sensor MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 964 of 1232

HYDRAULIC CONTROL UNIT

Working Pressure Regulating Valve (Operating Pressure)

The working pressure (p-A) is regulated at the

working pressure regulating valve (22) (Fig. 100) in

relation to load (modulating pressure) and gear (K1

or K2 pressure). The spring in the working pressure

regulating valve sets a minimum pressure level

(basic pressure).

Torque Converter Lockup Clutch Regulating Valve

The torque converter lockup clutch regulating

valve (6) (Fig. 101) regulates the torque converter

lock-up clutch working pressure in relation to the

torque converter clutch control pressure. According to

the size of the working pressure, the torque converter

lockup clutch is either Engaged, Disengaged, or Slip-

ping. When the regulating valve (6) is in the lower

position, lubricating oil flows through the torque con-

verter and oil cooler (8) into the transmission (torque

converter lockup clutch unpressurized). In its regu-

lating position (slipping, torque converter lockup

clutch pressurized), a reduced volume of lubricating

oil flows through the annular passage (7) bypassingthe torque converter and passing direct through the

oil cooler into the transmission. The rest of the lubri-

cating oil is directed via the throttle9a9into the

torque converter in order to cool the torque converter

lockup clutch.

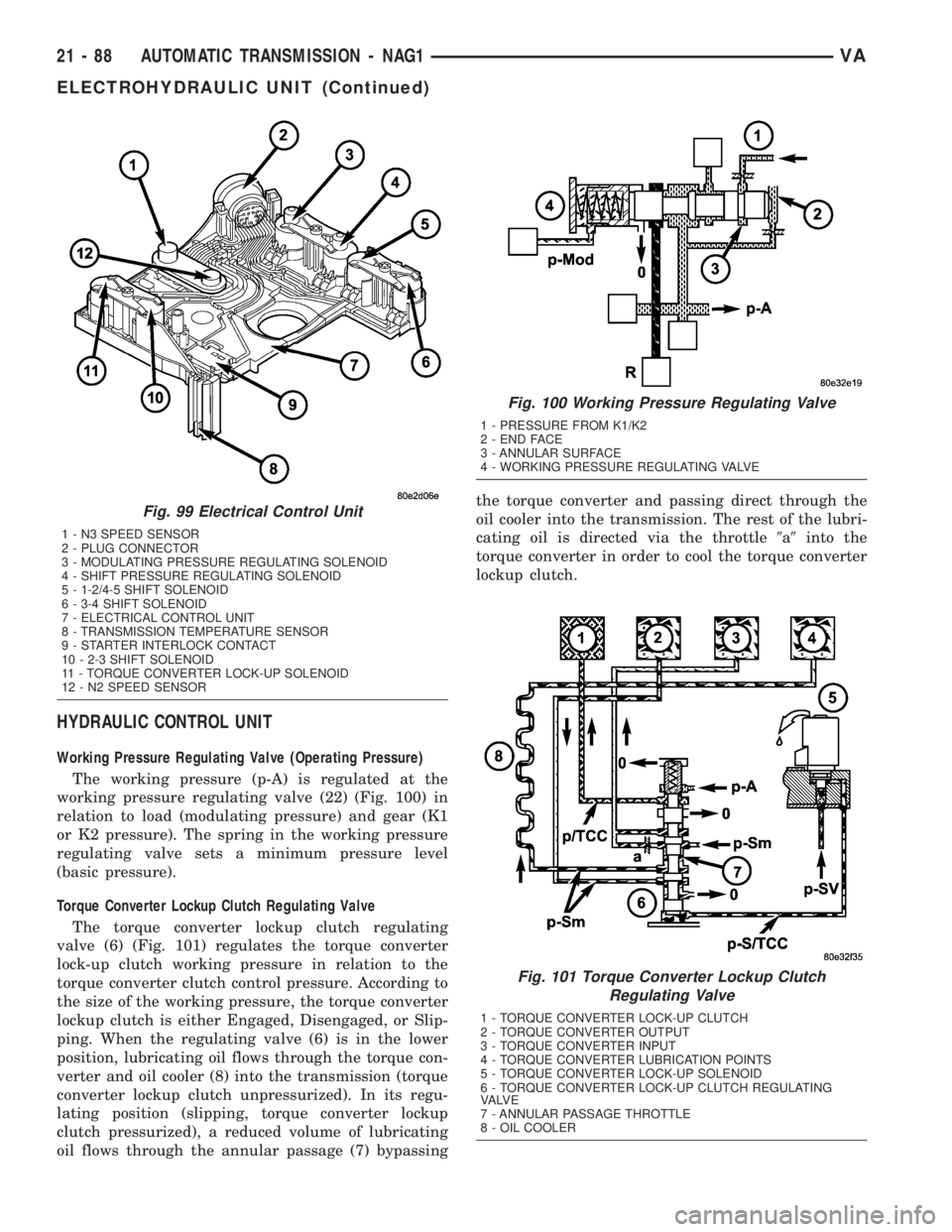

Fig. 99 Electrical Control Unit

1 - N3 SPEED SENSOR

2 - PLUG CONNECTOR

3 - MODULATING PRESSURE REGULATING SOLENOID

4 - SHIFT PRESSURE REGULATING SOLENOID

5 - 1-2/4-5 SHIFT SOLENOID

6 - 3-4 SHIFT SOLENOID

7 - ELECTRICAL CONTROL UNIT

8 - TRANSMISSION TEMPERATURE SENSOR

9 - STARTER INTERLOCK CONTACT

10 - 2-3 SHIFT SOLENOID

11 - TORQUE CONVERTER LOCK-UP SOLENOID

12 - N2 SPEED SENSOR

Fig. 100 Working Pressure Regulating Valve

1 - PRESSURE FROM K1/K2

2 - END FACE

3 - ANNULAR SURFACE

4 - WORKING PRESSURE REGULATING VALVE

Fig. 101 Torque Converter Lockup Clutch

Regulating Valve

1 - TORQUE CONVERTER LOCK-UP CLUTCH

2 - TORQUE CONVERTER OUTPUT

3 - TORQUE CONVERTER INPUT

4 - TORQUE CONVERTER LUBRICATION POINTS

5 - TORQUE CONVERTER LOCK-UP SOLENOID

6 - TORQUE CONVERTER LOCK-UP CLUTCH REGULATING

VA LV E

7 - ANNULAR PASSAGE THROTTLE

8 - OIL COOLER

21 - 88 AUTOMATIC TRANSMISSION - NAG1VA

ELECTROHYDRAULIC UNIT (Continued)

Page 969 of 1232

NOTE: Check O-rings on solenoid valves for dam-

age and replace if necessary.

(6) Bend away retaining lug on stiffening rib on

transmission oil temperature sensor.

(7) Remove electrohydraulic control module (12)

from the shift plate (13).

