sensor MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1157 of 1232

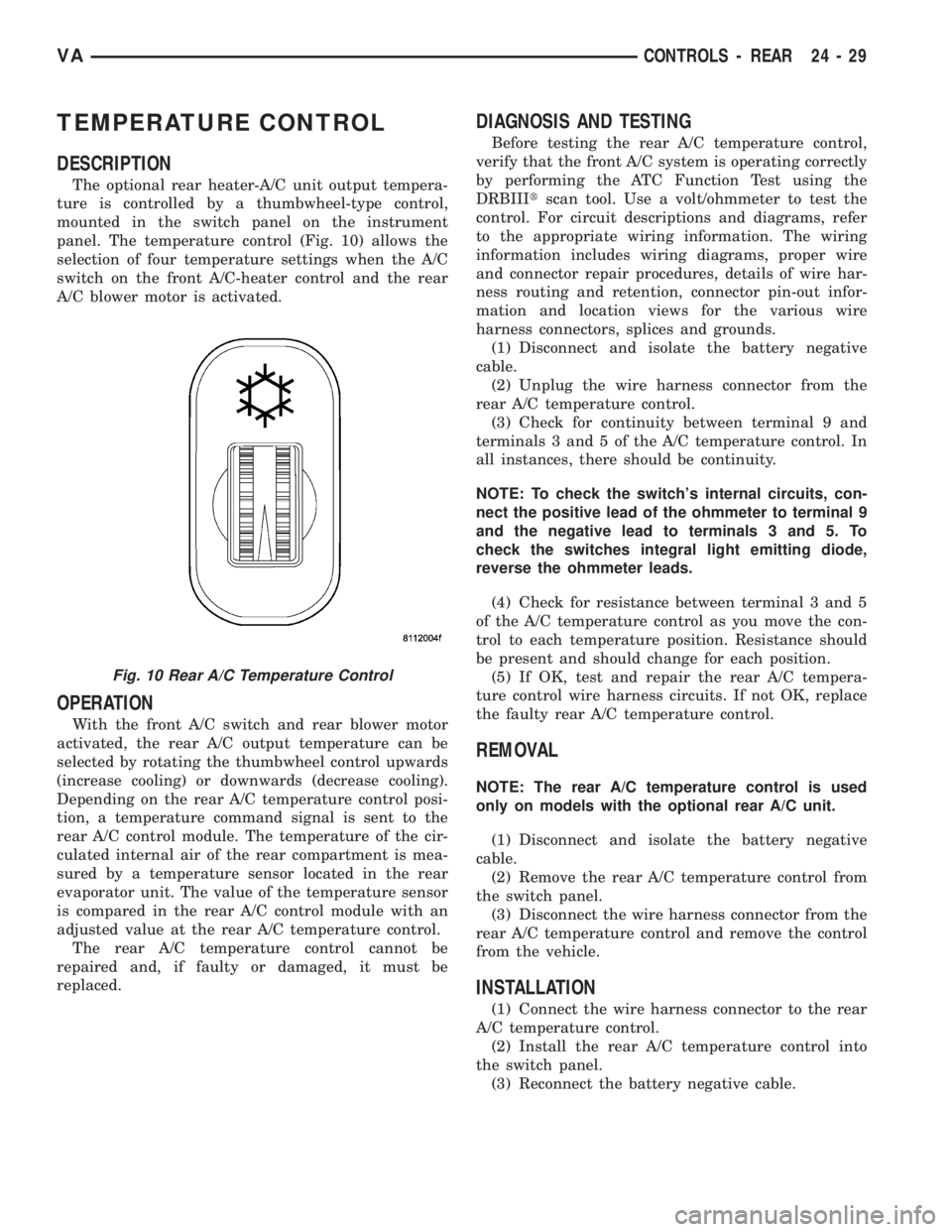

TEMPERATURE CONTROL

DESCRIPTION

The optional rear heater-A/C unit output tempera-

ture is controlled by a thumbwheel-type control,

mounted in the switch panel on the instrument

panel. The temperature control (Fig. 10) allows the

selection of four temperature settings when the A/C

switch on the front A/C-heater control and the rear

A/C blower motor is activated.

OPERATION

With the front A/C switch and rear blower motor

activated, the rear A/C output temperature can be

selected by rotating the thumbwheel control upwards

(increase cooling) or downwards (decrease cooling).

Depending on the rear A/C temperature control posi-

tion, a temperature command signal is sent to the

rear A/C control module. The temperature of the cir-

culated internal air of the rear compartment is mea-

sured by a temperature sensor located in the rear

evaporator unit. The value of the temperature sensor

is compared in the rear A/C control module with an

adjusted value at the rear A/C temperature control.

The rear A/C temperature control cannot be

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING

Before testing the rear A/C temperature control,

verify that the front A/C system is operating correctly

by performing the ATC Function Test using the

DRBIIItscan tool. Use a volt/ohmmeter to test the

control. For circuit descriptions and diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the

rear A/C temperature control.

(3) Check for continuity between terminal 9 and

terminals 3 and 5 of the A/C temperature control. In

all instances, there should be continuity.

NOTE: To check the switch's internal circuits, con-

nect the positive lead of the ohmmeter to terminal 9

and the negative lead to terminals 3 and 5. To

check the switches integral light emitting diode,

reverse the ohmmeter leads.

(4) Check for resistance between terminal 3 and 5

of the A/C temperature control as you move the con-

trol to each temperature position. Resistance should

be present and should change for each position.

(5) If OK, test and repair the rear A/C tempera-

ture control wire harness circuits. If not OK, replace

the faulty rear A/C temperature control.

REMOVAL

NOTE: The rear A/C temperature control is used

only on models with the optional rear A/C unit.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear A/C temperature control from

the switch panel.

(3) Disconnect the wire harness connector from the

rear A/C temperature control and remove the control

from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the rear

A/C temperature control.

(2) Install the rear A/C temperature control into

the switch panel.

(3) Reconnect the battery negative cable.

Fig. 10 Rear A/C Temperature Control

VACONTROLS - REAR 24 - 29

Page 1158 of 1232

TEMPERATURE SENSOR

DESCRIPTION

The rear A/C air temperature sensor is located in

the rear evaporator housing. The rear temperature

sensor provides an air outlet temperature signal to

the rear A/C control module through a two-wire har-

ness lead and connector.

The temperature sensor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The rear A/C temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the rear A/C control module. The resis-

tance in the sensor changes as air temperature

changes. Based upon the resistance in the sensor, a

specific voltage on the temperature sensor signal cir-

cuit is returned to the rear control module, which is

programmed to correspond to a specific temperature.

DIAGNOSIS AND TESTING

Before testing the rear air temperature sensor, ver-

ify that the front A/C system is operating correctly by

performing the ATC Function Test using the DRBIIIt

scan tool. For circuit descriptions and diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector for the rear

air temperature sensor.

(3) Measure the resistance of the temperature sen-

sor. At ±40É C (±40É F), the sensor resistance is 336

kilohms. At 55É C (131É F), the sensor resistance is

25 kilohms. The sensor resistance should read

between these two values.

