sensor MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1144 of 1232

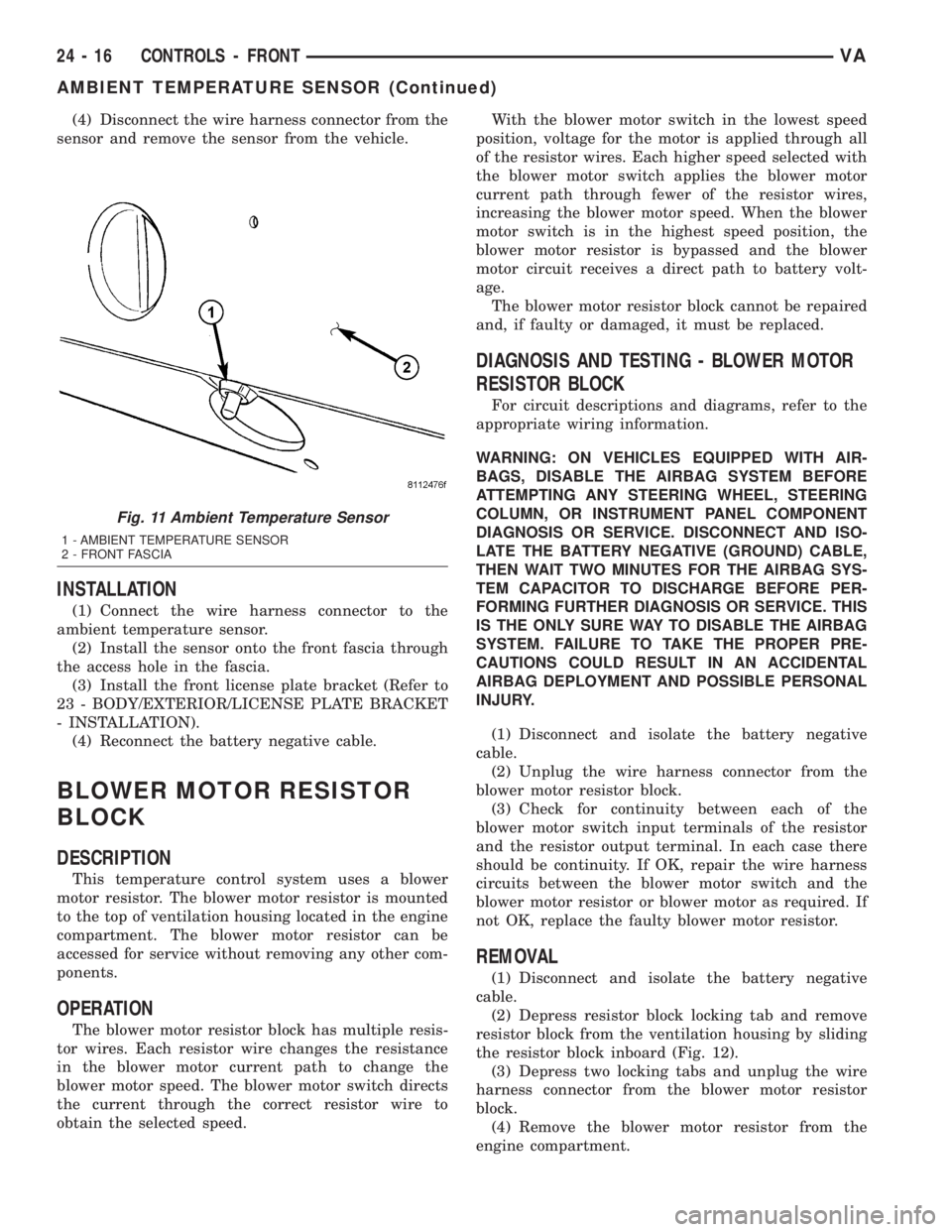

(4) Disconnect the wire harness connector from the

sensor and remove the sensor from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the

ambient temperature sensor.

(2) Install the sensor onto the front fascia through

the access hole in the fascia.

(3) Install the front license plate bracket (Refer to

23 - BODY/EXTERIOR/LICENSE PLATE BRACKET

- INSTALLATION).

(4) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

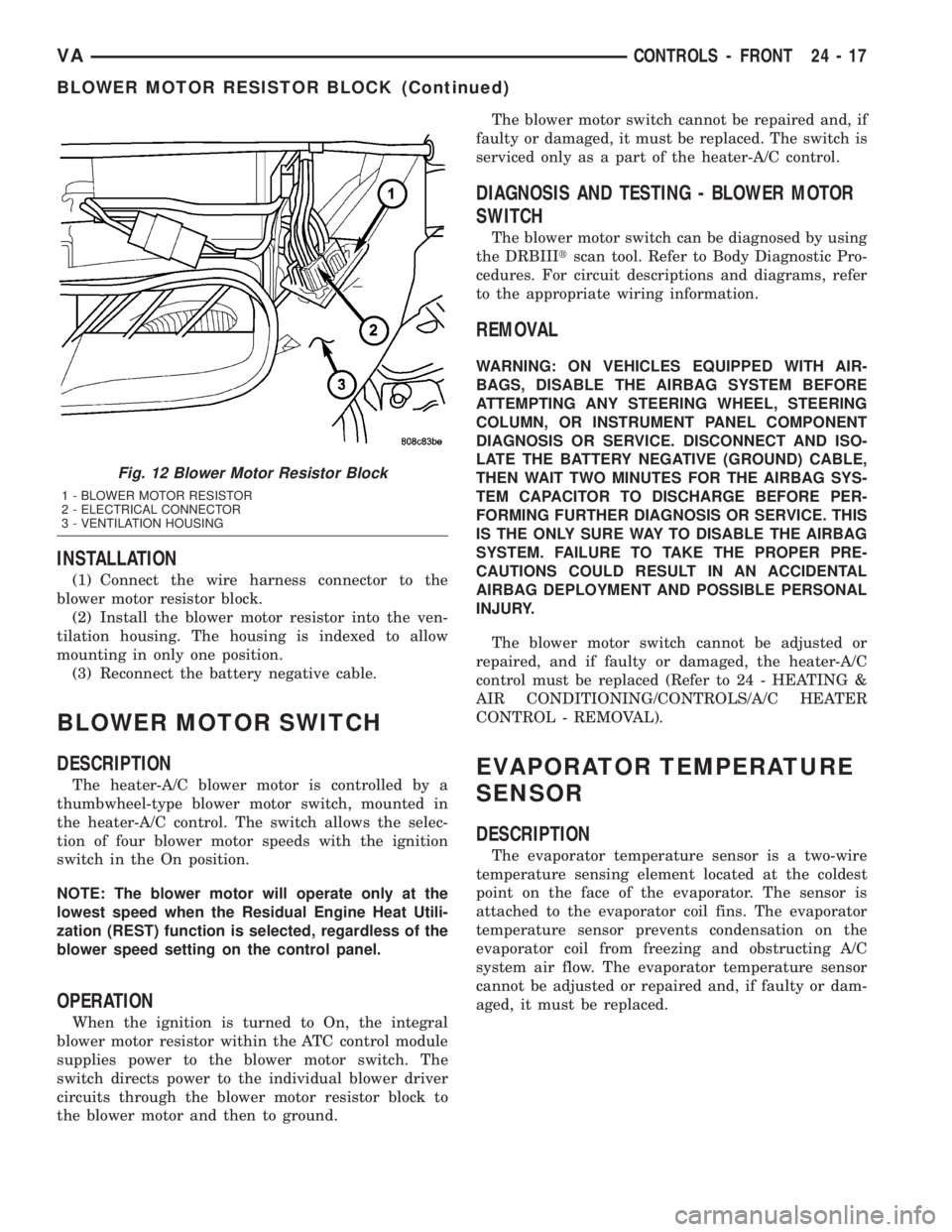

This temperature control system uses a blower

motor resistor. The blower motor resistor is mounted

to the top of ventilation housing located in the engine

compartment. The blower motor resistor can be

accessed for service without removing any other com-

ponents.