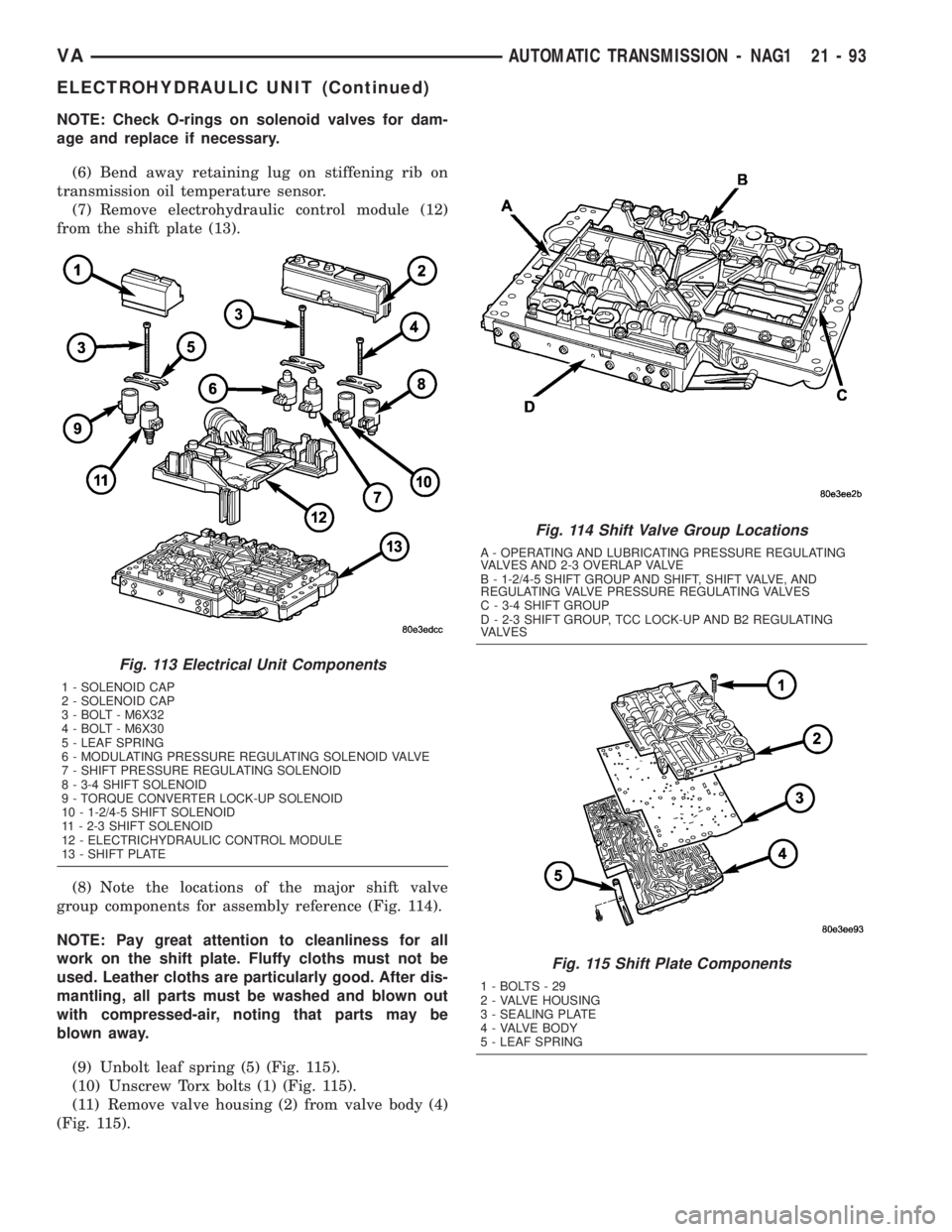

(8) Note the locations of the major shift valve

group components for assembly reference (Fig. 114).

NOTE: Pay great attention to cleanliness for all

work on the shift plate. Fluffy cloths must not be

used. Leather cloths are particularly good. After dis-

mantling, all parts must be washed and blown out

with compressed-air, noting that parts may be

blown away.

(9) Unbolt leaf spring (5) (Fig. 115).

(10) Unscrew Torx bolts (1) (Fig. 115).

(11) Remove valve housing (2) from valve body (4)

(Fig. 115).

Fig. 113 Electrical Unit Components

1 - SOLENOID CAP

2 - SOLENOID CAP

3 - BOLT - M6X32

4 - BOLT - M6X30

5 - LEAF SPRING

6 - MODULATING PRESSURE REGULATING SOLENOID VALVE

7 - SHIFT PRESSURE REGULATING SOLENOID

8 - 3-4 SHIFT SOLENOID

9 - TORQUE CONVERTER LOCK-UP SOLENOID

10 - 1-2/4-5 SHIFT SOLENOID

11 - 2-3 SHIFT SOLENOID

12 - ELECTRICHYDRAULIC CONTROL MODULE

13 - SHIFT PLATE

Fig. 114 Shift Valve Group Locations

A - OPERATING AND LUBRICATING PRESSURE REGULATING

VALVES AND 2-3 OVERLAP VALVE

B - 1-2/4-5 SHIFT GROUP AND SHIFT, SHIFT VALVE, AND

REGULATING VALVE PRESSURE REGULATING VALVES

C - 3-4 SHIFT GROUP

D - 2-3 SHIFT GROUP, TCC LOCK-UP AND B2 REGULATING

VA LV E S

Fig. 115 Shift Plate Components

1-BOLTS-29

2 - VALVE HOUSING

3 - SEALING PLATE

4 - VALVE BODY

5 - LEAF SPRING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 93

ELECTROHYDRAULIC UNIT (Continued)

