engine MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 874 of 1232

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Power Steering Pump To

Timing Case Cover/

Support21 15 185

High Pressure Flexible

Hose To Power Steering

Pump38 28 336

Power Steering Pulley To

Pump30 22 265

FLUID

STANDARD PROCEDURE

POWER STEERING PUMP FILL AND BLEED

PROCEDURE

(1) Remove the cap from the fluid reservoir.

Check cap seal for damage and replace if

needed.

(2) Fill the power steering pump with Mopar

ATF+4 Automatic Transmission fluid or equivalent.

Do not fill fluid beyond the MAX mark.

(3) Raise the vehicles front wheels off the ground.

(4) With the engine off turn the steering wheel

from right to left.Perform this step until all the

bubble formations can no longer be seen in the

power steering reservoir.

(5) Start the engine and turn the steering wheel

with the engine at idle speed then shut the engine off

and check for correct oil level and no bubble in the

system.

(6) Reinstall power steering cap tightly.

(7) Test the system for leaks and proper operation.

FLUID COOLER TUBE

REMOVAL

(1) Siphon as much power steering fluid as possi-

ble out of the reservoir.

(2) Remove the grille (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL).

(3) Remove the left headlight assembly.

(4) Disconnect the return lines from the cooler

tube.

(5) Remove the radiator clips (2).

(6) Remove the heat shield bolt for the turbo at

the core support.