(4) If OK, test and repair the rear air temperature

sensor wire harness circuits. If not OK, replace the

faulty air temperature sensor.

REMOVAL

(1) Disconnect and isolate the battery negative

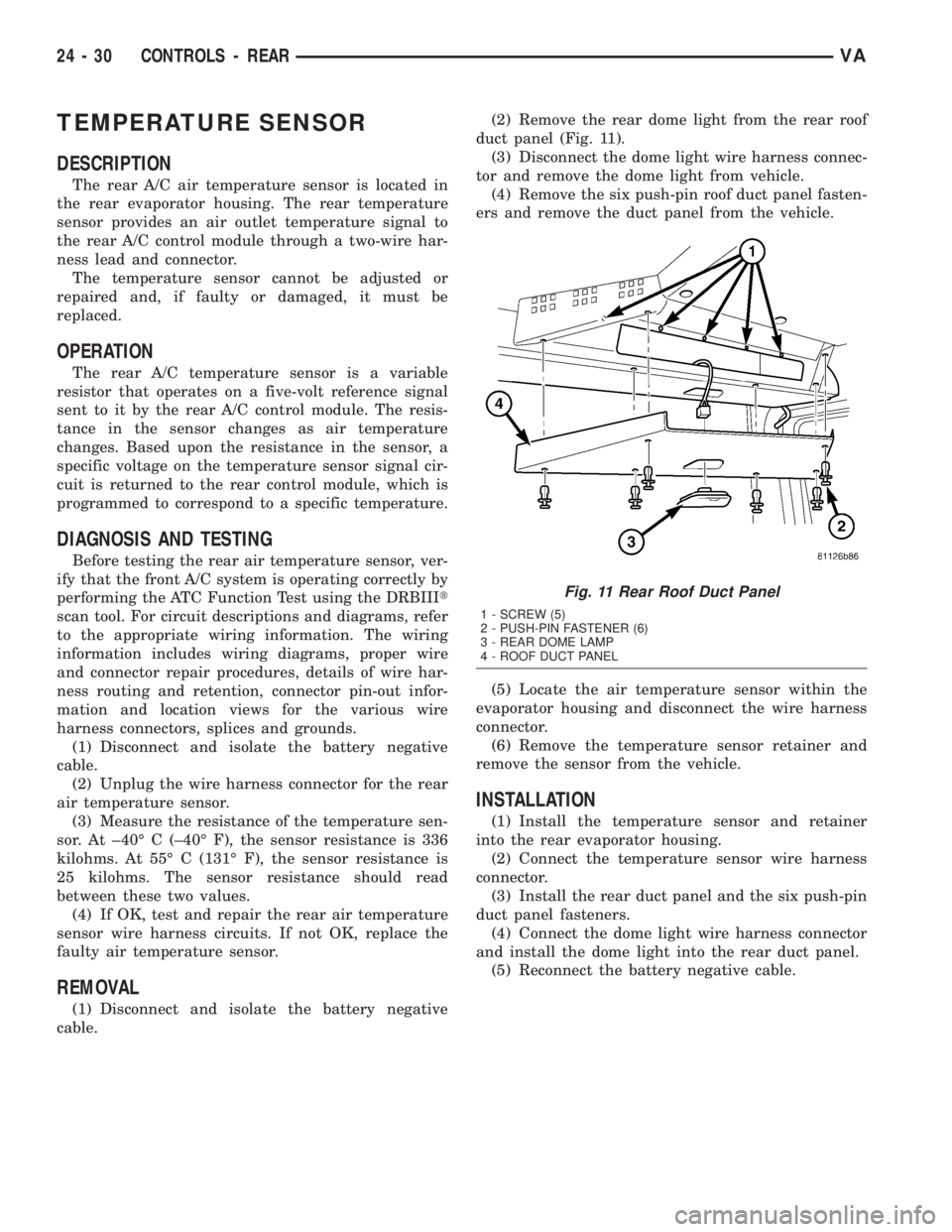

cable.(2) Remove the rear dome light from the rear roof

duct panel (Fig. 11).

(3) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(4) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(5) Locate the air temperature sensor within the

evaporator housing and disconnect the wire harness

connector.

(6) Remove the temperature sensor retainer and

remove the sensor from the vehicle.

INSTALLATION

(1) Install the temperature sensor and retainer

into the rear evaporator housing.

(2) Connect the temperature sensor wire harness

connector.

(3) Install the rear duct panel and the six push-pin

duct panel fasteners.

(4) Connect the dome light wire harness connector

and install the dome light into the rear duct panel.

(5) Reconnect the battery negative cable.

