engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 837 of 1232

(3) Unplug electrical connector at high pressure

pump.

CAUTION: DO NOT slacken the threaded connec-

tion. Use a wrench to counterhold at the threaded

connection when loosening and tightening the

union nut. DO NOT EXCEED tightening torque.

CAUTION: DO NOT crimp or bend fuel line. Capture

all fluids that flow out of connections.

NOTE: Using a marking pen, make a mark on the

outside fuel return line to easily identify proper

position during assembly.

(4) Unbolt bracket and pressure line at pressure

pump.

(5) Detach fuel supply and return flow line at high

pressure pump.NOTE: Care must be taken not to drop the high

pressure pump driver and intermediate piece if

pump is being replaced.

(6) Remove bolts attaching high pressure pump

and remove pump.

REMOVAL - LOW PRESSURE PUMP

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Disconnect negative battery cable.

(2) Remove vacuum pump (Refer to 9 - ENGINE/

ENGINE BLOCK/INTERNAL VACUUM PUMP -

REMOVAL).

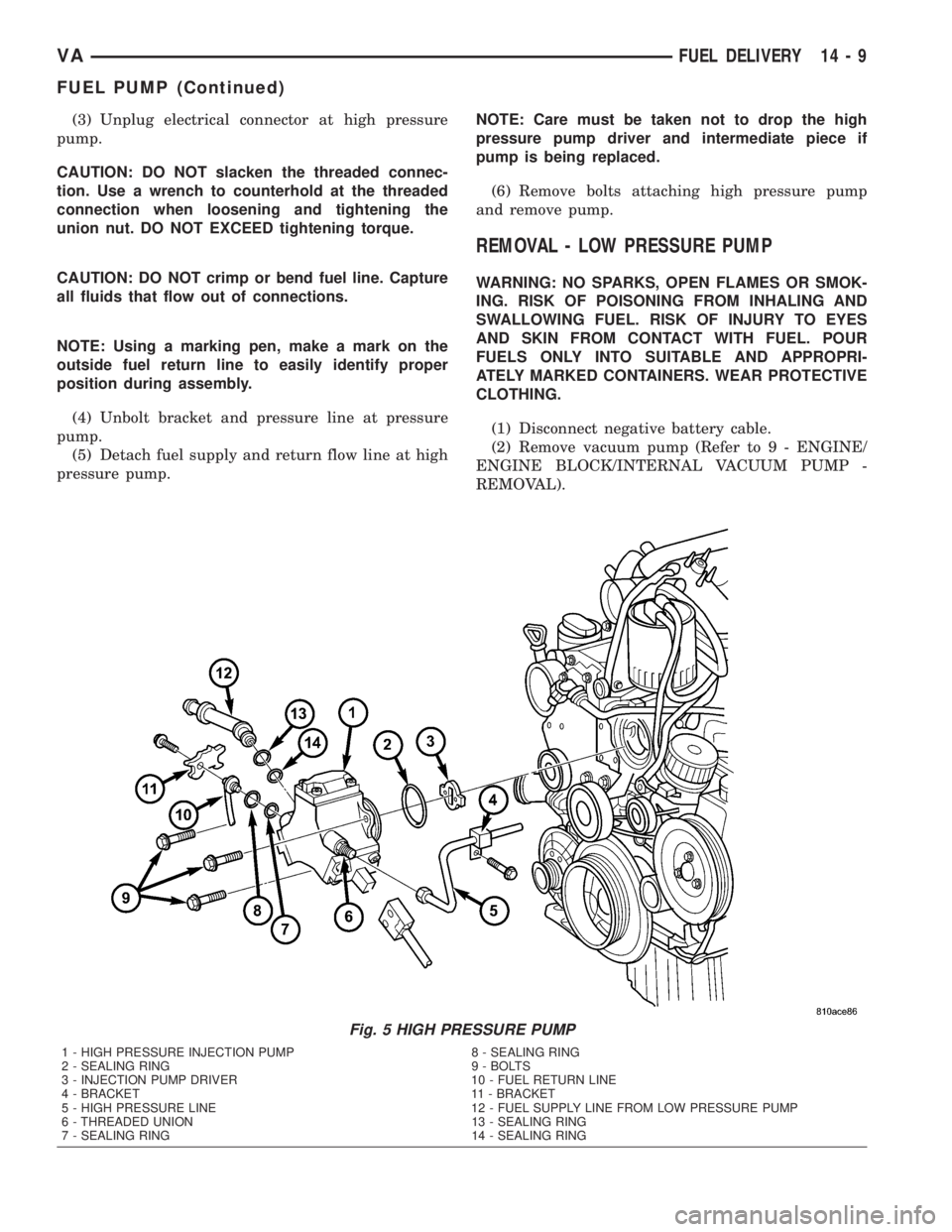

Fig. 5 HIGH PRESSURE PUMP

1 - HIGH PRESSURE INJECTION PUMP 8 - SEALING RING

2 - SEALING RING 9 - BOLTS

3 - INJECTION PUMP DRIVER 10 - FUEL RETURN LINE

4 - BRACKET 11 - BRACKET

5 - HIGH PRESSURE LINE 12 - FUEL SUPPLY LINE FROM LOW PRESSURE PUMP

6 - THREADED UNION 13 - SEALING RING

7 - SEALING RING 14 - SEALING RING

VAFUEL DELIVERY 14 - 9

FUEL PUMP (Continued)

