MERCEDES-BENZ E-CLASS CABRIOLET 2015 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: E-CLASS CABRIOLET, Model: MERCEDES-BENZ E-CLASS CABRIOLET 2015Pages: 349, PDF Size: 12.51 MB

Page 331 of 349

tyre pressure of the wheel that has been

removed. If this occurs, note that the value dis-

played for the position where the spare wheel is fitted is not the same as the current tyre pres-

sure of the emergency spare wheel.

Warning messages of the tyre pressure monitor If the tyre pressure monitor detects a pressure

loss in one or more tyres, a warning message is

shown in the multifunction display. The yellow

tyre pressure warning lamp then lights up.

R If the Please correct tyre pressure

Please correct tyre pressure

message appears in the multifunction display,

the tyre pressure in at least one tyre is too

low. The tyre pressure must be corrected

when the opportunity arises.

R If the Check

Check tyre(s)

tyre(s) message appears in the

multifunction display, the tyre pressure in at

least one tyre has dropped significantly. The

tyres must be checked.

R If the Warning tyre defect Warning tyre defect message

appears in the multifunction display, the tyre

pressure in at least one tyre has dropped sud- denly. The tyres must be checked.

Observe the instructions and safety notes in the display messages in the "Tyres" section

(Y page 246).

If the wheel positions on the vehicle are inter-

changed, the tyre pressures may be displayed

for the wrong positions for a short time. After a few minutes of driving, this is rectified and the

tyre pressures are displayed for the correct

positions.

Restarting the tyre pressure monitor When you restart the tyre pressure monitor, all

existing warning messages are deleted and the

warning lamps go out. The monitor uses the cur-

rently set tyre pressures as the reference values

for monitoring. In most cases, the tyre pressure monitor will automatically detect the new refer-

ence values after you have changed the tyre

pressure. However, you can also set reference

values manually as described here. The tyre

pressure monitor then monitors the new tyre

pressure values.

X Use the table on the inside of the fuel filler flap

to ensure that the tyre pressure is set cor-

rectly in all four tyres for the current operating

conditions. Also observe the notes in the section on tyre

pressures (Y page 324).

X Make sure that the key is in position 2in the

ignition lock.

X Press the =or; button on the steering

wheel to select the Service

Service menu.

X Press the 9or: button to select

Tyre pressure Tyre pressure.

X Press the abutton.

The multifunction display shows the current

tyre pressure for the individual tyres or the

Tyre pressures will be displayed Tyre pressures will be displayed

after a few minutes of driving after a few minutes of driving mes-

sage.

X Press the :button.

The Use

Use current

current pressures

pressures as

asnew

new ref‐

ref‐

erence

erence values

valuesmessage appears in the mul-

tifunction display.

If you wish to confirm the restart: X Press the abutton.

The Tyre

Tyre press.

press. monitor

monitor restarted

restarted mes-

sage appears in the multifunction display.

After you have driven for a few minutes, the

system checks whether the current tyre pres-

sures are within the specified range. The new tyre pressures are then accepted as refer-

ence values and monitored.

If you wish to cancel the restart:

X Press the %button.

The tyre pressure values stored at the last

restart will continue to be monitored. Changing a wheel

Flat tyre

You can find information on what to do in the

event of a flat tyre in the "Breakdown assis-

tance" section (Y page 306). Information on

driving with MOExtended tyres in the event of a flat tyre can be found under "Breakdown assis-

tance" (Y page 306).

Vehicles with an emergency spare wheel: in

the event of a flat tyre, the emergency spare

wheel is fitted according to the description

under "Fitting a wheel" (Y page 329).328

Changing a

wheelWheels and tyres

Page 332 of 349

Interchanging the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tyres have different dimensions. The wheel brakes or suspension components may also be damaged. There is a risk of acci-

dent.

Interchange front and rear wheels only if the

wheels and tyres are of the same dimensions.

! On vehicles fitted with a tyre pressure mon-

itor, electronic components are located in the wheel.

Tyre-fitting tools should not be applied in thearea of the valve, as this could damage the

electronic components.

Only have tyres changed at a qualified spe-

cialist workshop.

Interchanging the front and rear wheels of dif-

fering dimensions can render the general oper-

ating permit invalid.

Observe the instructions and safety notes in the "Fitting a wheel" section (Y page 329).

The wear patterns on the front and rear tyres

differ depending on the operating conditions.

Interchange the wheels before a clear wear pat-

tern has formed on the tyres. Front tyres typi-

cally wear more on the shoulders and the rear

tyres in the centre.

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5,000 to 10,000 km depending on the

degree of tyre wear. Ensure that the direction of

rotation is maintained.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is

interchanged. Check the tyre pressure and, if

necessary, restart the tyre pressure loss warn-

ing system (Y page 326) or the tyre pressure

monitor (Y page 328). Direction of rotation

Tyres with a specified direction of rotation have additional benefits, e.g. if there is a risk of aqua- planing. These advantages can only be gained if

the tyres are fitted corresponding to the direc-

tion of rotation. An arrow on the sidewall of the tyre indicates its

correct direction of rotation. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tyres

against oil, grease, petrol and diesel. Fitting a wheel

Preparing the vehicle X

Stop the vehicle on solid, non-slippery and

level ground.

X Apply the parking brake.

X Move the front wheels to the straight-ahead

position.

X Vehicles with manual transmission:

depress the clutch pedal fully and engage first

or reverse gear.

X Vehicles with automatic transmission:

shift the automatic transmission to position

P.

X Switch off the engine.

X Remove the key from the ignition lock.

or, on vehicles with KEYLESS‑GO:

X Open the driver's door.

The on-board electronics now have status 0.

This is the same as the key having been

removed.

X Remove the Start/Stop button from the igni-

tion lock (Y page 139).

X If included in the vehicle equipment, remove

the tyre-change tool kit from the vehicle

(Y page 305).

X Safeguard the vehicle against rolling away.

i Apart from some country-specific variants,

vehicles are not equipped with tyre-changing

tools. Some tools for changing a wheel are

specific to the vehicle. For more information

on which tools are required to perform a

wheel change on your vehicle, consult a quali- fied specialist workshop.