Fig. 11 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

24 - 30 CONTROLS - REARVA

Page 1163 of 1232

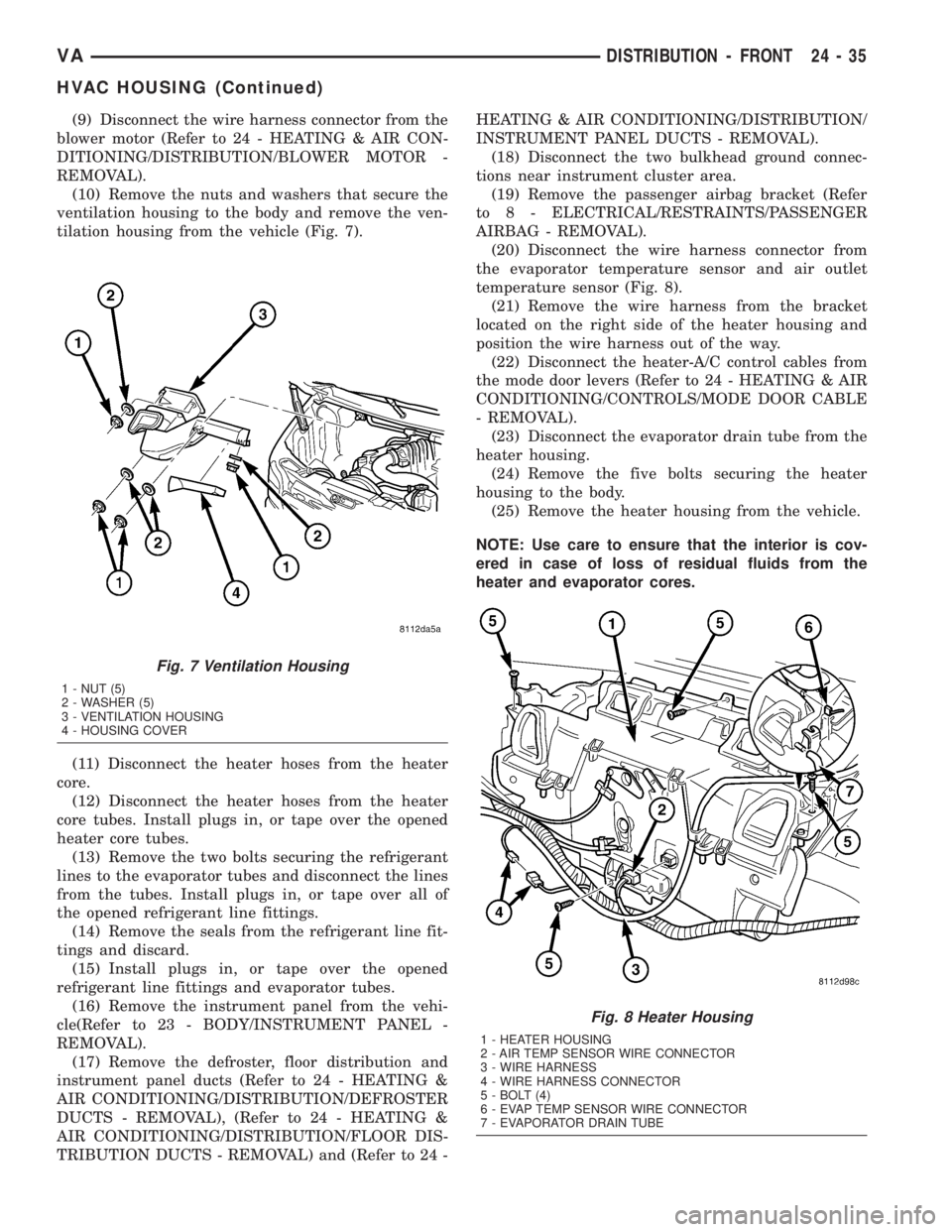

(9) Disconnect the wire harness connector from the

blower motor (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/BLOWER MOTOR -

REMOVAL).

(10) Remove the nuts and washers that secure the

ventilation housing to the body and remove the ven-

tilation housing from the vehicle (Fig. 7).

(11) Disconnect the heater hoses from the heater

core.

(12) Disconnect the heater hoses from the heater

core tubes. Install plugs in, or tape over the opened

heater core tubes.

(13) Remove the two bolts securing the refrigerant

lines to the evaporator tubes and disconnect the lines

from the tubes. Install plugs in, or tape over all of

the opened refrigerant line fittings.

(14) Remove the seals from the refrigerant line fit-

tings and discard.

(15) Install plugs in, or tape over the opened

refrigerant line fittings and evaporator tubes.

(16) Remove the instrument panel from the vehi-

cle(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(17) Remove the defroster, floor distribution and

instrument panel ducts (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION/DEFROSTER

DUCTS - REMOVAL), (Refer to 24 - HEATING &

AIR CONDITIONING/DISTRIBUTION/FLOOR DIS-

TRIBUTION DUCTS - REMOVAL) and (Refer to 24 -HEATING & AIR CONDITIONING/DISTRIBUTION/

INSTRUMENT PANEL DUCTS - REMOVAL).

(18) Disconnect the two bulkhead ground connec-

tions near instrument cluster area.

(19) Remove the passenger airbag bracket (Refer

to 8 - ELECTRICAL/RESTRAINTS/PASSENGER

AIRBAG - REMOVAL).

(20) Disconnect the wire harness connector from

the evaporator temperature sensor and air outlet

temperature sensor (Fig. 8).

(21) Remove the wire harness from the bracket

located on the right side of the heater housing and

position the wire harness out of the way.

(22) Disconnect the heater-A/C control cables from

the mode door levers (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/MODE DOOR CABLE

- REMOVAL).

(23) Disconnect the evaporator drain tube from the

heater housing.

(24) Remove the five bolts securing the heater

housing to the body.

(25) Remove the heater housing from the vehicle.

NOTE: Use care to ensure that the interior is cov-

ered in case of loss of residual fluids from the

heater and evaporator cores.

Fig. 7 Ventilation Housing

1 - NUT (5)

2 - WASHER (5)

3 - VENTILATION HOUSING

4 - HOUSING COVER

Fig. 8 Heater Housing

1 - HEATER HOUSING

2 - AIR TEMP SENSOR WIRE CONNECTOR

3 - WIRE HARNESS

4 - WIRE HARNESS CONNECTOR

5 - BOLT (4)

6 - EVAP TEMP SENSOR WIRE CONNECTOR

7 - EVAPORATOR DRAIN TUBE

VADISTRIBUTION - FRONT 24 - 35

HVAC HOUSING (Continued)