OPERATION

The blower motor resistor block has multiple resis-

tor wires. Each resistor wire changes the resistance

in the blower motor current path to change the

blower motor speed. The blower motor switch directs

the current through the correct resistor wire to

obtain the selected speed.With the blower motor switch in the lowest speed

position, voltage for the motor is applied through all

of the resistor wires. Each higher speed selected with

the blower motor switch applies the blower motor

current path through fewer of the resistor wires,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistor is bypassed and the blower

motor circuit receives a direct path to battery volt-

age.

The blower motor resistor block cannot be repaired

and, if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the

blower motor resistor block.

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor as required. If

not OK, replace the faulty blower motor resistor.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Depress resistor block locking tab and remove

resistor block from the ventilation housing by sliding

the resistor block inboard (Fig. 12).

(3) Depress two locking tabs and unplug the wire

harness connector from the blower motor resistor

block.

(4) Remove the blower motor resistor from the

engine compartment.

Fig. 11 Ambient Temperature Sensor

1 - AMBIENT TEMPERATURE SENSOR

2 - FRONT FASCIA

24 - 16 CONTROLS - FRONTVA

AMBIENT TEMPERATURE SENSOR (Continued)

Page 1145 of 1232

INSTALLATION

(1) Connect the wire harness connector to the

blower motor resistor block.

(2) Install the blower motor resistor into the ven-

tilation housing. The housing is indexed to allow

mounting in only one position.

(3) Reconnect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The heater-A/C blower motor is controlled by a

thumbwheel-type blower motor switch, mounted in

the heater-A/C control. The switch allows the selec-

tion of four blower motor speeds with the ignition

switch in the On position.

NOTE: The blower motor will operate only at the

lowest speed when the Residual Engine Heat Utili-

zation (REST) function is selected, regardless of the

blower speed setting on the control panel.

OPERATION

When the ignition is turned to On, the integral

blower motor resistor within the ATC control module

supplies power to the blower motor switch. The

switch directs power to the individual blower driver

circuits through the blower motor resistor block to

the blower motor and then to ground.The blower motor switch cannot be repaired and, if

faulty or damaged, it must be replaced. The switch is

serviced only as a part of the heater-A/C control.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

The blower motor switch can be diagnosed by using

the DRBIIItscan tool. Refer to Body Diagnostic Pro-

cedures. For circuit descriptions and diagrams, refer

to the appropriate wiring information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be adjusted or

repaired, and if faulty or damaged, the heater-A/C

control must be replaced (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL).

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

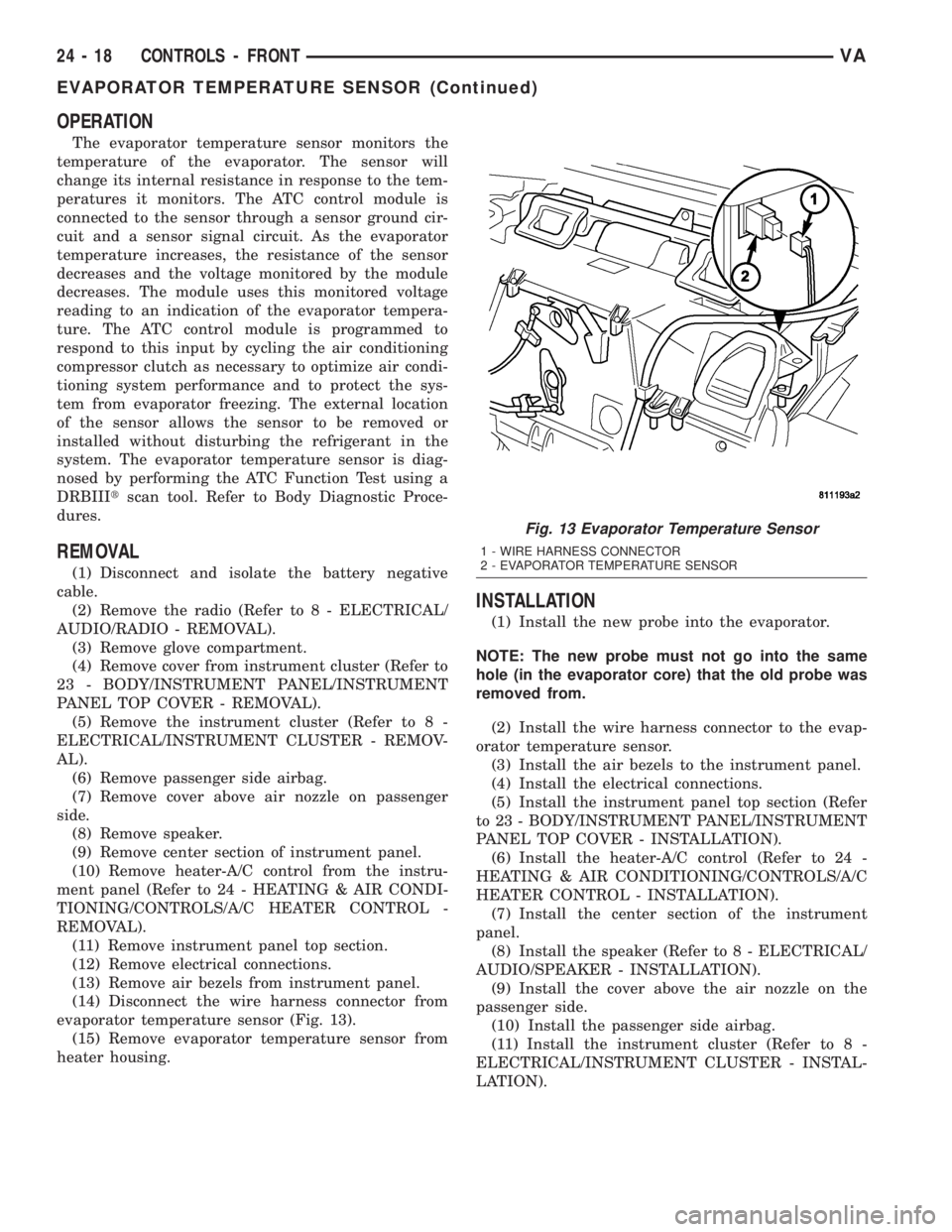

The evaporator temperature sensor is a two-wire

temperature sensing element located at the coldest

point on the face of the evaporator. The sensor is

attached to the evaporator coil fins. The evaporator

temperature sensor prevents condensation on the

evaporator coil from freezing and obstructing A/C

system air flow. The evaporator temperature sensor

cannot be adjusted or repaired and, if faulty or dam-

aged, it must be replaced.