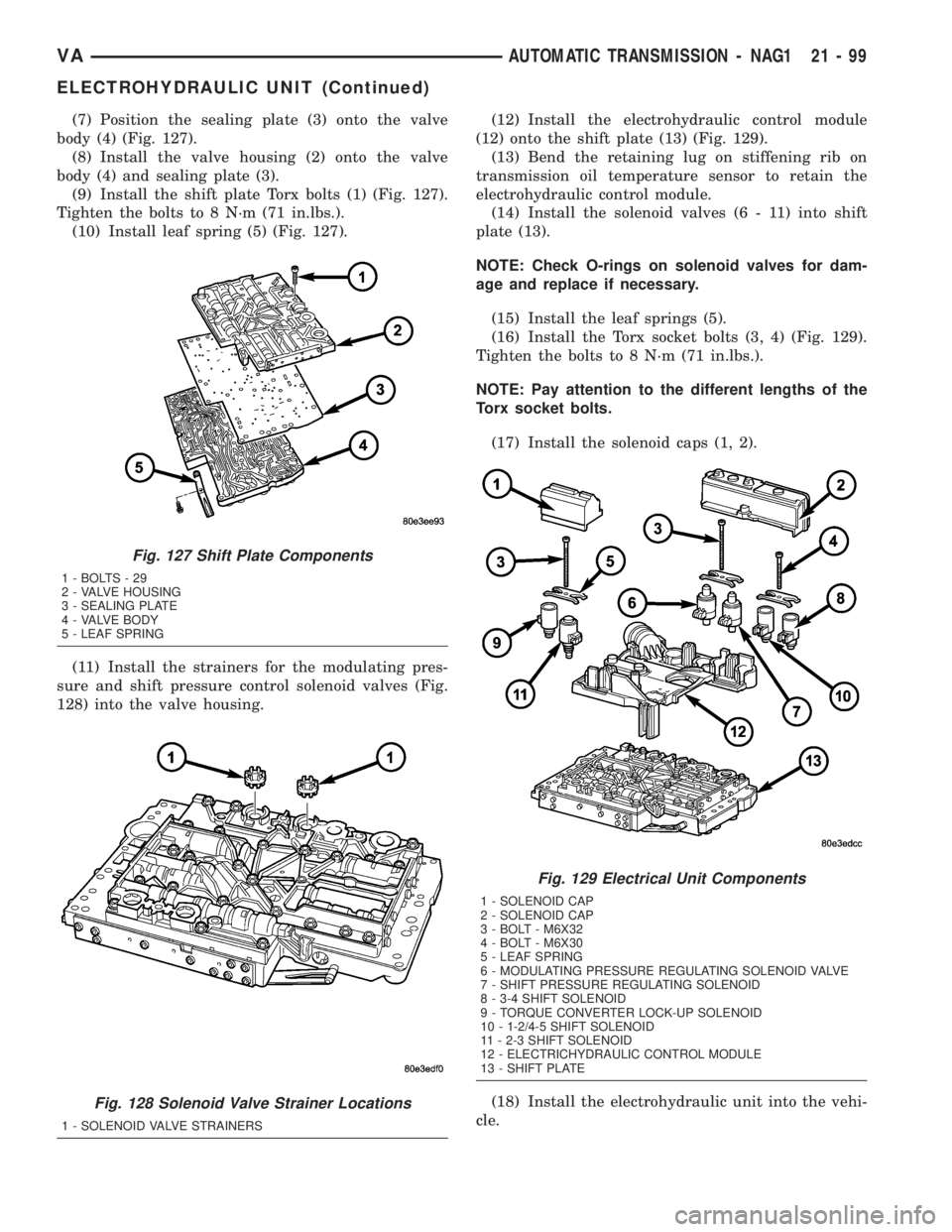

Page 975 of 1232

(7) Position the sealing plate (3) onto the valve

body (4) (Fig. 127).

(8) Install the valve housing (2) onto the valve

body (4) and sealing plate (3).

(9) Install the shift plate Torx bolts (1) (Fig. 127).

Tighten the bolts to 8 N´m (71 in.lbs.).

(10) Install leaf spring (5) (Fig. 127).

(11) Install the strainers for the modulating pres-

sure and shift pressure control solenoid valves (Fig.

128) into the valve housing.(12) Install the electrohydraulic control module

(12) onto the shift plate (13) (Fig. 129).

(13) Bend the retaining lug on stiffening rib on

transmission oil temperature sensor to retain the

electrohydraulic control module.

(14) Install the solenoid valves (6 - 11) into shift

plate (13).

NOTE: Check O-rings on solenoid valves for dam-

age and replace if necessary.

(15) Install the leaf springs (5).

(16) Install the Torx socket bolts (3, 4) (Fig. 129).

Tighten the bolts to 8 N´m (71 in.lbs.).

NOTE: Pay attention to the different lengths of the

Torx socket bolts.

(17) Install the solenoid caps (1, 2).

(18) Install the electrohydraulic unit into the vehi-

cle.

Fig. 127 Shift Plate Components

1-BOLTS-29

2 - VALVE HOUSING

3 - SEALING PLATE

4 - VALVE BODY

5 - LEAF SPRING

Fig. 128 Solenoid Valve Strainer Locations

1 - SOLENOID VALVE STRAINERS

Fig. 129 Electrical Unit Components

1 - SOLENOID CAP

2 - SOLENOID CAP

3 - BOLT - M6X32

4 - BOLT - M6X30

5 - LEAF SPRING

6 - MODULATING PRESSURE REGULATING SOLENOID VALVE

7 - SHIFT PRESSURE REGULATING SOLENOID

8 - 3-4 SHIFT SOLENOID

9 - TORQUE CONVERTER LOCK-UP SOLENOID

10 - 1-2/4-5 SHIFT SOLENOID

11 - 2-3 SHIFT SOLENOID

12 - ELECTRICHYDRAULIC CONTROL MODULE

13 - SHIFT PLATE

VAAUTOMATIC TRANSMISSION - NAG1 21 - 99

ELECTROHYDRAULIC UNIT (Continued)

Page 979 of 1232

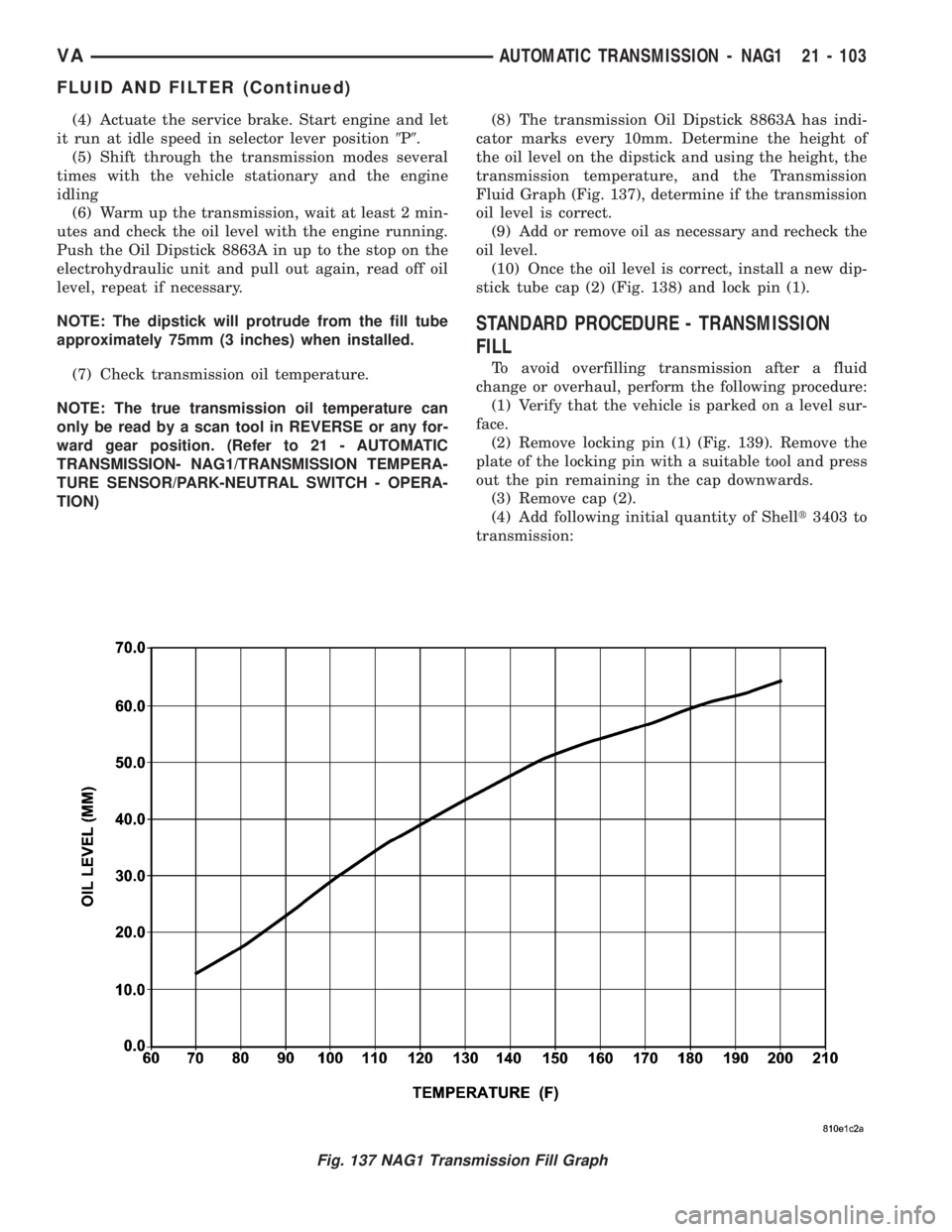

(4) Actuate the service brake. Start engine and let

it run at idle speed in selector lever position9P9.

