MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 141 of 1232

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Remove the battery hold downs from the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - REMOVAL).

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(7) Remove the battery from the battery tray.

AUXILIARY BATTERY REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the passenger front seat assembly.

Refer to the Body section for procedure.

(3) Remove the top cover from the seat base

assembly.

(4) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post.

(6) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(7) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(8) Remove the battery hold downs from the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - REMOVAL).

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(9) Remove the battery from the battery tray.

INSTALLATION

UNDER HOOD BATTERY INSTALLATION

(1) Position the battery onto the battery tray.

Ensure that the battery positive and negative termi-

nal posts are correctly positioned. The battery cable

terminal clamps must reach the correct battery ter-

minal post without stretching the cables.(2) Reinstall the battery hold downs onto the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - INSTALLATION).

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reverse battery polarity may damage

electrical components of the vehicle.

(3) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 11.8 N´m

(105 in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 7.9 N´m (70

in. lbs.).

(5) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

AUXILIARY BATTERY INSTALLATION

(1) Position the battery onto the battery tray.

Ensure that the battery positive and negative termi-

nal posts are correctly positioned. The battery cable

terminal clamps must reach the correct battery ter-

minal post without stretching the cables.

(2) Reinstall the battery hold downs onto the bat-

tery (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY HOLDDOWN - INSTALLATION).

CAUTION: Be certain that the battery cable terminal

clamps are connected to the correct battery termi-

nal posts. Reverse battery polarity may damage

electrical components of the vehicle.

(3) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 11.8 N´m

(105 in. lbs.).

(4) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 7.9 N´m (70

in. lbs.).

(5) Apply a thin coating of petroleum jelly or chas-

sis grease to the exposed surfaces of the battery cable

terminal clamps and the battery terminal posts.

(6) Install the top cover on the seat base assembly.

(7) Install the passenger front seat assembly. Refer

to the Body section for procedure.

VABATTERY SYSTEM 8F - 13

BATTERY (Continued)

Page 142 of 1232

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware includes two hex

nuts with washers and two hold down brackets. The

battery hold down brackets are formed of stamped

steel. The hold down assembly is coated for corrosion

protection.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the two nuts that secure the battery

hold down brackets to the battery tray.

(3) Remove the battery hold down brackets.

INSTALLATION

(1) Install the battery hold down brackets.

(2) Install the two nuts that secure the battery

hold down brackets to the battery tray. Tighten to 70

in. lbs.

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

positive cable wire harness or the battery negative

cable wire harness, which may include portions of

the wiring circuits for the generator and other com-

ponents on some models.

The battery cables feature a stamped brass clamp-

ing type female battery terminal crimped onto one

end of the battery cable wire and then solder-dipped.

A square headed pinch-bolt and hex nut are installed

at the open end of the female battery terminal clamp.

The battery positive cable also includes a red molded

rubber protective cover for the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a return path for electrical current gen-

erated by the charging system for restoring the volt-

age potential of the battery. The female battery

terminal clamps on the ends of the battery cable

wires provide a strong and reliable connection of the

battery cable to the battery terminal posts. The ter-

minal pinch bolts allow the female terminal clamps

to be tightened around the male terminal posts on

the top of the battery. The eyelet terminals secured

to the ends of the battery cable wires opposite the

female battery terminal clamps provide secure and

reliable connection of the battery to the vehicle elec-

trical system.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cables. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, OR LOW

ELECTROLYTE LEVEL, DO NOT TEST, ASSIST-

BOOST, OR CHARGE. THE BATTERY MAY ARC

INTERNALLY AND EXPLODE. PERSONAL INJURY

AND/OR VEHICLE DAMAGE MAY RESULT.

8F - 14 BATTERY SYSTEMVA

Page 143 of 1232

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE, USE

FLAME, OR CREATE SPARKS NEAR THE BATTERY.

PERSONAL INJURY AND/OR VEHICLE DAMAGE MAY

RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.

WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT BEFORE

THE BATTERY IS RETURNED TO SERVICE. PER-

SONAL INJURY AND/OR VEHICLE DAMAGE MAY

RESULT FROM LOOSE OR MISSING CELL CAPS.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and tested. (Refer to

8 - ELECTRICAL/BATTERY SYSTEM/BATTERY -

STANDARD PROCEDURE).

²Fully engage the parking brake.

²Place the automatic transmission gearshift selec-

tor lever in the Park position.

²Verify that all lamps and accessories are turned

off.

²Prevent the engine from starting.