Fig. 12 Blower Motor Resistor Block

1 - BLOWER MOTOR RESISTOR

2 - ELECTRICAL CONNECTOR

3 - VENTILATION HOUSING

VACONTROLS - FRONT 24 - 17

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 1146 of 1232

OPERATION

The evaporator temperature sensor monitors the

temperature of the evaporator. The sensor will

change its internal resistance in response to the tem-

peratures it monitors. The ATC control module is

connected to the sensor through a sensor ground cir-

cuit and a sensor signal circuit. As the evaporator

temperature increases, the resistance of the sensor

decreases and the voltage monitored by the module

decreases. The module uses this monitored voltage

reading to an indication of the evaporator tempera-

ture. The ATC control module is programmed to

respond to this input by cycling the air conditioning

compressor clutch as necessary to optimize air condi-

tioning system performance and to protect the sys-

tem from evaporator freezing. The external location

of the sensor allows the sensor to be removed or

installed without disturbing the refrigerant in the

system. The evaporator temperature sensor is diag-

nosed by performing the ATC Function Test using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the radio (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - REMOVAL).

(3) Remove glove compartment.

(4) Remove cover from instrument cluster (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL).

(5) Remove the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - REMOV-

AL).

(6) Remove passenger side airbag.

(7) Remove cover above air nozzle on passenger

side.

(8) Remove speaker.

(9) Remove center section of instrument panel.

(10) Remove heater-A/C control from the instru-

ment panel (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS/A/C HEATER CONTROL -

REMOVAL).

(11) Remove instrument panel top section.

(12) Remove electrical connections.

(13) Remove air bezels from instrument panel.

(14) Disconnect the wire harness connector from

evaporator temperature sensor (Fig. 13).

(15) Remove evaporator temperature sensor from

heater housing.

INSTALLATION

(1) Install the new probe into the evaporator.

NOTE: The new probe must not go into the same

hole (in the evaporator core) that the old probe was

removed from.

(2) Install the wire harness connector to the evap-

orator temperature sensor.

(3) Install the air bezels to the instrument panel.

(4) Install the electrical connections.

(5) Install the instrument panel top section (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION).

(6) Install the heater-A/C control (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - INSTALLATION).

(7) Install the center section of the instrument

panel.

(8) Install the speaker (Refer to 8 - ELECTRICAL/

AUDIO/SPEAKER - INSTALLATION).

(9) Install the cover above the air nozzle on the

passenger side.

(10) Install the passenger side airbag.

(11) Install the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - INSTAL-

LATION).

Fig. 13 Evaporator Temperature Sensor

1 - WIRE HARNESS CONNECTOR

2 - EVAPORATOR TEMPERATURE SENSOR

24 - 18 CONTROLS - FRONTVA

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 1147 of 1232

(12) Install the cover to the instrument cluster.

(13) Install glove compartment.

(14) Install the radio (Refer to 8 - ELECTRICAL/

AUDIO/RADIO - INSTALLATION).

(15) Reconnect the battery negative cable.

IN-CAR TEMPERATURE

SENSOR

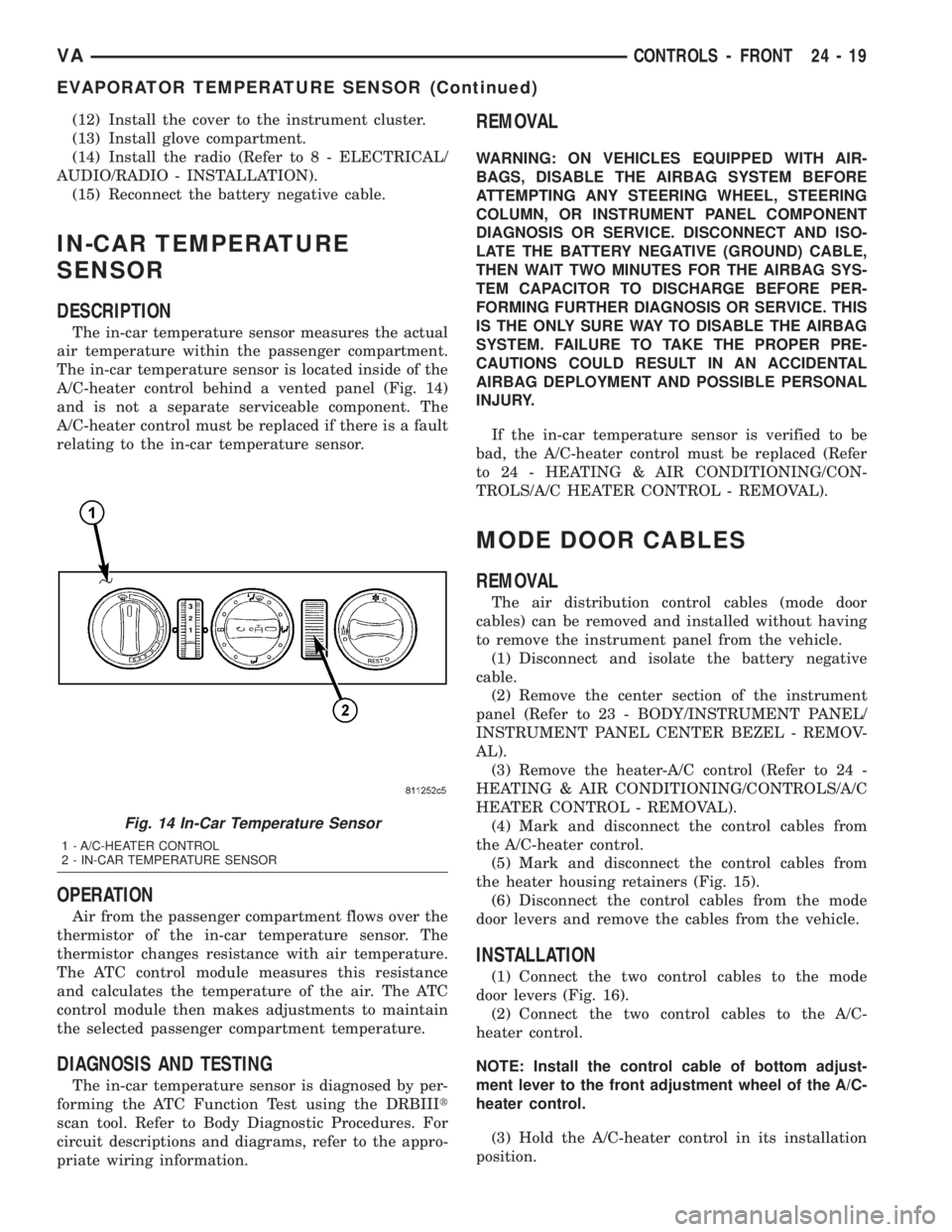

DESCRIPTION

The in-car temperature sensor measures the actual

air temperature within the passenger compartment.

The in-car temperature sensor is located inside of the

A/C-heater control behind a vented panel (Fig. 14)

and is not a separate serviceable component. The

A/C-heater control must be replaced if there is a fault

relating to the in-car temperature sensor.

OPERATION

Air from the passenger compartment flows over the

thermistor of the in-car temperature sensor. The

thermistor changes resistance with air temperature.

The ATC control module measures this resistance

and calculates the temperature of the air. The ATC

control module then makes adjustments to maintain

the selected passenger compartment temperature.

DIAGNOSIS AND TESTING

The in-car temperature sensor is diagnosed by per-

forming the ATC Function Test using the DRBIIIt

scan tool. Refer to Body Diagnostic Procedures. For

circuit descriptions and diagrams, refer to the appro-

priate wiring information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

If the in-car temperature sensor is verified to be

bad, the A/C-heater control must be replaced (Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C HEATER CONTROL - REMOVAL).

MODE DOOR CABLES

REMOVAL

The air distribution control cables (mode door

cables) can be removed and installed without having

to remove the instrument panel from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center section of the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) Remove the heater-A/C control (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL).

(4) Mark and disconnect the control cables from

the A/C-heater control.