Page 838 of 1232

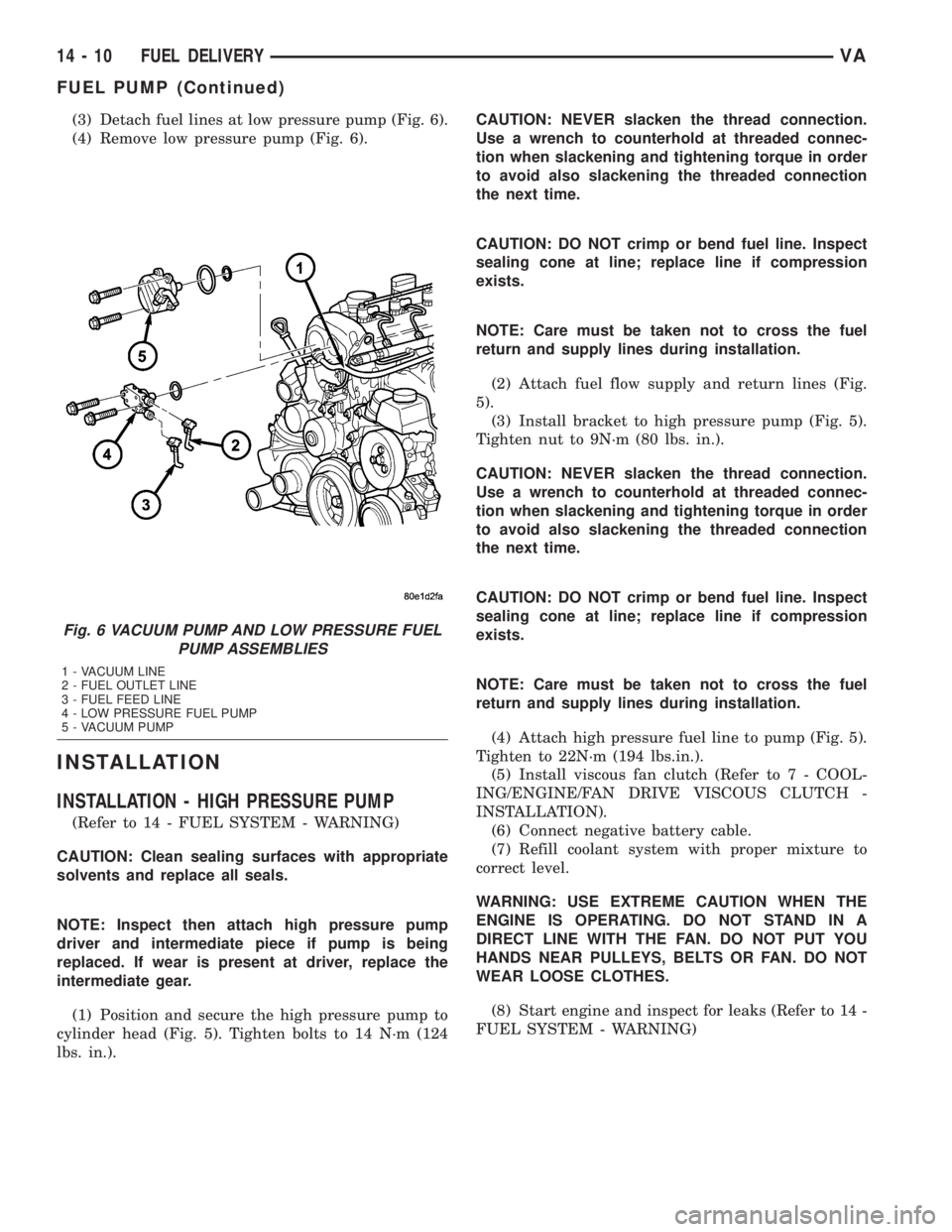

(3) Detach fuel lines at low pressure pump (Fig. 6).

(4) Remove low pressure pump (Fig. 6).

INSTALLATION

INSTALLATION - HIGH PRESSURE PUMP

(Refer to 14 - FUEL SYSTEM - WARNING)

CAUTION: Clean sealing surfaces with appropriate

solvents and replace all seals.

NOTE: Inspect then attach high pressure pump

driver and intermediate piece if pump is being

replaced. If wear is present at driver, replace the

intermediate gear.

(1) Position and secure the high pressure pump to

cylinder head (Fig. 5). Tighten bolts to 14 N´m (124

lbs. in.).CAUTION: NEVER slacken the thread connection.

Use a wrench to counterhold at threaded connec-

tion when slackening and tightening torque in order

to avoid also slackening the threaded connection

the next time.

CAUTION: DO NOT crimp or bend fuel line. Inspect

sealing cone at line; replace line if compression

exists.

NOTE: Care must be taken not to cross the fuel

return and supply lines during installation.

(2) Attach fuel flow supply and return lines (Fig.

5).

(3) Install bracket to high pressure pump (Fig. 5).

Tighten nut to 9N´m (80 lbs. in.).

CAUTION: NEVER slacken the thread connection.

Use a wrench to counterhold at threaded connec-

tion when slackening and tightening torque in order

to avoid also slackening the threaded connection

the next time.

CAUTION: DO NOT crimp or bend fuel line. Inspect

sealing cone at line; replace line if compression

exists.

NOTE: Care must be taken not to cross the fuel

return and supply lines during installation.

(4) Attach high pressure fuel line to pump (Fig. 5).

Tighten to 22N´m (194 lbs.in.).

(5) Install viscous fan clutch (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(6) Connect negative battery cable.

(7) Refill coolant system with proper mixture to

correct level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOU

HANDS NEAR PULLEYS, BELTS OR FAN. DO NOT

WEAR LOOSE CLOTHES.

(8) Start engine and inspect for leaks (Refer to 14 -

FUEL SYSTEM - WARNING)

Fig. 6 VACUUM PUMP AND LOW PRESSURE FUEL

PUMP ASSEMBLIES

1 - VACUUM LINE

2 - FUEL OUTLET LINE

3 - FUEL FEED LINE

4 - LOW PRESSURE FUEL PUMP

5 - VACUUM PUMP

14 - 10 FUEL DELIVERYVA

FUEL PUMP (Continued)

Page 839 of 1232

INSTALLATION - LOW PRESSURE PUMP

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: Clean sealing surfaces, replace seal if nec-

essary.

(1) Prime the low pressure pump with the appro-

priate fuel.

(2) Attach low pressure fuel pump to cylinder head

front cover. Tighten bolt to 9N´m (80 lbs. in.).

(3) Attach fuel lines to low pressure pump.

(4) Install vacuum pump (Refer to 9 - ENGINE/

ENGINE BLOCK/INTERNAL VACUUM PUMP -

INSTALLATION).

(5) Reconnect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH FAN. DO NOT PUT YOUR

HANDS NEAR PULLEYS, BELTS OR FAN. DO NOT

WEAR LOOSE CLOTHING.

(6) Start engine and inspect for leaks.