Necessary tyre-changing tools may include,

for example:

R jack

R wheel chock Changing a wheel

329Wheels and tyres Z

Page 333 of 349

R

wheel wrench

R centring pin

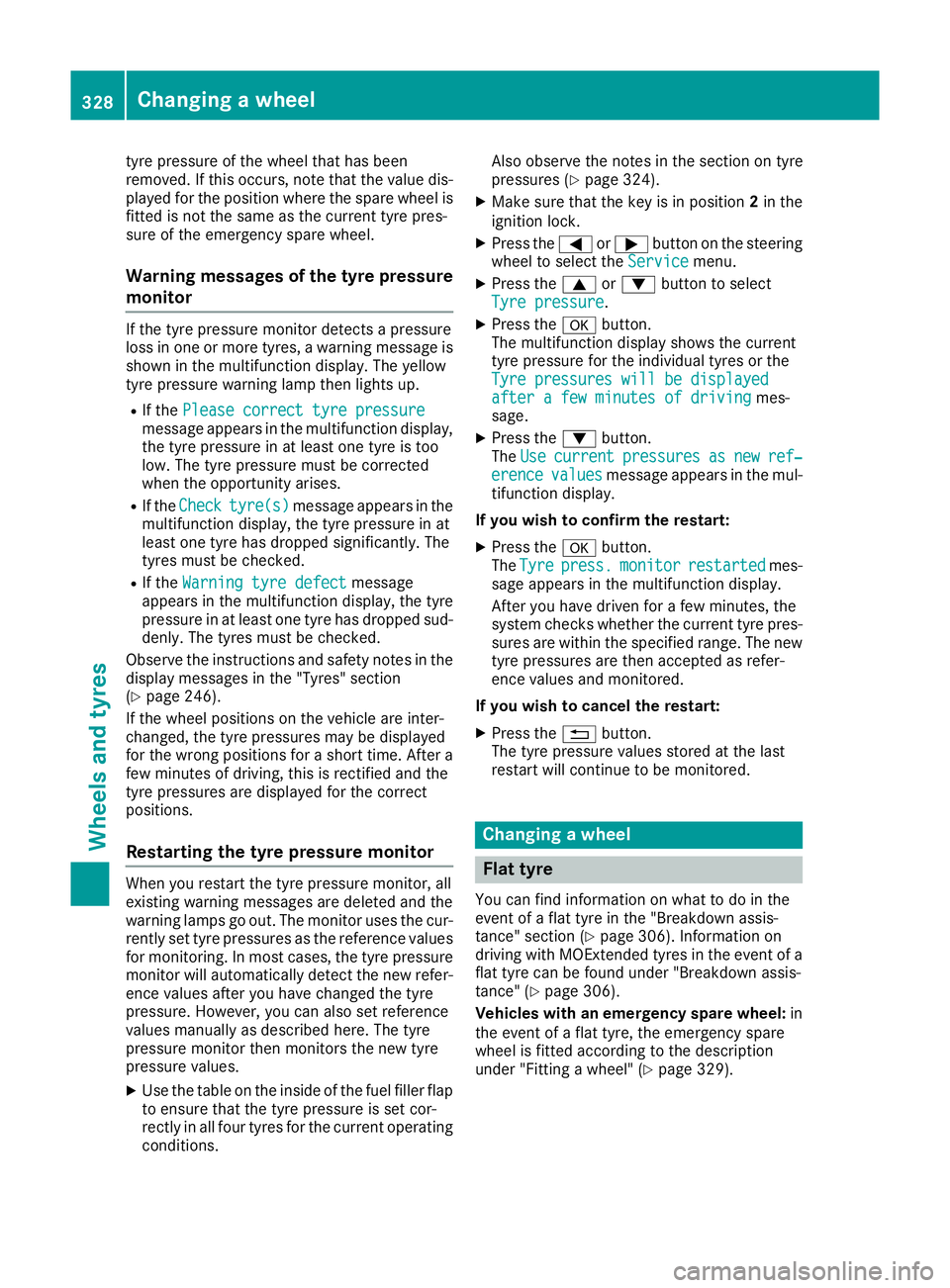

Securing the vehicle against rolling

away If your vehicle is equipped with a wheel chock, it

can be found in the tyre-change tool kit

(Y page 305).

The folding wheel chock is an additional secur-

ing measure to safeguard the vehicle from roll-

ing away, for example when changing a wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Insert the lugs on the lower plate fully into the

openings in base plate =.X

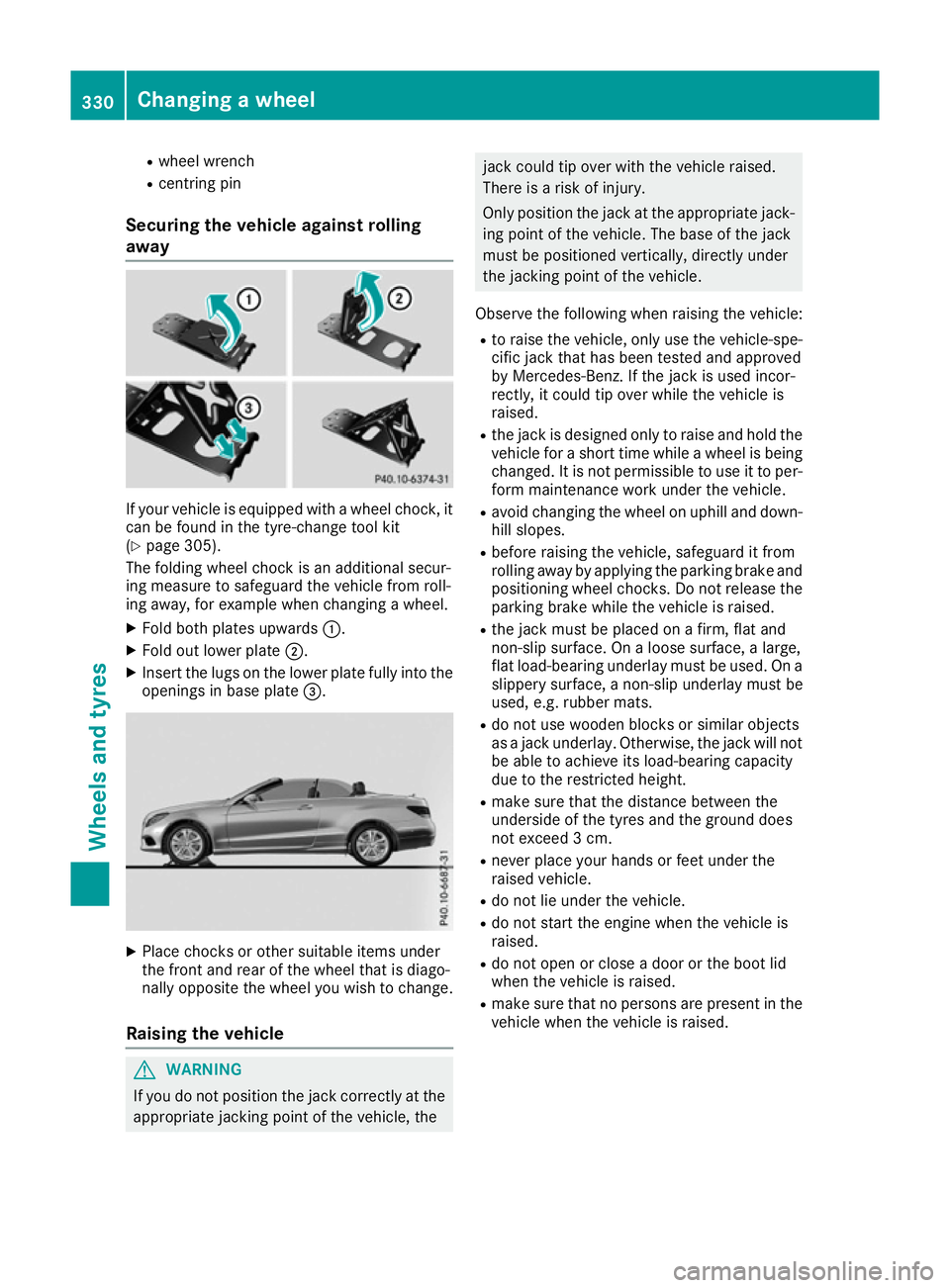

Place chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack- ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

Observe the following when raising the vehicle:

R to raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If the jack is used incor-

rectly, it could tip over while the vehicle is

raised.