(5) Shift through the transmission modes several

times with the vehicle stationary and the engine

idling

(6) Warm up the transmission, wait at least 2 min-

utes and check the oil level with the engine running.

Push the Oil Dipstick 8863A in up to the stop on the

electrohydraulic unit and pull out again, read off oil

level, repeat if necessary.

NOTE: The dipstick will protrude from the fill tube

approximately 75mm (3 inches) when installed.

(7) Check transmission oil temperature.

NOTE: The true transmission oil temperature can

only be read by a scan tool in REVERSE or any for-

ward gear position. (Refer to 21 - AUTOMATIC

TRANSMISSION- NAG1/TRANSMISSION TEMPERA-

TURE SENSOR/PARK-NEUTRAL SWITCH - OPERA-

TION)(8) The transmission Oil Dipstick 8863A has indi-

cator marks every 10mm. Determine the height of

the oil level on the dipstick and using the height, the

transmission temperature, and the Transmission

Fluid Graph (Fig. 137), determine if the transmission

oil level is correct.

(9) Add or remove oil as necessary and recheck the

oil level.

(10) Once the oil level is correct, install a new dip-

stick tube cap (2) (Fig. 138) and lock pin (1).

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Verify that the vehicle is parked on a level sur-

face.

(2) Remove locking pin (1) (Fig. 139). Remove the

plate of the locking pin with a suitable tool and press

out the pin remaining in the cap downwards.

(3) Remove cap (2).

(4) Add following initial quantity of Shellt3403 to

transmission:

Fig. 137 NAG1 Transmission Fill Graph

VAAUTOMATIC TRANSMISSION - NAG1 21 - 103

FLUID AND FILTER (Continued)

Page 995 of 1232

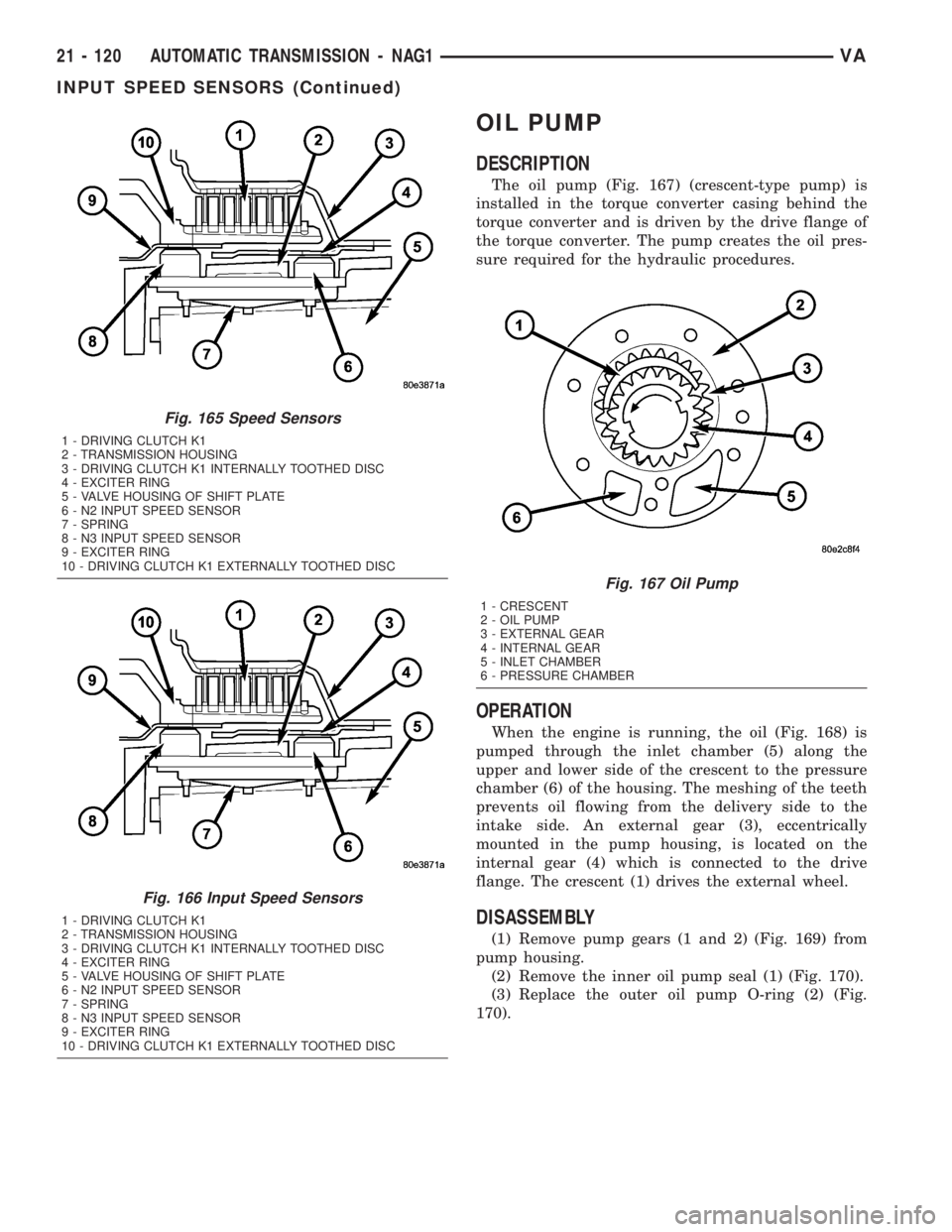

INPUT SPEED SENSORS

DESCRIPTION

The input speed sensors (6, 8) (Fig. 165) are fixed

to the shell of the control unit via contact blades. The

speed sensors are pressed against the transmission

housing (2) by a spring (7) which is held against the

valve housing of the shift plate (5). This ensures a

defined distance between the speed sensors and the

exciter ring (4).

OPERATION

Signals from the input speed sensors (6, 8) (Fig.

166) are recorded in the transmission control module

(TCM) together with the wheel and engine speeds

and other information and are processed into an

input signal for electronic control.