FUEL RAIL

DESCRIPTION

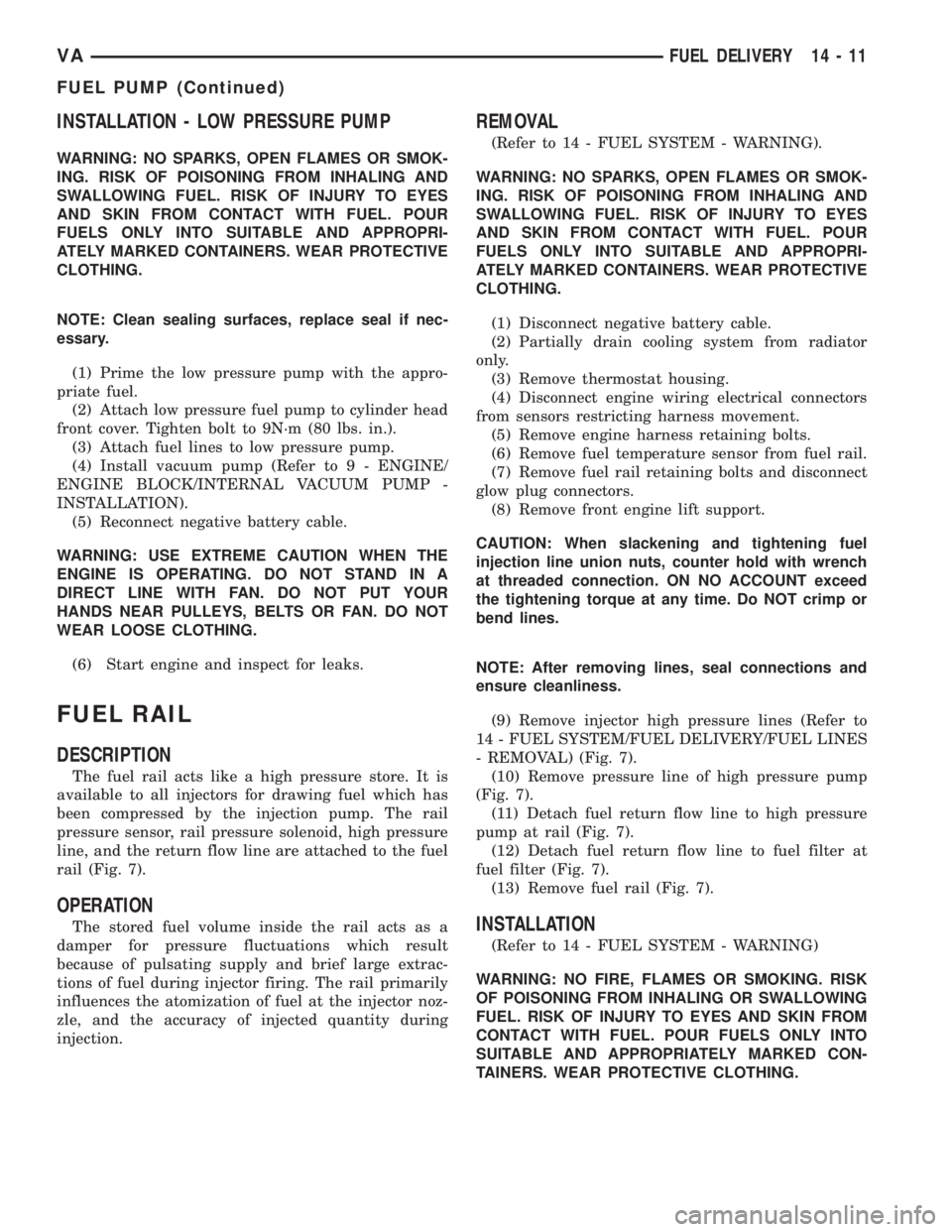

The fuel rail acts like a high pressure store. It is

available to all injectors for drawing fuel which has

been compressed by the injection pump. The rail

pressure sensor, rail pressure solenoid, high pressure

line, and the return flow line are attached to the fuel

rail (Fig. 7).

OPERATION

The stored fuel volume inside the rail acts as a

damper for pressure fluctuations which result

because of pulsating supply and brief large extrac-

tions of fuel during injector firing. The rail primarily

influences the atomization of fuel at the injector noz-

zle, and the accuracy of injected quantity during

injection.

REMOVAL

(Refer to 14 - FUEL SYSTEM - WARNING).

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Disconnect negative battery cable.

(2) Partially drain cooling system from radiator

only.

(3) Remove thermostat housing.

(4) Disconnect engine wiring electrical connectors

from sensors restricting harness movement.

(5) Remove engine harness retaining bolts.

(6) Remove fuel temperature sensor from fuel rail.

(7) Remove fuel rail retaining bolts and disconnect

glow plug connectors.

(8) Remove front engine lift support.

CAUTION: When slackening and tightening fuel

injection line union nuts, counter hold with wrench

at threaded connection. ON NO ACCOUNT exceed

the tightening torque at any time. Do NOT crimp or

bend lines.

NOTE: After removing lines, seal connections and

ensure cleanliness.

(9) Remove injector high pressure lines (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- REMOVAL) (Fig. 7).

(10) Remove pressure line of high pressure pump

(Fig. 7).

(11) Detach fuel return flow line to high pressure

pump at rail (Fig. 7).

(12) Detach fuel return flow line to fuel filter at

fuel filter (Fig. 7).

(13) Remove fuel rail (Fig. 7).

INSTALLATION

(Refer to 14 - FUEL SYSTEM - WARNING)

WARNING: NO FIRE, FLAMES OR SMOKING. RISK

OF POISONING FROM INHALING OR SWALLOWING

FUEL. RISK OF INJURY TO EYES AND SKIN FROM

CONTACT WITH FUEL. POUR FUELS ONLY INTO

SUITABLE AND APPROPRIATELY MARKED CON-

TAINERS. WEAR PROTECTIVE CLOTHING.

VAFUEL DELIVERY 14 - 11

FUEL PUMP (Continued)

Page 840 of 1232

(1) Loosely position fuel rail into position on cylin-

der head.

(2) Position and loosely install fuel return line

from fuel filter, with new seals to rail (Fig. 7).

(3) Position fuel rail to cylinder head, feed in high

pressure line with new seals (Fig. 7).

CAUTION: Inspect sealing cones at the lines.

Replace as necessary. Ensure that all fuel pressure

lines are exactly located in original position.

(4) Hand start all injector lines (Fig. 7).

CAUTION: When tightening fuel injection line union

nuts, counter hold with a wrench at the thread con-

nection. ON NO ACCOUNT exceed the tightening

torque at any time.

(5) Tighten fuel rail bolts to 14 N´m (124 lbs.in.)

(Fig. 7).

(6) Tighten nut of pressure line to rail/injector to

22N´m (194 lbs.in.).

(7) Tighten nut of pressure line to high pressure

pump/rail to 22N´m (194 lbs.in.).(8) Tighten banjo bolt of fuel return line to fuel

rail to 20N´m (177 lbs.in.).

(9) Install fuel temperature sensor.

(10) Install front engine support lift.

(11) Install thermostat housing.

(12) Reconnect engine harness electrical connec-

tors (Fig. 7).

(13) Refill cooling system.

(14) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH FAN. DO NOT PUT YOUR

HANDS NEAR PULLEYS, BELTS OR FAN. DO NOT

WEAR LOOSE CLOTHING.

(15) Start engine and inspect for leaks (Refer to 14

- FUEL SYSTEM - WARNING).