R the jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It is not permissible to use it to per- form maintenance work under the vehicle.

R avoid changing the wheel on uphill and down-

hill slopes.

R before raising the vehicle, safeguard it from

rolling away by applying the parking brake and

positioning wheel chocks. Do not release the parking brake while the vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

R do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

R make sure that the distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R never place your hands or feet under the

raised vehicle.

R do not lie under the vehicle.

R do not start the engine when the vehicle is

raised.

R do not open or close a door or the boot lid

when the vehicle is raised.

R make sure that no persons are present in the

vehicle when the vehicle is raised. 330

Changing a wheelWheels and tyres

Page 334 of 349

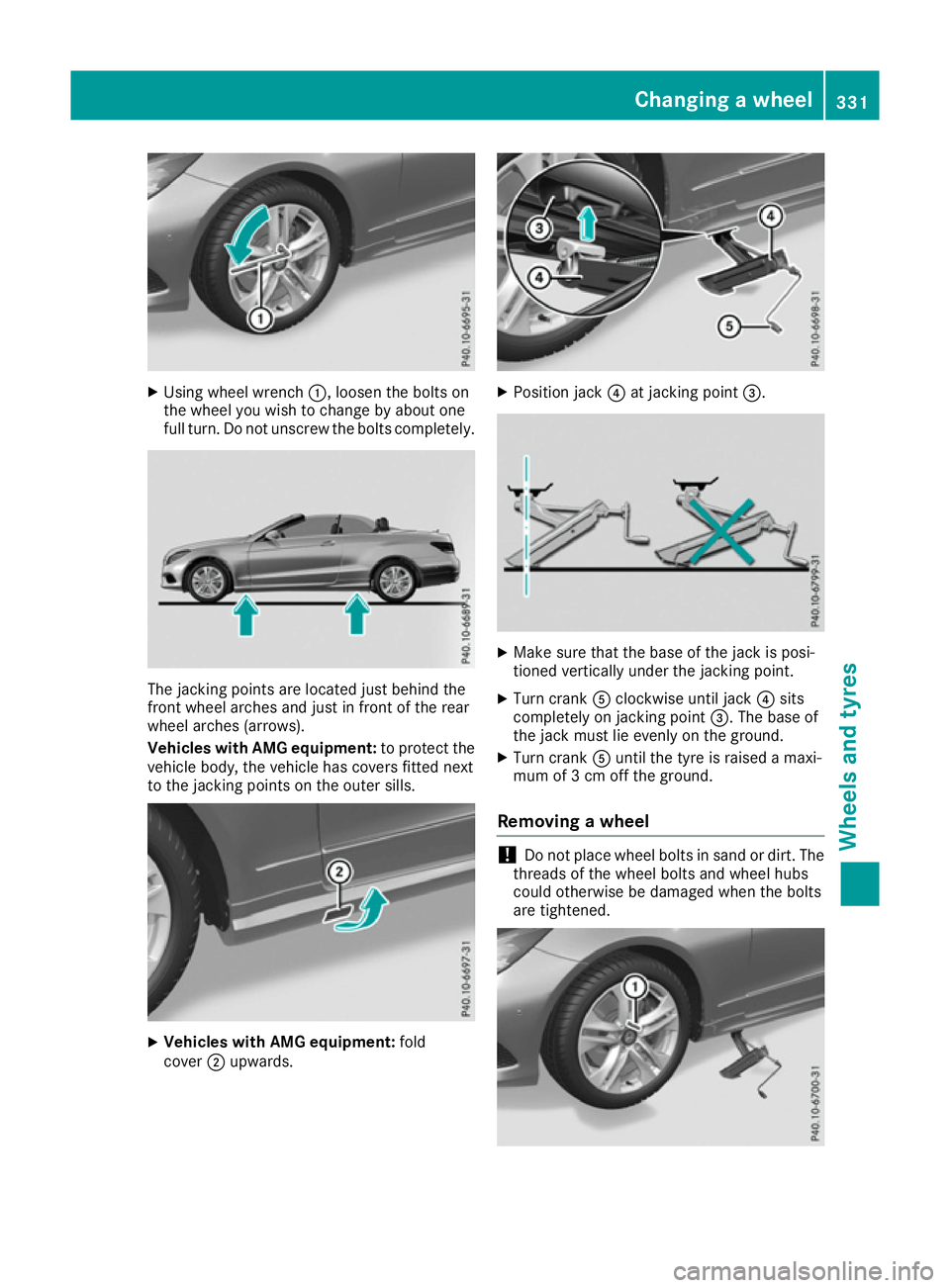

X

Using wheel wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts completely. The jacking points are located just behind the

front wheel arches and just in front of the rear

wheel arches (arrows).

Vehicles with AMG equipment: to protect the

vehicle body, the vehicle has covers fitted next

to the jacking points on the outer sills. X

Vehicles with AMG equipment: fold

cover ;upwards. X

Position jack ?at jacking point =. X

Make sure that the base of the jack is posi-

tioned vertically under the jacking point.

X Turn crank Aclockwise until jack ?sits

completely on jacking point =. The base of

the jack must lie evenly on the ground.

X Turn crank Auntil the tyre is raised a maxi-

mum of 3 cm off the ground.

Removing a wheel !

Do not place wheel bolts in sand or dirt. The

threads of the wheel bolts and wheel hubs

could otherwise be damaged when the bolts

are tightened. Changing a wheel

331Wheels and tyres Z

Page 335 of 349

X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw centring pin :into the thread instead

of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Fitting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

It is imperative to observe the instructions and

safety notes on "Changing a wheel"

(Y page 329).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel. X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the wheel to be mounted onto the cen-

tring pin and push it on.

X Tighten the wheel bolts until they are finger-

tight.

X Unscrew the centring pin.

X Tighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

X Turn the crank of the jack anti-clockwise until

the vehicle is once again standing firmly on

the ground.

