distributor MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 271 of 1164

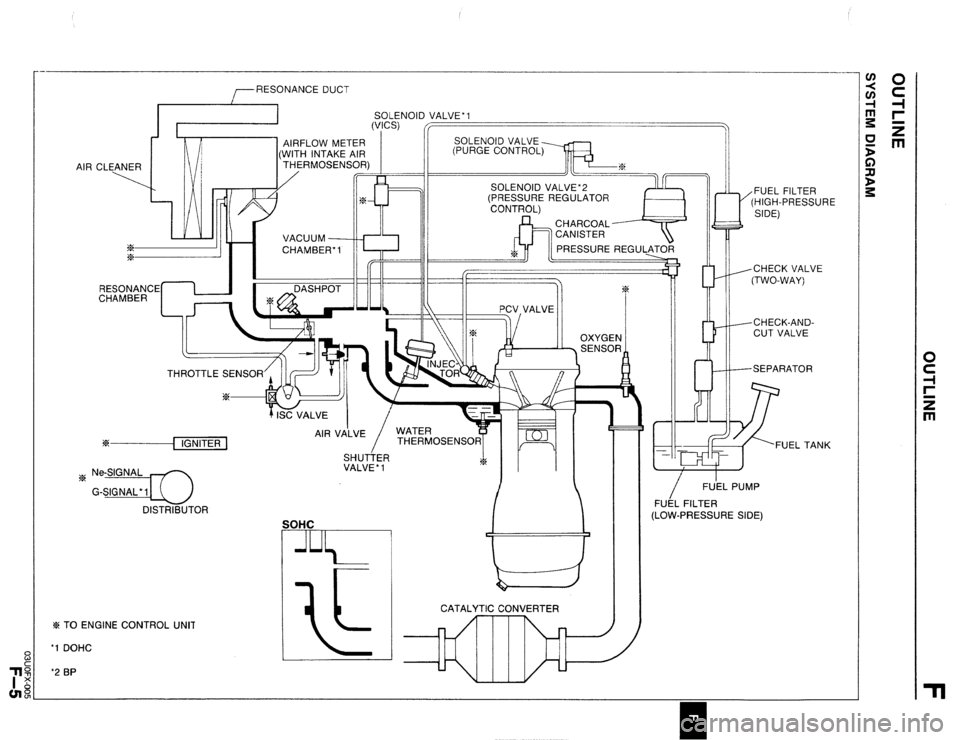

RESONANCE DUCT

SOLENOID VALVE’1

AIR CLEANER

ix

%

4.L VACUUM

CHAMBER-1

RESONANCE

CHAMBER DASHPOT

w/r) --CHECK VALVE

(TWO-WAY)

I II 14 J--CHECK-AND-

II l/%x II/ II _ \,\, _.-.,I CUT VALVE

TH

?z% ---{ IGNITER 1

~ Ne-SIGNAL 1/

G-SIGNAL’IU

DISTRIBUTOR AIR VA’LVE

/ WATER

THERMOSENSOR

SHUTTER 7

VALVE * 1 s%

SOHC

% TO ENGINE CONTROL UNIT

‘1 DOHC

‘2 BP

I CATALYTIC CONVERTER /

FU’EL PUMP

FUEL FILTER

(LOW-PRESSURE SIDE)