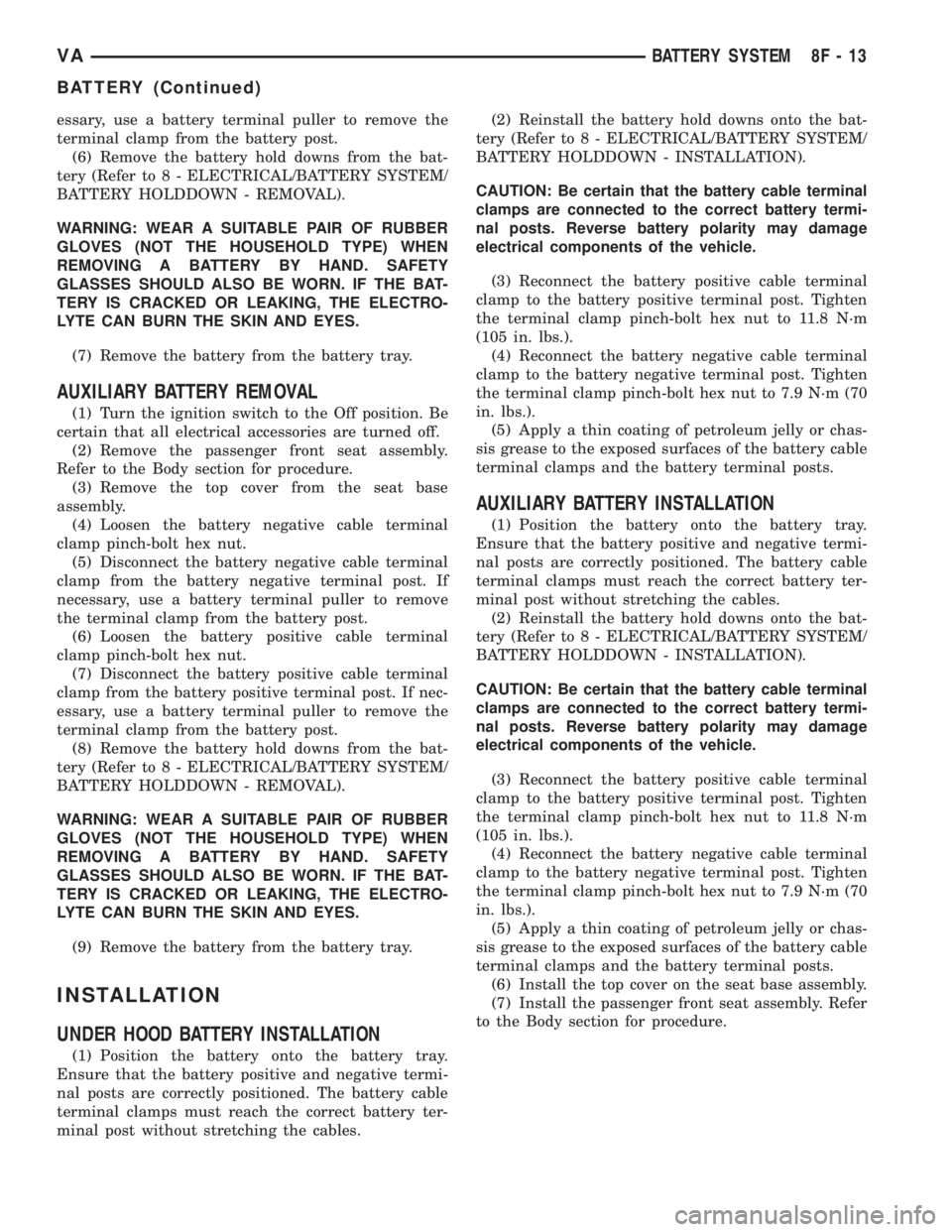

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 9). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

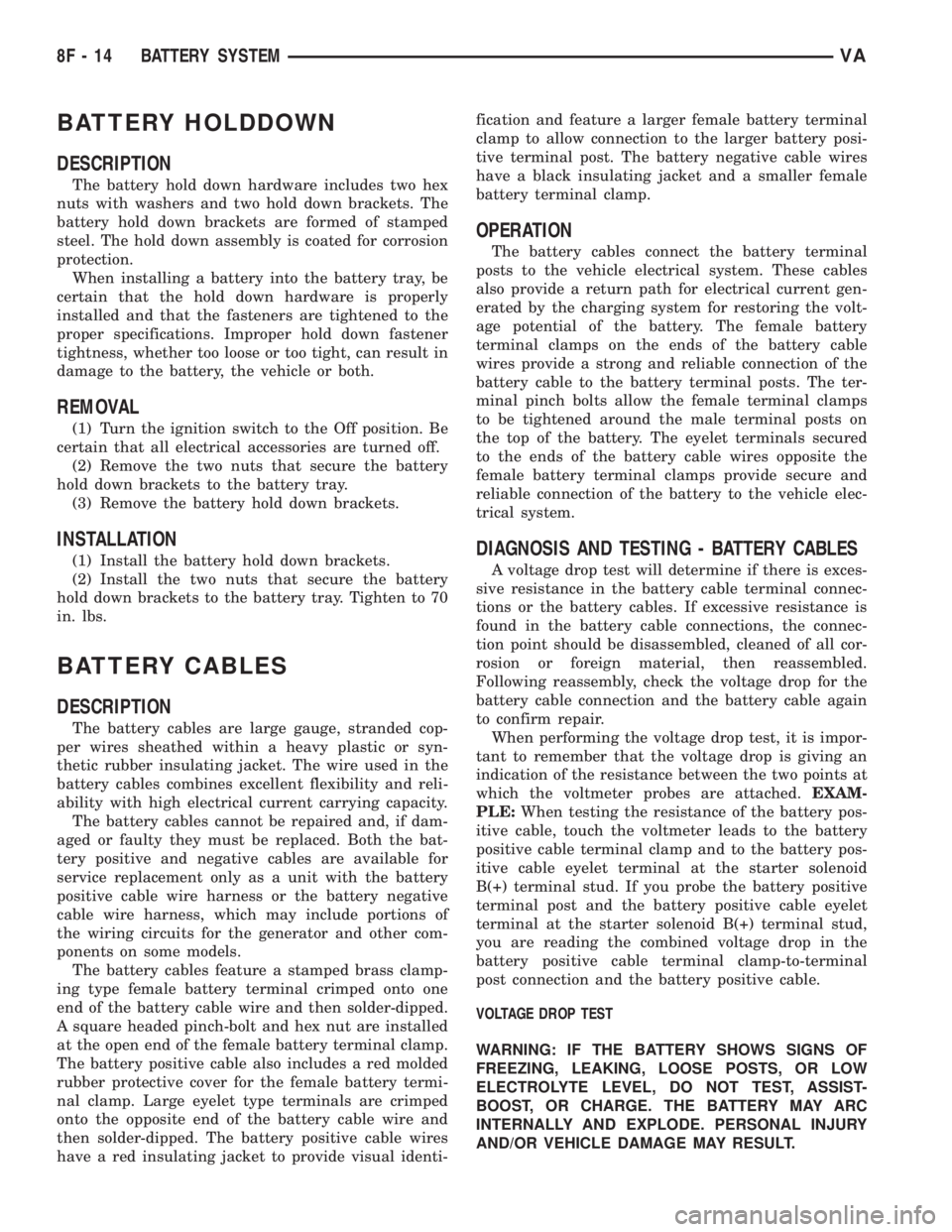

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 10). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