Page 1167 of 1232

DISTRIBUTION - REAR

TABLE OF CONTENTS

page page

AIR FILTER

REMOVAL.............................39

INSTALLATION.........................39

BLOWER MOTOR

REMOVAL.............................39INSTALLATION.........................40

REAR A/C HOUSING

REMOVAL.............................40

INSTALLATION.........................41

AIR FILTER

REMOVAL

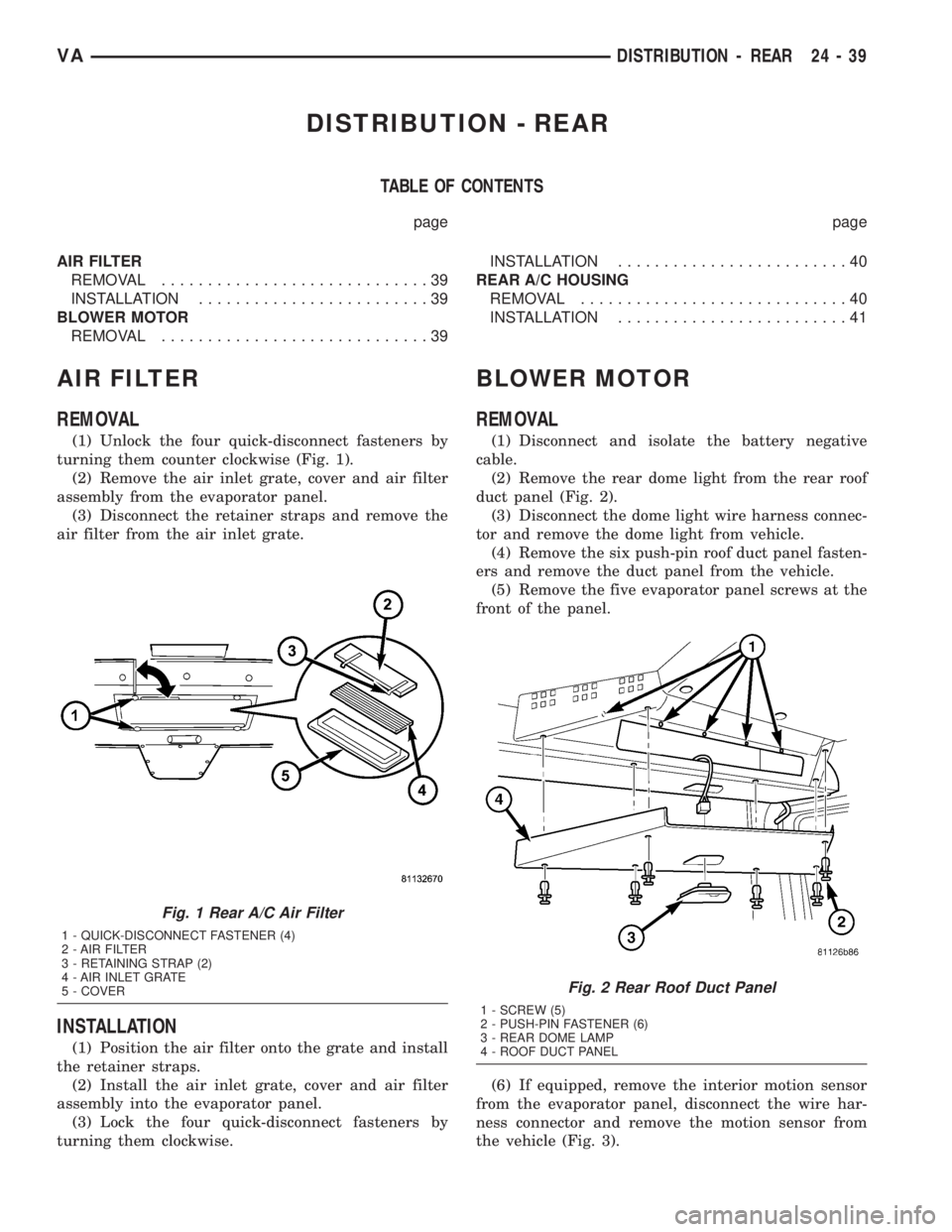

(1) Unlock the four quick-disconnect fasteners by

turning them counter clockwise (Fig. 1).

(2) Remove the air inlet grate, cover and air filter

assembly from the evaporator panel.

(3) Disconnect the retainer straps and remove the

air filter from the air inlet grate.

INSTALLATION

(1) Position the air filter onto the grate and install

the retainer straps.

(2) Install the air inlet grate, cover and air filter

assembly into the evaporator panel.

(3) Lock the four quick-disconnect fasteners by

turning them clockwise.

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear dome light from the rear roof

duct panel (Fig. 2).

(3) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(4) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(5) Remove the five evaporator panel screws at the

front of the panel.

(6) If equipped, remove the interior motion sensor

from the evaporator panel, disconnect the wire har-

ness connector and remove the motion sensor from

the vehicle (Fig. 3).

Fig. 1 Rear A/C Air Filter

1 - QUICK-DISCONNECT FASTENER (4)

2 - AIR FILTER

3 - RETAINING STRAP (2)

4 - AIR INLET GRATE

5 - COVER

Fig. 2 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

VADISTRIBUTION - REAR 24 - 39

Page 1168 of 1232

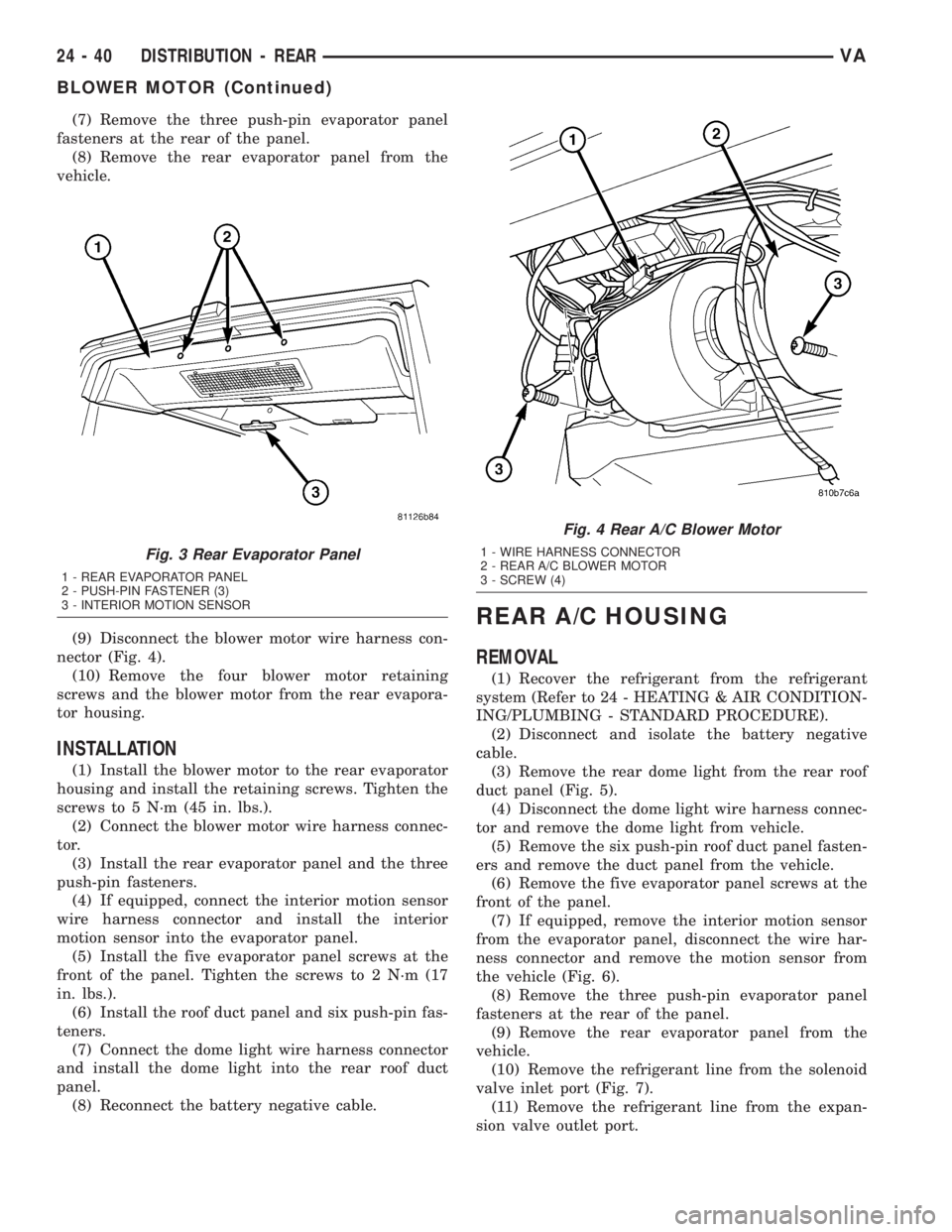

(7) Remove the three push-pin evaporator panel

fasteners at the rear of the panel.

(8) Remove the rear evaporator panel from the

vehicle.