Page 277 of 1164

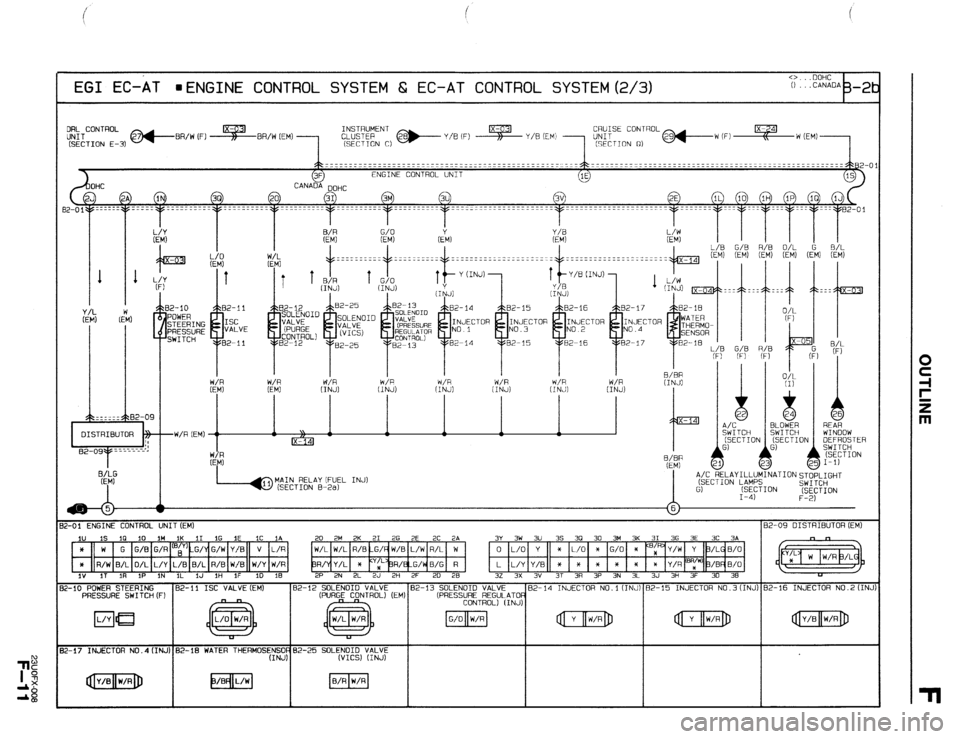

EGI EC-AT eENGINE CONTROL SYSTEM &i EC-AT CONTROL SYSTEM(2/3)

DISTRI8UTOR -W/R IEM) ::

MAIN RELAY [FUEL INJI

(SECTION B-2d

I-4)

F-2)

@

t-01 ENGINE CONTROL UNIT (EM) 82-09 DISTRIBUTOR (EM)

X L/O x G/O

!-17 INJECTOR N0,4(INJ) 82-18 WATER THERMOS:NSyFB2-25 SOLENOID VALVE

(vIcs) (INJ)

Page 280 of 1164

F OUTLINE

A comparison of the new and previous models is as follows.

Engine Control Unit Terminal Relation Ship Chart

Connected to

Headlight switch Terminal

Connected to Terminal

New Previous New Previou

1H IU

Water thermosensor 2E 2Q

Diagnosis connector

(TEN terminal) / II 1 IK 1 1 Throttle sensor

Rear window defroster switch

I I 21 2K

Ground (California)

Main relay (Canada)

A/C relay

Vehicle speed sensor

P/S pressure switch

A/C switch

Blower control switch 1K 2H

IL 1J

1M --

1N 1P

10 IQ

1P 1s Distributor

(G-signal) [DOHC]

Intake air thermosensor

Solenoid valve

(Purge control)

Ground (Injector)

Ground (Output)

Ground (CPU) 2J 2G

2K 2P

20 2x

___

Stoplight switch 1Q 10

Ground (Input)

1 I I 1 ! 3D ! 2D

Cruise control main switch

1 lS / - II8cRalnardega,y

Throttle sensor

(Idle switch)

Distributor

(Ne-signal) 1T 1N

2A 2E

2B 20

2C 2N Solenoid valve

(VICS)