Input speed sensor N2 (6) records the speed of the

front sun gear via the externally toothed disc carrier

of the multiple-disc clutch K1 (10) and input speed

sensor N3 (8) records the speed of the front planet

carrier via the internally toothed disc carrier of mul-

tiple-disc clutch K1 (3).

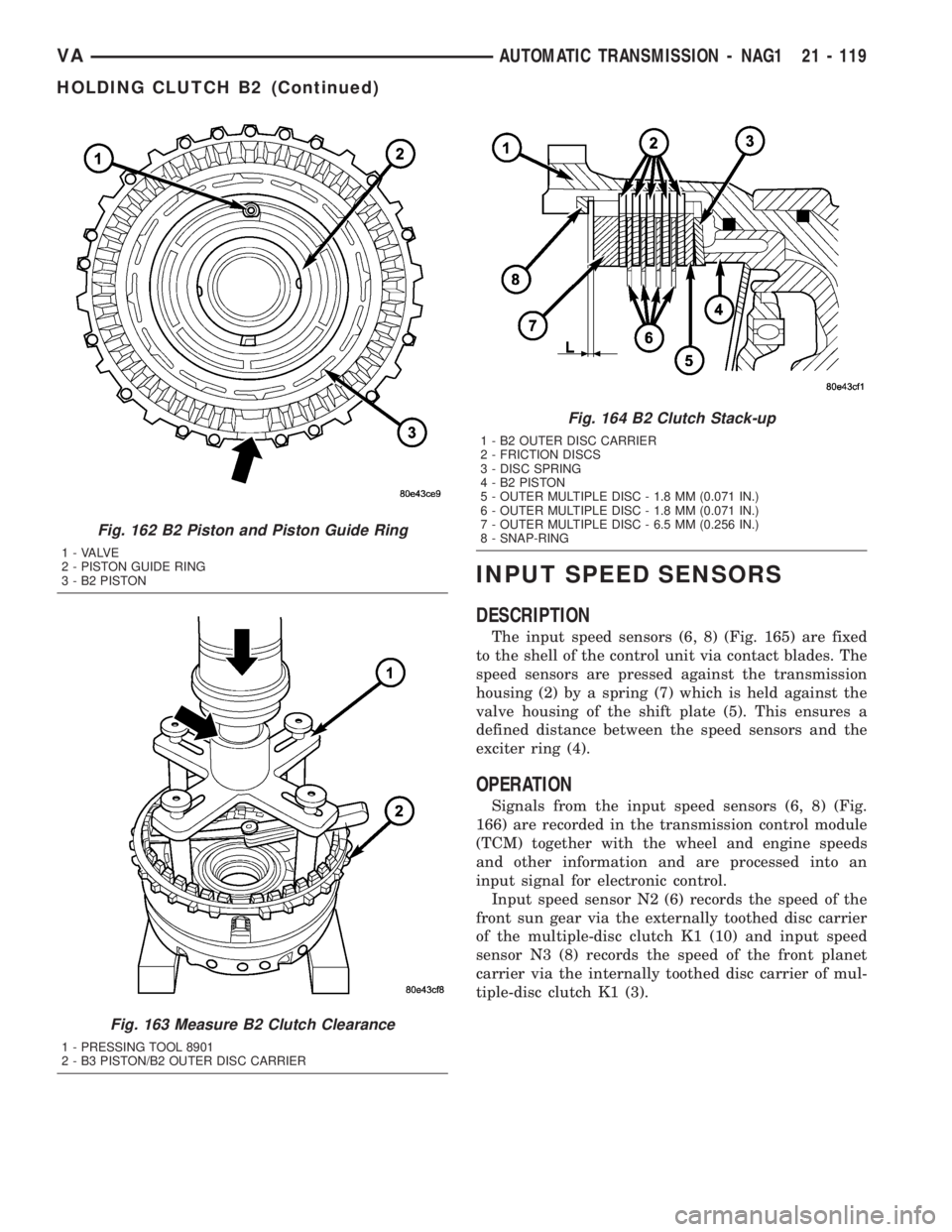

Fig. 162 B2 Piston and Piston Guide Ring

1 - VALVE

2 - PISTON GUIDE RING

3 - B2 PISTON

Fig. 163 Measure B2 Clutch Clearance

1 - PRESSING TOOL 8901

2 - B3 PISTON/B2 OUTER DISC CARRIER

Fig. 164 B2 Clutch Stack-up

1 - B2 OUTER DISC CARRIER

2 - FRICTION DISCS

3 - DISC SPRING

4 - B2 PISTON

5 - OUTER MULTIPLE DISC - 1.8 MM (0.071 IN.)

6 - OUTER MULTIPLE DISC - 1.8 MM (0.071 IN.)

7 - OUTER MULTIPLE DISC - 6.5 MM (0.256 IN.)

8 - SNAP-RING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 119

HOLDING CLUTCH B2 (Continued)

Page 996 of 1232

OIL PUMP

DESCRIPTION

The oil pump (Fig. 167) (crescent-type pump) is

installed in the torque converter casing behind the

torque converter and is driven by the drive flange of

the torque converter. The pump creates the oil pres-

sure required for the hydraulic procedures.

OPERATION

When the engine is running, the oil (Fig. 168) is

pumped through the inlet chamber (5) along the

upper and lower side of the crescent to the pressure

chamber (6) of the housing. The meshing of the teeth

prevents oil flowing from the delivery side to the

intake side. An external gear (3), eccentrically

mounted in the pump housing, is located on the

internal gear (4) which is connected to the drive

flange. The crescent (1) drives the external wheel.

DISASSEMBLY

(1) Remove pump gears (1 and 2) (Fig. 169) from

pump housing.

(2) Remove the inner oil pump seal (1) (Fig. 170).

(3) Replace the outer oil pump O-ring (2) (Fig.

170).

Fig. 165 Speed Sensors

1 - DRIVING CLUTCH K1

2 - TRANSMISSION HOUSING

3 - DRIVING CLUTCH K1 INTERNALLY TOOTHED DISC

4 - EXCITER RING

5 - VALVE HOUSING OF SHIFT PLATE

6 - N2 INPUT SPEED SENSOR

7 - SPRING

8 - N3 INPUT SPEED SENSOR

9 - EXCITER RING

10 - DRIVING CLUTCH K1 EXTERNALLY TOOTHED DISC

Fig. 166 Input Speed Sensors

1 - DRIVING CLUTCH K1

2 - TRANSMISSION HOUSING

3 - DRIVING CLUTCH K1 INTERNALLY TOOTHED DISC

4 - EXCITER RING

5 - VALVE HOUSING OF SHIFT PLATE

6 - N2 INPUT SPEED SENSOR

7 - SPRING

8 - N3 INPUT SPEED SENSOR

9 - EXCITER RING

10 - DRIVING CLUTCH K1 EXTERNALLY TOOTHED DISC

Fig. 167 Oil Pump

1 - CRESCENT

2 - OIL PUMP

3 - EXTERNAL GEAR

4 - INTERNAL GEAR

5 - INLET CHAMBER

6 - PRESSURE CHAMBER

21 - 120 AUTOMATIC TRANSMISSION - NAG1VA

INPUT SPEED SENSORS (Continued)