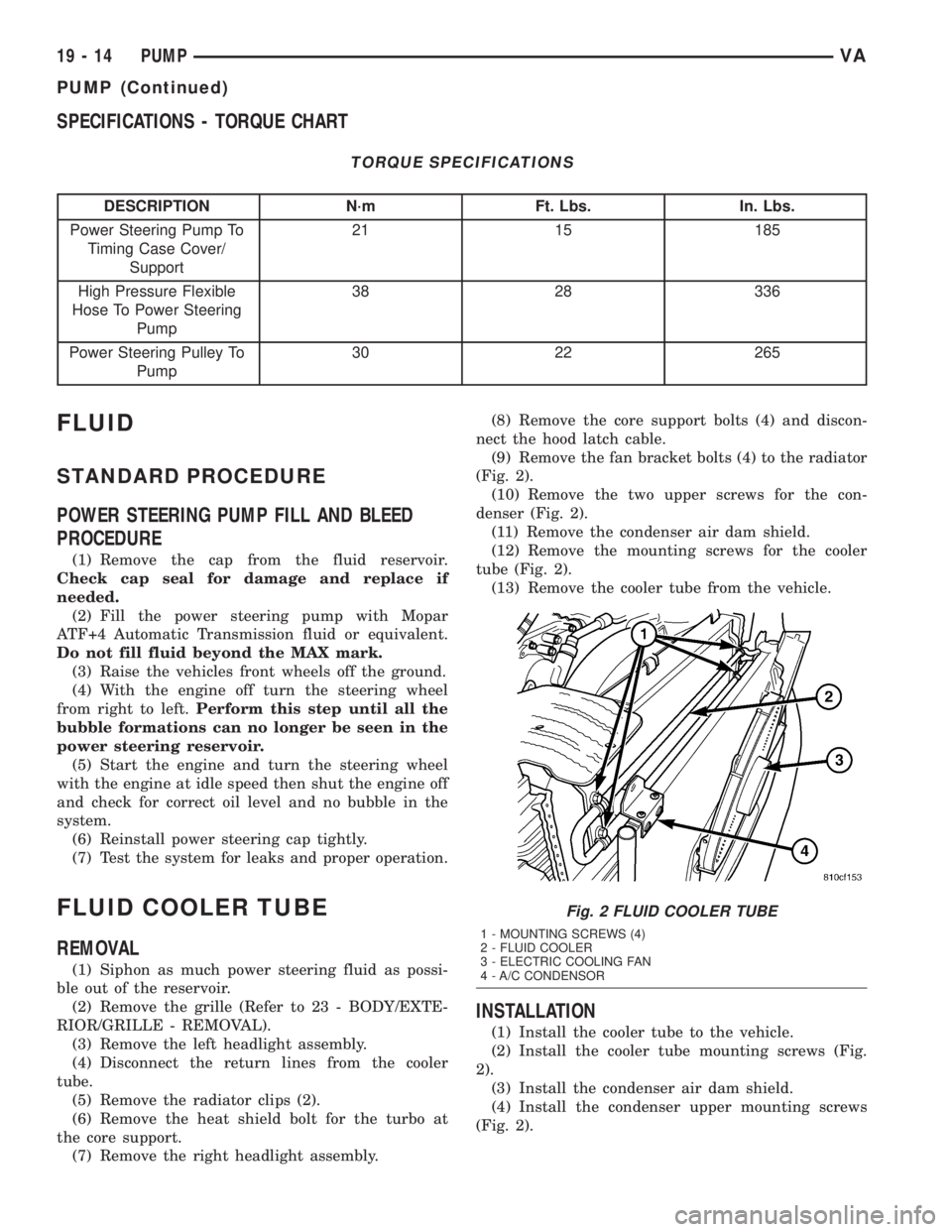

(7) Remove the right headlight assembly.(8) Remove the core support bolts (4) and discon-

nect the hood latch cable.

(9) Remove the fan bracket bolts (4) to the radiator

(Fig. 2).

(10) Remove the two upper screws for the con-

denser (Fig. 2).

(11) Remove the condenser air dam shield.

(12) Remove the mounting screws for the cooler

tube (Fig. 2).

(13) Remove the cooler tube from the vehicle.

INSTALLATION

(1) Install the cooler tube to the vehicle.

(2) Install the cooler tube mounting screws (Fig.

2).

(3) Install the condenser air dam shield.

(4) Install the condenser upper mounting screws

(Fig. 2).

Fig. 2 FLUID COOLER TUBE

1 - MOUNTING SCREWS (4)

2 - FLUID COOLER

3 - ELECTRIC COOLING FAN

4 - A/C CONDENSOR

19 - 14 PUMPVA

PUMP (Continued)

Page 878 of 1232

OUTPUT SHAFT SEAL

REMOVAL............................125

INSTALLATION........................125

PARK LOCK CABLE

REMOVAL............................125

INSTALLATION........................126

PISTONS

DESCRIPTION........................128

OPERATION..........................128

PLANETARY GEARTRAIN

DESCRIPTION........................130

OPERATION..........................130

DISASSEMBLY........................131

ASSEMBLY...........................131

SHIFT MECHANISM

DESCRIPTION........................133

OPERATION..........................133

REMOVAL............................134

INSTALLATION........................135

SOLENOID

DESCRIPTION........................136OPERATION..........................138

TEMPERATURE SENSOR/PARK-NEUTRAL

CONTACT

DESCRIPTION

DESCRIPTION - PARK/NEUTRAL CONTACT . 139

DESCRIPTION - TRANSMISSION

TEMPERATURE SENSOR..............140

OPERATION

OPERATION - PARK/NEUTRAL CONTACT . . 140

OPERATION - TRANSMISSION

TEMPERATURE SENSOR..............141

TORQUE CONVERTER

DESCRIPTION........................141

OPERATION..........................143

REMOVAL............................146

INSTALLATION........................146

TORQUE CONVERTER HUB SEAL

REMOVAL............................147

INSTALLATION........................147

AUTOMATIC TRANSMISSION -

NAG1

DESCRIPTION

The NAG1 automatic transmission (Fig. 1) is an

electronically controlled 5-speed transmission with a

lock-up clutch in the torque converter. The ratios for

the gear stages are obtained by 3 planetary gear sets.

Fifth gear is designed as an overdrive with a high-

speed ratio.

The gears are actuated electronically/hydraulically.

The gears are shifted by means of an appropriate

combination of three multi-disc holding clutches,

three multi-disc driving clutches, and two freewheel-

ing clutches.

Electronic transmission control enables precise

adaptation of pressures to the respective operating

conditions and to the engine output during the shift

phase which results in a significant improvement in

shift quality.