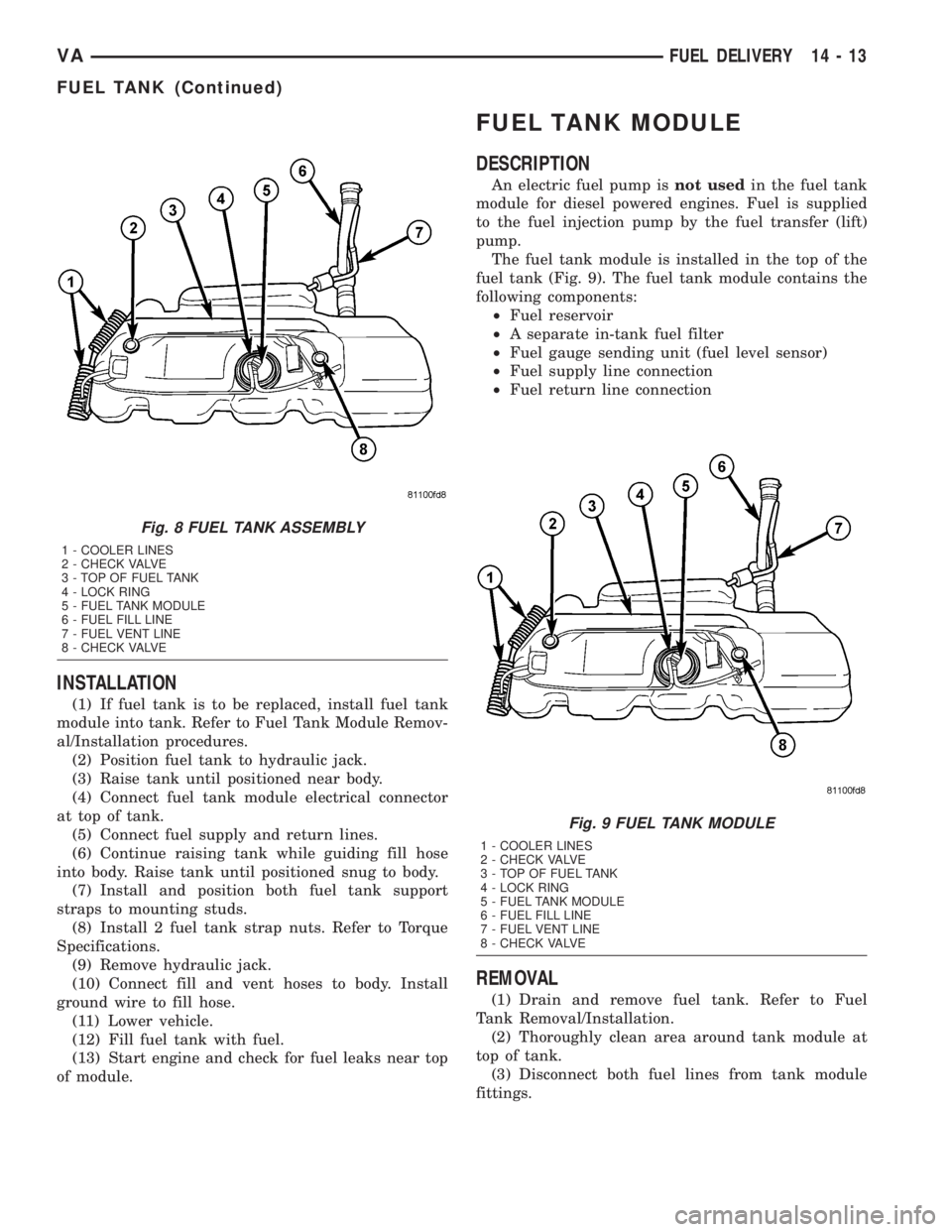

FUEL TANK

DESCRIPTION

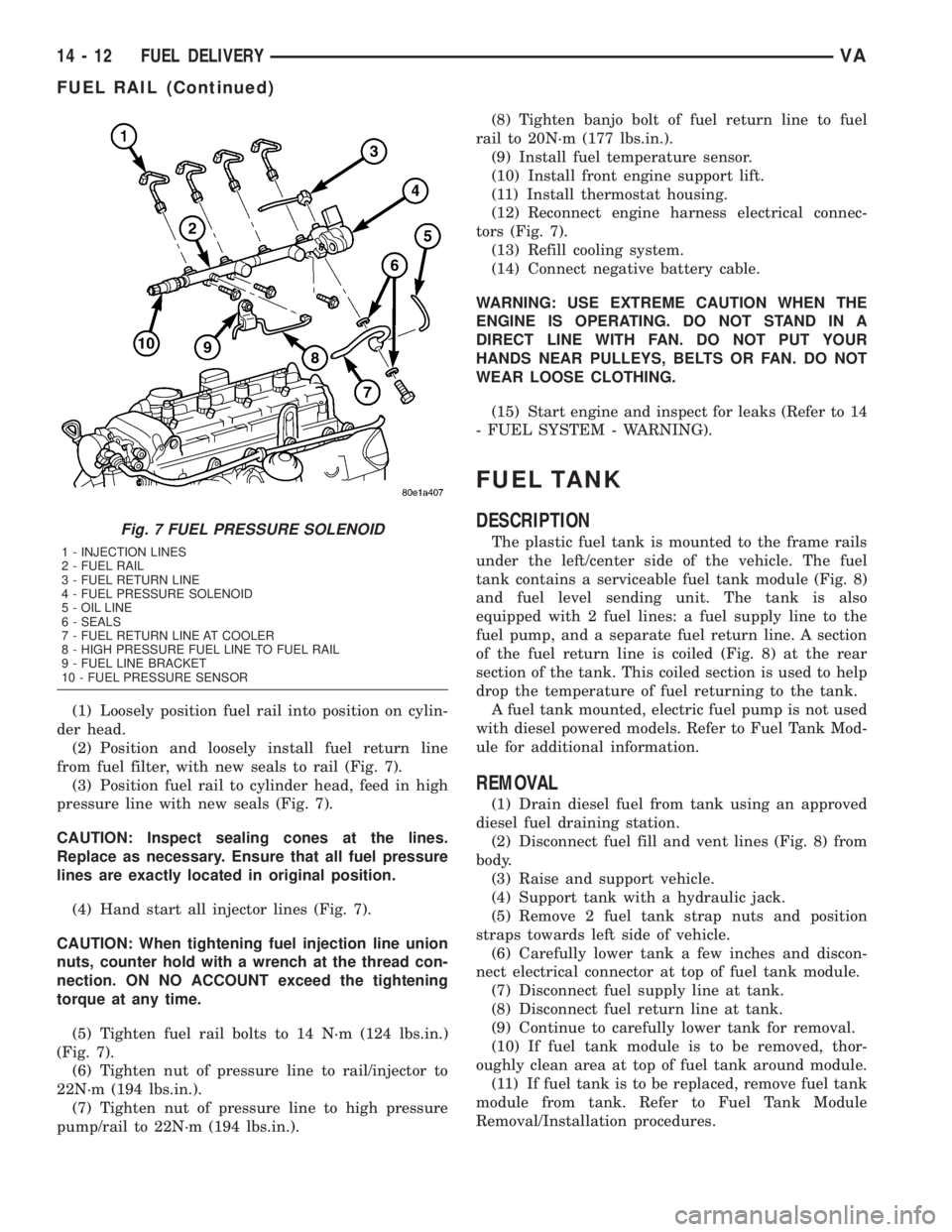

The plastic fuel tank is mounted to the frame rails

under the left/center side of the vehicle. The fuel

tank contains a serviceable fuel tank module (Fig. 8)

and fuel level sending unit. The tank is also

equipped with 2 fuel lines: a fuel supply line to the

fuel pump, and a separate fuel return line. A section

of the fuel return line is coiled (Fig. 8) at the rear

section of the tank. This coiled section is used to help

drop the temperature of fuel returning to the tank.

A fuel tank mounted, electric fuel pump is not used

with diesel powered models. Refer to Fuel Tank Mod-

ule for additional information.

REMOVAL

(1) Drain diesel fuel from tank using an approved

diesel fuel draining station.

(2) Disconnect fuel fill and vent lines (Fig. 8) from

body.

(3) Raise and support vehicle.

(4) Support tank with a hydraulic jack.

(5) Remove 2 fuel tank strap nuts and position

straps towards left side of vehicle.