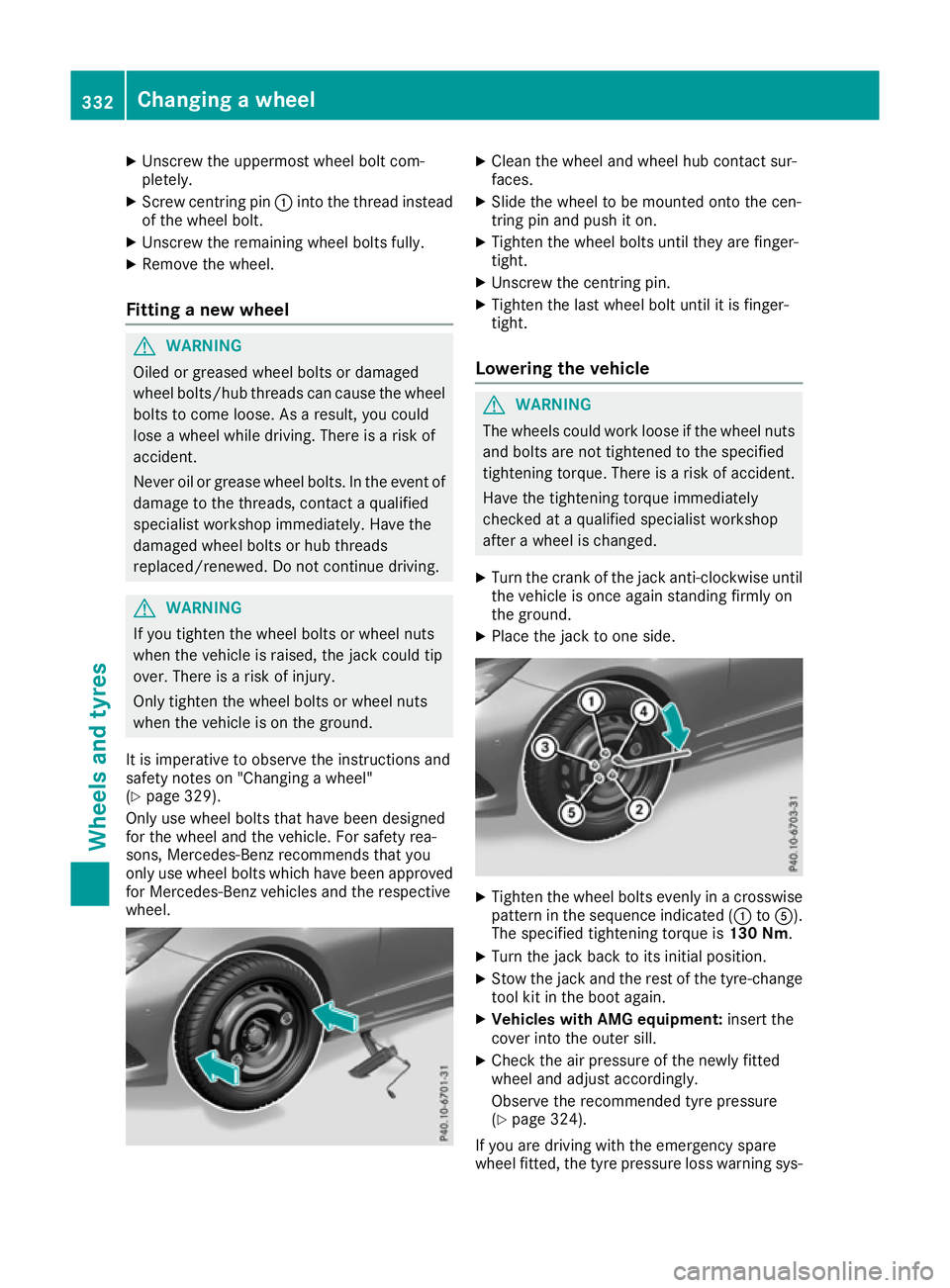

X Place the jack to one side. X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

The specified tightening torque is 130 Nm.

X Turn the jack back to its initial position.

X Stow the jack and the rest of the tyre-change

tool kit in the boot again.

X Vehicles with AMG equipment: insert the

cover into the outer sill.

X Check the air pressure of the newly fitted

wheel and adjust accordingly.

Observe the recommended tyre pressure

(Y page 324).

If you are driving with the emergency spare

wheel fitted, the tyre pressure loss warning sys- 332

Changing a wheelWheels and tyres

Page 336 of 349

tem or the tyre pressure monitor cannot func-

tion reliably. Only restart the tyre pressure loss

warning system or tyre pressure monitor when

the defective wheel has been replaced with a

new wheel.

Vehicles with a tyre pressure monitor: all fit-

ted wheels must be equipped with functioning

sensors. Wheel and tyre combinations

You can ask for information regarding permitted wheel-tyre combinations at a Mercedes-Benz

Service Centre.

! For safety reasons, Mercedes-Benz recom-

mends that you only use tyres and wheels

which have been approved by Mercedes-Benz specifically for your vehicle.

These are specially adapted to the control

systems, such as ABS or ESP ®

and are

marked as follows:

R MO = Mercedes-Benz Original

R MOE = Mercedes-Benz Original Extended

(tyres featuring run-flat characteristics)

R MO1 = Mercedes-Benz Original (only cer-

tain AMG tyres)

Mercedes-Benz Original Extended tyres may

only be used on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tyres, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when driving with a load, tyre dimension variations

could cause the tyres to come into contact

with the bodywork and axle components. This

could result in damage to the tyres or the

vehicle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tyres, wheels or

accessories other than those tested and

approved.

Further information about wheels, tyres and

approved combinations can be obtained from any qualified specialist workshop.

! Retreaded tyres are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tyres. As a result, Mercedes-Benz cannot guarantee vehicle safety if retreaded

tyres are fitted. Do not fit used tyres if you

have no information about their previous

usage.

! Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll comfort and suspension comfort are reduced and therisk of damage to the wheels and tyres as a

result of driving over obstacles increases.

The recommended tyre pressures can be found

in the tyre pressure table on the fuel filler flap.

For further information on tyre pressure, see

(Y page 324). Check tyre pressures regularly

and only when the tyres are cold.

Notes on the vehicle equipment – always fit the

vehicle:

R with tyres of the same size across an axle

(left/right)

R with the same type of tyres at a given time

(summer tyres, winter tyres, MOExtended

tyres)

Exception: it is permissible to fit a different

type or make in the event of a flat tyre.

Observe the "MOExtended tyres (tyres with

run-flat characteristics)" section

(Y page 306).

Vehicles with MOExtended tyres are not equip-

ped with a TIREFIT kit at the factory. It is there-

fore recommended that you additionally equip

your vehicle with a TIREFIT kit if you fit tyres that do not feature run-flat characteristics, e.g. win-

ter tyres. A TIREFIT kit can be obtained from a

qualified specialist workshop. Emergency spare wheel

Important safety notes

G

WARNING

The wheel/tyre dimensions and the tyre type of the spare wheel/emergency spare wheel

and the wheel to be replaced may differ. Fit-

ting a spare wheel/emergency spare wheel

may severely impair the driving characteris-

tics. There is a risk of accident. Emergency spare

wheel

333Wheels an d tyres

Z

Page 337 of 349

To prevent hazardous situations:

R Adapt your driving style accordingly and

drive carefully.

R Never fit more than one spare wheel/emer-

gency spare wheel if the dimensions are

different to those of the wheel being

replaced.

R Only use a spare wheel/emergency spare

wheel briefly if the dimensions are different

to those of the wheel being replaced.