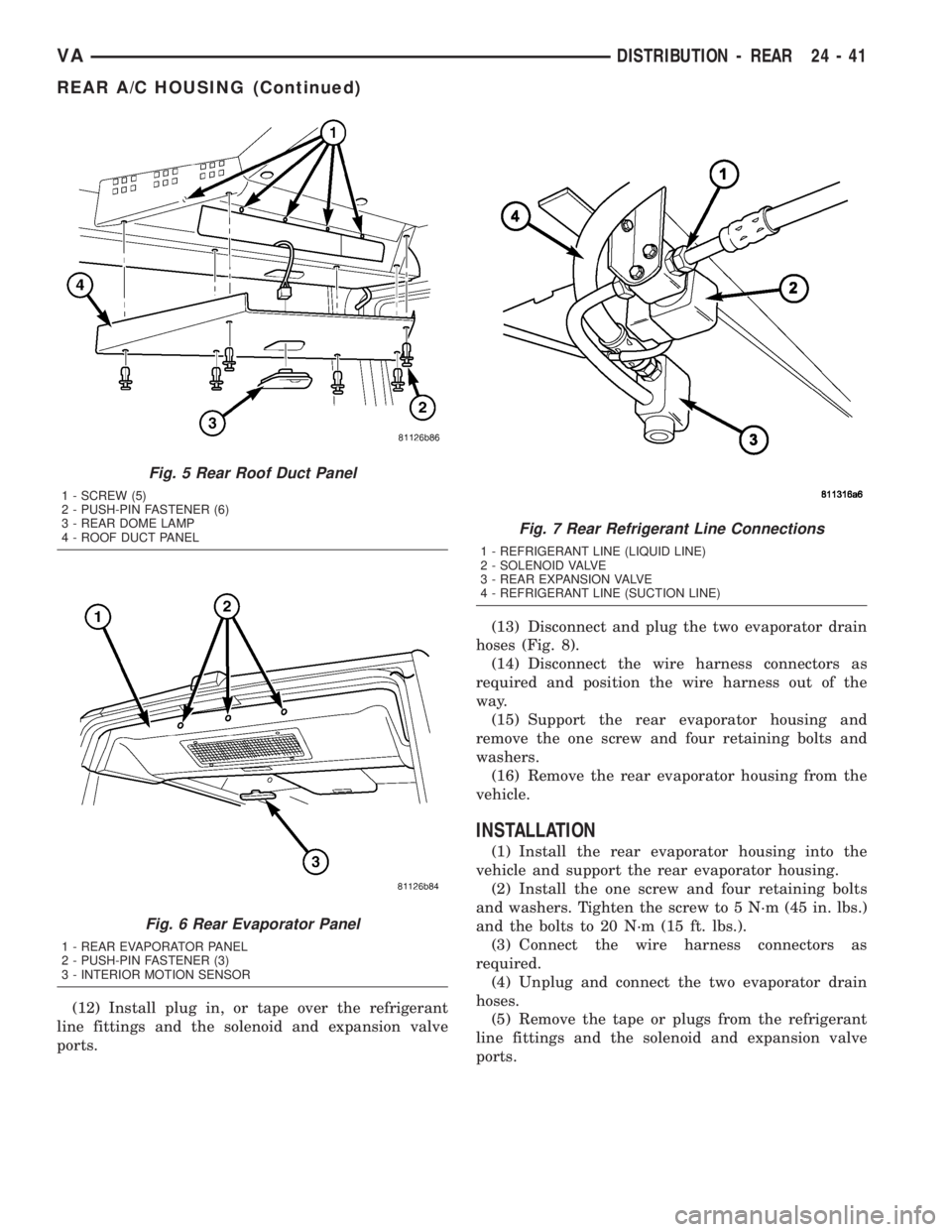

(9) Disconnect the blower motor wire harness con-

nector (Fig. 4).

(10) Remove the four blower motor retaining

screws and the blower motor from the rear evapora-

tor housing.

INSTALLATION

(1) Install the blower motor to the rear evaporator

housing and install the retaining screws. Tighten the

screws to 5 N´m (45 in. lbs.).

(2) Connect the blower motor wire harness connec-

tor.

(3) Install the rear evaporator panel and the three

push-pin fasteners.

(4) If equipped, connect the interior motion sensor

wire harness connector and install the interior

motion sensor into the evaporator panel.

(5) Install the five evaporator panel screws at the

front of the panel. Tighten the screws to 2 N´m (17

in. lbs.).

(6) Install the roof duct panel and six push-pin fas-

teners.

(7) Connect the dome light wire harness connector

and install the dome light into the rear roof duct

panel.

(8) Reconnect the battery negative cable.

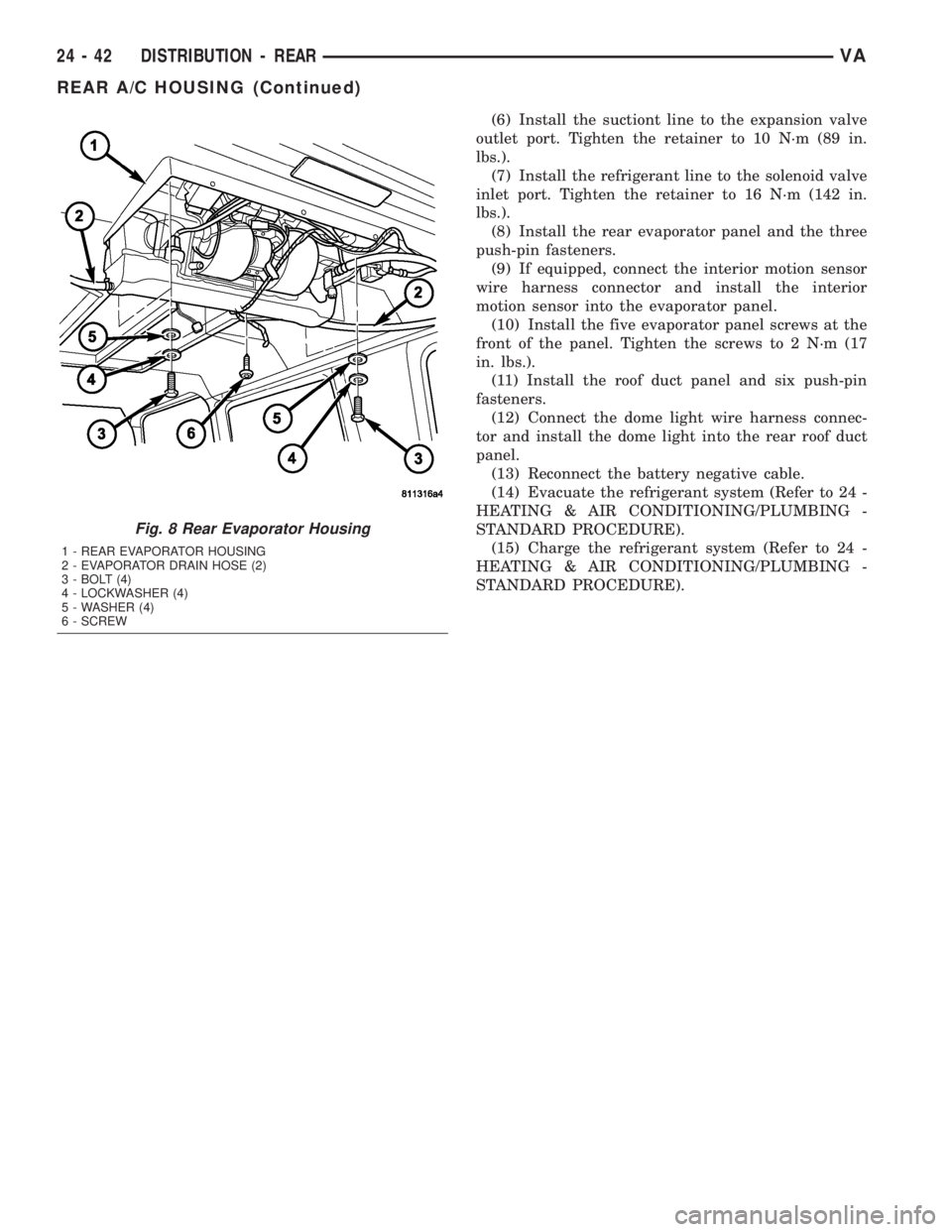

REAR A/C HOUSING

REMOVAL

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the rear dome light from the rear roof

duct panel (Fig. 5).