(5) Mark and disconnect the control cables from

the heater housing retainers (Fig. 15).

(6) Disconnect the control cables from the mode

door levers and remove the cables from the vehicle.

INSTALLATION

(1) Connect the two control cables to the mode

door levers (Fig. 16).

(2) Connect the two control cables to the A/C-

heater control.

NOTE: Install the control cable of bottom adjust-

ment lever to the front adjustment wheel of the A/C-

heater control.

(3) Hold the A/C-heater control in its installation

position.

Fig. 14 In-Car Temperature Sensor

1 - A/C-HEATER CONTROL

2 - IN-CAR TEMPERATURE SENSOR

VACONTROLS - FRONT 24 - 19

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 1150 of 1232

CONTROLS - REAR

TABLE OF CONTENTS

page page

BLOWER MOTOR SWITCH

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING................23

REMOVAL.............................23

INSTALLATION.........................23

BLOWER MOTOR RELAY

DESCRIPTION.........................23

OPERATION...........................23

DIAGNOSIS AND TESTING................24

REMOVAL.............................24

INSTALLATION.........................24

CONTROL MODULE

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING................24

REMOVAL.............................24

INSTALLATION.........................25

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................25

OPERATION...........................26DIAGNOSIS AND TESTING................26

REMOVAL.............................26

INSTALLATION.........................26

SOLENOID VALVE

DESCRIPTION.........................27

OPERATION...........................27

DIAGNOSIS AND TESTING................27

REMOVAL.............................27

INSTALLATION.........................28

TEMPERATURE CONTROL

DESCRIPTION.........................29

OPERATION...........................29

DIAGNOSIS AND TESTING................29

REMOVAL.............................29

INSTALLATION.........................29

TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

DIAGNOSIS AND TESTING................30

REMOVAL.............................30

INSTALLATION.........................30

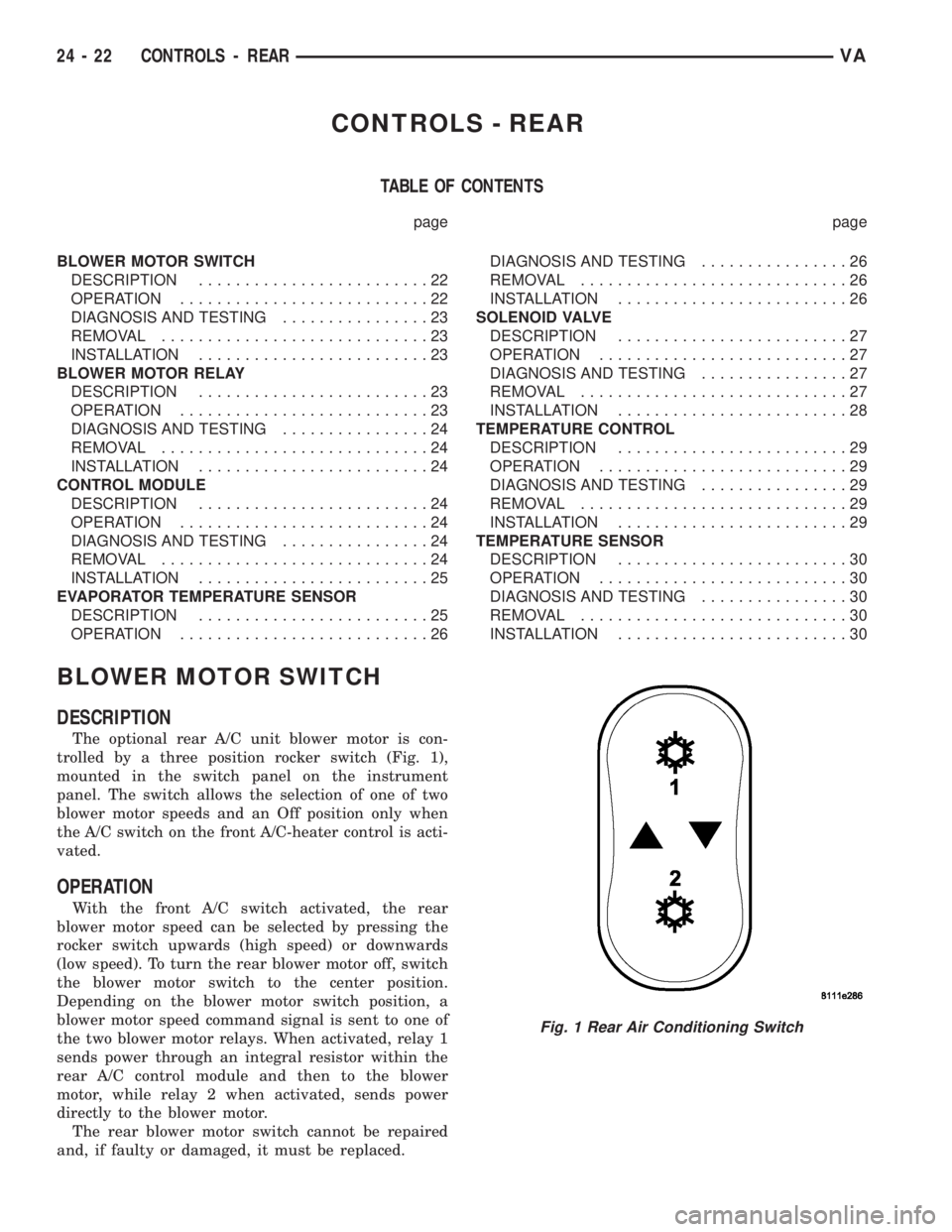

BLOWER MOTOR SWITCH

DESCRIPTION

The optional rear A/C unit blower motor is con-

trolled by a three position rocker switch (Fig. 1),

mounted in the switch panel on the instrument

panel. The switch allows the selection of one of two

blower motor speeds and an Off position only when

the A/C switch on the front A/C-heater control is acti-

vated.

OPERATION

With the front A/C switch activated, the rear

blower motor speed can be selected by pressing the

rocker switch upwards (high speed) or downwards

(low speed). To turn the rear blower motor off, switch

the blower motor switch to the center position.

Depending on the blower motor switch position, a

blower motor speed command signal is sent to one of

the two blower motor relays. When activated, relay 1

sends power through an integral resistor within the

rear A/C control module and then to the blower

motor, while relay 2 when activated, sends power

directly to the blower motor.

The rear blower motor switch cannot be repaired

and, if faulty or damaged, it must be replaced.