R Do not switch off ESP ®

.

R Have the spare wheel/emergency spare

wheel in question replaced at the nearest

qualified specialist workshop. Make sure

that the wheel/tyre dimensions and tyre

type are correct.

When using an emergency spare wheel or spare wheel of a different size, you must not exceed

the maximum speed of 80 km/h.

Snow chains must not be fitted to emergency

spare wheels. General notes

You can ask for information regarding permitted

emergency spare wheels at a Mercedes-Benz

Service Centre.

You should regularly check the pressure of all

your tyres, including the emergency spare

wheel, particularly prior to long trips, and cor-

rect the pressure as necessary (Y page 324).

The value on the wheel is valid.

An emergency spare wheel may also be fitted

against the direction of rotation. Observe the

time restriction on use as well as the speed lim- itation specified on the emergency spare wheel.

Replace the tyres after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

i If you are driving with the emergency spare

wheel fitted, the tyre pressure loss warning

system or the tyre pressure monitor cannot

function reliably. Only restart the tyre pres-

sure loss warning system or tyre pressure

monitor when the defective wheel has been

replaced with a new wheel.

Vehicles with a tyre pressure monitor: for a

few minutes after an emergency spare wheel is fitted, the system may still display the tyre

pressure of the removed wheel. The value dis-

played for the position where the emergency

spare wheel is fitted is not the same as the

current tyre pressure of the emergency spare

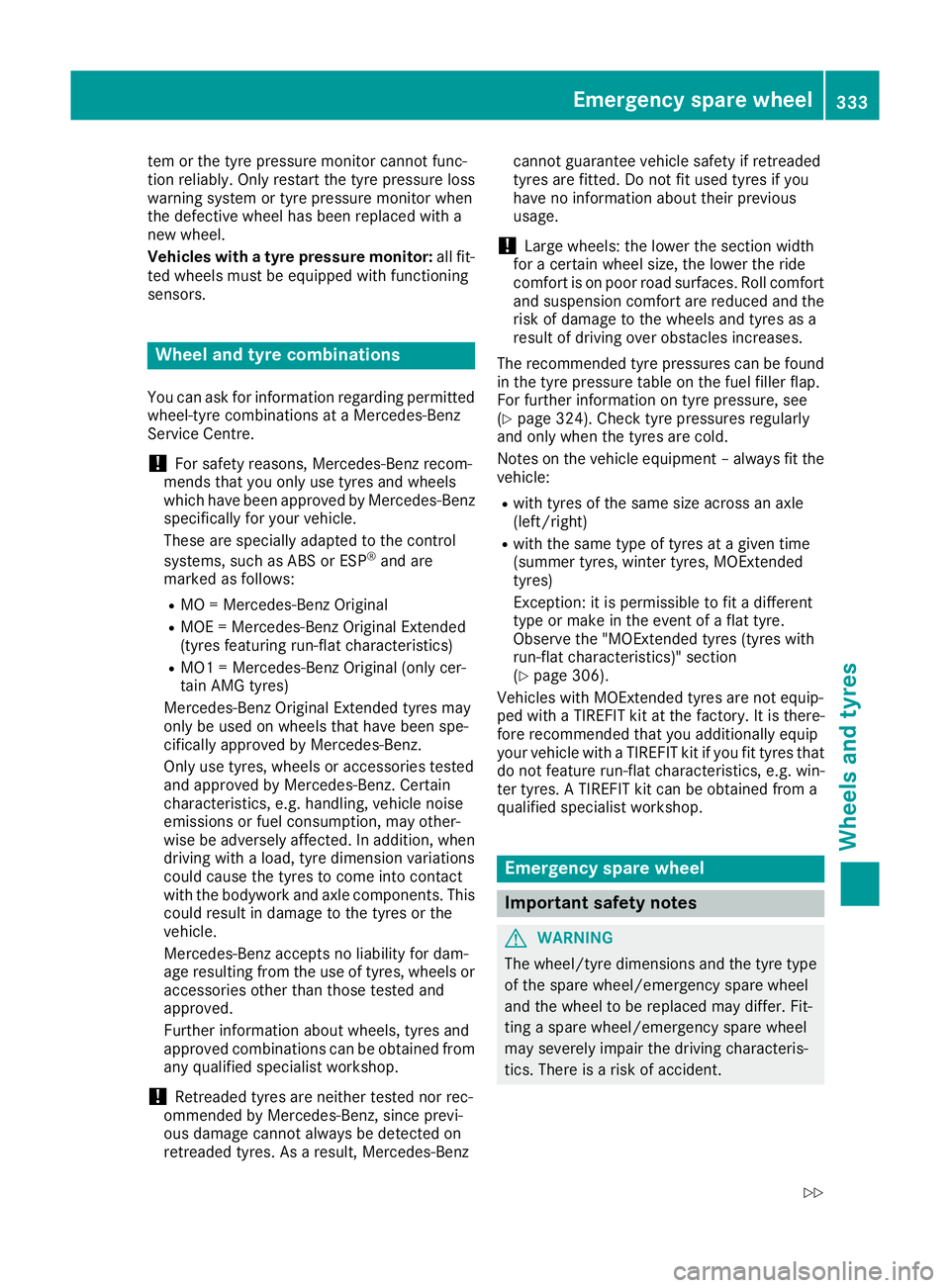

wheel. "Minispare" emergency spare wheel

:

"Minispare" emergency spare wheel

; Vehicle tool kit tray

= Stowage tray

The "Minispare" emergency spare wheel can be found in the stowage well under the boot floor.

X Lift the boot floor upwards (Y page 277).

X Remove vehicle tool kit tray ;.

X Turn stowage tray =anti-clockwise and

remove it.

X Remove "Minispare" emergency spare

wheel :.

Observe the instructions and safety notes in the "Fitting a wheel" section (Y page 329).334

Emergency spare wheelWheels and tyres

Page 338 of 349

Information on technical data

i The technical data was determined in

accordance with EU Directives. All data

applies to the vehicle's standard equipment.

The data may therefore differ for vehicles with

optional equipment. You can obtain further

information from a Mercedes-Benz Service

Centre. Vehicle electronics

Tampering with the engine electron-

ics

! Only have work carried out on the engine

electronics and its associated parts, such as

control units, sensors, actuating components

and connector leads, at a qualified specialist

workshop. Vehicle components may other-

wise wear more quickly and the vehicle's

operating permit may be invalidated. Retrofitting two-way radios and

mobile phones (RF transmitters)

G

WARNING

If RF transmitters are tampered with or not

properly retrofitted, the electromagnetic radi- ation they emit can interfere with the vehicle

electronics. This may jeopardise the opera-

tional safety of the vehicle. There is a risk of an

accident.

You should have all work on electrical and

electronic components carried out at a quali-

fied specialist workshop. G

WARNING

If you operate RF transmitters incorrectly in

the vehicle, the electromagnetic radiation

could interfere with the vehicle electronics,

e.g.:

R if the RF transmitter is not connected to an

exterior aerial

R the exterior aerial has been fitted incor-

rectly or is not a low-reflection type This could jeopardise the operating safety of

the vehicle. There is a risk of an accident.