(6) Carefully lower tank a few inches and discon-

nect electrical connector at top of fuel tank module.

(7) Disconnect fuel supply line at tank.

(8) Disconnect fuel return line at tank.

(9) Continue to carefully lower tank for removal.

(10) If fuel tank module is to be removed, thor-

oughly clean area at top of fuel tank around module.

(11) If fuel tank is to be replaced, remove fuel tank

module from tank. Refer to Fuel Tank Module

Removal/Installation procedures.

Fig. 7 FUEL PRESSURE SOLENOID

1 - INJECTION LINES

2 - FUEL RAIL

3 - FUEL RETURN LINE

4 - FUEL PRESSURE SOLENOID

5 - OIL LINE

6 - SEALS

7 - FUEL RETURN LINE AT COOLER

8 - HIGH PRESSURE FUEL LINE TO FUEL RAIL

9 - FUEL LINE BRACKET

10 - FUEL PRESSURE SENSOR

14 - 12 FUEL DELIVERYVA

FUEL RAIL (Continued)

Page 841 of 1232

INSTALLATION

(1) If fuel tank is to be replaced, install fuel tank

module into tank. Refer to Fuel Tank Module Remov-

al/Installation procedures.

(2) Position fuel tank to hydraulic jack.

(3) Raise tank until positioned near body.

(4) Connect fuel tank module electrical connector

at top of tank.

(5) Connect fuel supply and return lines.

(6) Continue raising tank while guiding fill hose

into body. Raise tank until positioned snug to body.

(7) Install and position both fuel tank support

straps to mounting studs.

(8) Install 2 fuel tank strap nuts. Refer to Torque

Specifications.

(9) Remove hydraulic jack.

(10) Connect fill and vent hoses to body. Install

ground wire to fill hose.

(11) Lower vehicle.

(12) Fill fuel tank with fuel.

(13) Start engine and check for fuel leaks near top

of module.

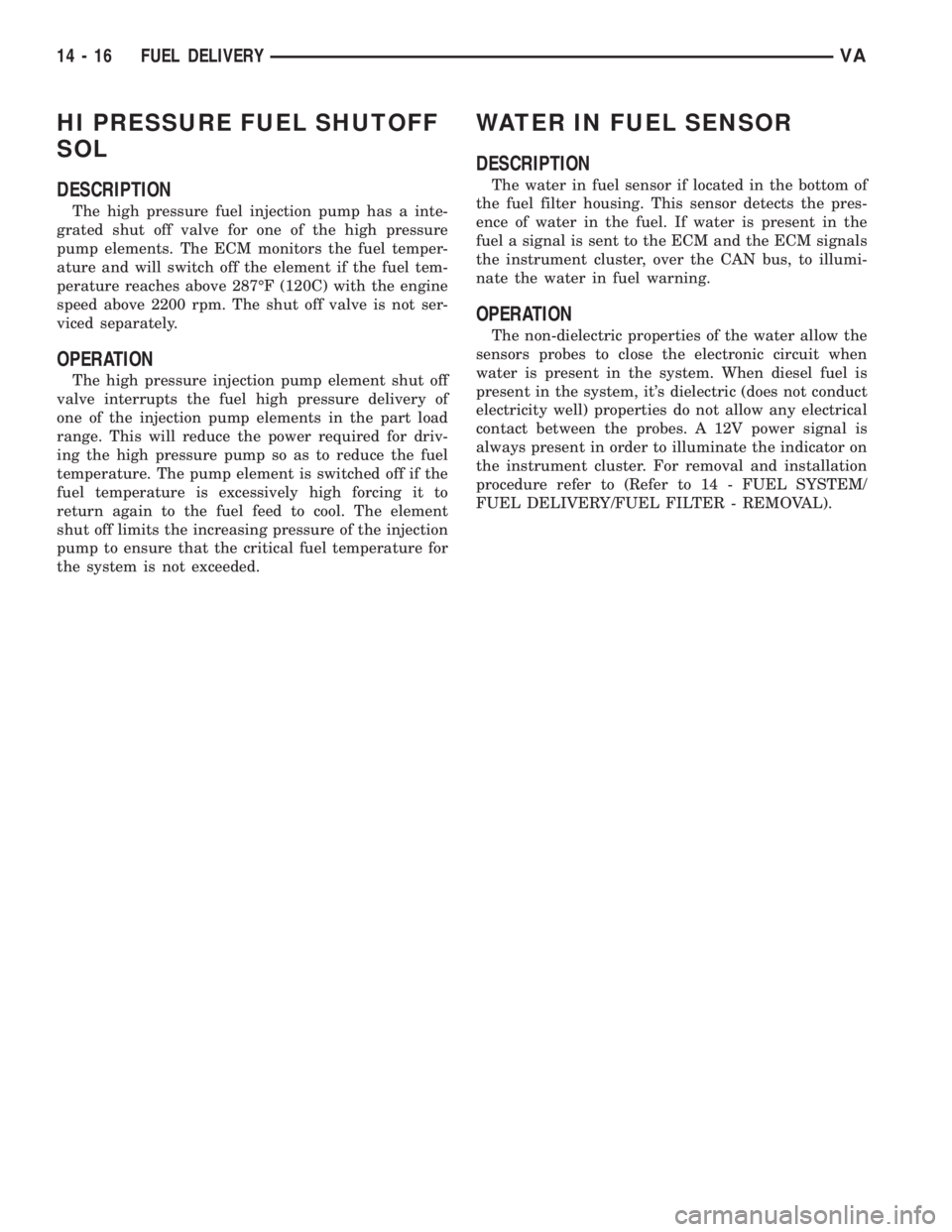

FUEL TANK MODULE

DESCRIPTION

An electric fuel pump isnot usedin the fuel tank

module for diesel powered engines. Fuel is supplied

to the fuel injection pump by the fuel transfer (lift)

pump.

The fuel tank module is installed in the top of the

fuel tank (Fig. 9). The fuel tank module contains the

following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection

²Fuel return line connection

REMOVAL

(1) Drain and remove fuel tank. Refer to Fuel

Tank Removal/Installation.

(2) Thoroughly clean area around tank module at

top of tank.

(3) Disconnect both fuel lines from tank module

fittings.

Fig. 8 FUEL TANK ASSEMBLY

1 - COOLER LINES

2 - CHECK VALVE

3 - TOP OF FUEL TANK

4 - LOCK RING

5 - FUEL TANK MODULE

6 - FUEL FILL LINE

7 - FUEL VENT LINE

8 - CHECK VALVE

Fig. 9 FUEL TANK MODULE

1 - COOLER LINES

2 - CHECK VALVE

3 - TOP OF FUEL TANK

4 - LOCK RING

5 - FUEL TANK MODULE

6 - FUEL FILL LINE

7 - FUEL VENT LINE

8 - CHECK VALVE

VAFUEL DELIVERY 14 - 13

FUEL TANK (Continued)

Page 844 of 1232

HI PRESSURE FUEL SHUTOFF

SOL

DESCRIPTION

The high pressure fuel injection pump has a inte-

grated shut off valve for one of the high pressure

pump elements. The ECM monitors the fuel temper-

ature and will switch off the element if the fuel tem-

perature reaches above 287ÉF (120C) with the engine

speed above 2200 rpm. The shut off valve is not ser-

viced separately.