(4) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(5) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(6) Remove the five evaporator panel screws at the

front of the panel.

(7) If equipped, remove the interior motion sensor

from the evaporator panel, disconnect the wire har-

ness connector and remove the motion sensor from

the vehicle (Fig. 6).

(8) Remove the three push-pin evaporator panel

fasteners at the rear of the panel.

(9) Remove the rear evaporator panel from the

vehicle.

(10) Remove the refrigerant line from the solenoid

valve inlet port (Fig. 7).

(11) Remove the refrigerant line from the expan-

sion valve outlet port.

Fig. 3 Rear Evaporator Panel

1 - REAR EVAPORATOR PANEL

2 - PUSH-PIN FASTENER (3)

3 - INTERIOR MOTION SENSOR

Fig. 4 Rear A/C Blower Motor

1 - WIRE HARNESS CONNECTOR

2 - REAR A/C BLOWER MOTOR

3 - SCREW (4)

24 - 40 DISTRIBUTION - REARVA

BLOWER MOTOR (Continued)

Page 1169 of 1232

(12) Install plug in, or tape over the refrigerant

line fittings and the solenoid and expansion valve

ports.(13) Disconnect and plug the two evaporator drain

hoses (Fig. 8).

(14) Disconnect the wire harness connectors as

required and position the wire harness out of the

way.

(15) Support the rear evaporator housing and

remove the one screw and four retaining bolts and

washers.

(16) Remove the rear evaporator housing from the

vehicle.

INSTALLATION

(1) Install the rear evaporator housing into the

vehicle and support the rear evaporator housing.

(2) Install the one screw and four retaining bolts

and washers. Tighten the screw to 5 N´m (45 in. lbs.)

and the bolts to 20 N´m (15 ft. lbs.).

(3) Connect the wire harness connectors as

required.

(4) Unplug and connect the two evaporator drain

hoses.

(5) Remove the tape or plugs from the refrigerant

line fittings and the solenoid and expansion valve

ports.

Fig. 5 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

Fig. 6 Rear Evaporator Panel

1 - REAR EVAPORATOR PANEL

2 - PUSH-PIN FASTENER (3)

3 - INTERIOR MOTION SENSOR

Fig. 7 Rear Refrigerant Line Connections

1 - REFRIGERANT LINE (LIQUID LINE)

2 - SOLENOID VALVE

3 - REAR EXPANSION VALVE

4 - REFRIGERANT LINE (SUCTION LINE)

VADISTRIBUTION - REAR 24 - 41

REAR A/C HOUSING (Continued)

Page 1170 of 1232

(6) Install the suctiont line to the expansion valve

outlet port. Tighten the retainer to 10 N´m (89 in.

lbs.).

(7) Install the refrigerant line to the solenoid valve

inlet port. Tighten the retainer to 16 N´m (142 in.

lbs.).

(8) Install the rear evaporator panel and the three

push-pin fasteners.

(9) If equipped, connect the interior motion sensor

wire harness connector and install the interior

motion sensor into the evaporator panel.

(10) Install the five evaporator panel screws at the

front of the panel. Tighten the screws to 2 N´m (17

in. lbs.).

(11) Install the roof duct panel and six push-pin

fasteners.

(12) Connect the dome light wire harness connec-

tor and install the dome light into the rear roof duct

panel.

(13) Reconnect the battery negative cable.

(14) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(15) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

Fig. 8 Rear Evaporator Housing

1 - REAR EVAPORATOR HOUSING

2 - EVAPORATOR DRAIN HOSE (2)

3 - BOLT (4)

4 - LOCKWASHER (4)

5 - WASHER (4)

6 - SCREW

24 - 42 DISTRIBUTION - REARVA

REAR A/C HOUSING (Continued)

Page 1183 of 1232

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

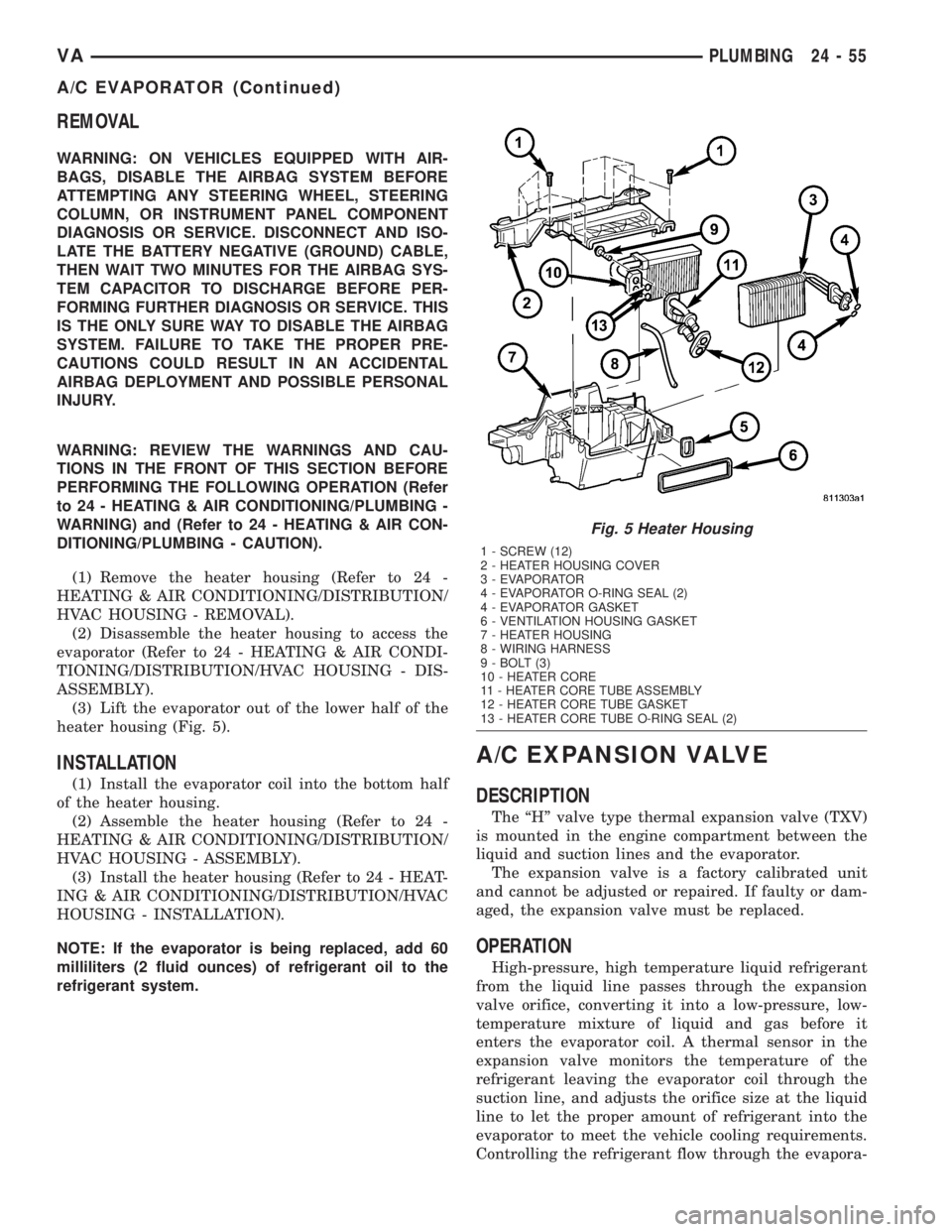

(1) Remove the heater housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

(2) Disassemble the heater housing to access the

evaporator (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING - DIS-

ASSEMBLY).