Have the low-reflection exterior aerial fitted at

a qualified specialist workshop. When oper-

ating RF transmitters in the vehicle, always

connect them to the low-reflection exterior

aerial.

! The operating permit may be invalidated if

the instructions for installation and use of RF

transmitters are not observed.

In particular, the following conditions must be complied with:

R only approved wavebands may be used.

R observe the maximum permissible output

in these wavebands.

R only approved aerial positions may be

used.

Excessive levels of electromagnetic radiation

may cause damage to your health and to the

health of others. The use of an exterior aerial

takes into consideration the scientific discus-

sion surrounding the possible health risk posed

by electromagnetic fields.

Observe the notes on operating mobile phones

(Y page 281).

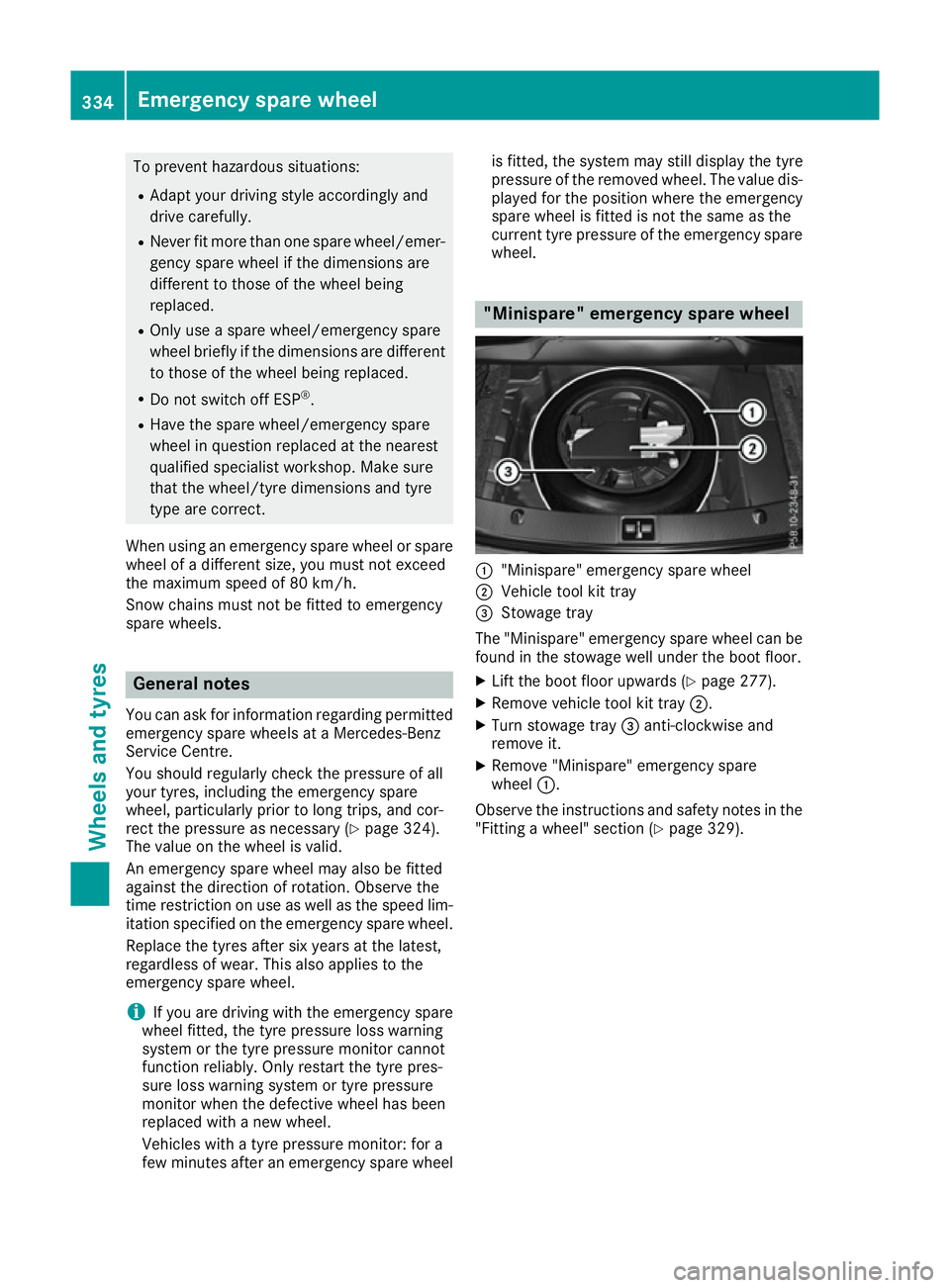

The following aerial positions may be used for

the correct installation of RF transmitters: Approved aerial positions

:

Rear wing

i On the rear wing, it is recommended that

you position the aerial on the side of the vehi-

cle closest to the centre of the road.

Use Technical Specification ISO/TS 21609

(Road Vehicles – "EMC guidelines for fitting

aftermarket radio frequency transmitting equip- ment") when retrofitting RF (radio frequency) Vehicle electronics

335Technical data Z

Page 339 of 349

transmitters. Comply with the legal require-

ments for add-on parts.

If your vehicle has fittings for two-way radio

equipment, use the power supply or aerial con-

nections intended for use with the basic wiring. Be sure to observe the manufacturer's addi-

tional instructions when installing.

Deviations with respect to wavebands, maxi-

mum transmission outputs or aerial positions

must be approved by Mercedes-Benz.