Page 1015 of 1232

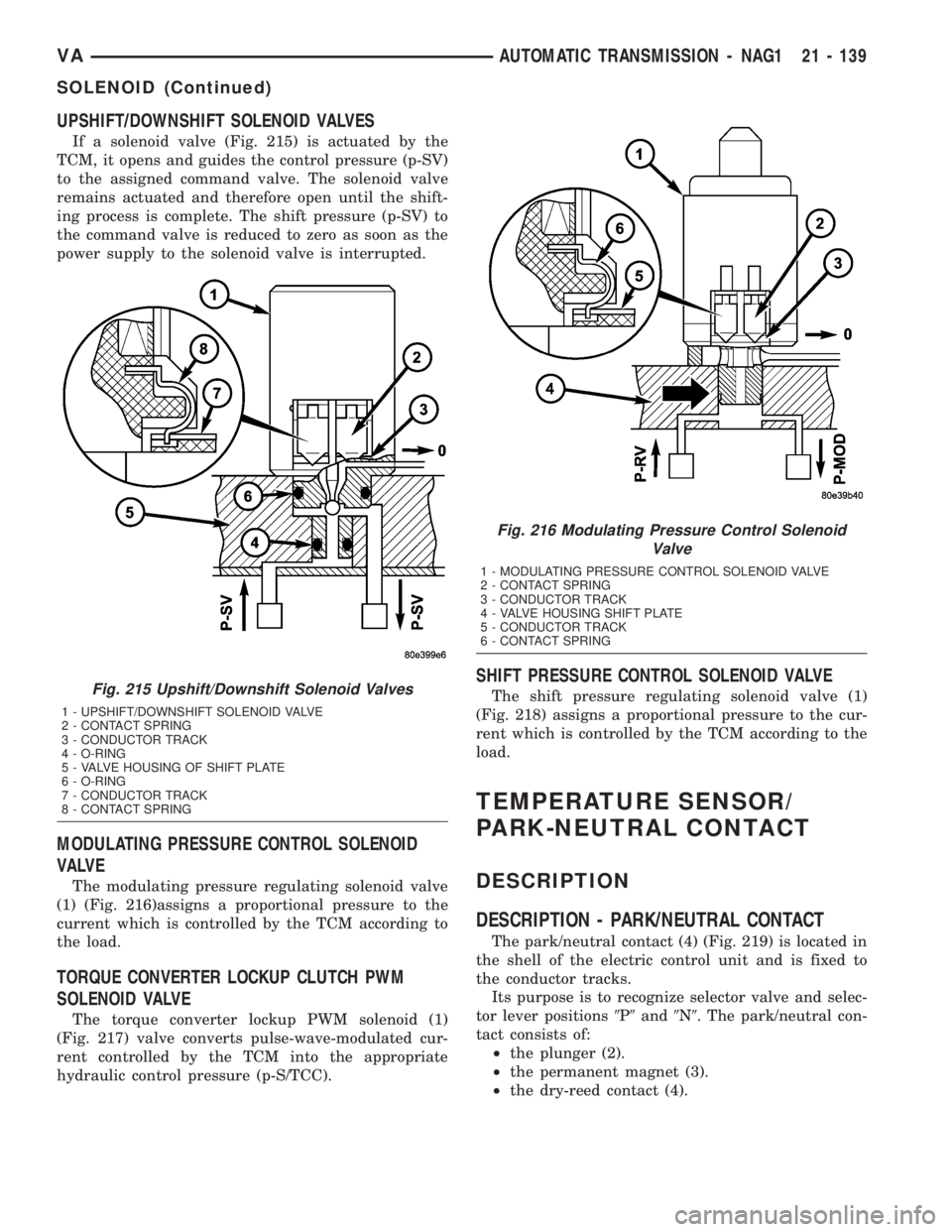

UPSHIFT/DOWNSHIFT SOLENOID VALVES

If a solenoid valve (Fig. 215) is actuated by the

TCM, it opens and guides the control pressure (p-SV)

to the assigned command valve. The solenoid valve

remains actuated and therefore open until the shift-

ing process is complete. The shift pressure (p-SV) to

the command valve is reduced to zero as soon as the

power supply to the solenoid valve is interrupted.

MODULATING PRESSURE CONTROL SOLENOID

VALVE

The modulating pressure regulating solenoid valve

(1) (Fig. 216)assigns a proportional pressure to the

current which is controlled by the TCM according to

the load.

TORQUE CONVERTER LOCKUP CLUTCH PWM

SOLENOID VALVE

The torque converter lockup PWM solenoid (1)

(Fig. 217) valve converts pulse-wave-modulated cur-

rent controlled by the TCM into the appropriate

hydraulic control pressure (p-S/TCC).

SHIFT PRESSURE CONTROL SOLENOID VALVE

The shift pressure regulating solenoid valve (1)

(Fig. 218) assigns a proportional pressure to the cur-

rent which is controlled by the TCM according to the

load.

TEMPERATURE SENSOR/

PARK-NEUTRAL CONTACT

DESCRIPTION

DESCRIPTION - PARK/NEUTRAL CONTACT

The park/neutral contact (4) (Fig. 219) is located in

the shell of the electric control unit and is fixed to

the conductor tracks.

Its purpose is to recognize selector valve and selec-

tor lever positions9P9and9N9. The park/neutral con-

tact consists of:

²the plunger (2).

²the permanent magnet (3).

²the dry-reed contact (4).

Fig. 215 Upshift/Downshift Solenoid Valves

1 - UPSHIFT/DOWNSHIFT SOLENOID VALVE

2 - CONTACT SPRING

3 - CONDUCTOR TRACK

4 - O-RING

5 - VALVE HOUSING OF SHIFT PLATE

6 - O-RING

7 - CONDUCTOR TRACK

8 - CONTACT SPRING

Fig. 216 Modulating Pressure Control Solenoid

Valve

1 - MODULATING PRESSURE CONTROL SOLENOID VALVE

2 - CONTACT SPRING

3 - CONDUCTOR TRACK

4 - VALVE HOUSING SHIFT PLATE

5 - CONDUCTOR TRACK

6 - CONTACT SPRING

VAAUTOMATIC TRANSMISSION - NAG1 21 - 139

SOLENOID (Continued)