--.-- I_-

Solenoid valve

(Pressure regulator) [BP] 31 2s

-- -_

3M 2T

Airflow meter

Oxygen sensor

-

Fan switch 1 2D 1 IR 1 1 lniector (Nos. 2, 4) I 3v I 2v

23UOFX-01 I

F-l 4

Page 282 of 1164

F OUTLINE

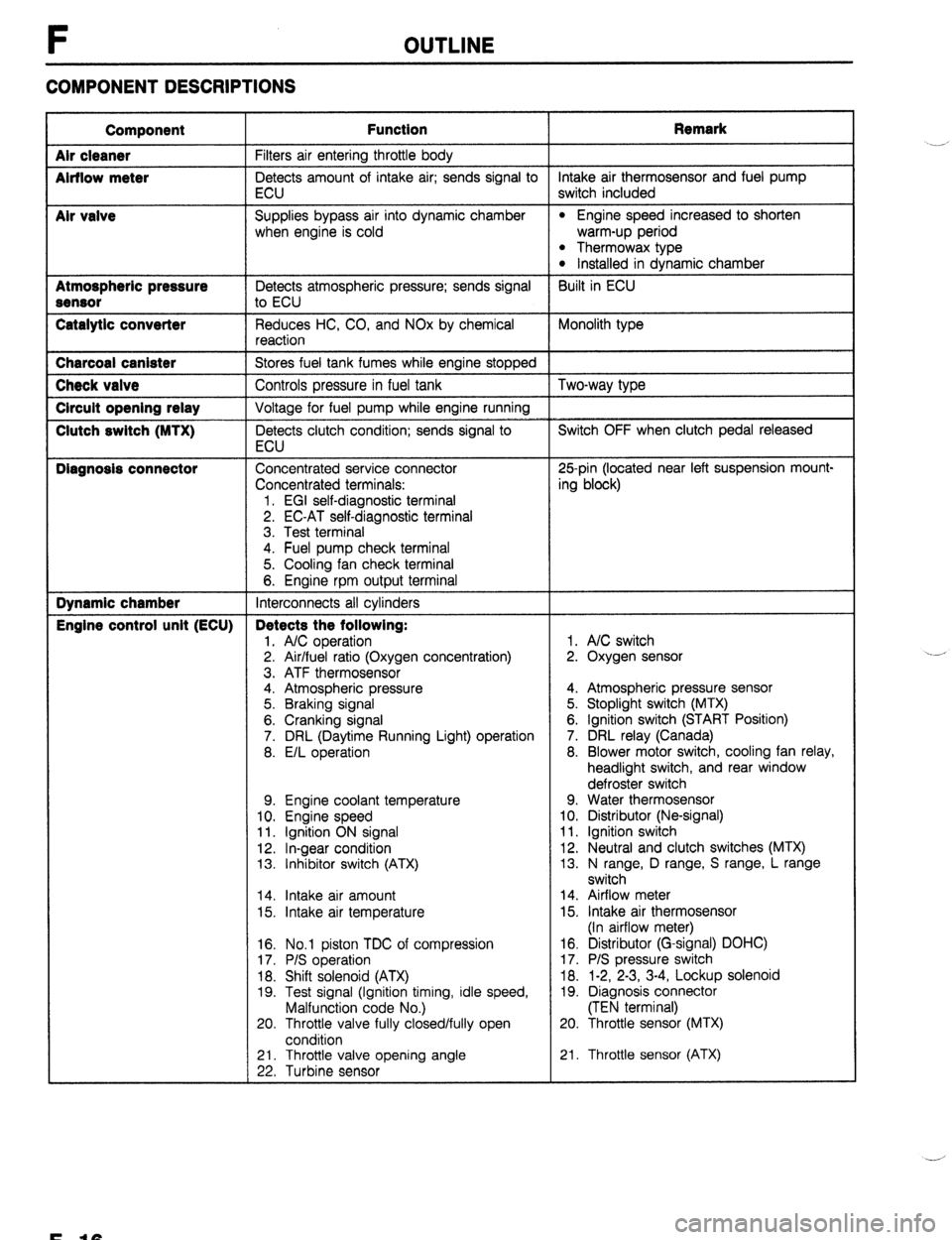

COMPONENT DESCRIPTIONS

Component

Air cleaner

Airflow meter

Mr valve

Atmospheric pressure

Sensor

Catalytic converter Function Remark

Filters air entering throttle body

Detects amount of intake air; sends signal to intake air thermosensor and fuel pump