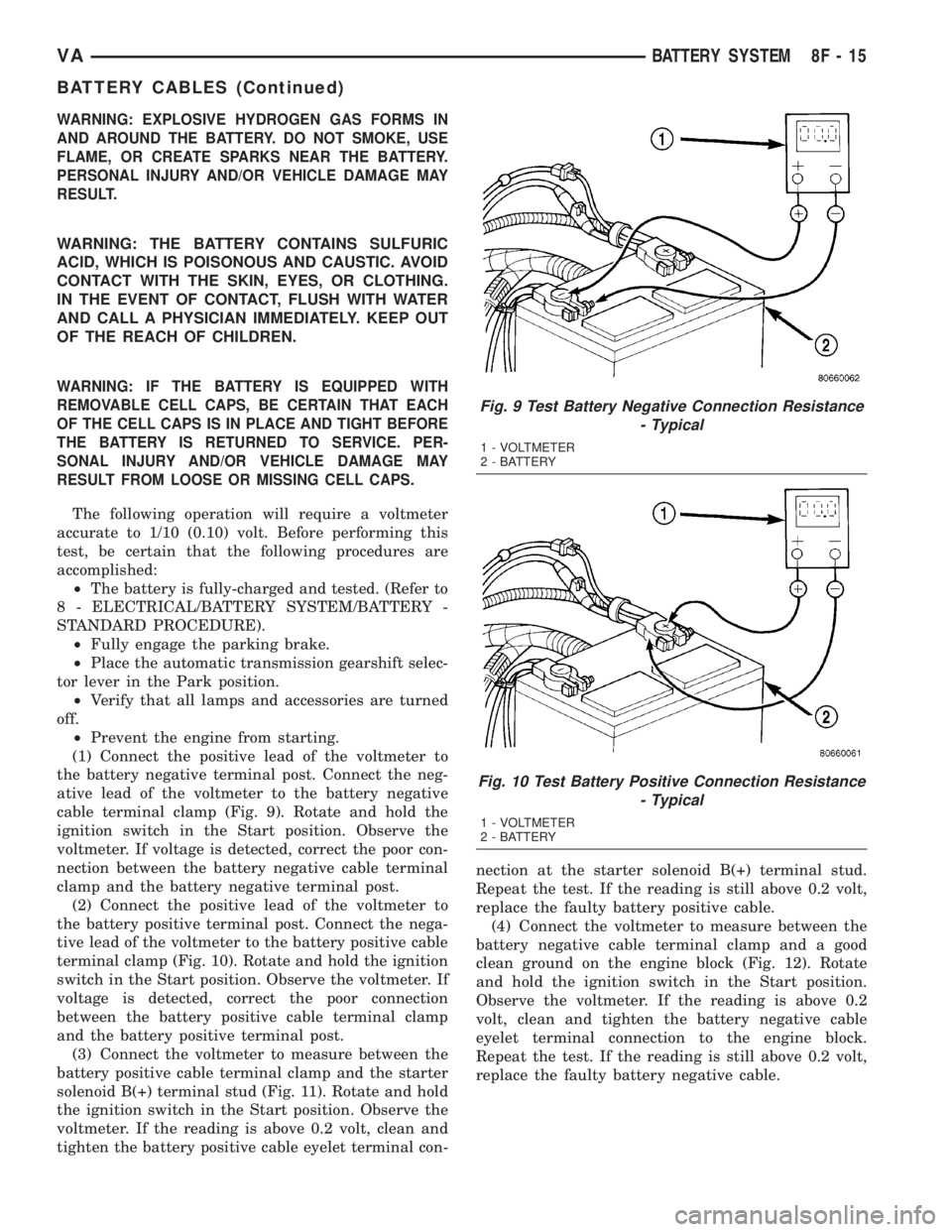

(3) Connect the voltmeter to measure between the

battery positive cable terminal clamp and the starter

solenoid B(+) terminal stud (Fig. 11). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery positive cable eyelet terminal con-nection at the starter solenoid B(+) terminal stud.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.

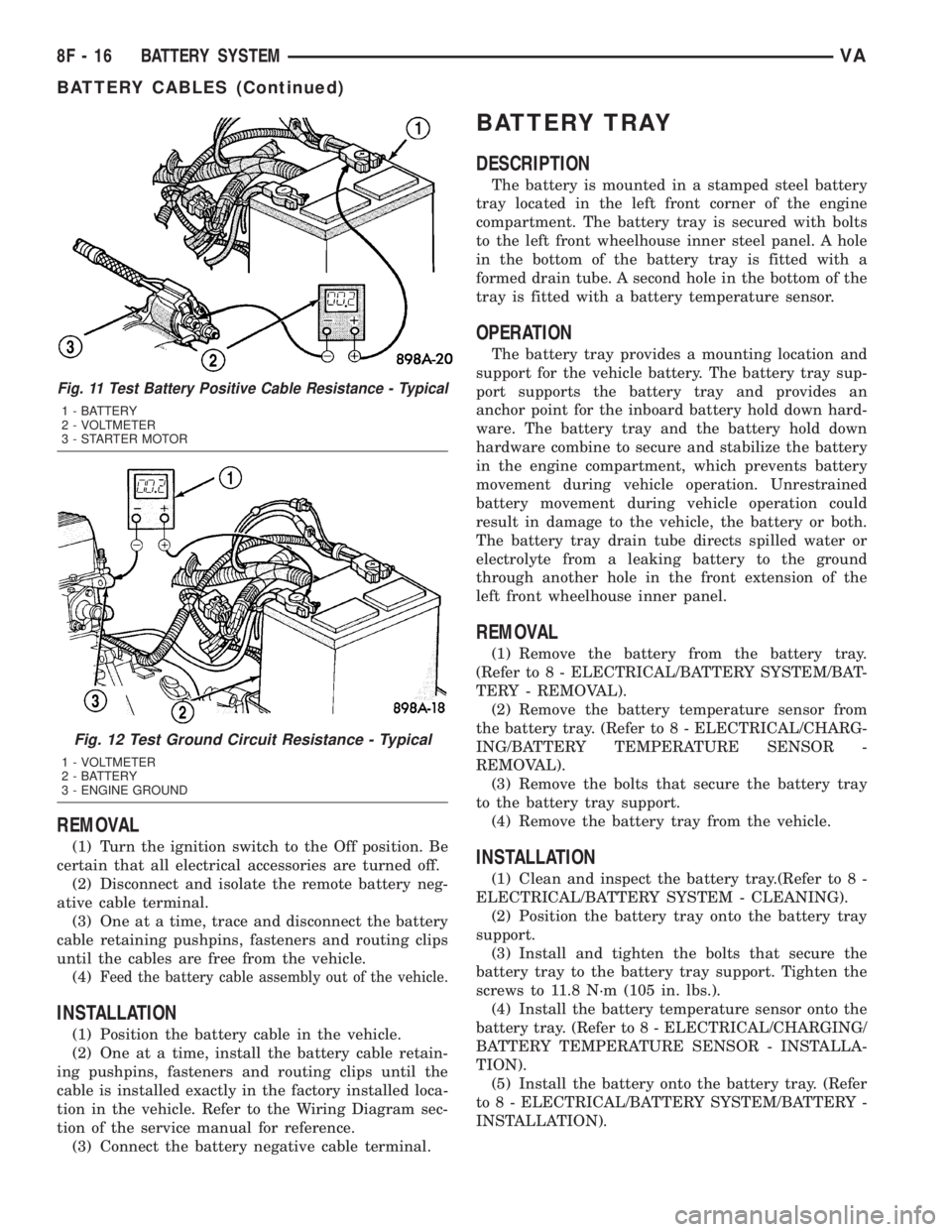

(4) Connect the voltmeter to measure between the

battery negative cable terminal clamp and a good

clean ground on the engine block (Fig. 12). Rotate

and hold the ignition switch in the Start position.

Observe the voltmeter. If the reading is above 0.2

volt, clean and tighten the battery negative cable

eyelet terminal connection to the engine block.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery negative cable.

Fig. 9 Test Battery Negative Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 10 Test Battery Positive Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

VABATTERY SYSTEM 8F - 15

BATTERY CABLES (Continued)

Page 144 of 1232

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the remote battery neg-

ative cable terminal.

(3) One at a time, trace and disconnect the battery

cable retaining pushpins, fasteners and routing clips

until the cables are free from the vehicle.

(4)

Feed the battery cable assembly out of the vehicle.