(3) Lift the evaporator out of the lower half of the

heater housing (Fig. 5).

INSTALLATION

(1) Install the evaporator coil into the bottom half

of the heater housing.

(2) Assemble the heater housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY).

(3) Install the heater housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

NOTE: If the evaporator is being replaced, add 60

milliliters (2 fluid ounces) of refrigerant oil to the

refrigerant system.

A/C EXPANSION VALVE

DESCRIPTION

The ªHº valve type thermal expansion valve (TXV)

is mounted in the engine compartment between the

liquid and suction lines and the evaporator.

The expansion valve is a factory calibrated unit

and cannot be adjusted or repaired. If faulty or dam-

aged, the expansion valve must be replaced.

OPERATION

High-pressure, high temperature liquid refrigerant

from the liquid line passes through the expansion

valve orifice, converting it into a low-pressure, low-

temperature mixture of liquid and gas before it

enters the evaporator coil. A thermal sensor in the

expansion valve monitors the temperature of the

refrigerant leaving the evaporator coil through the

suction line, and adjusts the orifice size at the liquid

line to let the proper amount of refrigerant into the

evaporator to meet the vehicle cooling requirements.

Controlling the refrigerant flow through the evapora-

Fig. 5 Heater Housing

1 - SCREW (12)

2 - HEATER HOUSING COVER

3 - EVAPORATOR

4 - EVAPORATOR O-RING SEAL (2)

4 - EVAPORATOR GASKET

6 - VENTILATION HOUSING GASKET

7 - HEATER HOUSING

8 - WIRING HARNESS

9 - BOLT (3)

10 - HEATER CORE

11 - HEATER CORE TUBE ASSEMBLY

12 - HEATER CORE TUBE GASKET

13 - HEATER CORE TUBE O-RING SEAL (2)

VAPLUMBING 24 - 55

A/C EVAPORATOR (Continued)

Page 1186 of 1232

blower motor speed controls the volume of air flowing

through the heater housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the heater housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

(2) Disassemble the heater housing to access the

heater core (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING - DIS-

ASSEMBLY).

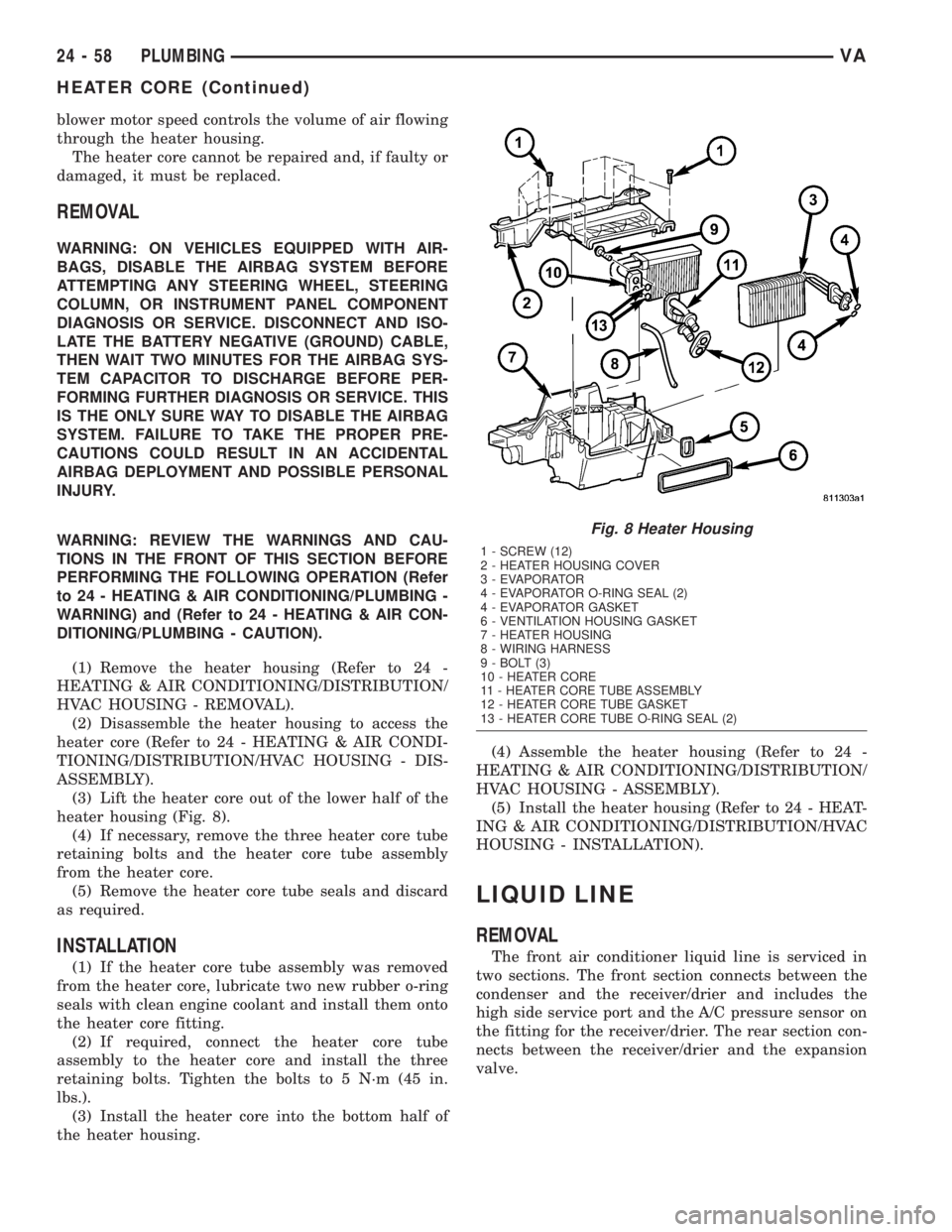

(3) Lift the heater core out of the lower half of the

heater housing (Fig. 8).

(4) If necessary, remove the three heater core tube

retaining bolts and the heater core tube assembly

from the heater core.

(5) Remove the heater core tube seals and discard

as required.

INSTALLATION

(1) If the heater core tube assembly was removed

from the heater core, lubricate two new rubber o-ring

seals with clean engine coolant and install them onto

the heater core fitting.

(2) If required, connect the heater core tube

assembly to the heater core and install the three

retaining bolts. Tighten the bolts to 5 N´m (45 in.

lbs.).

(3) Install the heater core into the bottom half of

the heater housing.(4) Assemble the heater housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY).