OPERATION

The high pressure injection pump element shut off

valve interrupts the fuel high pressure delivery of

one of the injection pump elements in the part load

range. This will reduce the power required for driv-

ing the high pressure pump so as to reduce the fuel

temperature. The pump element is switched off if the

fuel temperature is excessively high forcing it to

return again to the fuel feed to cool. The element

shut off limits the increasing pressure of the injection

pump to ensure that the critical fuel temperature for

the system is not exceeded.

WATER IN FUEL SENSOR

DESCRIPTION

The water in fuel sensor if located in the bottom of

the fuel filter housing. This sensor detects the pres-

ence of water in the fuel. If water is present in the

fuel a signal is sent to the ECM and the ECM signals

the instrument cluster, over the CAN bus, to illumi-

nate the water in fuel warning.

OPERATION

The non-dielectric properties of the water allow the

sensors probes to close the electronic circuit when

water is present in the system. When diesel fuel is

present in the system, it's dielectric (does not conduct

electricity well) properties do not allow any electrical

contact between the probes. A 12V power signal is

always present in order to illuminate the indicator on

the instrument cluster. For removal and installation

procedure refer to (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL FILTER - REMOVAL).

14 - 16 FUEL DELIVERYVA

Page 845 of 1232

FUEL INJECTION

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................17

BOOST PRESSURE SENSOR

DESCRIPTION.........................17

OPERATION...........................18

DIAGNOSIS AND TESTING - BOOST

PRESSURE SENSOR..................18

REMOVAL.............................18

INSTALLATION.........................18

CAMSHAFT POSITION SENSOR

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

FUEL INJECTOR

DESCRIPTION

FUEL INJECTOR......................20

OPERATION...........................20

STANDARD PROCEDURE

STANDARD PROCEDURE - INJECTOR

CLASSIFICATION.....................22

STANDARD PROCEDURE - CLEANING

FUEL INJECTORS.....................22

REMOVAL.............................23

INSTALLATION.........................23

FUEL PRESSURE SENSOR

DESCRIPTION

DESCRIPTION........................25DESCRIPTION........................25

OPERATION

OPERATION.........................25

OPERATION.........................25

REMOVAL

REMOVAL...........................26

REMOVAL...........................26

INSTALLATION

INSTALLATION.......................26

INSTALLATION.......................27

FUEL PRESSURE SOLENOID

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

FUEL TEMPERATURE SENSOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................29

INLET AIR TEMPERATURE SENSOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................30

INSTALLATION.........................30

MANIFOLD AIR FLOW (MAF) SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................31

INSTALLATION.........................31

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

The accelerator pedal position sensor is located on

the accelerator pedal assembly. The driver supplies

the torque requirements for the engine by operating

the accelerator pedal in accordance with the desired

speed or acceleration. The pedal sensor converts the

mechanical operation of the pedal into an electrical

signal and sends the information to the ECM. The

ECM adjusts the quantity of the fuel that is injected

into the engine (Fig. 1).The accelerator pedal position sensor is serviced as

an assembly with the accelerator assembly.

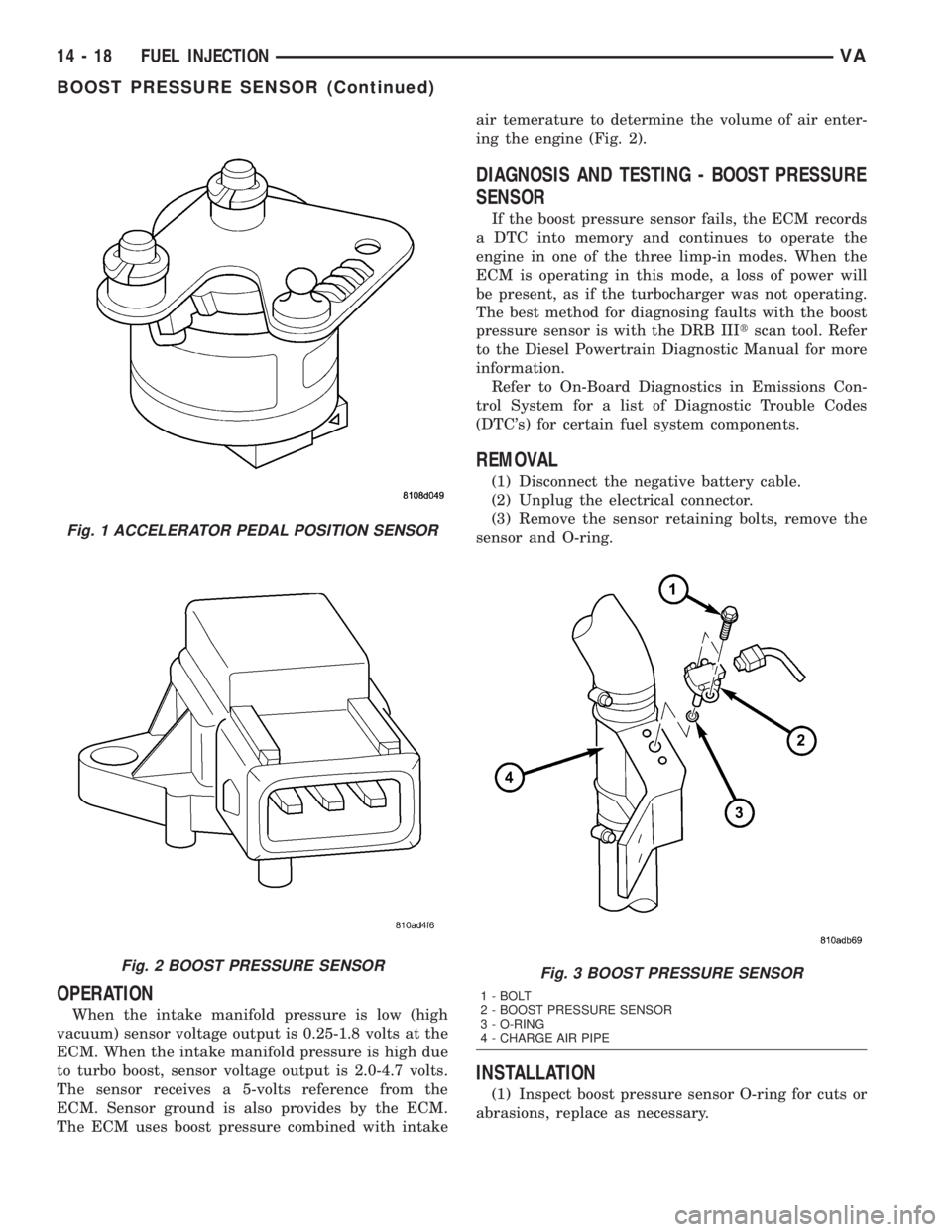

BOOST PRESSURE SENSOR

DESCRIPTION

The boost pressure sensor is mounted to the charge

air pipe (Fig. 2). The sensor allows the ECM to mon-

itor intake air down stream of the turbocharger.