INSTALLATION

(1) Position the battery cable in the vehicle.

(2) One at a time, install the battery cable retain-

ing pushpins, fasteners and routing clips until the

cable is installed exactly in the factory installed loca-

tion in the vehicle. Refer to the Wiring Diagram sec-

tion of the service manual for reference.

(3) Connect the battery negative cable terminal.

BATTERY TRAY

DESCRIPTION

The battery is mounted in a stamped steel battery

tray located in the left front corner of the engine

compartment. The battery tray is secured with bolts

to the left front wheelhouse inner steel panel. A hole

in the bottom of the battery tray is fitted with a

formed drain tube. A second hole in the bottom of the

tray is fitted with a battery temperature sensor.

OPERATION

The battery tray provides a mounting location and

support for the vehicle battery. The battery tray sup-

port supports the battery tray and provides an

anchor point for the inboard battery hold down hard-

ware. The battery tray and the battery hold down

hardware combine to secure and stabilize the battery

in the engine compartment, which prevents battery

movement during vehicle operation. Unrestrained

battery movement during vehicle operation could

result in damage to the vehicle, the battery or both.

The battery tray drain tube directs spilled water or

electrolyte from a leaking battery to the ground

through another hole in the front extension of the

left front wheelhouse inner panel.

REMOVAL

(1) Remove the battery from the battery tray.

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - REMOVAL).

(2) Remove the battery temperature sensor from

the battery tray. (Refer to 8 - ELECTRICAL/CHARG-

ING/BATTERY TEMPERATURE SENSOR -

REMOVAL).

(3) Remove the bolts that secure the battery tray

to the battery tray support.

(4) Remove the battery tray from the vehicle.

INSTALLATION

(1) Clean and inspect the battery tray.(Refer to 8 -

ELECTRICAL/BATTERY SYSTEM - CLEANING).

(2) Position the battery tray onto the battery tray

support.

(3) Install and tighten the bolts that secure the

battery tray to the battery tray support. Tighten the

screws to 11.8 N´m (105 in. lbs.).

(4) Install the battery temperature sensor onto the

battery tray. (Refer to 8 - ELECTRICAL/CHARGING/

BATTERY TEMPERATURE SENSOR - INSTALLA-

TION).

(5) Install the battery onto the battery tray. (Refer

to 8 - ELECTRICAL/BATTERY SYSTEM/BATTERY -

INSTALLATION).

Fig. 11 Test Battery Positive Cable Resistance - Typical

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 12 Test Ground Circuit Resistance - Typical

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

8F - 16 BATTERY SYSTEMVA

BATTERY CABLES (Continued)

Page 145 of 1232

CHARGING SYSTEM

TABLE OF CONTENTS

page page

CHARGING SYSTEM

SPECIFICATIONS

TORQUE ± 2.7L DIESEL................17

SPECIAL TOOLS.......................17

GENERATOR

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................18GENERATOR DECOUPLER PULLEY

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - GENERATOR

DECOUPLER.........................19

REMOVAL.............................20

INSTALLATION.........................21

VOLTAGE REGULATOR

DESCRIPTION.........................23

CHARGING SYSTEM

SPECIFICATIONS

TORQUE ± 2.7L DIESEL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

B+ Terminal Nut at Top of Generator 13 - 115

Generator Mounting Bolts/Nut 54 40 -

Rear Generator Support Bracket Bolts (to engine) 28 - 250

Generator Decoupler 110 81 -

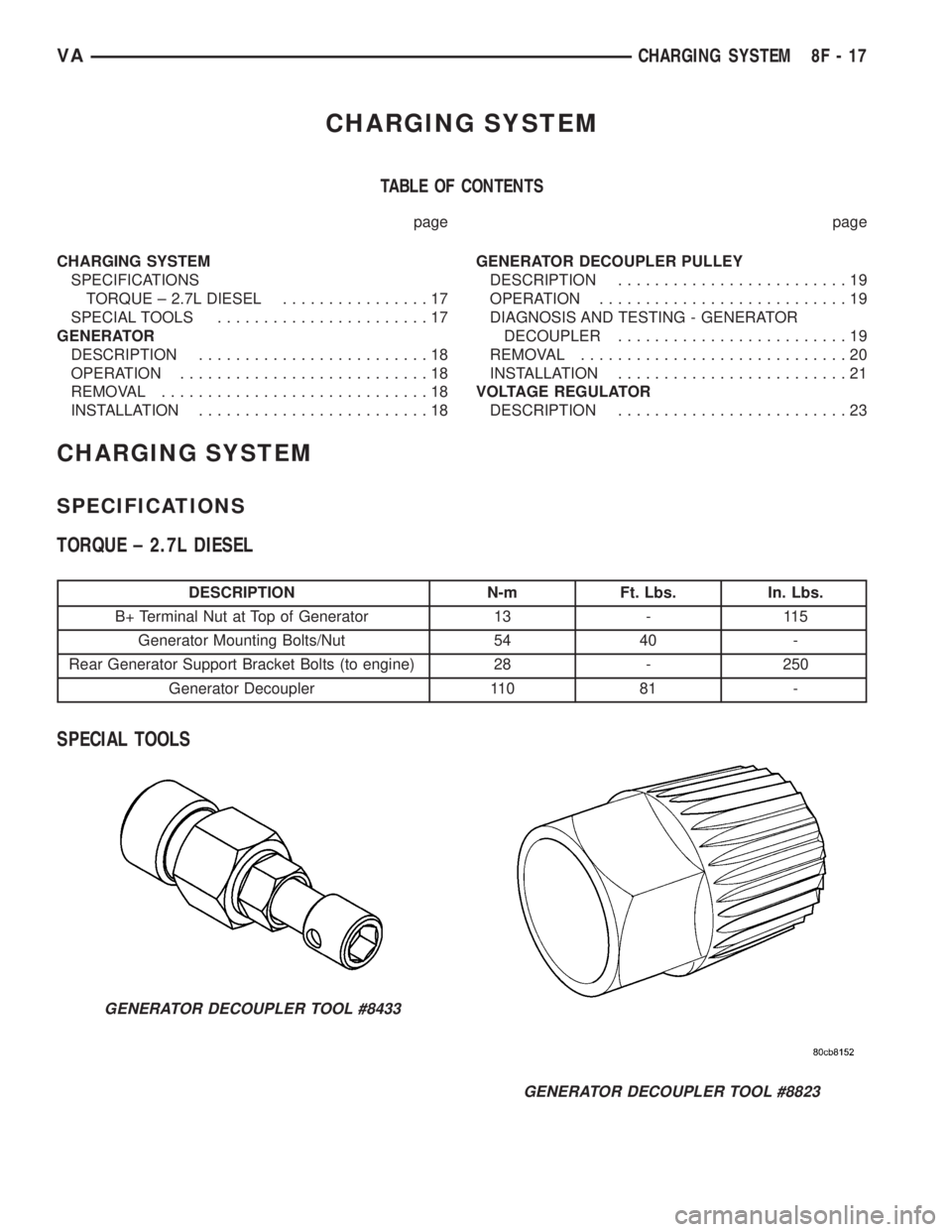

SPECIAL TOOLS

GENERATOR DECOUPLER TOOL #8433

GENERATOR DECOUPLER TOOL #8823

VACHARGING SYSTEM 8F - 17

Page 146 of 1232

GENERATOR

DESCRIPTION

The generator is belt-driven by the engine using a

serpentine-type drive belt. It is serviced only as a

complete assembly. If the generator fails for any rea-

son, the entire assembly must be replaced.