Fig. 1 Rear Air Conditioning Switch

24 - 22 CONTROLS - REARVA

Page 1152 of 1232

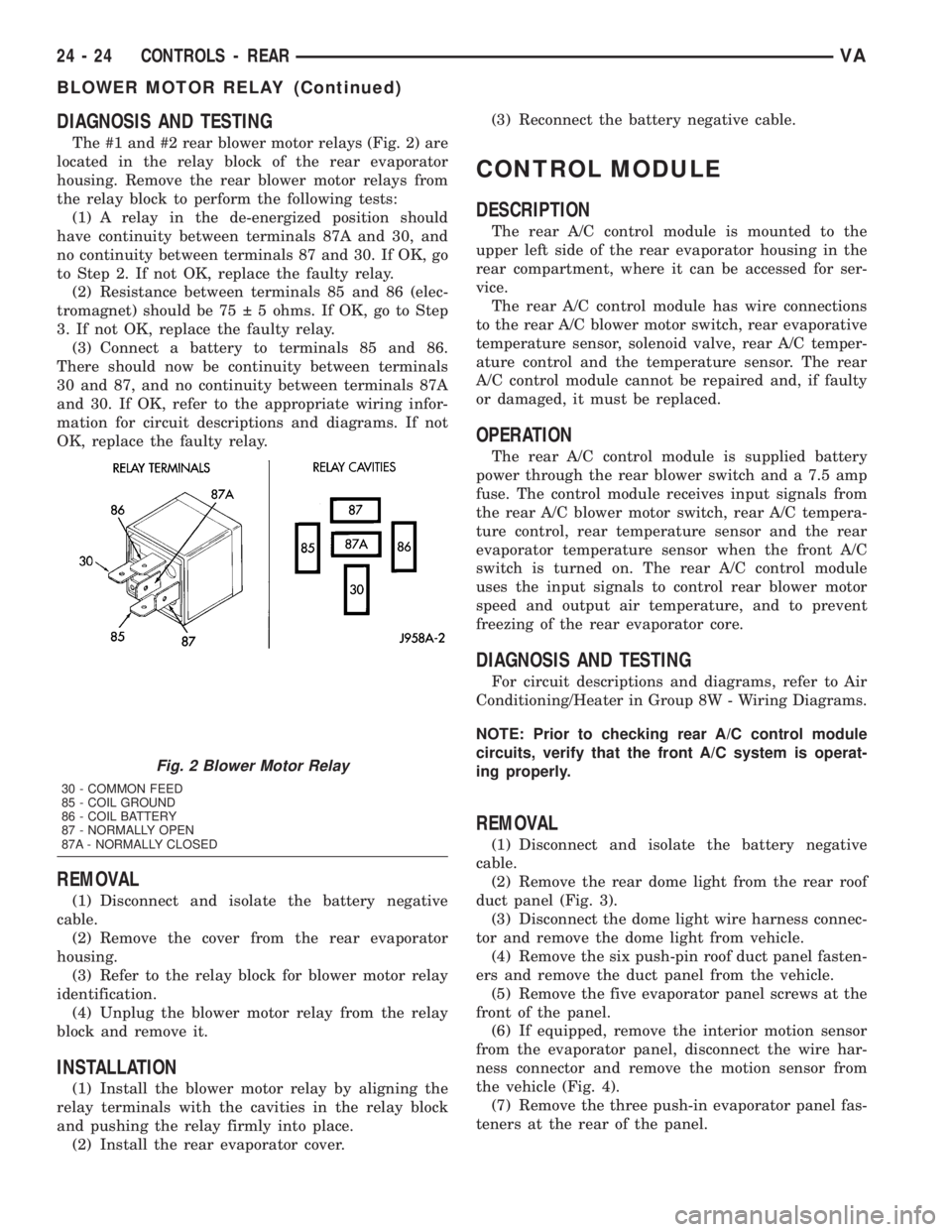

DIAGNOSIS AND TESTING

The #1 and #2 rear blower motor relays (Fig. 2) are

located in the relay block of the rear evaporator

housing. Remove the rear blower motor relays from

the relay block to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, refer to the appropriate wiring infor-

mation for circuit descriptions and diagrams. If not

OK, replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the rear evaporator

housing.

(3) Refer to the relay block for blower motor relay

identification.

(4) Unplug the blower motor relay from the relay

block and remove it.

INSTALLATION

(1) Install the blower motor relay by aligning the

relay terminals with the cavities in the relay block

and pushing the relay firmly into place.

(2) Install the rear evaporator cover.(3) Reconnect the battery negative cable.

CONTROL MODULE

DESCRIPTION

The rear A/C control module is mounted to the

upper left side of the rear evaporator housing in the

rear compartment, where it can be accessed for ser-

vice.

The rear A/C control module has wire connections

to the rear A/C blower motor switch, rear evaporative

temperature sensor, solenoid valve, rear A/C temper-

ature control and the temperature sensor. The rear

A/C control module cannot be repaired and, if faulty

or damaged, it must be replaced.

OPERATION

The rear A/C control module is supplied battery

power through the rear blower switch and a 7.5 amp

fuse. The control module receives input signals from

the rear A/C blower motor switch, rear A/C tempera-

ture control, rear temperature sensor and the rear

evaporator temperature sensor when the front A/C

switch is turned on. The rear A/C control module

uses the input signals to control rear blower motor

speed and output air temperature, and to prevent

freezing of the rear evaporator core.

DIAGNOSIS AND TESTING

For circuit descriptions and diagrams, refer to Air

Conditioning/Heater in Group 8W - Wiring Diagrams.

NOTE: Prior to checking rear A/C control module

circuits, verify that the front A/C system is operat-

ing properly.

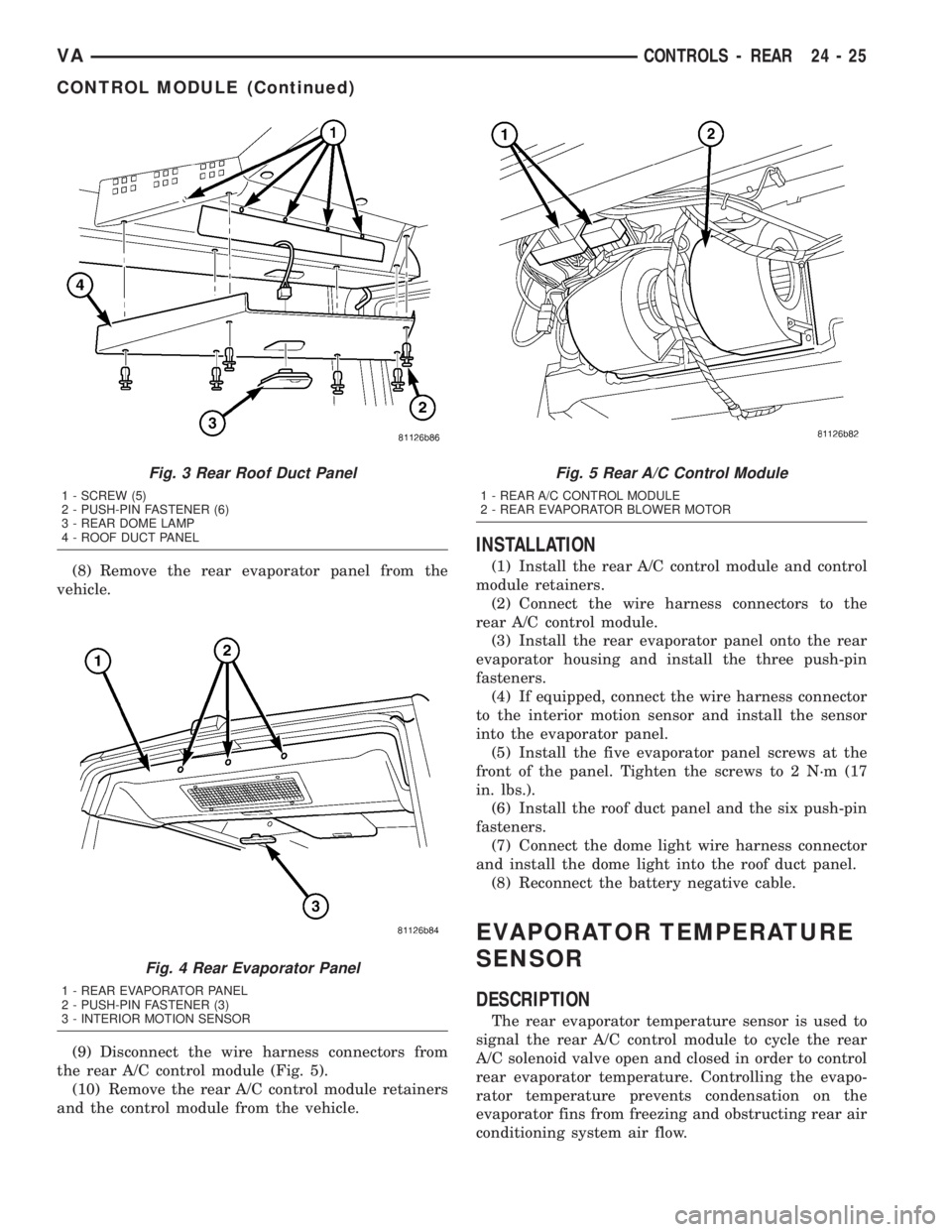

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear dome light from the rear roof

duct panel (Fig. 3).