Page 1016 of 1232

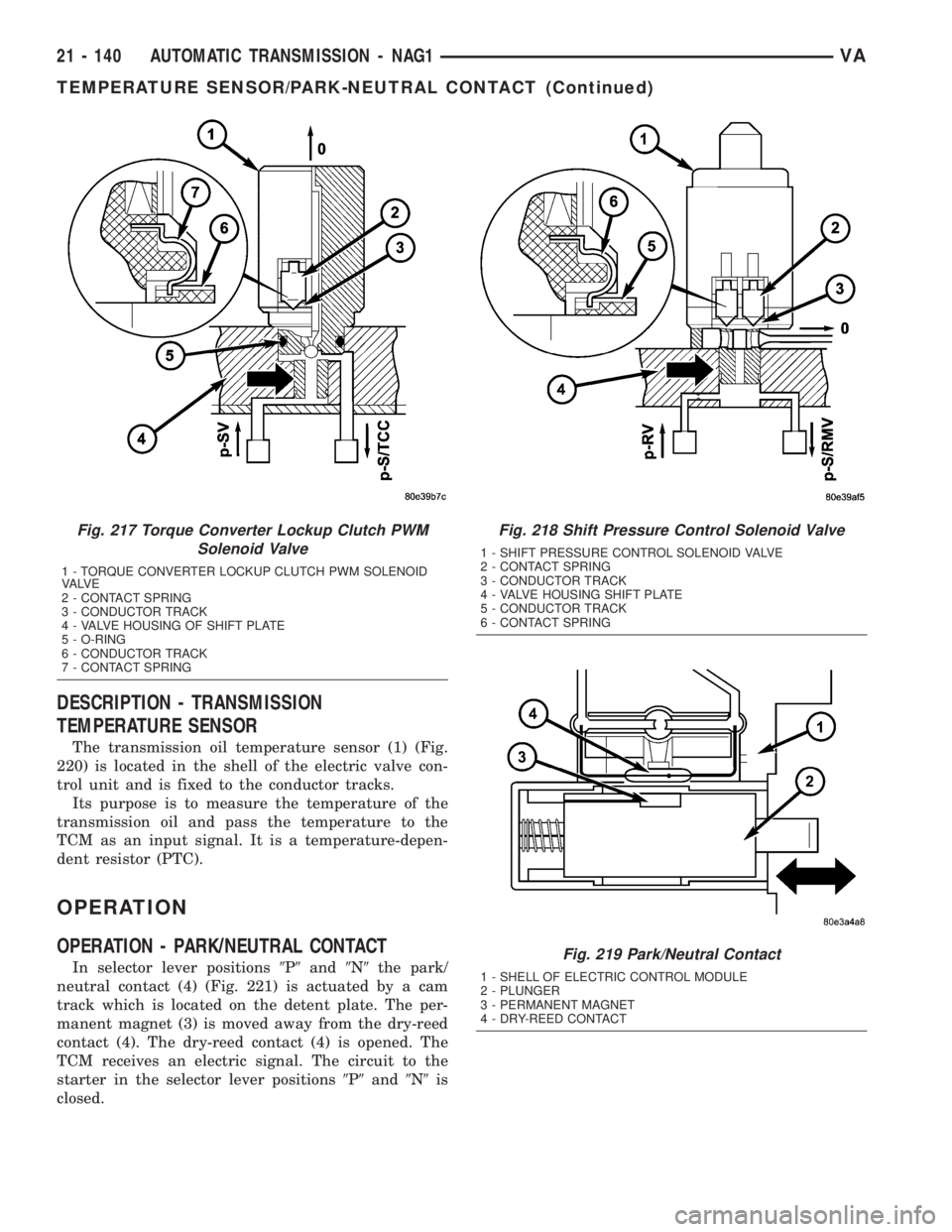

DESCRIPTION - TRANSMISSION

TEMPERATURE SENSOR

The transmission oil temperature sensor (1) (Fig.

220) is located in the shell of the electric valve con-

trol unit and is fixed to the conductor tracks.

Its purpose is to measure the temperature of the

transmission oil and pass the temperature to the

TCM as an input signal. It is a temperature-depen-

dent resistor (PTC).

OPERATION

OPERATION - PARK/NEUTRAL CONTACT

In selector lever positions9P9and9N9the park/

neutral contact (4) (Fig. 221) is actuated by a cam

track which is located on the detent plate. The per-

manent magnet (3) is moved away from the dry-reed

contact (4). The dry-reed contact (4) is opened. The

TCM receives an electric signal. The circuit to the

starter in the selector lever positions9P9and9N9is

closed.

Fig. 217 Torque Converter Lockup Clutch PWM

Solenoid Valve

1 - TORQUE CONVERTER LOCKUP CLUTCH PWM SOLENOID

VA LV E

2 - CONTACT SPRING

3 - CONDUCTOR TRACK

4 - VALVE HOUSING OF SHIFT PLATE

5 - O-RING

6 - CONDUCTOR TRACK

7 - CONTACT SPRING

Fig. 218 Shift Pressure Control Solenoid Valve

1 - SHIFT PRESSURE CONTROL SOLENOID VALVE

2 - CONTACT SPRING

3 - CONDUCTOR TRACK

4 - VALVE HOUSING SHIFT PLATE

5 - CONDUCTOR TRACK

6 - CONTACT SPRING

Fig. 219 Park/Neutral Contact

1 - SHELL OF ELECTRIC CONTROL MODULE

2 - PLUNGER

3 - PERMANENT MAGNET

4 - DRY-REED CONTACT

21 - 140 AUTOMATIC TRANSMISSION - NAG1VA

TEMPERATURE SENSOR/PARK-NEUTRAL CONTACT (Continued)

Page 1017 of 1232

OPERATION - TRANSMISSION TEMPERATURE

SENSOR

The temperature of the transmission oil has a con-

siderable effect on the shifting time and therefore the

shift quality. By measuring the oil temperature, shift

operations can be optimized in all temperature

ranges. The transmission oil temperature sensor (1)