On certain engines, the decoupler pulley may be

replaced separately.

OPERATION

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The stator winding connections deliver the induced

AC current to 3 positive and 3 negative diodes for

rectification. From the diodes, rectified DC current is

delivered to the vehicle electrical system through the

generator battery terminal.

Although the generators appear the same exter-

nally, different generators with different output rat-

ings are used on this vehicle. Be certain that the

replacement generator has the same output rating

and part number as the original unit. Refer to Spec-

ifications and see Generator Ratings for amperage

ratings and part numbers.

Noise emitting from the generator may be caused

by: worn, loose or defective bearings; a loose or defec-

tive drive pulley (decoupler pulley); incorrect, worn,

damaged or misadjusted fan drive belt; loose mount-

ing bolts; a misaligned drive pulley or a defective sta-

tor or diode.

An instrument panel mounted, battery charge indi-

cator lamp is used. When the key is in the on posi-

tion, the lamp will be illuminated. This is done as a

bulb check. If this lamp remains illuminated while

the engine is running, a Diagnostic Trouble Code

(DTC) has been detected for the charging system.

REMOVAL

CAUTION: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction ifthe belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

(1) Disconnect and isolate negative battery cable.

(2) Remove generator drive belt. Refer to Cooling

System for procedure.

(3) Raise and support vehicle.

(4) Remove protective plastic cover from B+ stud

at top of generator.

(5) Remove nut securing battery output cable to

B+ terminal at top of generator.

(6) Unplug field terminal connector at rear of gen-

erator.

(7) Remove 4 generator mounting bolts (Torx-style

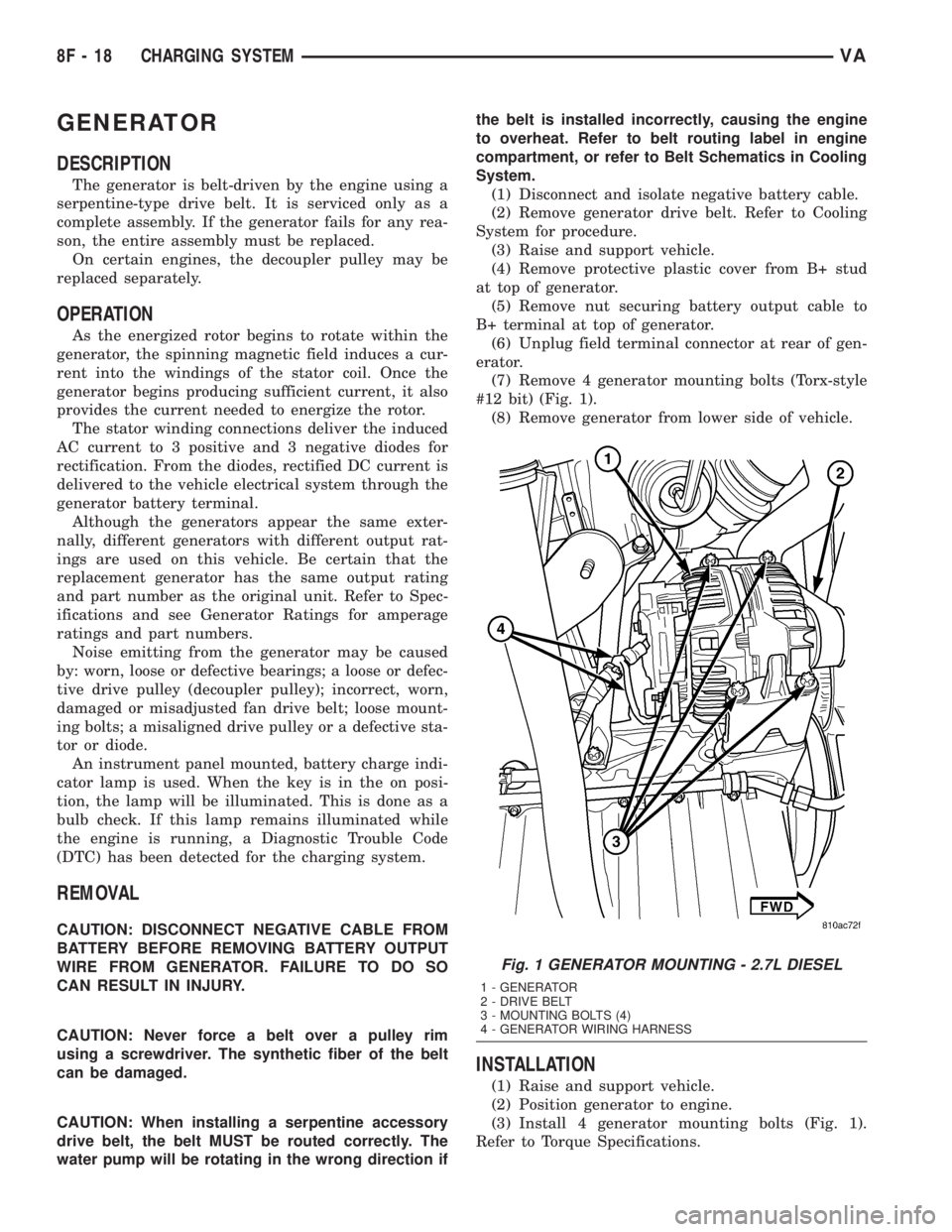

#12 bit) (Fig. 1).

(8) Remove generator from lower side of vehicle.

INSTALLATION

(1) Raise and support vehicle.

(2) Position generator to engine.

(3) Install 4 generator mounting bolts (Fig. 1).

Refer to Torque Specifications.

Fig. 1 GENERATOR MOUNTING - 2.7L DIESEL

1 - GENERATOR

2 - DRIVE BELT

3 - MOUNTING BOLTS (4)

4 - GENERATOR WIRING HARNESS

8F - 18 CHARGING SYSTEMVA

Page 147 of 1232

(4) Connect field terminal connector at rear of gen-

erator.

(5) Install battery output cable and nut to B+ ter-

minal at top of generator. Refer to Torque Specifica-

tions.