VAFUEL INJECTION 14 - 17

Page 846 of 1232

OPERATION

When the intake manifold pressure is low (high

vacuum) sensor voltage output is 0.25-1.8 volts at the

ECM. When the intake manifold pressure is high due

to turbo boost, sensor voltage output is 2.0-4.7 volts.

The sensor receives a 5-volts reference from the

ECM. Sensor ground is also provides by the ECM.

The ECM uses boost pressure combined with intakeair temerature to determine the volume of air enter-

ing the engine (Fig. 2).

DIAGNOSIS AND TESTING - BOOST PRESSURE

SENSOR

If the boost pressure sensor fails, the ECM records

a DTC into memory and continues to operate the

engine in one of the three limp-in modes. When the

ECM is operating in this mode, a loss of power will

be present, as if the turbocharger was not operating.

The best method for diagnosing faults with the boost

pressure sensor is with the DRB IIItscan tool. Refer

to the Diesel Powertrain Diagnostic Manual for more

information.

Refer to On-Board Diagnostics in Emissions Con-

trol System for a list of Diagnostic Trouble Codes

(DTC's) for certain fuel system components.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Unplug the electrical connector.

(3) Remove the sensor retaining bolts, remove the

sensor and O-ring.

INSTALLATION

(1) Inspect boost pressure sensor O-ring for cuts or

abrasions, replace as necessary.

Fig. 1 ACCELERATOR PEDAL POSITION SENSOR

Fig. 2 BOOST PRESSURE SENSORFig. 3 BOOST PRESSURE SENSOR

1 - BOLT

2 - BOOST PRESSURE SENSOR

3 - O-RING

4 - CHARGE AIR PIPE

14 - 18 FUEL INJECTIONVA

BOOST PRESSURE SENSOR (Continued)

Page 847 of 1232

(2) Position the boost pressure sensor above access

hole in the charge air pipe and push down to fit flush

(Fig. 3).

(3) Install the bolts and tighten to 44 lbs. in. (5

N´m) (Fig. 3).

(4) Reconnect the sensor electrical connector (Fig.

3).

(5) Connect negative battery cable

CAMSHAFT POSITION

SENSOR

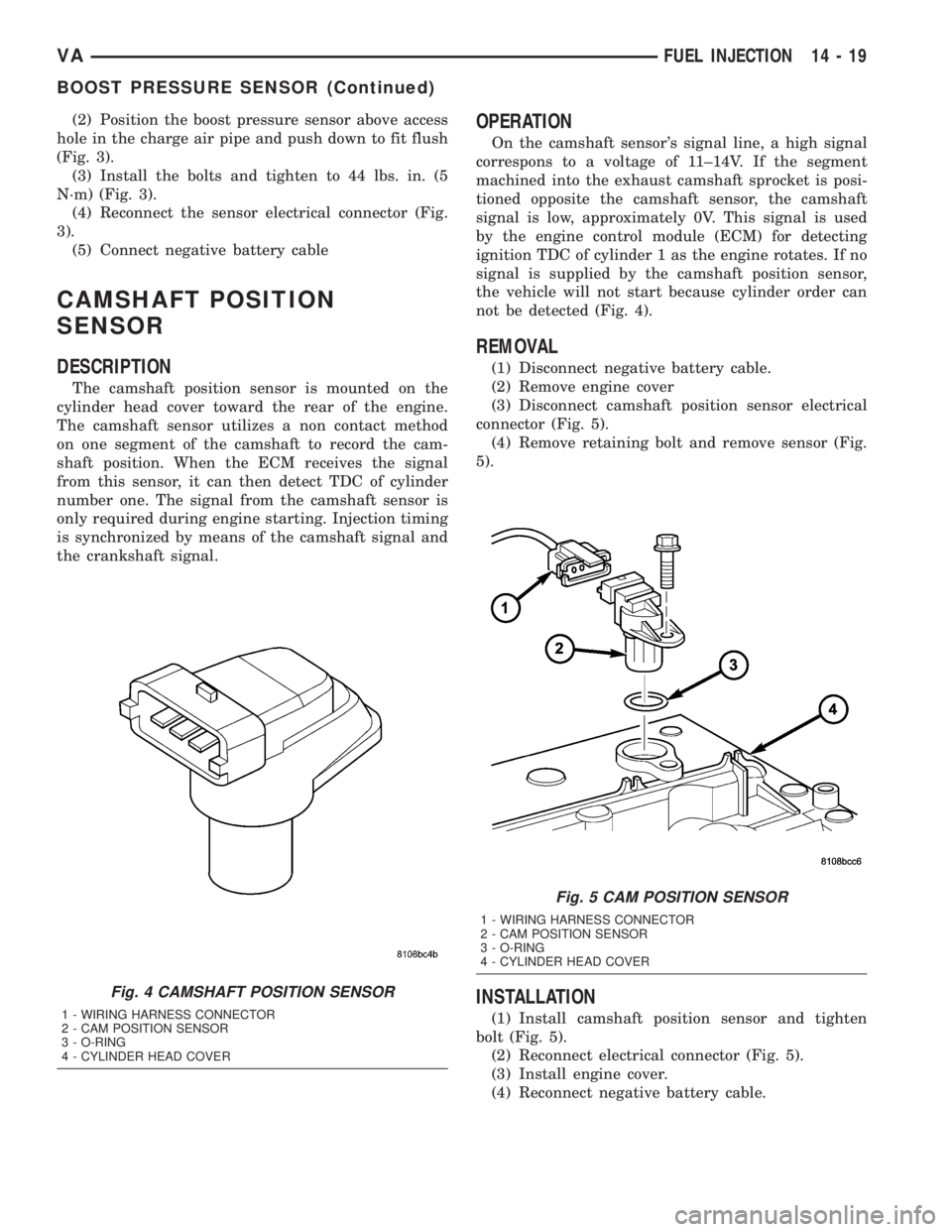

DESCRIPTION

The camshaft position sensor is mounted on the

cylinder head cover toward the rear of the engine.

The camshaft sensor utilizes a non contact method

on one segment of the camshaft to record the cam-

shaft position. When the ECM receives the signal

from this sensor, it can then detect TDC of cylinder

number one. The signal from the camshaft sensor is

only required during engine starting. Injection timing

is synchronized by means of the camshaft signal and

the crankshaft signal.

OPERATION

On the camshaft sensor's signal line, a high signal

correspons to a voltage of 11±14V. If the segment

machined into the exhaust camshaft sprocket is posi-

tioned opposite the camshaft sensor, the camshaft

signal is low, approximately 0V. This signal is used

by the engine control module (ECM) for detecting

ignition TDC of cylinder 1 as the engine rotates. If no

signal is supplied by the camshaft position sensor,

the vehicle will not start because cylinder order can

not be detected (Fig. 4).

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover

(3) Disconnect camshaft position sensor electrical

connector (Fig. 5).

(4) Remove retaining bolt and remove sensor (Fig.

