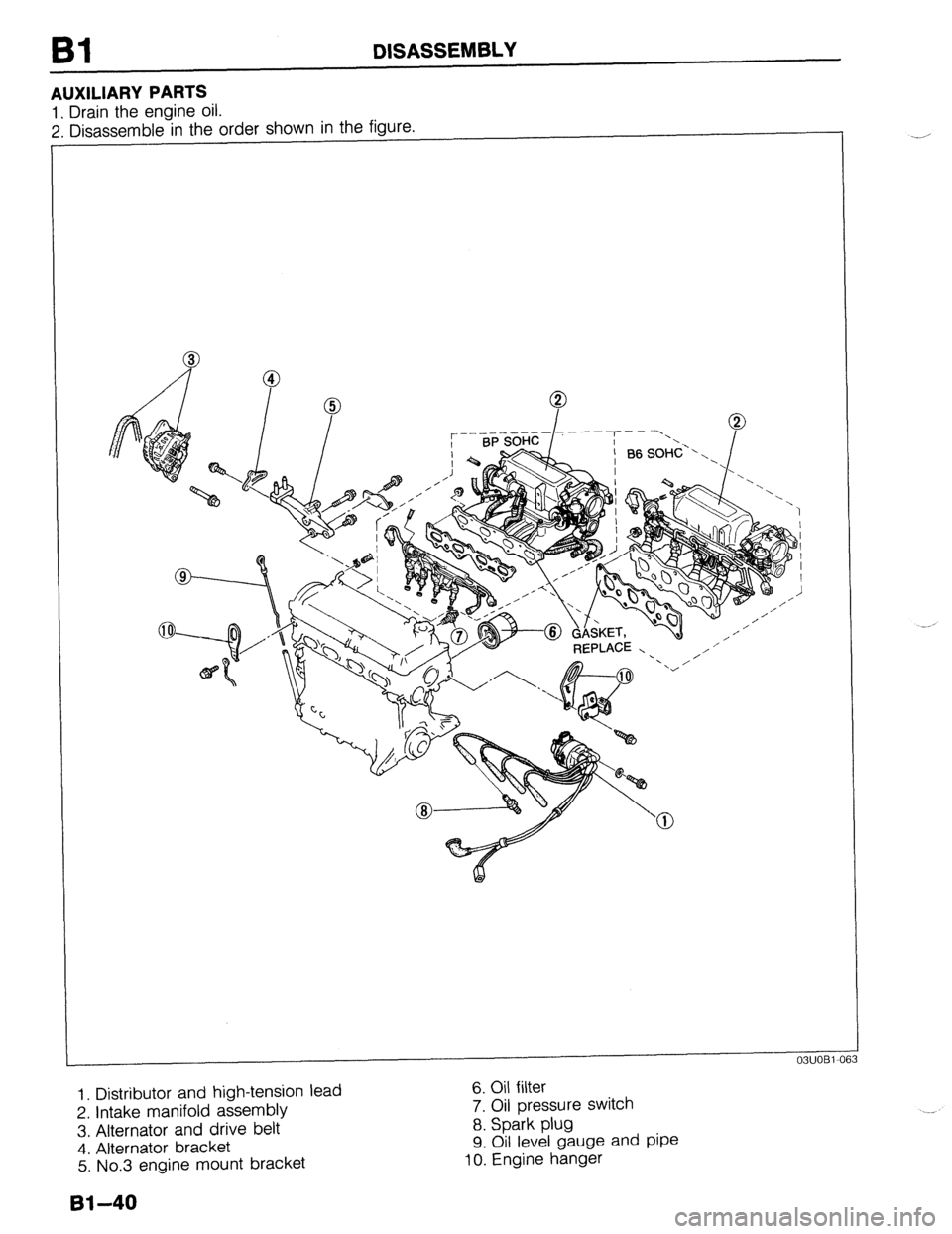

Bl DISASSEMBLY

AUXILIARY PARTS

1. Drain the engine oil.

2. Disassemble in the order shown in the figure.

- REPLACE - ’ ,/ I’

1. Distributor and high-tension lead

2. Intake manifold assembly

3, Alternator and drive belt

4. Alternator bracket

5. No.3 engine mount bracket 6. Oil filter

7. Oil pressure switch

8. Spark plug

9. Oil level gauge and pipe 10. Engine hanger

61-40

Page 121 of 1164

ASSEMBLY Bl

03UOBl-16

03UOB1.21 38

Injector and Distribution Pipe Assembly (BP SOHC)

1. Install the injector and distribution pipe assembly with new

insulators.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

Intake Manifold Assembly

1, Remove all foreign material from the intake manifold con-

tact surface.