(6) Install protective plastic cover to B+ stud at

top of generator.

(7) Lower vehicle.

CAUTION: Never force a belt over a pulley rim

using a screwdriver. The synthetic fiber of the belt

can be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to belt routing label in engine

compartment, or refer to Belt Schematics in Cooling

System.

(8) Install generator drive belt. Refer to Cooling

System for procedure.

(9) Connect negative battery cable.

(10) Check charging system for proper operation.

GENERATOR DECOUPLER

PULLEY

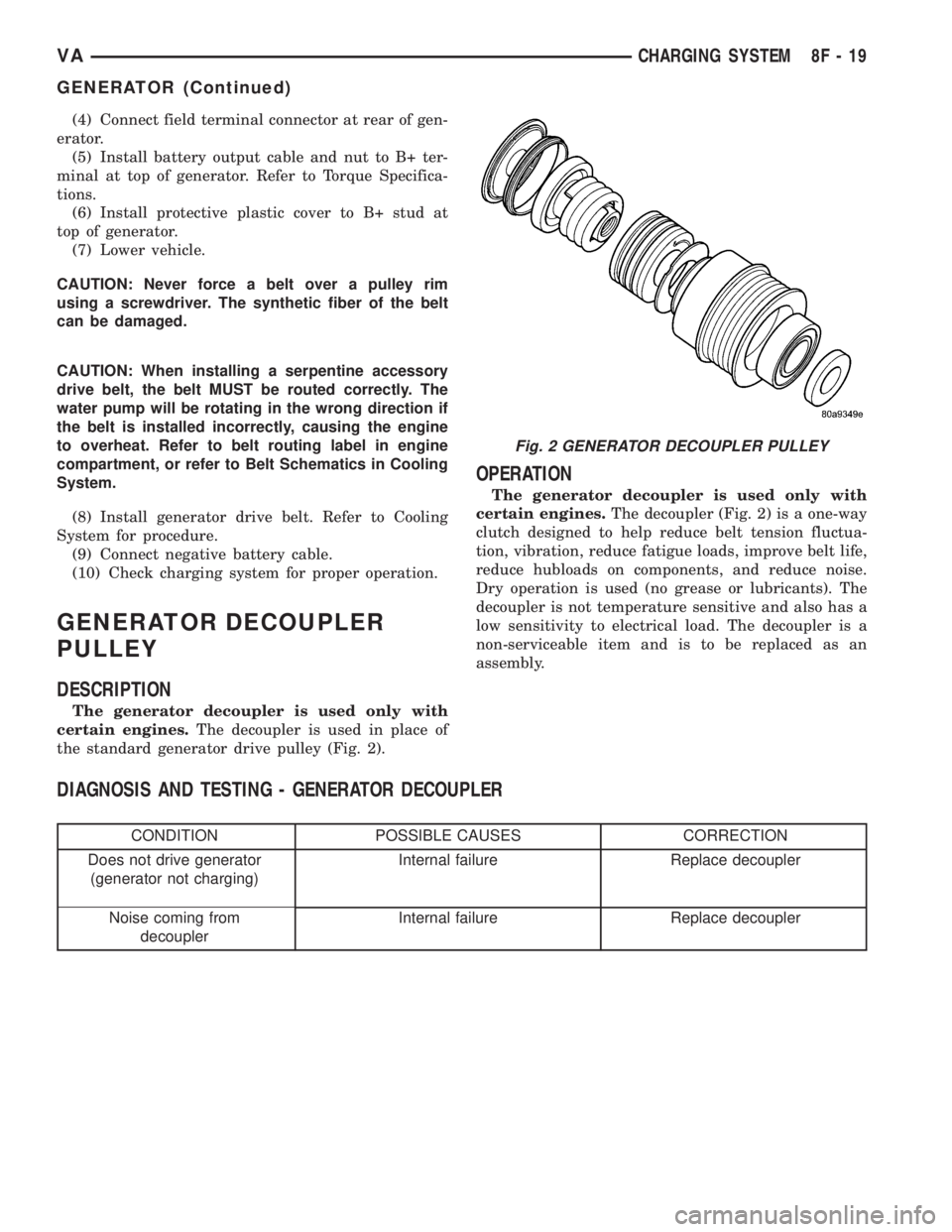

DESCRIPTION

The generator decoupler is used only with

certain engines.The decoupler is used in place of

the standard generator drive pulley (Fig. 2).

OPERATION

The generator decoupler is used only with

certain engines.The decoupler (Fig. 2) is a one-way

clutch designed to help reduce belt tension fluctua-

tion, vibration, reduce fatigue loads, improve belt life,

reduce hubloads on components, and reduce noise.

Dry operation is used (no grease or lubricants). The

decoupler is not temperature sensitive and also has a

low sensitivity to electrical load. The decoupler is a

non-serviceable item and is to be replaced as an

assembly.

DIAGNOSIS AND TESTING - GENERATOR DECOUPLER

CONDITION POSSIBLE CAUSES CORRECTION

Does not drive generator

(generator not charging)Internal failure Replace decoupler

Noise coming from

decouplerInternal failure Replace decoupler

Fig. 2 GENERATOR DECOUPLER PULLEY

VACHARGING SYSTEM 8F - 19

GENERATOR (Continued)