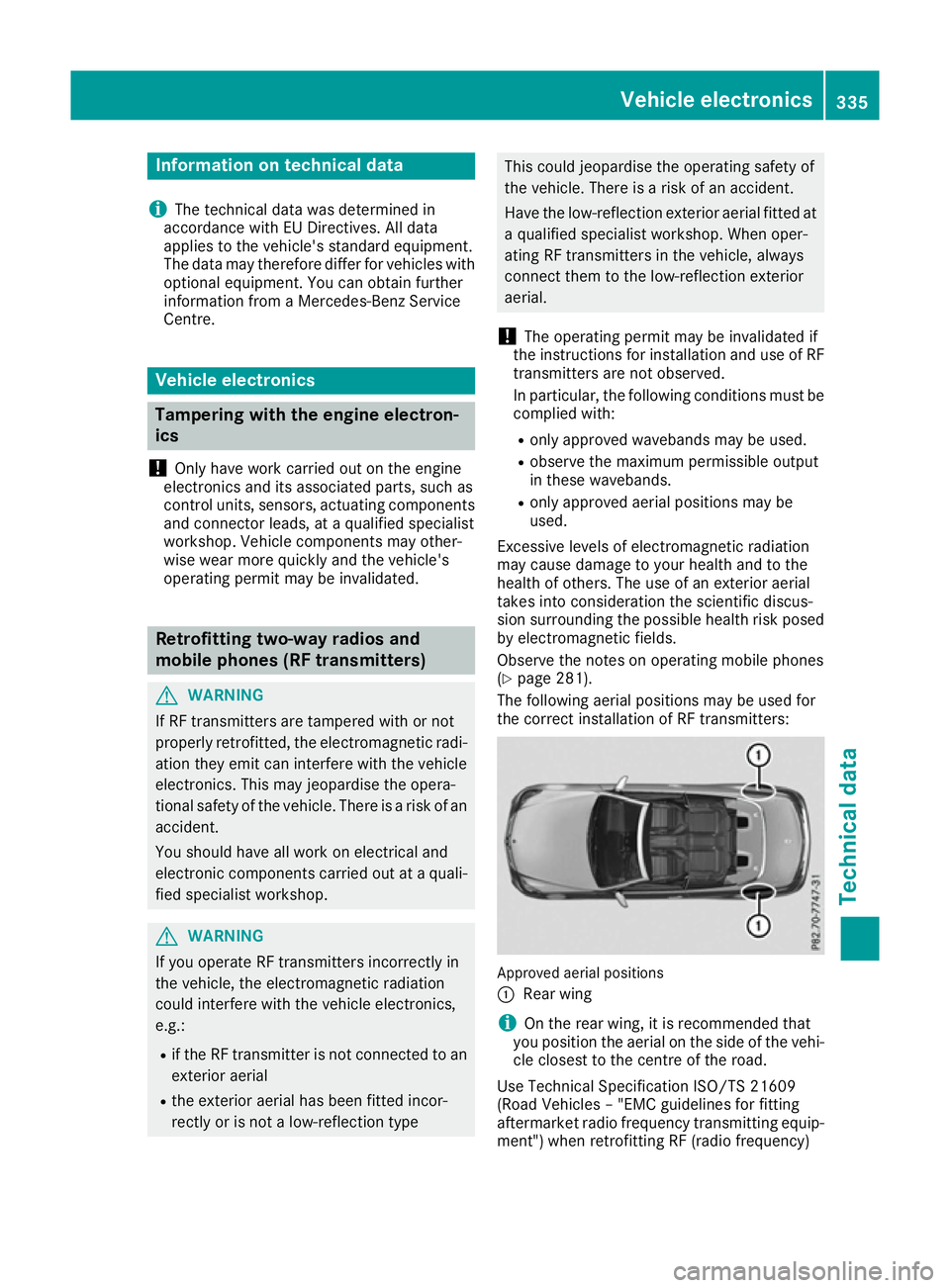

The maximum transmission output (PEAK) at the

base of the aerial must not exceed the values in the following table:

The maximum transmission output (PEAK) at the base of the aerial must not exceed the followingvalues: Waveband Maximum

transmission output Short wave

3 - 54 MHz 30 W

4 m waveband

74 - 88 MHz 15 W

2 m waveband

144 - 174 MHz 25 W

Trunked radio/Tetra

380 - 460 MHz 10 W

70 cm waveband

400 - 460 MHz 15 W

Mobile communications

(3G/3G/4G) 10 W

The following can be used in the vehicle without

restrictions:

R RF transmitters with a maximum transmis-

sion output of up to 100 mW

R RF transmitters with transmitter frequencies

in the 380 - 410 MHz waveband and a maxi-

mum transmission output of up to 2 W

(trunked radio/Tetra)

R Mobile telephones (2G/3G/4G) There are no restrictions when positioning the

aerial on the outside of the vehicle for the fol-

lowing wavebands:

R Trunked radio/Tetra

R 70 cm waveband

R 2G/3G/4G Identification plates

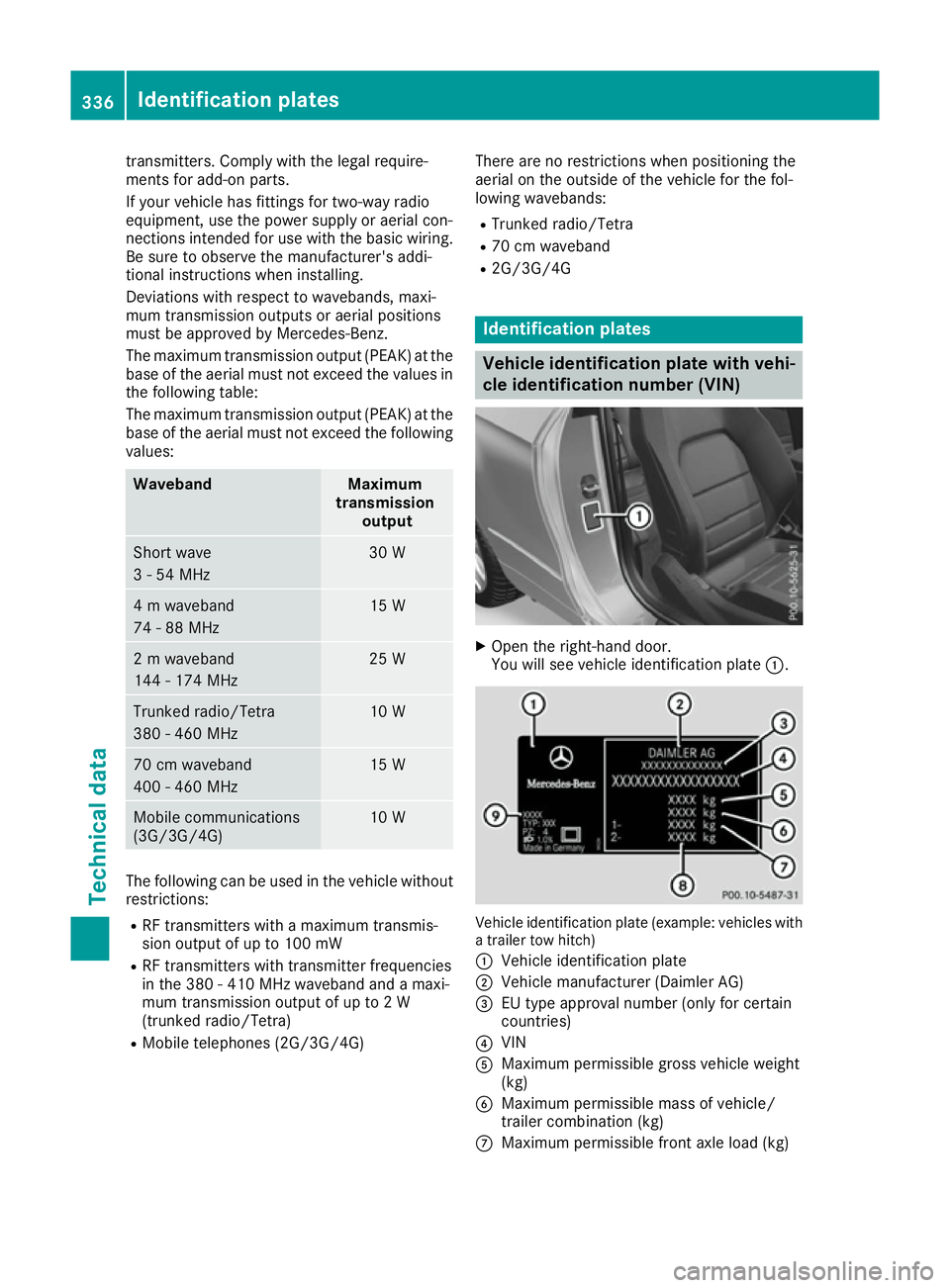

Vehicle identification plate with vehi-

cle identification number (VIN)

X

Open the right-hand door.