ECU switch included

Supplies bypass air into dynamic chamber

l Engine speed increased to shorten

when engine is cold warm-up period

l Thermowax type l Installed in dynamic chamber

Detects atmospheric pressure; sends signal Built in ECU

to ECU

Reduces HC, CO, and NOx by chemical Monolith type

reaction Charcoal canister

Stores fuel tank fumes while engine stopped Check valve

Controls pressure in fuel tank Two-way type Circuit opening relay

Voltage for fuel pump while engine running Clutch switch (MTX)

Detects clutch condition; sends signal to Switch OFF when clutch pedal released

ECU Diagnosis connector

Concentrated service connector 25pin (located near left suspension mount-

Concentrated terminals: ing block)

1. EGI self-diagnostic terminal

2. EC-AT self-diagnostic terminal

3. Test terminal

4. Fuel pump check terminal

5. Cooling fan check terminal

6. Engine rpm output terminal Dynamic chamber

Interconnects all cylinders Engine control unit (ECU) Detects the following:

1. A/C operation 1. A/C switch

2. Air/fuel ratio (Oxygen concentration) 2. Oxygen sensor

3. ATF thermosensor

4. Atmospheric pressure 4. Atmospheric pressure sensor

5. Braking signal 5. Stoplight switch (MTX)

6. Cranking signal 6. Ignition switch (START Position)

7. DRL (Daytime Running Light) operation 7. DRL relay (Canada)

8. E/L operation 8. Blower motor switch, cooling fan relay,

headlight switch, and rear window

defroster switch

9. Engine coolant temperature 9. Water thermosensor

10. Engine speed 10. Distributor (Ne-signal)

11. Ignition ON signal 11. Ignition switch

12. In-gear condition 12. Neutral and clutch switches (MTX)

13. Inhibitor switch (ATX) 13. N range, D range, S range, L range

switch

14. Intake air amount 14. Airflow meter

15. Intake air temperature 15. Intake air thermosensor

(In airflow meter)

16. No.1 piston TDC of compression

17. P/S operation

18. Shift solenoid (ATX)

19. Test signal (Ignition timing, idle speed,

Malfunction code No.)

20. Throttle valve fully closed/fully open

condition 16. Distributor (G-signal) DOHC)

17. P/S pressure switch

18. 1-2, 2-3, 3-4, Lockup solenoid

19. Diagnosis connector

(TEN terminal)

20. Throttle sensor (MTX)

21. Throttle valve opening angle

22. Turbine sensor 21. Throttle sensor (ATX) .__r

F-10

Page 308 of 1164

![MAZDA PROTEGE 1992 User Guide F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D MAZDA PROTEGE 1992 User Guide F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D](/img/28/57077/w960_57077-307.png)

F TROUBLESHOOTING GUIDE

8 ROUGH IDLE/ENGINE STALLS AT IDLE - ALWAYS

bESCRIP- l Engine starts normally but stalls or vibrates excessively at idle in every condition

‘ION TROUBLESHOOTING HINTS]

D Air/Fuel mixture too lean @ Incorrect idle speed

l Air leakage l Idle speed misadjustment l Fuel injection control malfunction l Idle speed control malfunction

*Low fuel line pressure @ One or more spark plugs not firing

3 One or more injectors clogged or not operating @ Low engine compression

3 Low intake air amount @ Airflow meter stuck INSPECTION

1

1

2

3

4

5

6

- Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON w page F-82

SYSTEM2ELECT: 1

M v’SELECT SW: A TEST

Check if ECU terminal voltages are OK

MTX...Especially 2D, 20 and 2Q

ATX... Especially 2B, 2E and 3D CT page F-150

Disconnect high-tension lead at idle and check if

engine speed decreases equally at each cylinder

Check for injector operating sound at idle

Check if battery voltage exists at injector connec-

tor (W/R) wire

Check if strong blue spark is visible at discon-

nected high-tension lead

, Yes No Service Code No. displayed

Check for cause (Refer to specified

:heck sequence) “88” flashes

Check ECU terminal IF voltage CT page F-150

Specification: Battery voltage

(Ignition switch ON)