(3) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(4) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(5) Remove the five evaporator panel screws at the

front of the panel.

(6) If equipped, remove the interior motion sensor

from the evaporator panel, disconnect the wire har-

ness connector and remove the motion sensor from

the vehicle (Fig. 4).

(7) Remove the three push-in evaporator panel fas-

teners at the rear of the panel.

Fig. 2 Blower Motor Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 24 CONTROLS - REARVA

BLOWER MOTOR RELAY (Continued)

Page 1153 of 1232

(8) Remove the rear evaporator panel from the

vehicle.

(9) Disconnect the wire harness connectors from

the rear A/C control module (Fig. 5).

(10) Remove the rear A/C control module retainers

and the control module from the vehicle.

INSTALLATION

(1) Install the rear A/C control module and control

module retainers.

(2) Connect the wire harness connectors to the

rear A/C control module.

(3) Install the rear evaporator panel onto the rear

evaporator housing and install the three push-pin

fasteners.

(4) If equipped, connect the wire harness connector

to the interior motion sensor and install the sensor

into the evaporator panel.

(5) Install the five evaporator panel screws at the

front of the panel. Tighten the screws to 2 N´m (17

in. lbs.).

(6) Install the roof duct panel and the six push-pin

fasteners.

(7) Connect the dome light wire harness connector

and install the dome light into the roof duct panel.

(8) Reconnect the battery negative cable.

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

The rear evaporator temperature sensor is used to

signal the rear A/C control module to cycle the rear

A/C solenoid valve open and closed in order to control

rear evaporator temperature. Controlling the evapo-

rator temperature prevents condensation on the

evaporator fins from freezing and obstructing rear air

conditioning system air flow.

Fig. 3 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

Fig. 4 Rear Evaporator Panel

1 - REAR EVAPORATOR PANEL

2 - PUSH-PIN FASTENER (3)

3 - INTERIOR MOTION SENSOR

Fig. 5 Rear A/C Control Module

1 - REAR A/C CONTROL MODULE

2 - REAR EVAPORATOR BLOWER MOTOR

VACONTROLS - REAR 24 - 25

CONTROL MODULE (Continued)

Page 1154 of 1232

The rear evaporator temperature sensor consists of

a probe and a switch unit. The probe, which is a Neg-

ative Temperature Coefficient (NTC) thermistor in a

capillary tube, is inserted between the rear evapora-

tor coil fins to monitor evaporator temperature. The

switch unit contains internal control logic that mon-

itors the input from the probe in order to switch an

internal transistor that controls the output signal to

the rear A/C control module.

OPERATION

When the rear evaporator temperature sensor sees

a temperature input below about 1.6É C (35É F), it

signals the rear A/C control module to cycle the rear

A/C solenoid valve closed. When the temperature

input reaches above about 3.9É C (39É F), the switch

signals the control module to cycle the valve open.

The rear evaporator temperature sensor can be

accessed for service by removing the air inlet grate

from the rear evaporator housing. The rear evapora-

tor temperature sensor cannot be adjusted or

repaired. If faulty or damaged, the sensor must be

replaced.

DIAGNOSIS AND TESTING

Before testing the rear evaporator temperature

sensor, verify that the front A/C system is operating

correctly by performing the ATC Function Test using

the DRBIIItscan tool. Use a volt/ohmmeter to test

the sensor. For circuit descriptions and diagrams,

refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Turn the ignition switch and the front A/C

switch to the On position. Place the rear blower

motor switch in either low or high speed position.

Check for voltage to the rear evaporator relay from

the rear evaporator temperature sensor. If OK, go to

Step 2. If not OK, repair the open or shorted evapo-

rator temperature sensor circuit as required.

(2) With the ambient temperature between 20 to

30É C (68 to 90É F), start the engine and run the rear

air conditioning system. The rear A/C solenoid valve

should cycle open and closed. Use a voltmeter con-

nected to the output side of the sensor for this check.

If the A/C solenoid valve fails to cycle in these tem-

peratures, replace the faulty rear evaporator temper-

ature sensor.

NOTE: If the ambient temperature is above 32É C

(90É F) the rear A/C solenoid valve may not cycle

due to the high heat load. This condition is normal.