(Fig. 222) is switched in series with the park/neutral

contact. The temperature signal is transferred to the

TCM only when the dry-reed contact of the park/neu-

tral contact is closed in REVERSE or a forward gear

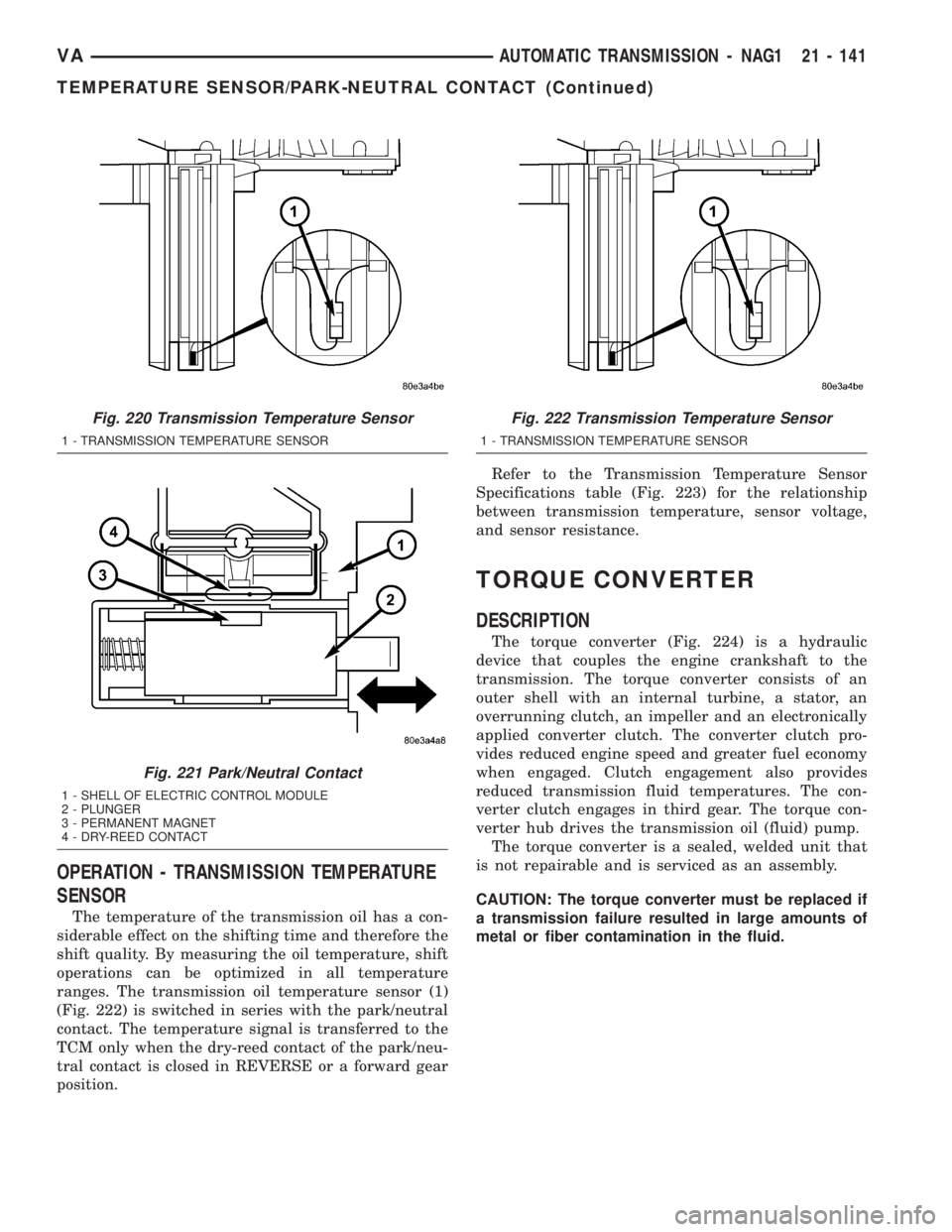

position.Refer to the Transmission Temperature Sensor

Specifications table (Fig. 223) for the relationship

between transmission temperature, sensor voltage,

and sensor resistance.

TORQUE CONVERTER

DESCRIPTION

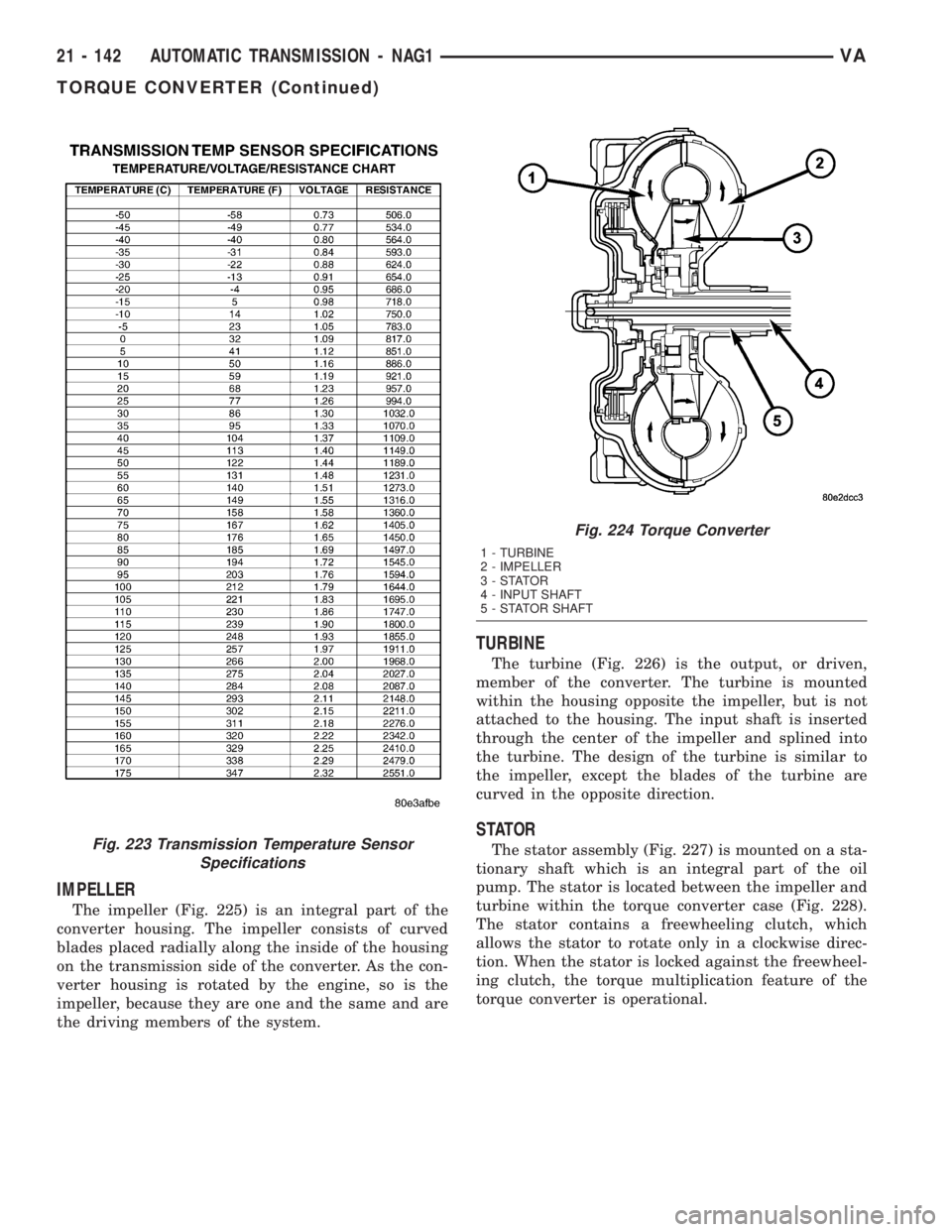

The torque converter (Fig. 224) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid.

Fig. 220 Transmission Temperature Sensor

1 - TRANSMISSION TEMPERATURE SENSOR

Fig. 221 Park/Neutral Contact

1 - SHELL OF ELECTRIC CONTROL MODULE

2 - PLUNGER

3 - PERMANENT MAGNET

4 - DRY-REED CONTACT

Fig. 222 Transmission Temperature Sensor

1 - TRANSMISSION TEMPERATURE SENSOR

VAAUTOMATIC TRANSMISSION - NAG1 21 - 141

TEMPERATURE SENSOR/PARK-NEUTRAL CONTACT (Continued)

Page 1018 of 1232

IMPELLER

The impeller (Fig. 225) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

TURBINE

The turbine (Fig. 226) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

STATOR

The stator assembly (Fig. 227) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 228).

The stator contains a freewheeling clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the freewheel-

ing clutch, the torque multiplication feature of the

torque converter is operational.Fig. 223 Transmission Temperature Sensor

Specifications

Fig. 224 Torque Converter

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

21 - 142 AUTOMATIC TRANSMISSION - NAG1VA

TORQUE CONVERTER (Continued)