3 If OK, replace ECU w page F-149 3 If not OK, check wiring between

ECU and Self-Diaanosis Checker Yes

Go to next step No

Check for cause Yes

Go to Step 8 No

Go to next step

Go to Step 6

Go to Step 5 Yes

No

Yes

No

Yes

No I-

30 to next step w page F-83

0 page F-151

Check if injector resistance is OK c7 page F-131

Resistance: Approx. 12-l 852

c3 If OK, check wiring between ECU

and injector

c3 If not OK, replace injector w page F-131

Check wiring between ECU and injector

Go to next step

Check high-tension lead w page G-17

Q If OK, check distributor cap and

rotor w page G-22

c3 If not OK, replace high-tension lead

F-42

Page 313 of 1164

TROUBLESHOOTING GUIDE F

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm’, 36-46 psi)

(Vacuum hose to pressure regulator Ine pressure while pinching

d If fuel line pressure quickly in-

creases, check pressure regulator w page F-129

* If fuel line pressure gradually in-

If not clogged, check fuel pump

maximum pressure w page F-126

Ignition timing (BTDC)

l BP DOHC : go-1 1 o l BP SOHC : 4”-6O

Resistance: 12-l 60

eck wiring between ECU

Engine compression (Minimum):

l BP SOHC :

634 kPa (6.5 kg/cm2, 121 psi)900 rpm

check distributor cap and

23UOFX-02

F-47

Page 319 of 1164

TROUBLESHOOTING GUIDE F

No Replace airflow meter

9

Check for injector operating sound at idle Yes Go to Step 11

No Go to next Step

10 Check if battery voltage exists at injector connec- Yes Check if injector resistance is OK CT page F-131

tor (W/R) wire Resistance: 12-l 6fi

c3 If OK, check wiring between ECU

and injector

c3 If not OK, replace injector CT page F-131

No

Check wiring between ECU and injector

11 Check if strong blue spark is visible at discon-

Yes Go to next step

netted high-tension lead

No Check high-tension lead

+ If OK, check distributor cap and

rotor w page G-22

* If not OK, replace high-tension lead

12

Check if spark plugs are OK Yes Check for correct engine compression CT page Bl-10

w page G-16 82-10

Compression (Minimum):

. BP SOHC

834 kPa (8.5 kg/cm2, 121 psi)300 rpm

BON BUILDUP l BP DOHC

883 kPa (9.0 kg/cm*, 128 psi)-300 rpm

l.O-l.lmm ’ B6 DAMAGE AND 932 kPa (9.5 kg/cm’, 135 psi)-300 rpm DETERIORATION

c3 If OK, go to next step

c13 If not OK, check for cause CT page Bl-10

B2-10

No

Clean or replace w page G-18

13

Check for injector leakage Yes Replace injector CT page F-131

w page F-132

No Go

to next step

14 Try known good ECU and check if condition im-

proves cc7 page F-149

23UOFX-030

F-53

Page 320 of 1164

F TROUBLESHOOTING GUIDE

15

ENGINE STALLS ON DECELERATION

DESCRIP-

l Engine unexpectedly stops running while decelerating or after deceleration

TION l Idle condition normal

[TROUBLESHOOTING HINTS]

Engine speed drops too much when releasing accelerator or poor connector connection disconnected by deceleration

force

3 Idle speed control malfunction

3 Fuel cut control malfunction @ Idle speed misadjustment

TEP INSPECTION

ACTION

1

Check if idle condition is normal Yes

Go to next step

No Adjust or perform troubleshooting

Nos. 8-11 “ROUGH IDLE” v page F-42

F-48

--

2

Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with ignition switch ON

W page F-82 No

SYSTEM SELECT: 1 Service Code No. displayed

Check for cause (Refer to specified

check sequence) w page F-83

“88” flashes

Check ECU terminal IF voltage LIT= page F-150

Specification: Battery voltage

(Ignition switch ON)