2. Install a new gasket and the intake manifold assembly.

Tightening torque:

19-25 N*m (1.9-2.6 m-kg, 14-19 ft-lb)

Distributor and High-tension Lead

1. Apply engine oil to the O-ring, and position it on the dis-

tributor.

2. Apply engine oil to the blade.

3. Install the distributor with the blade fit into the camshaft

groove.

4. Temporarily, loosely tighten the distributor installing bolt.

5. Adjust the ignition timing after engine installation.

(Refer to Section G.)

6. Connect the high-tension leads.

81-91

Page 140 of 1164

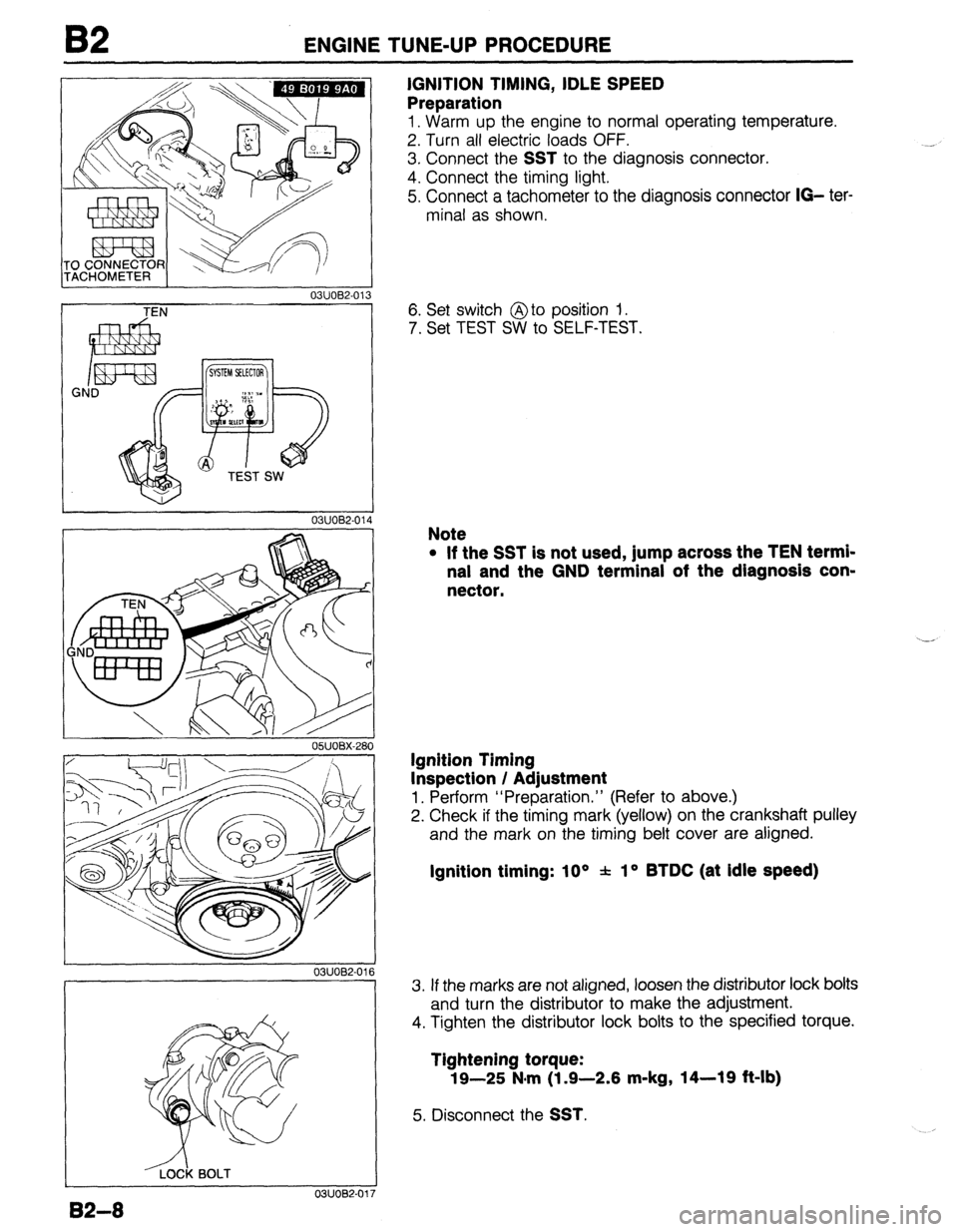

82 ENGINE TUNE-UP PROCEDURE

03UOB2-013

IGNITION TIMING, IDLE SPEED

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect the timing light.