You will see vehicle identification plate :. Vehicle identification plate (example: vehicles with

a trailer tow hitch)

: Vehicle identification plate

; Vehicle manufacturer (Daimler AG)

= EU type approval number (only for certain

countries)

? VIN

A Maximum permissible gross vehicle weight

(kg)

B Maximum permissible mass of vehicle/

trailer combination (kg)

C Maximum permissible front axle load (kg) 336

Identification platesTechnical data

Page 340 of 349

D

Maximum permissible rear axle load (kg)

E Paint code

i The data shown on the vehicle identification

plate is example data. This data is different for

every vehicle and can deviate from the data

shown here. You can find the data applicable to your vehicle on the vehicle's identification

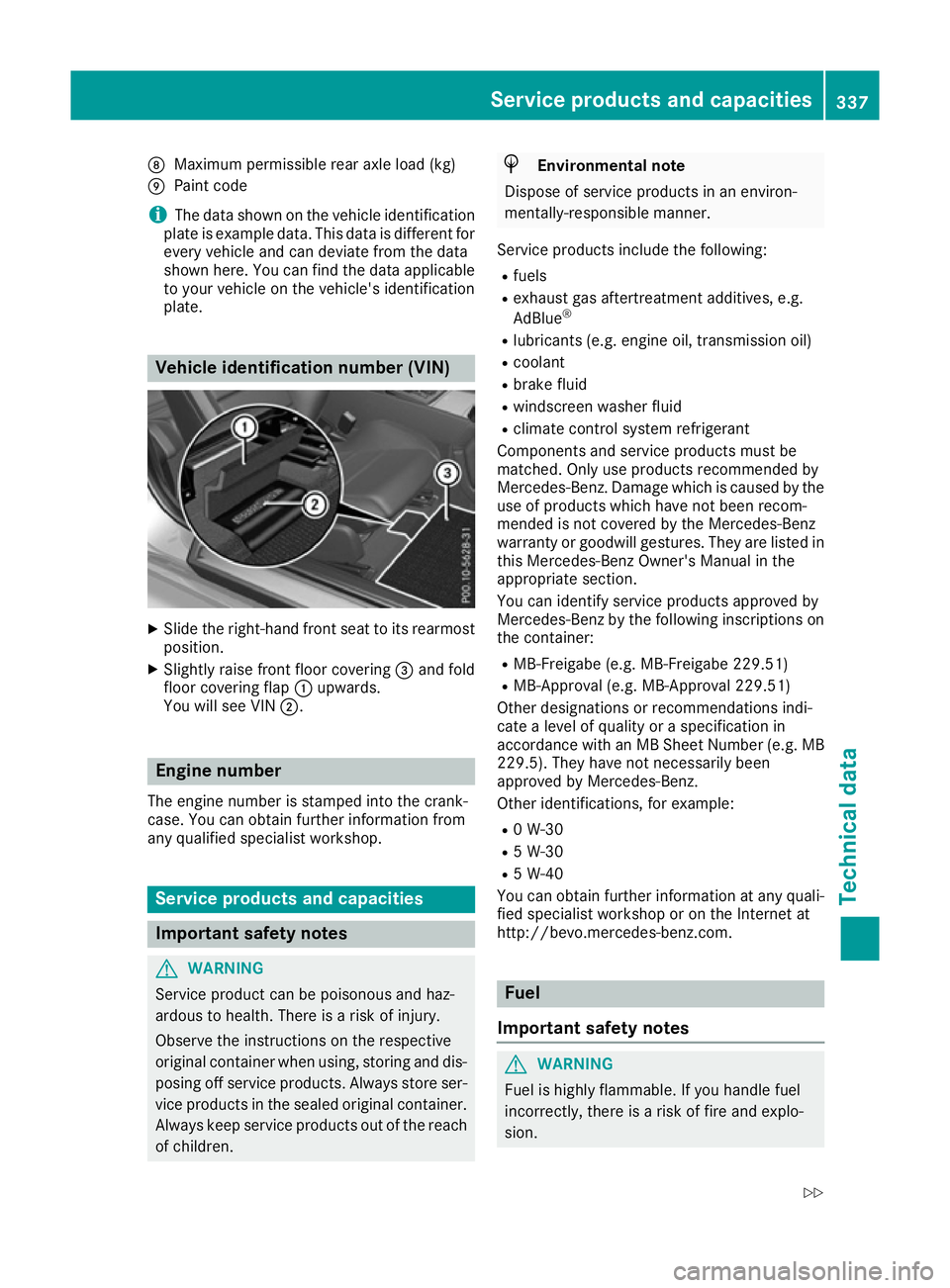

plate. Vehicle identification number (VIN)

X

Slide the right-hand front seat to its rearmost

position.

X Slightly raise front floor covering =and fold

floor covering flap :upwards.

You will see VIN ;. Engine number

The engine number is stamped into the crank-

case. You can obtain further information from

any qualified specialist workshop. Service products and capacities

Important safety notes

G

WARNING

Service product can be poisonous and haz-

ardous to health. There is a risk of injury.

Observe the instructions on the respective

original container when using, storing and dis- posing off service products. Always store ser-

vice products in the sealed original container. Always keep service products out of the reach

of children. H

Environmental note

Dispose of service products in an environ-

mentally-responsible manner.

Service products include the following:

R fuels

R exhaust gas aftertreatment additives, e.g.

AdBlue ®

R lubricants (e.g. engine oil, transmission oil)

R coolant

R brake fluid

R windscreen washer fluid

R climate control system refrigerant

Components and service products must be

matched. Only use products recommended by

Mercedes-Benz. Damage which is caused by the use of products which have not been recom-

mended is not covered by the Mercedes-Benz

warranty or goodwill gestures. They are listed inthis Mercedes-Benz Owner's Manual in the

appropriate section.

You can identify service products approved by

Mercedes-Benz by the following inscriptions on

the container:

R MB-Freigabe (e.g. MB-Freigabe 229.51)

R MB-Approval (e.g. MB-Approval 229.51)

Other designations or recommendations indi-

cate a level of quality or a specification in

accordance with an MB Sheet Number (e.g. MB

229.5). They have not necessarily been

approved by Mercedes-Benz.

Other identifications, for example:

R 0 W-30

R 5 W-30

R 5 W-40

You can obtain further information at any quali-

fied specialist workshop or on the Internet at

http://bevo.mercedes-benz.com. Fuel

Important safety notes G

WARNING

Fuel is highly flammable. If you handle fuel

incorrectly, there is a risk of fire and explo-

sion. Service products and capacities

337Technical data

Z