W: SELF TEST + If OK, replace ECU w page F-149

Q If not OK, check wiring between

ECU and Self-Diagnosis Checker

3 Check switches for correct operation with Self-

Yes Go to next step

Diagnosis Checker Monitor Lamp with ignition

switch ON

w page F-105 No

Lamp not ON or OFF with specified

switch

Check for cause (Refer to specified

check sequence) CT page F-106

-,-y/

,’ Lamp always ON

Check wiring between ECU terminal 1 D

and Self-Diagnosis Checker

W: SELF

TEST

4 Check if ECU terminal voltages are OK

Yes Go to next step

MTX...Especially IV, 2D, 20, 2U, 2V and 2Q

ATX... Especially 28, 2E, 30, 3U, and 3V

w page F-150 No Check for cause w page F-151

5

Check for poor connection of following parts

Yes Repair or replace

. Ignition coil

l Igniter l Distributor

-- l High-tension lead

No l Injector Go to next step l Circuit opening relay l ECU

F-54

Page 322 of 1164

![MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently n MAZDA PROTEGE 1992 User Guide TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently n](/img/28/57077/w960_57077-321.png)

TROUBLESHOOTING GUIDE

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP- l Engine intermittently stops running

TION l Before stalling, engine condition OK [TROUBLESHOOTING HINTS]

@ Intermittently no spark or no-fuel injection caused by ve-

hicle vibration, acceleration, or deceleration

*Poor connection in wire harness

3 INSPECTION

Check if “00” is displayed on Self-Diagnosis

Checker with ignition switch ON c7 page F-82

g

-%ELECT SW: A

Check for poor connection of following parts l ignition coil

l igniter l Distributor l High-tension lead l lniector

l Ci;cuit opening relay l ECU

Check if ECU terminal voltages are OK

MTX...Especially lB, 2A, 28 and 2C

ATX... Especially lB, 3A, 38 and 3C w page F-150

Note

l When checking voltages, tap, move, and

wiggle harness and connector to recreate

problem

Yes

No Service Code No. displayed

Check for cause (Refer to specified

check sequence) Note

l When checking wiring harness and

connectors, tap, move, and wiggle

suspect sensor and/or harness to

recreate problem

“88” flashes

Check ECU terminal IF voltage w page F-150

Specification: Battery voltage

(Ignition switch ON)