5. Connect a tachometer to the diagnosis connector

IO- ter-

minal as shown.

TEN

03UOB2-01

I

-&k BOLT

0311082-01’

82-8

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

Inspection / Adjustment

1. Perform “Preparation.” (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Ignition timing: 10 * f lo BTDC (at Idle speed)

3. If the marks are not aligned, loosen the distributor lock bolts

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N*m (1 .Q-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

Page 154 of 1164

B2 ON-VEHICLE MAINTENANCE

HLA

Removal / Installation

1. Disconnect the negative battery cable.

2. Remove in the order shown in the figure, referring to

Removal Note.

3. install in the reverse order of removal, referring to Installation Note --- ----- -__ __-- ,‘.

11.3-14.2 N.m

(1.15-1.45 m-\g, 100-126 in-lb)

49-61

(5.0~6.2,-36-45)

4.9-6.6 N.m

(50-90 cm-kg, 43-76 in-lb)

7.6All N-m

(80-110 cm-kg, 69-95 in-lb) 1 Q’-25

(1.9-2.6, 14-19)

N.m (m-kg, ft-lb)

0311082-03

1. High-tension lead

10. Cylinder head cover

2. Distributor

Installation Note..

....................

Installation Note.. ......................

page 62-25

11. Camshaft pulley

3. P/S and/or A/C drive belt

Removal note ..........................

Removal / Installation..

.............. page E32-

6

Installation Note .......................

4. Alternator drive belt

12. Seal plate

Removal / Installation

......... . ...... page B2- 6

13. Camshaft

5. Water pump pulley

Removal Note.. ........................

6. Timing belt cover, upper

Installation Note.. .....................

7. Timing belt cover, middle

14. HLA

8. Spark plug

Removal note ..........................

9. Timing belt

Installation

Note.. .....................

Removal Note.. .........................

page B2-18 Inspection

................................

Installation Note.. ......................

page B2-20

7

page 62-19

page 82-23

page 82-24

page B2-23

page 62-23

page B2-23

page B2-23 ‘--’

page 82-60

82-22

Page 155 of 1164

ON-VEHICLE MAINTENANCE 82

I 05UOBX-049

05UOBX-C

05UOBX-0

03UOB2-1

Removal note

Camshaft pulley

1, Hold the camshaft with a wrench at hexagonal portion.

2. Remove the camshaft pulley lock bolt.

3. Remove the camshaft pulley.

Camshaft

1. Loosen the camshaft cap bolts in two or three steps in the

order shown in the figure.

2. Remove the camshaft caps.

3. Remove the camshaft.

4. Remove the camshaft oil seal from the camshaft.

HLA

Caution

l Mark the HLA with a felt pen so that they can be rein-

stalled in the position from which they were

removed.

1. Remove the HLA from the cylinder head.

Installation note

HLA

1. Apply clean engine oil to the friction surfaces.

2. If the HLA are being reused, install them in the position from

which they were removed.

3. Verify that the HLA move smoothly in their bores.

Camshaft

Note

l The intake camshaft is grooved for the distributor

drive.

1. Apply clean engine oil to the camshaft journals and bearings.

2. Install the camshaft in position.

82-23

Page 157 of 1164

ON-VEHICLE MAINTENANCE B2

05UOBX-05

BLA-DE 0-dlNG

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and check as follows:

l Ignition timing. (Refer to page 82-8.) 3. Install the camshaft pulley lock bolts.

4. Hold the camshaft with a wrench.

5. Tighten the camshaft pulley lock bolt.

Tightening torque:

49-61 N-m (5.0-6.2 m-kg, 36-45 ft-lb)