Page 148 of 1232

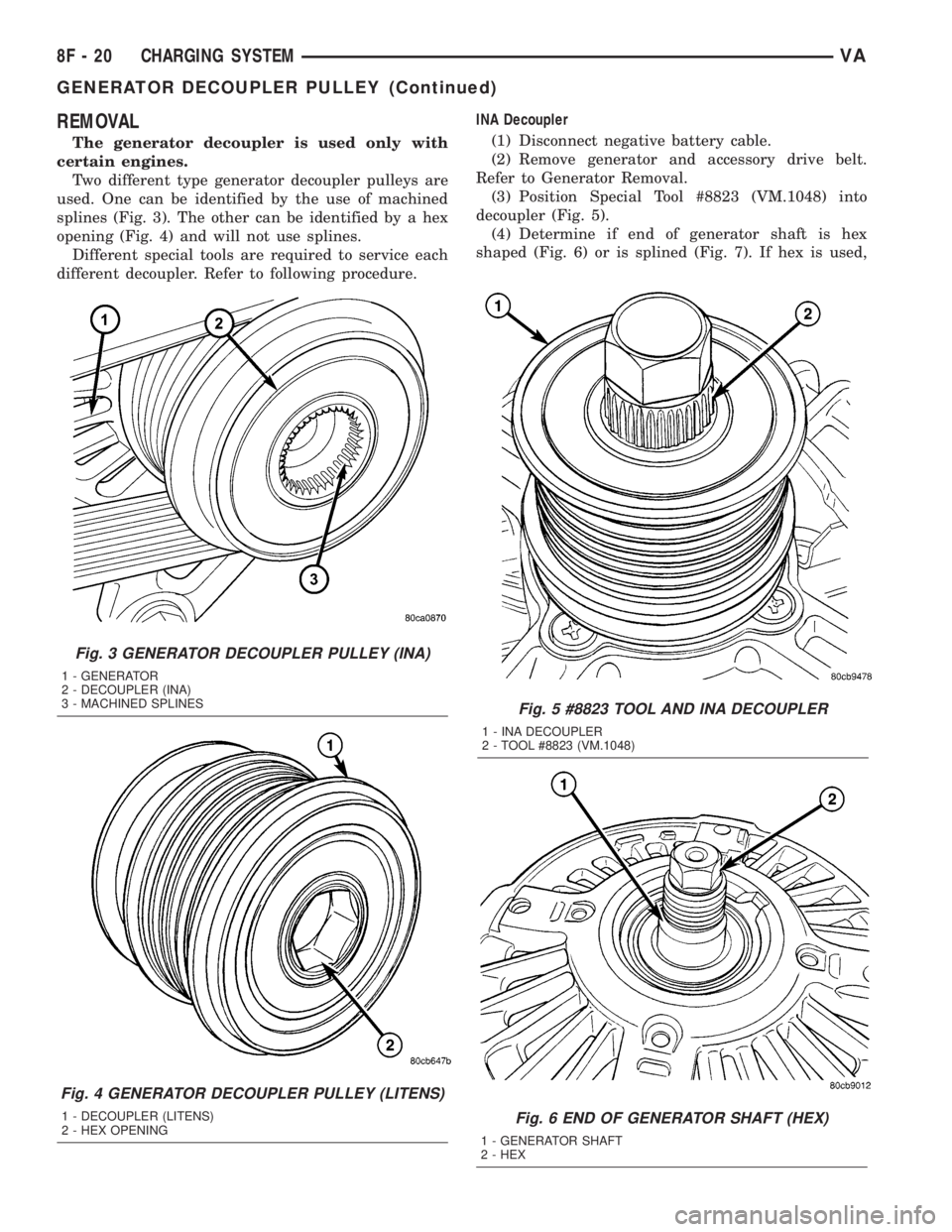

REMOVAL

The generator decoupler is used only with

certain engines.

Two different type generator decoupler pulleys are

used. One can be identified by the use of machined

splines (Fig. 3). The other can be identified by a hex

opening (Fig. 4) and will not use splines.

Different special tools are required to service each

different decoupler. Refer to following procedure.INA Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

(3) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 5).

(4) Determine if end of generator shaft is hex

shaped (Fig. 6) or is splined (Fig. 7). If hex is used,

Fig. 5 #8823 TOOL AND INA DECOUPLER

1 - INA DECOUPLER

2 - TOOL #8823 (VM.1048)

Fig. 6 END OF GENERATOR SHAFT (HEX)

1 - GENERATOR SHAFT

2 - HEX

Fig. 3 GENERATOR DECOUPLER PULLEY (INA)

1 - GENERATOR

2 - DECOUPLER (INA)

3 - MACHINED SPLINES

Fig. 4 GENERATOR DECOUPLER PULLEY (LITENS)

1 - DECOUPLER (LITENS)

2 - HEX OPENING

8F - 20 CHARGING SYSTEMVA

GENERATOR DECOUPLER PULLEY (Continued)

Page 149 of 1232

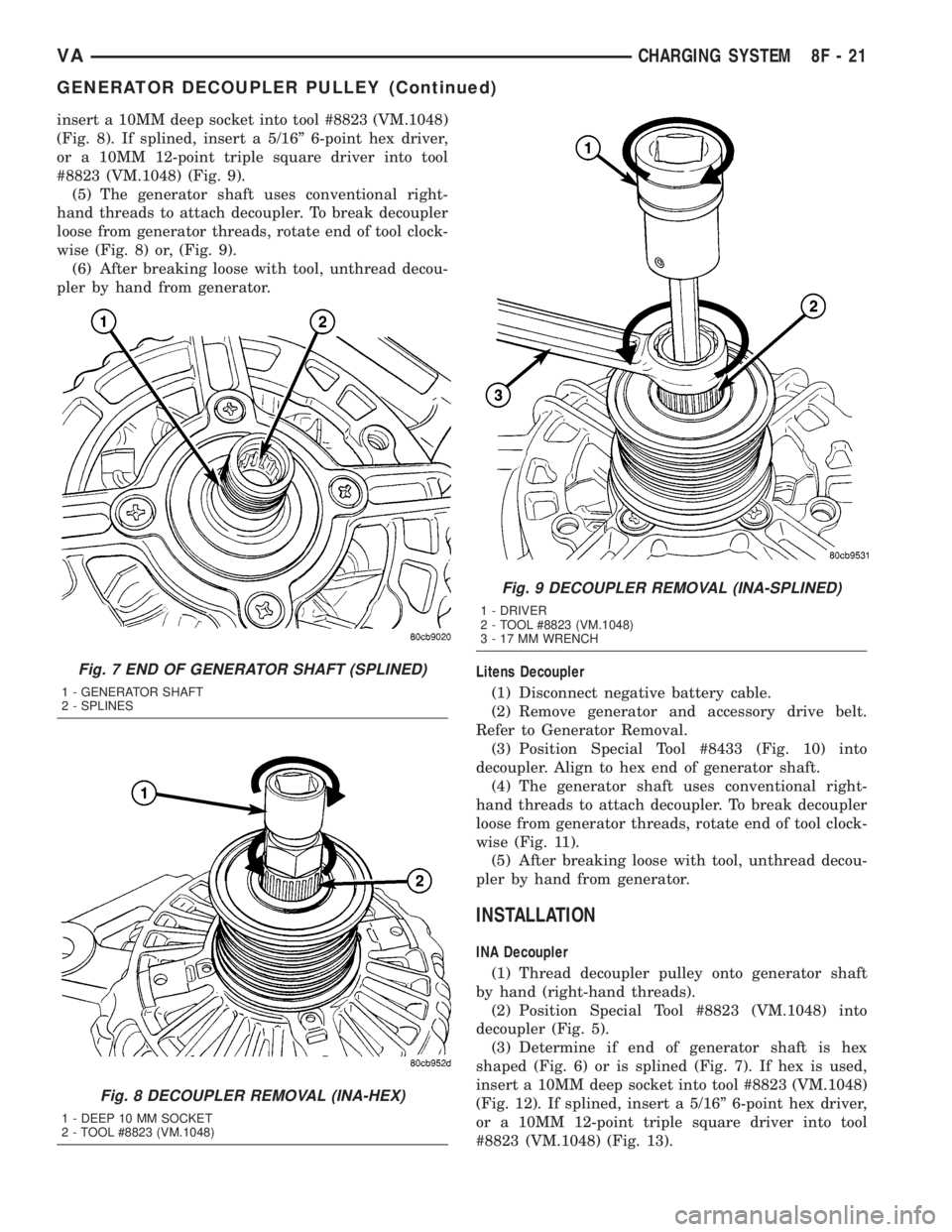

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 8). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 9).