c3 If OK, replace ECU CT= page F-149

+ If not OK, check wiring between

ECU and Self-Diagnosis Checker

Yes

Repair or replace

No Go to next step

Yes

No

T ACTION

Go to next step w page F-83

Go to Troubleshooting No.2

‘CRANKS NORMALLY BUT WILL NOT

START (NO COMBUSTION)” CT- page F-30

Check for cause D page F-151

F-56

Page 345 of 1164

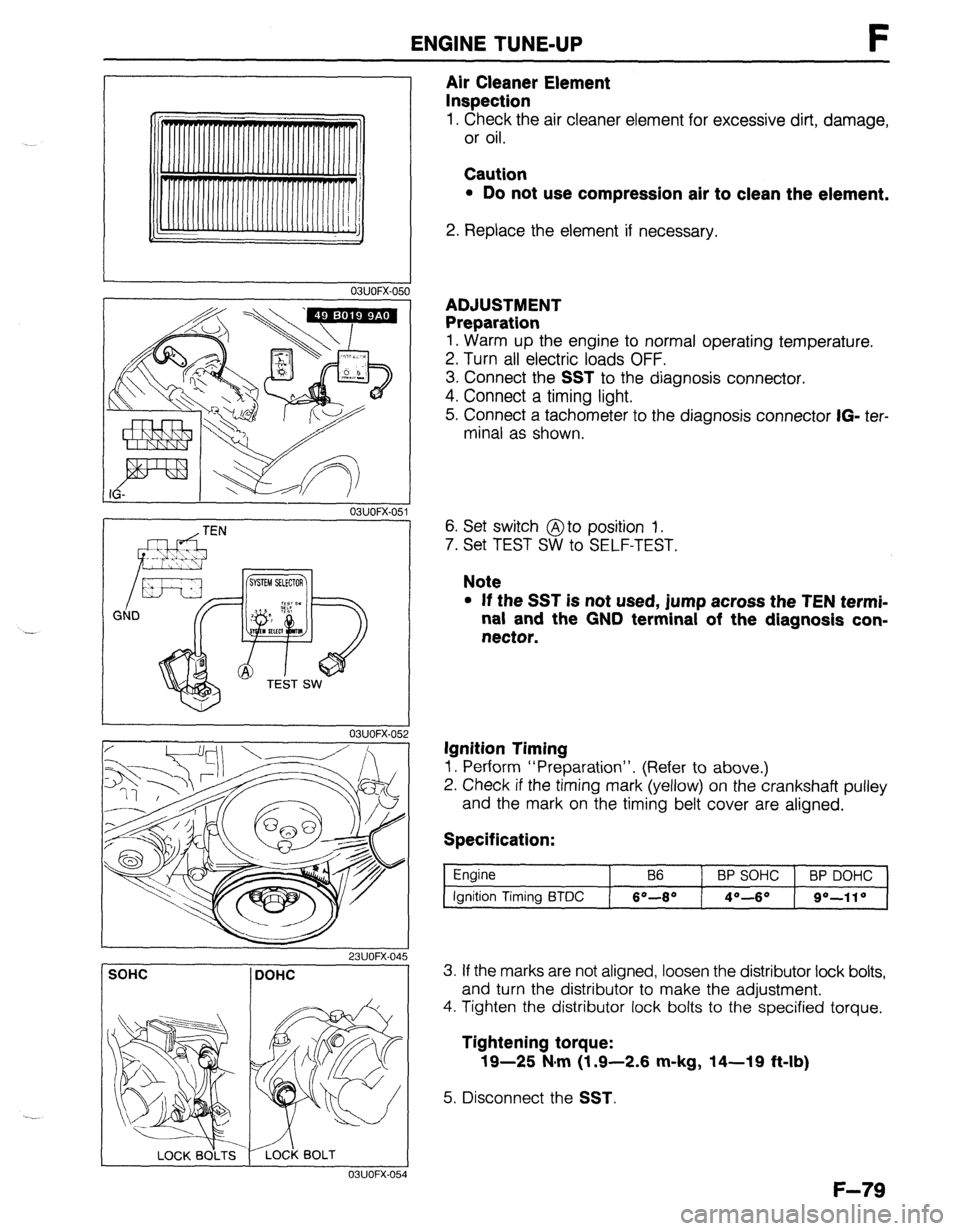

ENGINE TUNE-UP F

03UOFX.051

03UOFX-051

- w4TEN I

Air Cleaner Element

Inspection

1. Check the air cleaner element for excessive dirt, damage,

or oil.

Caution

l Do not use compression air to clean the element.

2. Replace the element if necessary.

ADJUSTMENT

Preparation

1. Warm up the engine to normal operating temperature.

2. Turn all electric loads OFF.

3. Connect the

SST to the diagnosis connector.

4. Connect a timing light.

5. Connect a tachometer to the diagnosis connector

IG- ter-

minal as shown.

6. Set switch @to position 1.

7. Set TEST SW to SELF-TEST.

Note

l If the SST is not used, jump across the TEN termi-

nal and the GND terminal of the diagnosis con-

nector.

Ignition Timing

1. Perform “Preparation”. (Refer to above.)

2. Check if the timing mark (yellow) on the crankshaft pulley

and the mark on the timing belt cover are aligned.

Specification:

Engine

Ignition Timing BTDC B6 BP SOHC BP DOHC

6O-8* 4O--6O go-110

SOHC DOHC

I 03UOFX-054

3. If the marks are not aligned, loosen the distributor lock bolts,

and turn the distributor to make the adjustment.

4. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Disconnect the SST.

F-79