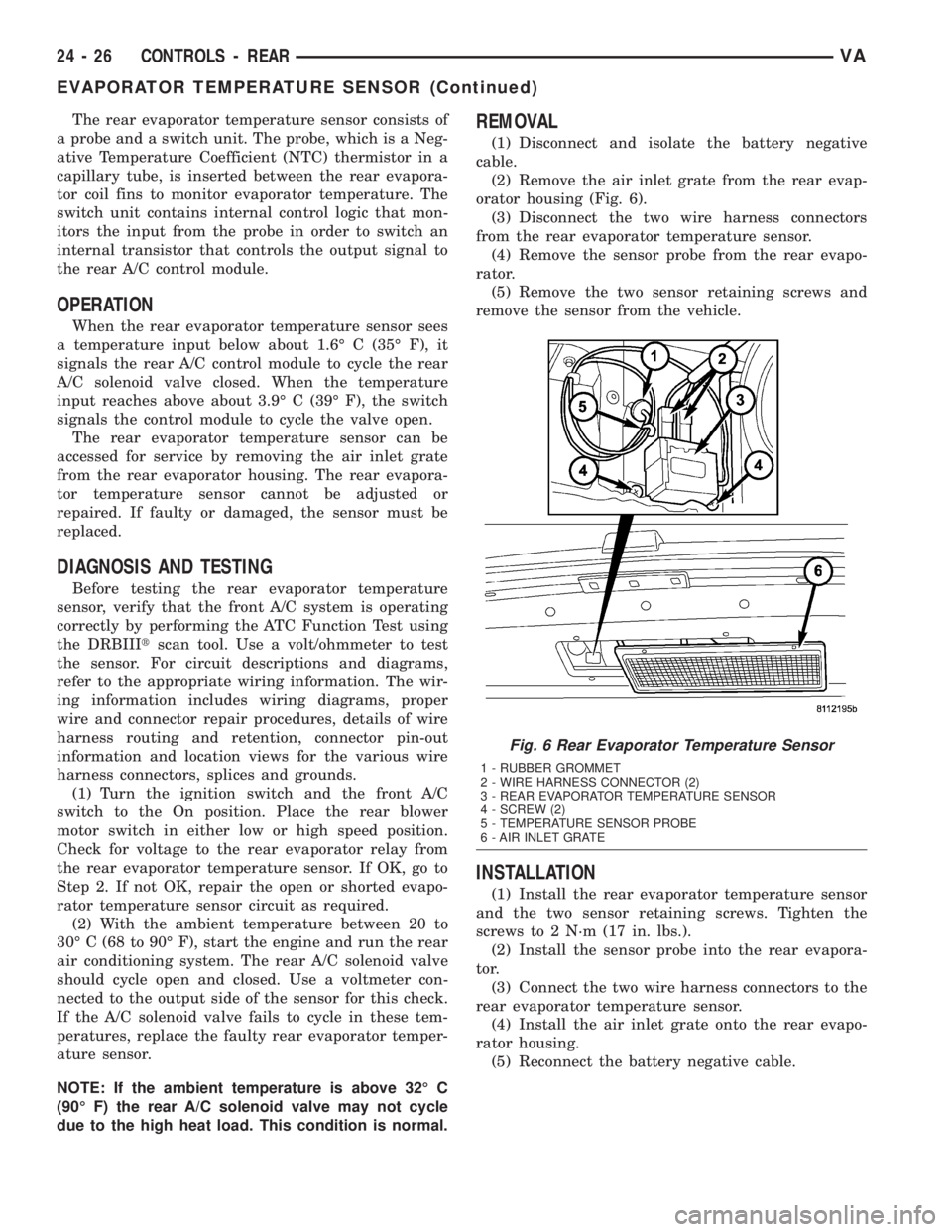

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air inlet grate from the rear evap-

orator housing (Fig. 6).

(3) Disconnect the two wire harness connectors

from the rear evaporator temperature sensor.

(4) Remove the sensor probe from the rear evapo-

rator.

(5) Remove the two sensor retaining screws and

remove the sensor from the vehicle.

INSTALLATION

(1) Install the rear evaporator temperature sensor

and the two sensor retaining screws. Tighten the

screws to 2 N´m (17 in. lbs.).

(2) Install the sensor probe into the rear evapora-

tor.

(3) Connect the two wire harness connectors to the

rear evaporator temperature sensor.

(4) Install the air inlet grate onto the rear evapo-

rator housing.

(5) Reconnect the battery negative cable.

Fig. 6 Rear Evaporator Temperature Sensor

1 - RUBBER GROMMET

2 - WIRE HARNESS CONNECTOR (2)

3 - REAR EVAPORATOR TEMPERATURE SENSOR

4 - SCREW (2)

5 - TEMPERATURE SENSOR PROBE

6 - AIR INLET GRATE

24 - 26 CONTROLS - REARVA

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 1155 of 1232

SOLENOID VALVE

DESCRIPTION

The rear A/C solenoid valve is a two-position elec-

trically operated shut-off valve, which is used to con-

trol refrigerant flow to the rear A/C evaporator from

the A/C compressor. The solenoid valve is located in

the rear A/C evaporator housing and is attached by a

bracket.

OPERATION

The solenoid valve is used by the rear A/C control

module to control rear A/C output temperature and

to prevent evaporator freezing. Evaporator tempera-

ture is controlled by cycling the solenoid valve open

and closed, thereby controlling refrigerant flow to the

rear evaporator. The normally closed valve only

allows refrigerant to flow through it when power is

supplied to the solenoid by the rear A/C control mod-

ule.

DIAGNOSIS AND TESTING

For circuit descriptions and diagrams, refer to Air

Conditioning/Heater in Group 8W - Wiring Diagrams.

NOTE: Prior to performing the following checks,

verify that the front A/C system is operating prop-

erly.

(1) With the engine running, the front A/C switch

in the On position and the rear A/C blower switch in

the Off position, check that the rear evaporator is not

colder than the ambient temperature. If the evapora-

tor temperature is colder than the ambient tempera-

ture, the solenoid is allowing refrigerant to flow

through the rear evaporator when in the closed posi-

tion. If OK, go to Step 2. If not OK, replace the rear

A/C solenoid valve (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/SOLENOID - REMOV-

AL).

(2) With the ignition switch in the Off position and

the rear A/C solenoid valve wire harness discon-

nected, check for continuity between the two solenoid

valve terminals. If OK, go to Step 3. If not OK,

replace the solenoid valve (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/SOLENOID -

REMOVAL).

(3) With the ignition switch in the Off position and

the rear A/C solenoid valve wire harness discon-

nected, check the solenoid valve ground circuits for a

good ground at all times. If OK, go to Step 4. If not

OK, repair the open circuit to ground as required.(4) With the ignition switch and the front A/C

switch in the On position and the rear A/C solenoid

valve wire harness disconnected, check the harness

for battery power at terminal 2. If OK, replace the

solenoid valve (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/SOLENOID - REMOVAL).

If not OK, test the A/C control module as required

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/POWER MODULE - DIAGNOSIS AND

TESTING).

REMOVAL

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE).

(2) Disconnect and isolate the battery negative

cable.

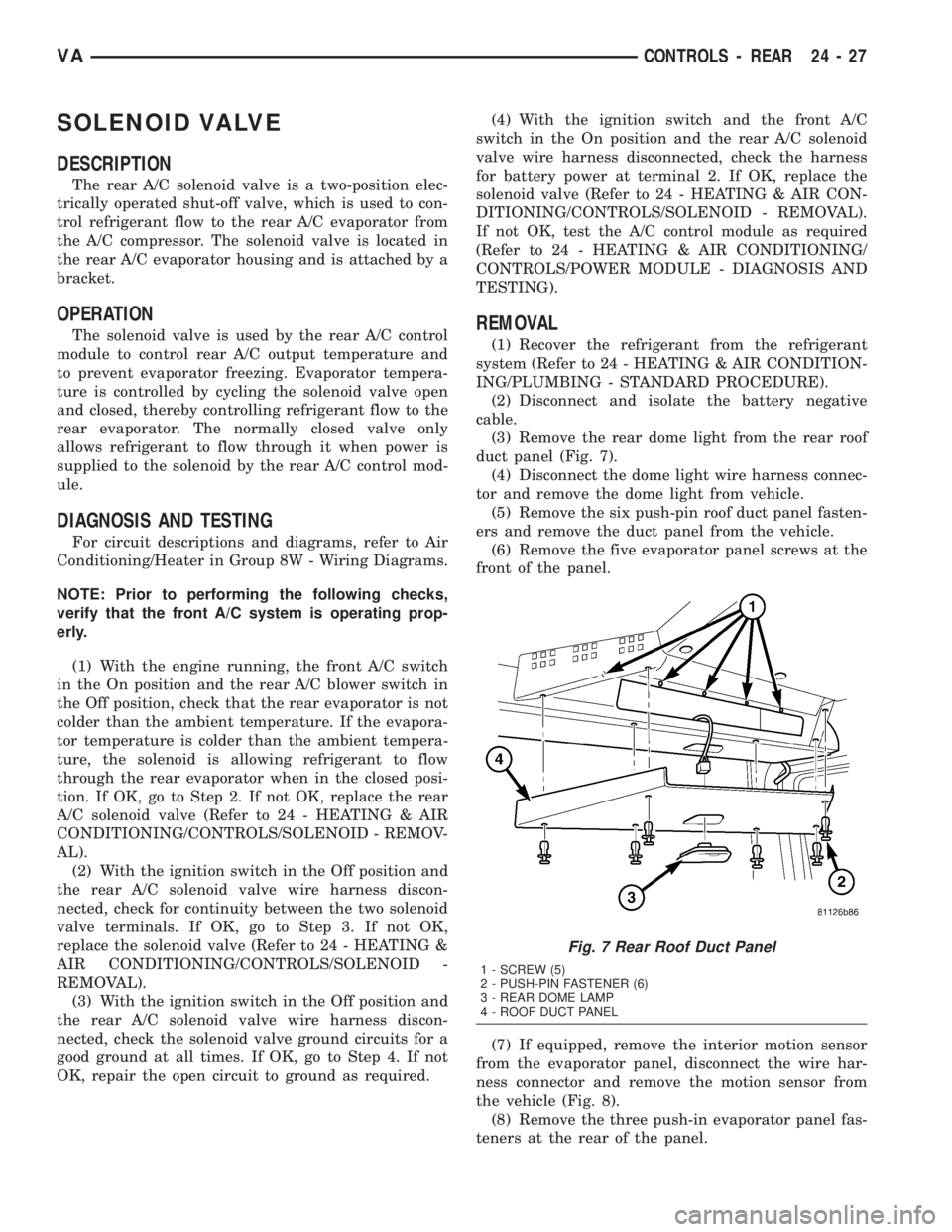

(3) Remove the rear dome light from the rear roof

duct panel (Fig. 7).