(5) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 8) or, (Fig. 9).

(6) After breaking loose with tool, unthread decou-

pler by hand from generator.

Litens Decoupler

(1) Disconnect negative battery cable.

(2) Remove generator and accessory drive belt.

Refer to Generator Removal.

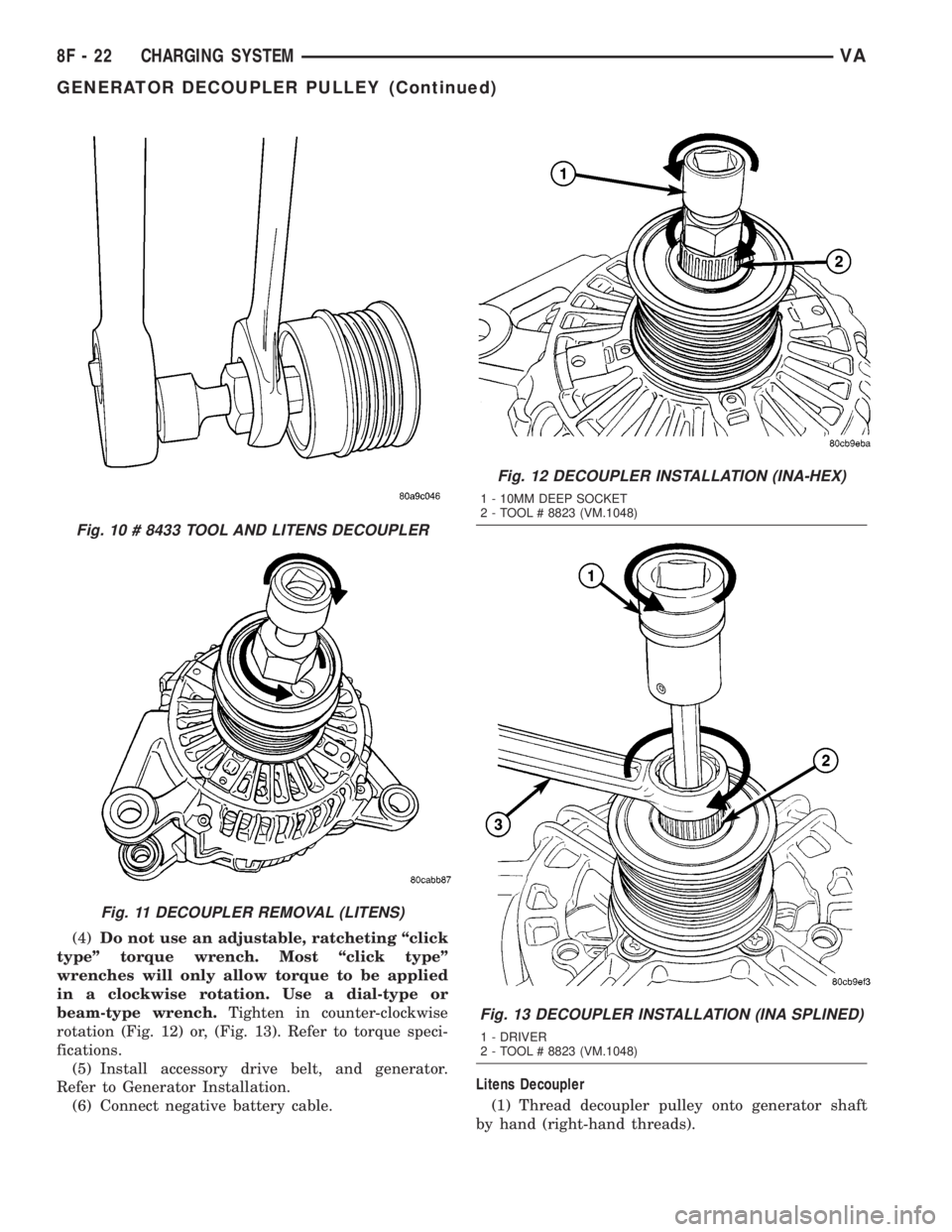

(3) Position Special Tool #8433 (Fig. 10) into

decoupler. Align to hex end of generator shaft.

(4) The generator shaft uses conventional right-

hand threads to attach decoupler. To break decoupler

loose from generator threads, rotate end of tool clock-

wise (Fig. 11).

(5) After breaking loose with tool, unthread decou-

pler by hand from generator.

INSTALLATION

INA Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

(2) Position Special Tool #8823 (VM.1048) into

decoupler (Fig. 5).

(3) Determine if end of generator shaft is hex

shaped (Fig. 6) or is splined (Fig. 7). If hex is used,

insert a 10MM deep socket into tool #8823 (VM.1048)

(Fig. 12). If splined, insert a 5/16º 6-point hex driver,

or a 10MM 12-point triple square driver into tool

#8823 (VM.1048) (Fig. 13).

Fig. 7 END OF GENERATOR SHAFT (SPLINED)

1 - GENERATOR SHAFT

2 - SPLINES

Fig. 8 DECOUPLER REMOVAL (INA-HEX)

1 - DEEP 10 MM SOCKET

2 - TOOL #8823 (VM.1048)

Fig. 9 DECOUPLER REMOVAL (INA-SPLINED)

1 - DRIVER

2 - TOOL #8823 (VM.1048)

3 - 17 MM WRENCH

VACHARGING SYSTEM 8F - 21

GENERATOR DECOUPLER PULLEY (Continued)

Page 150 of 1232

(4)Do not use an adjustable, ratcheting ªclick

typeº torque wrench. Most ªclick typeº

wrenches will only allow torque to be applied

in a clockwise rotation. Use a dial-type or

beam-type wrench.Tighten in counter-clockwise

rotation (Fig. 12) or, (Fig. 13). Refer to torque speci-

fications.

(5) Install accessory drive belt, and generator.

Refer to Generator Installation.

(6) Connect negative battery cable.Litens Decoupler

(1) Thread decoupler pulley onto generator shaft

by hand (right-hand threads).

Fig. 10 # 8433 TOOL AND LITENS DECOUPLER

Fig. 11 DECOUPLER REMOVAL (LITENS)

Fig. 12 DECOUPLER INSTALLATION (INA-HEX)

1 - 10MM DEEP SOCKET

2 - TOOL # 8823 (VM.1048)

Fig. 13 DECOUPLER INSTALLATION (INA SPLINED)

1 - DRIVER

2 - TOOL # 8823 (VM.1048)

8F - 22 CHARGING SYSTEMVA

GENERATOR DECOUPLER PULLEY (Continued)