Distributor

1. Apply grease to a new O-ring and the blade.

2. Install the distributor and loosely tighten the installation bolt.

3. Connect the distributor connector.

0311082-039

B2-25

Page 174 of 1164

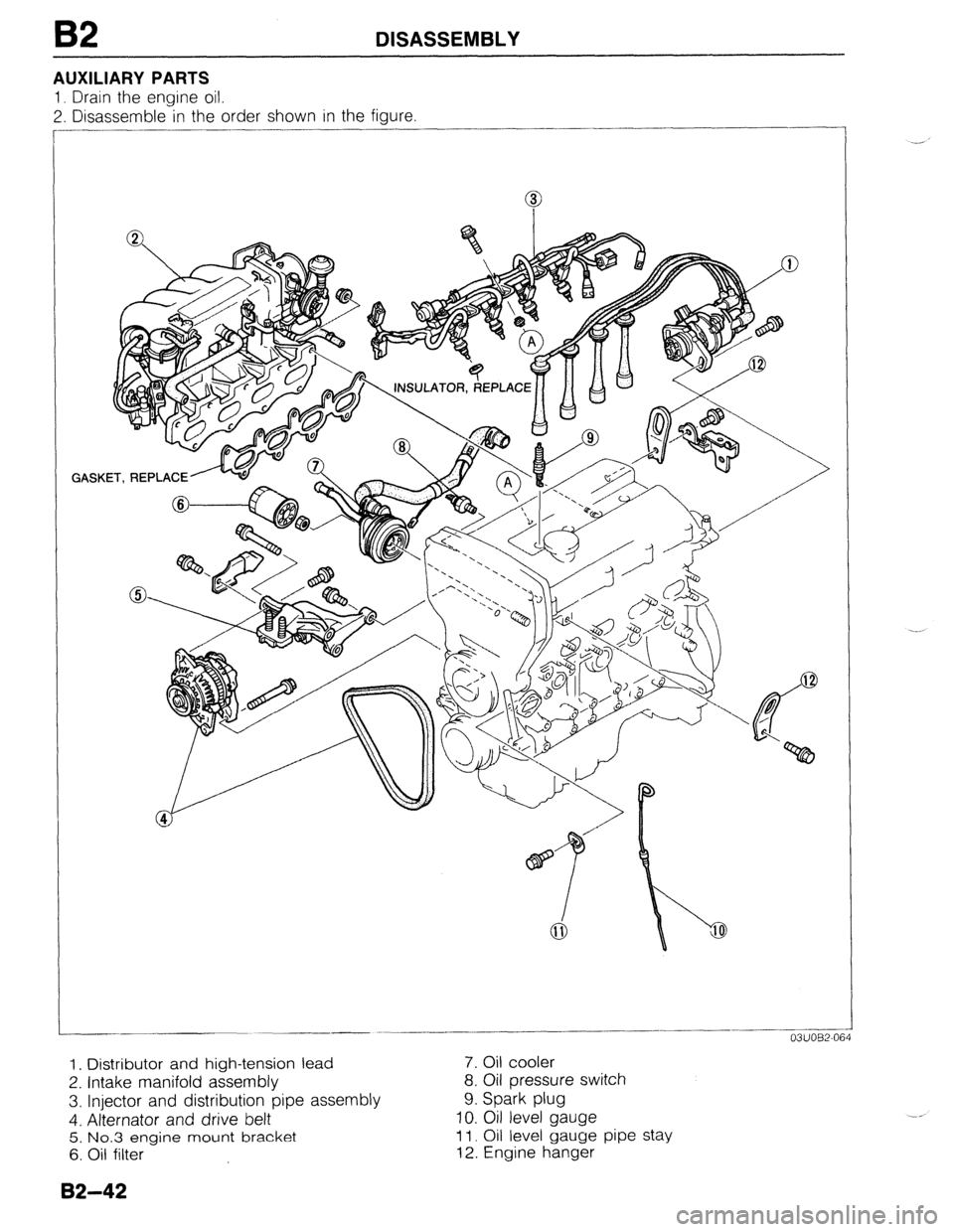

B2 DISASSEMBLY

AUXILIARY PARTS

1, Drain the engine oil.

2. Disassemble in the order shown in the figure

GASKET, REPLACE ..______-.

-___ -

03UOB2-064

1. Distributor and high-tension lead 7. Oil cooler

2. Intake manifold assembly 8. Oil pressure switch

3. Injector and distribution pipe assembly 9. Spark plug

4. Alternator and drive belt 10. Oil level gauge

5. No.3 engine mount bracket 11. Oil level gauge pipe stay

6. Oil filter 12. Engine hanger

82-42

Page 222 of 1164

B2 ASSEMBLY

03UOB2-15:

I

03UOB2-121

3. Connect the harness and hose.

--’

Distributor and High-tension Lead

1. Apply grease to a new O-ring and the blade.

2. Install the distributor and loosely tighten the installation bolts.

3. Connect the high-tension leads.

82-90