5).

INSTALLATION

(1) Install camshaft position sensor and tighten

bolt (Fig. 5).

(2) Reconnect electrical connector (Fig. 5).

(3) Install engine cover.

(4) Reconnect negative battery cable.

Fig. 4 CAMSHAFT POSITION SENSOR

1 - WIRING HARNESS CONNECTOR

2 - CAM POSITION SENSOR

3 - O-RING

4 - CYLINDER HEAD COVER

Fig. 5 CAM POSITION SENSOR

1 - WIRING HARNESS CONNECTOR

2 - CAM POSITION SENSOR

3 - O-RING

4 - CYLINDER HEAD COVER

VAFUEL INJECTION 14 - 19

BOOST PRESSURE SENSOR (Continued)

Page 848 of 1232

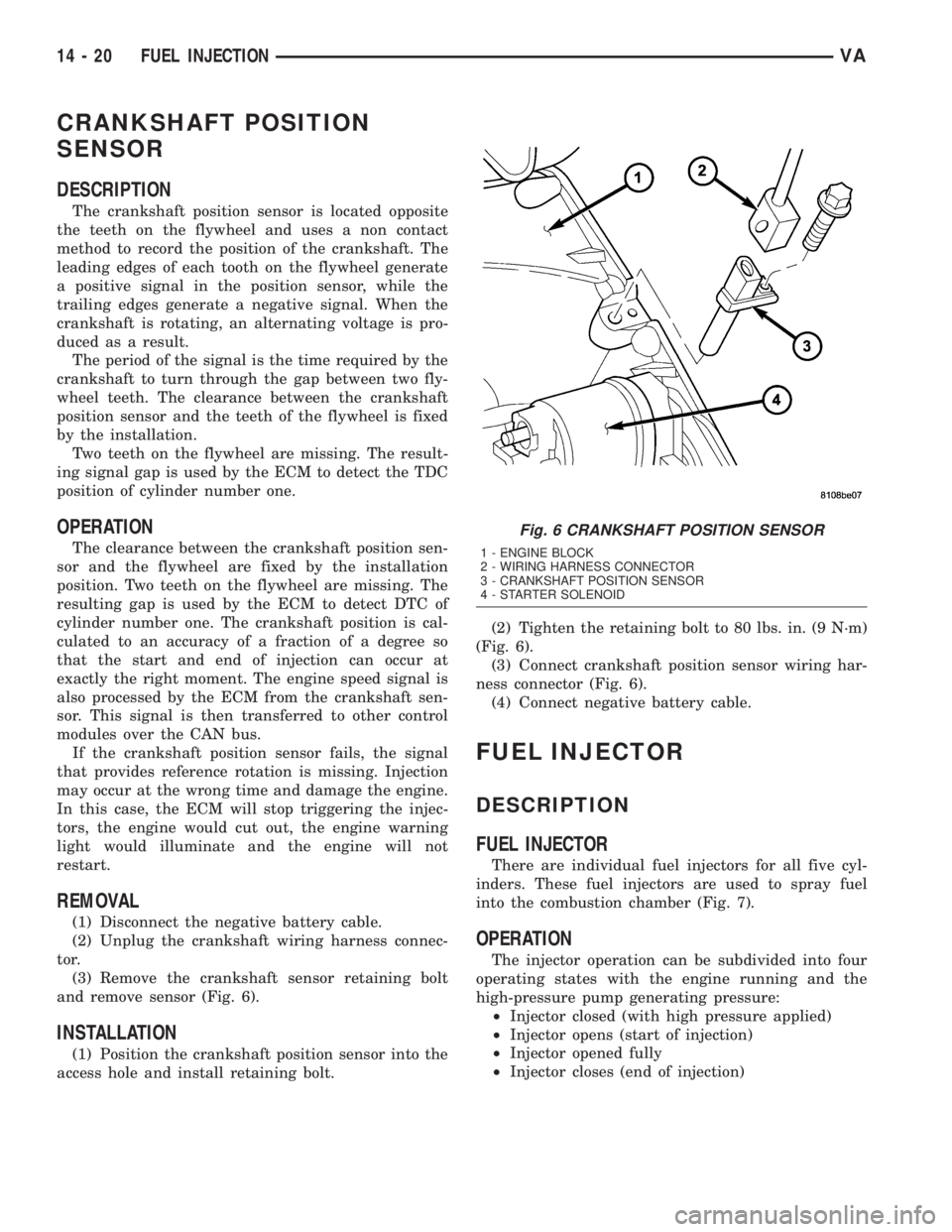

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

The crankshaft position sensor is located opposite

the teeth on the flywheel and uses a non contact

method to record the position of the crankshaft. The

leading edges of each tooth on the flywheel generate

a positive signal in the position sensor, while the

trailing edges generate a negative signal. When the

crankshaft is rotating, an alternating voltage is pro-

duced as a result.

The period of the signal is the time required by the

crankshaft to turn through the gap between two fly-

wheel teeth. The clearance between the crankshaft

position sensor and the teeth of the flywheel is fixed

by the installation.

Two teeth on the flywheel are missing. The result-

ing signal gap is used by the ECM to detect the TDC

position of cylinder number one.

OPERATION

The clearance between the crankshaft position sen-

sor and the flywheel are fixed by the installation

position. Two teeth on the flywheel are missing. The

resulting gap is used by the ECM to detect DTC of

cylinder number one. The crankshaft position is cal-

culated to an accuracy of a fraction of a degree so

that the start and end of injection can occur at

exactly the right moment. The engine speed signal is

also processed by the ECM from the crankshaft sen-

sor. This signal is then transferred to other control

modules over the CAN bus.

If the crankshaft position sensor fails, the signal

that provides reference rotation is missing. Injection

may occur at the wrong time and damage the engine.

In this case, the ECM will stop triggering the injec-

tors, the engine would cut out, the engine warning

light would illuminate and the engine will not

restart.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Unplug the crankshaft wiring harness connec-

tor.

(3) Remove the crankshaft sensor retaining bolt

and remove sensor (Fig. 6).

INSTALLATION

(1) Position the crankshaft position sensor into the

access hole and install retaining bolt.(2) Tighten the retaining bolt to 80 lbs. in. (9 N´m)

(Fig. 6).

(3) Connect crankshaft position sensor wiring har-

ness connector (Fig. 6).

(4) Connect negative battery cable.

FUEL INJECTOR

DESCRIPTION

FUEL INJECTOR

There are individual fuel injectors for all five cyl-

inders. These fuel injectors are used to spray fuel

into the combustion chamber (Fig. 7).

OPERATION

The injector operation can be subdivided into four

operating states with the engine running and the

high-pressure pump generating pressure:

²Injector closed (with high pressure applied)

²Injector opens (start of injection)

²Injector opened fully

²Injector closes (end of injection)

Fig. 6 CRANKSHAFT POSITION SENSOR

1 - ENGINE BLOCK

2 - WIRING HARNESS CONNECTOR

3 - CRANKSHAFT POSITION SENSOR

4 - STARTER SOLENOID

14 - 20 FUEL INJECTIONVA