Furthermore, it offers the advantage of a flexible

adaptation to various vehicle and engines.

Basically, the automatic transmission with elec-

tronic control offers the following advantages:

²Reduces fuel consumption.

²Improved shift comfort.

²More favourable step-up through the five gears.

²Increased service life and reliability.

²Lower maintenance costs.

TRANSMISSION IDENTIFICATION

The transmission name, NAG1, means New Auto-

matic Gearbox, generation 1.

The transmission can be generically identified

visually by the presence of a round 13-way connector

located near the front corner of the transmission oil

pan, on the right side. Specific transmission informa-

tion can be found stamped into a pad on the left side

of the transmission, above the oil pan rail.

TRANSMISSION GEAR RATIOS

The gear ratios for the NAG1 automatic transmis-

sion are as follows:

1st Gear.............................3.59:1

2nd Gear............................2.19:1

3rd Gear............................1.41:1

4th Gear............................1.00:1

5th Gear............................0.83:1

Reverse.............................3.16:1

TRANSMISSION HOUSING

The converter housing and transmission are made

from a light alloy. These are bolted together and cen-

tered via the outer multi-disc carrier of multi-disc

holding clutch, B1. A coated intermediate plate pro-

vides the sealing. The oil pump and the outer multi-

disc carrier of the multi-disc holding clutch, B1, are

bolted to the converter housing. The stator shaft is

pressed into it and prevented from rotating by

splines. The electrohydraulic unit is bolted to the

transmission housing from underneath. A sheet

metal steel oil pan forms the closure.

21 - 2 AUTOMATIC TRANSMISSION - NAG1VA

Page 880 of 1232

SHIFT GROUPS

The hydraulic control components (including actua-

tors) which are responsible for the pressure distribu-

tion before, during, and after a gear change are

described as a shift group. Each shift group contains

a command valve, a holding pressure shift valve, a

shift pressure shift valve, overlap regulating valve,

and a solenoid.

The hydraulic system contains three shift groups:

1-2/4-5, 2-3, and 3-4. Each shift group can also be

described as being in one of two possible states. The

active shift group is described as being in the shift

phase when it is actively engaging/disengaging a

clutch combination. The 1-2/4-5 shift group control

the B1 and K1 clutches. The 2-3 shift group controls

the K2 and K3 clutches. The 3-4 shift group controls

the K3 and B2 clutches.

OPERATION

The transmission control is divided into the elec-

tronic and hydraulic transmission control functions.

While the electronic transmission control is responsi-

ble for gear selection and for matching the pressures

to the torque to be transmitted, the transmission's

power supply control occurs via hydraulic elements

in the electrohydraulic control module. The oil supply

to the hydraulic elements, such as the hydrodynamic

torque converter, the shift elements and the hydrau-

lic transmission control, is provided by way of an oil

pump connected with the torque converter.

The Transmission Control Module (TCM) allows for

the precise adaptation of pressures to the correspond-

ing operating conditions and to the engine output

during the gearshift phase, resulting in a noticeable

improvement in shift quality. The engine speed limit

can be reached in the individual gears at full throttle

and kickdown. The shift range can be changed in the

forward gears while driving, but the TCM employs adownshift safeguard to prevent over-revving the

engine. The system offers the additional advantage of

flexible adaptation to different vehicle and engine

variants.

EMERGENCY RUNNING FUNCTION

In order to ensure a safe driving state and to pre-

vent damage to the automatic transmission, the TCM

control module switches to limp-home mode in the

event of critical faults. A DTC assigned to the fault is

stored in memory. All solenoid and regulating valves

are thus de-energized.

The net effect is:

²The last engaged gear remains engaged.

²The modulating pressure and shift pressures

rise to the maximum levels.

²The torque converter lockup clutch is deacti-

vated.

In order to preserve the operability of the vehicle

to some extent, the hydraulic control can be used to

engage 2nd gear or reverse using the following pro-

cedure:

²Stop the vehicle.

²Switch off engine.

²Move selector lever to9P9.

²Wait at least 10 seconds.

²Start engine.

²Move selector lever to D: 2nd gear.