(4) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(5) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(6) Remove the five evaporator panel screws at the

front of the panel.

(7) If equipped, remove the interior motion sensor

from the evaporator panel, disconnect the wire har-

ness connector and remove the motion sensor from

the vehicle (Fig. 8).

(8) Remove the three push-in evaporator panel fas-

teners at the rear of the panel.

Fig. 7 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

VACONTROLS - REAR 24 - 27

Page 1156 of 1232

(9) Remove the rear evaporator panel from the

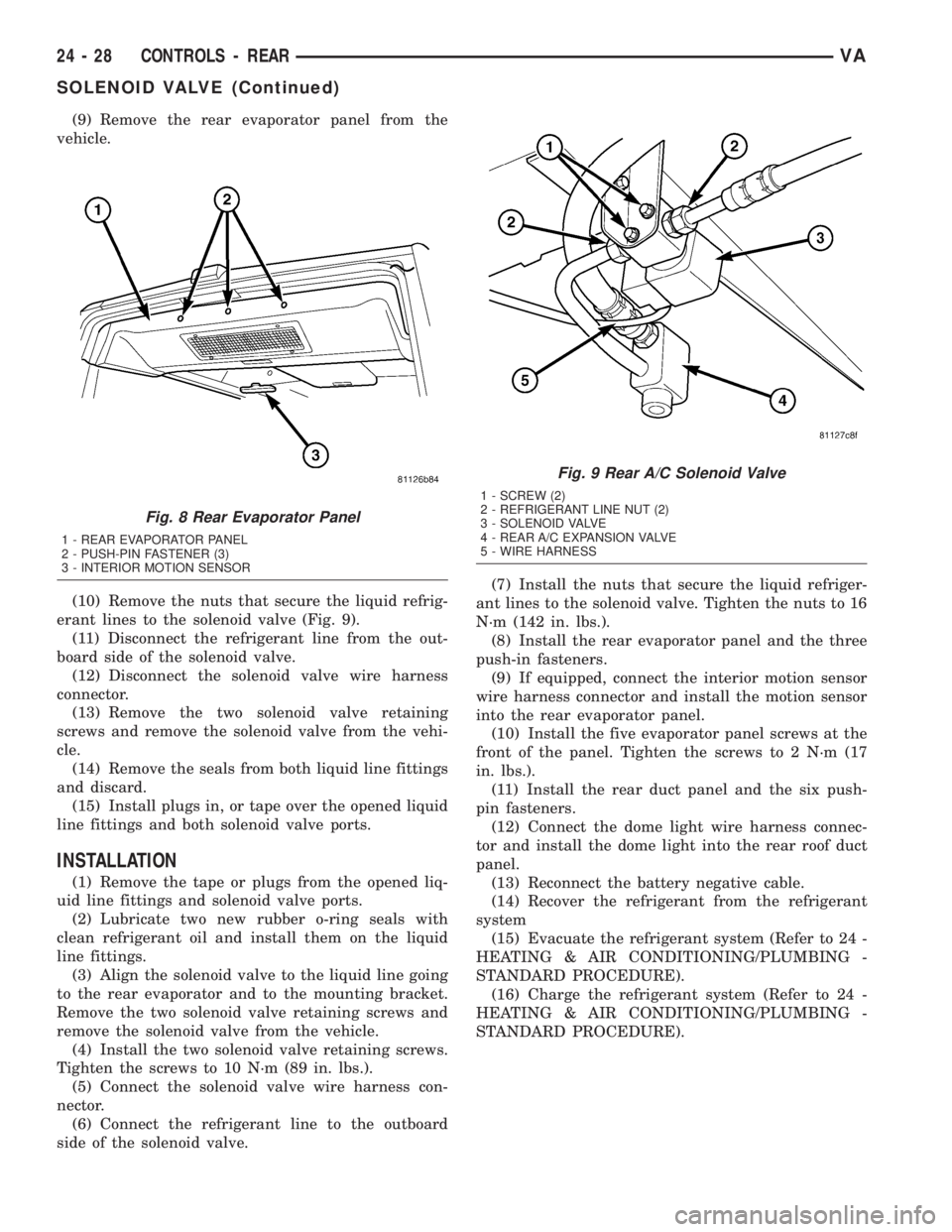

vehicle.

(10) Remove the nuts that secure the liquid refrig-

erant lines to the solenoid valve (Fig. 9).

(11) Disconnect the refrigerant line from the out-

board side of the solenoid valve.

(12) Disconnect the solenoid valve wire harness

connector.

(13) Remove the two solenoid valve retaining

screws and remove the solenoid valve from the vehi-

cle.

(14) Remove the seals from both liquid line fittings

and discard.

(15) Install plugs in, or tape over the opened liquid

line fittings and both solenoid valve ports.

INSTALLATION

(1) Remove the tape or plugs from the opened liq-

uid line fittings and solenoid valve ports.

(2) Lubricate two new rubber o-ring seals with

clean refrigerant oil and install them on the liquid

line fittings.

(3) Align the solenoid valve to the liquid line going

to the rear evaporator and to the mounting bracket.

Remove the two solenoid valve retaining screws and

remove the solenoid valve from the vehicle.

(4) Install the two solenoid valve retaining screws.

Tighten the screws to 10 N´m (89 in. lbs.).

(5) Connect the solenoid valve wire harness con-

nector.

(6) Connect the refrigerant line to the outboard

side of the solenoid valve.(7) Install the nuts that secure the liquid refriger-

ant lines to the solenoid valve. Tighten the nuts to 16

N´m (142 in. lbs.).

(8) Install the rear evaporator panel and the three

push-in fasteners.

(9) If equipped, connect the interior motion sensor

wire harness connector and install the motion sensor

into the rear evaporator panel.

(10) Install the five evaporator panel screws at the

front of the panel. Tighten the screws to 2 N´m (17

in. lbs.).

(11) Install the rear duct panel and the six push-

pin fasteners.

(12) Connect the dome light wire harness connec-

tor and install the dome light into the rear roof duct

panel.

(13) Reconnect the battery negative cable.

(14) Recover the refrigerant from the refrigerant

system

(15) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(16) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

Fig. 8 Rear Evaporator Panel

1 - REAR EVAPORATOR PANEL

2 - PUSH-PIN FASTENER (3)

3 - INTERIOR MOTION SENSOR

Fig. 9 Rear A/C Solenoid Valve

1 - SCREW (2)

2 - REFRIGERANT LINE NUT (2)

3 - SOLENOID VALVE

4 - REAR A/C EXPANSION VALVE

5 - WIRE HARNESS

24 - 28 CONTROLS - REARVA

SOLENOID VALVE (Continued)