(5) Install the heater housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

LIQUID LINE

REMOVAL

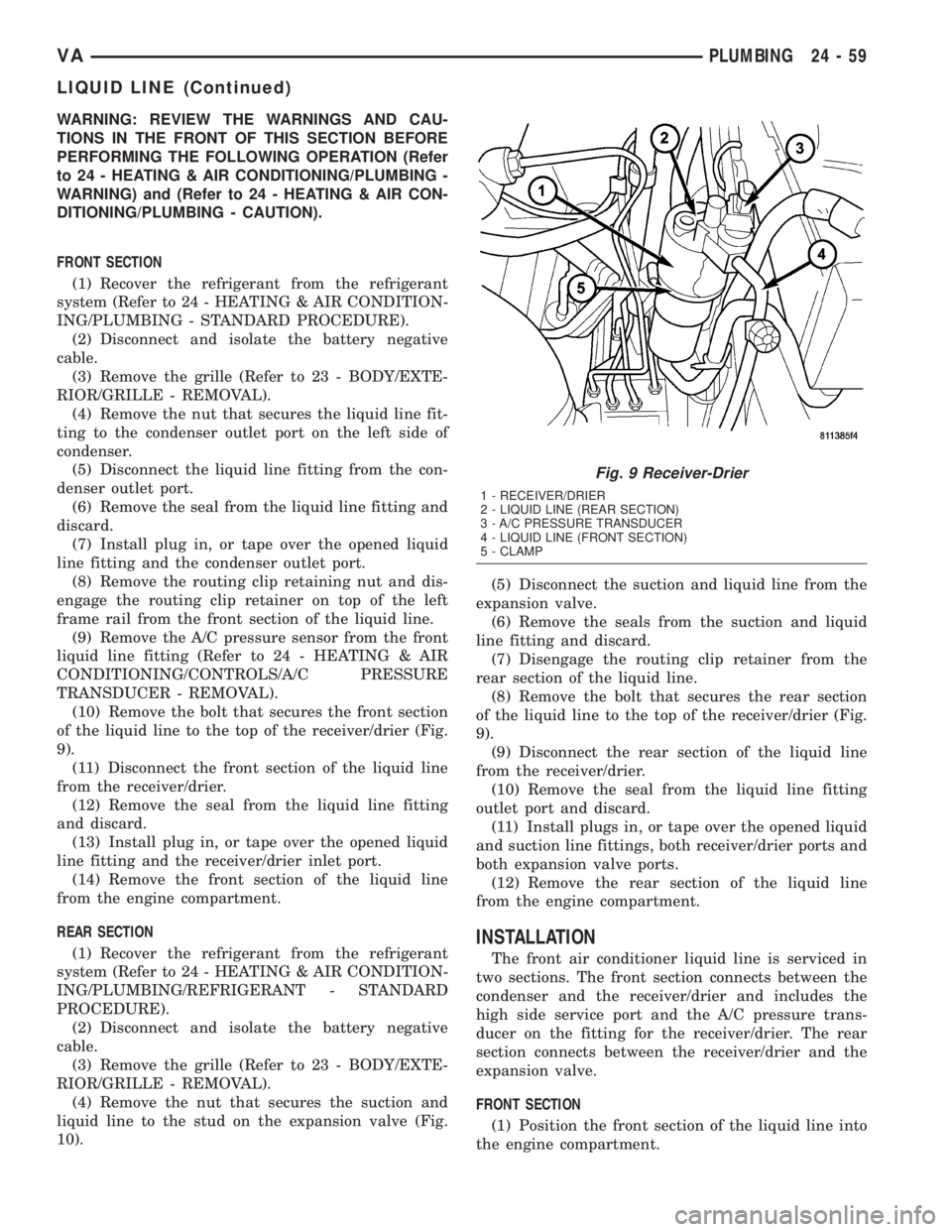

The front air conditioner liquid line is serviced in

two sections. The front section connects between the

condenser and the receiver/drier and includes the

high side service port and the A/C pressure sensor on

the fitting for the receiver/drier. The rear section con-

nects between the receiver/drier and the expansion

valve.

Fig. 8 Heater Housing

1 - SCREW (12)

2 - HEATER HOUSING COVER

3 - EVAPORATOR

4 - EVAPORATOR O-RING SEAL (2)

4 - EVAPORATOR GASKET

6 - VENTILATION HOUSING GASKET

7 - HEATER HOUSING

8 - WIRING HARNESS

9 - BOLT (3)

10 - HEATER CORE

11 - HEATER CORE TUBE ASSEMBLY

12 - HEATER CORE TUBE GASKET

13 - HEATER CORE TUBE O-RING SEAL (2)

24 - 58 PLUMBINGVA

HEATER CORE (Continued)

Page 1187 of 1232

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

FRONT SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(4) Remove the nut that secures the liquid line fit-

ting to the condenser outlet port on the left side of

condenser.

(5) Disconnect the liquid line fitting from the con-

denser outlet port.

(6) Remove the seal from the liquid line fitting and

discard.

(7) Install plug in, or tape over the opened liquid

line fitting and the condenser outlet port.

(8) Remove the routing clip retaining nut and dis-

engage the routing clip retainer on top of the left

frame rail from the front section of the liquid line.

(9) Remove the A/C pressure sensor from the front

liquid line fitting (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C PRESSURE

TRANSDUCER - REMOVAL).

(10) Remove the bolt that secures the front section

of the liquid line to the top of the receiver/drier (Fig.

9).

(11) Disconnect the front section of the liquid line

from the receiver/drier.

(12) Remove the seal from the liquid line fitting

and discard.

(13) Install plug in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

(14) Remove the front section of the liquid line

from the engine compartment.

REAR SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT - STANDARD

PROCEDURE).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(4) Remove the nut that secures the suction and

liquid line to the stud on the expansion valve (Fig.

10).(5) Disconnect the suction and liquid line from the

expansion valve.

(6) Remove the seals from the suction and liquid

line fitting and discard.

(7) Disengage the routing clip retainer from the

rear section of the liquid line.

(8) Remove the bolt that secures the rear section

of the liquid line to the top of the receiver/drier (Fig.

9).

(9) Disconnect the rear section of the liquid line

from the receiver/drier.

(10) Remove the seal from the liquid line fitting

outlet port and discard.

(11) Install plugs in, or tape over the opened liquid

and suction line fittings, both receiver/drier ports and

both expansion valve ports.

(12) Remove the rear section of the liquid line

from the engine compartment.

INSTALLATION

The front air conditioner liquid line is serviced in

two sections. The front section connects between the

condenser and the receiver/drier and includes the

high side service port and the A/C pressure trans-

ducer on the fitting for the receiver/drier. The rear

section connects between the receiver/drier and the

expansion valve.

FRONT SECTION

(1) Position the front section of the liquid line into

the engine compartment.

Fig. 9 Receiver-Drier

1 - RECEIVER/DRIER

2 - LIQUID LINE (REAR SECTION)

3 - A/C PRESSURE TRANSDUCER

4 - LIQUID LINE (FRONT SECTION)

5 - CLAMP

VAPLUMBING 24 - 59

LIQUID LINE (Continued)