²Move selector lever to R: Reverse gear.

The limp-home function remains active until the

DTC is rectified or the stored DTC is erased with the

DRBttool. Sporadic faults can be reset via ignition

OFF/ON.

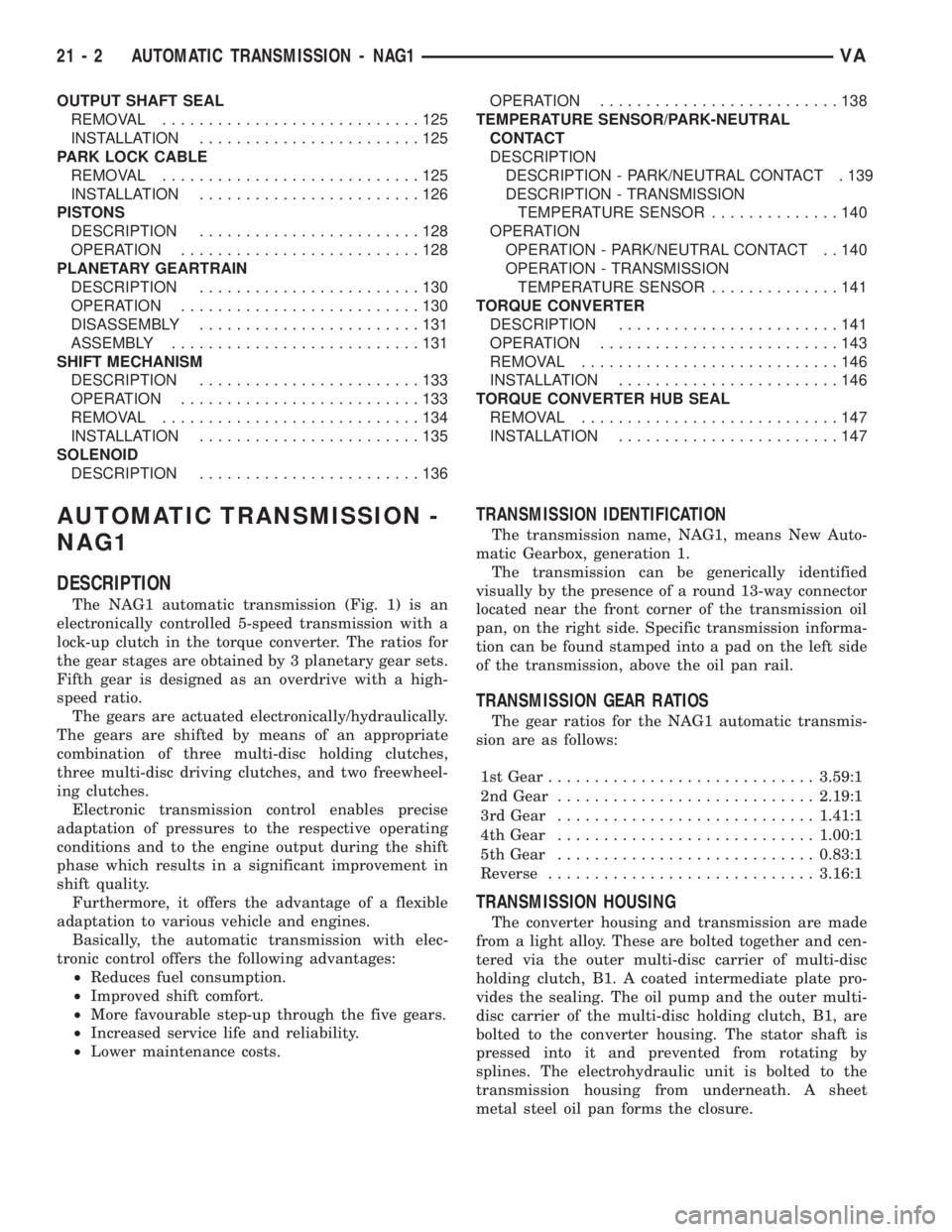

CLUTCH APPLICATION

Refer to CLUTCH APPLICATION for which shift

elements are applied in each gear position.

CLUTCH APPLICATION

GEAR RATIO B1 B2 B3 K1 K2 K3 F1 F2

1 3.59 X* X X* X X

2 2.19 X X X* X

3 1.41 X X X

4 1.00 X X X

5 0.83 X X X X*

NX X

R 3.16 X* X X X

* = The shift components required during coast.

21 - 4 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 881 of 1232

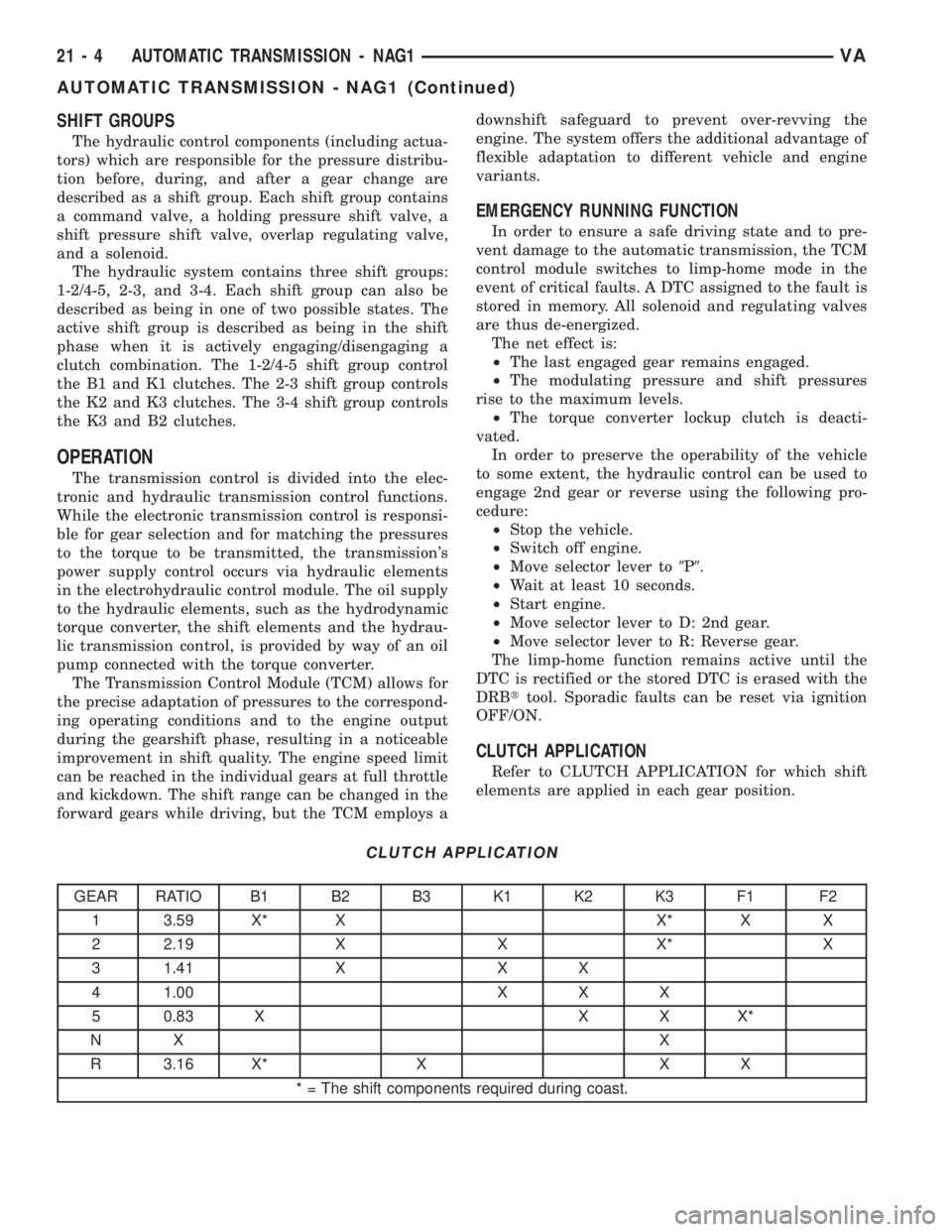

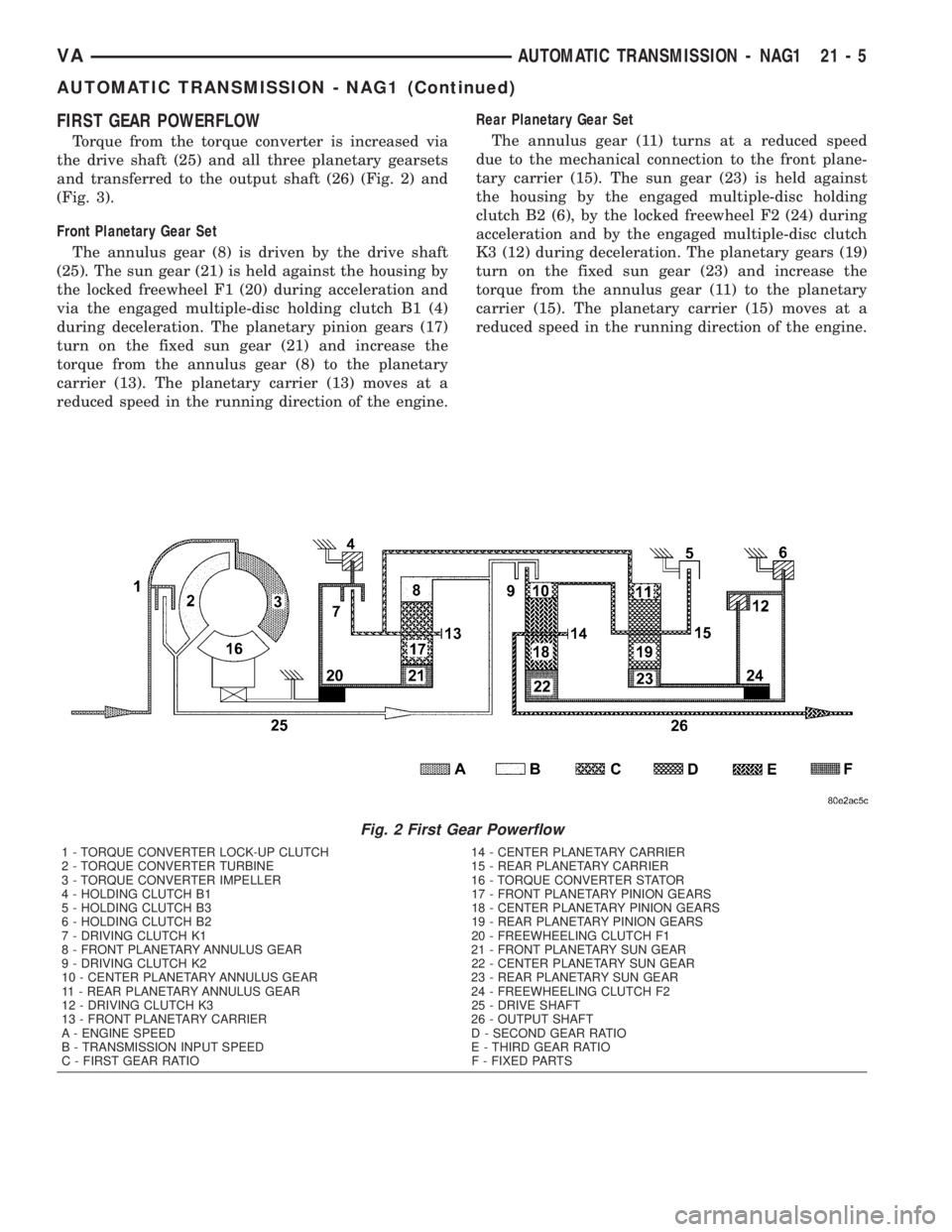

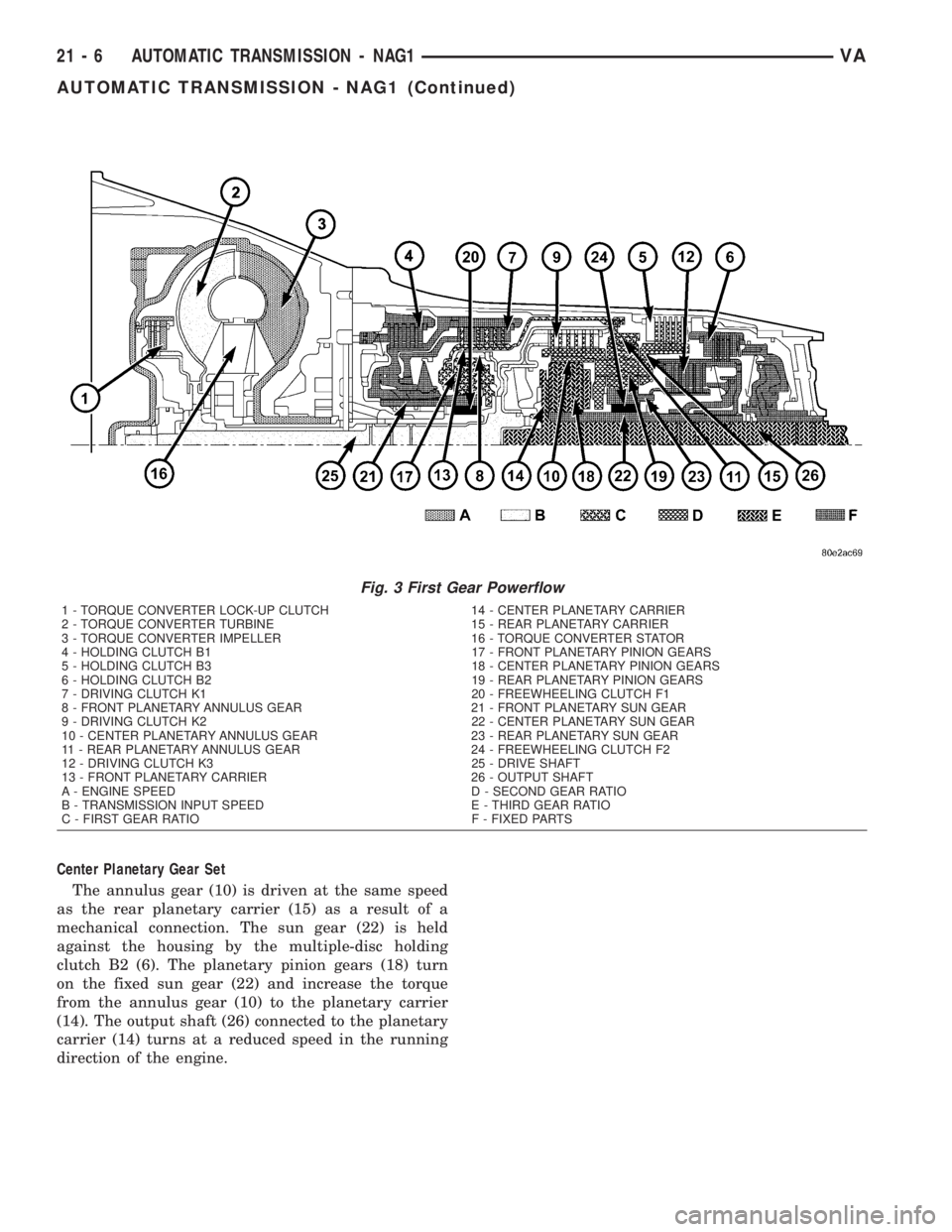

FIRST GEAR POWERFLOW

Torque from the torque converter is increased via

the drive shaft (25) and all three planetary gearsets

and transferred to the output shaft (26) (Fig. 2) and

(Fig. 3).

Front Planetary Gear Set

The annulus gear (8) is driven by the drive shaft

(25). The sun gear (21) is held against the housing by

the locked freewheel F1 (20) during acceleration and

via the engaged multiple-disc holding clutch B1 (4)

during deceleration. The planetary pinion gears (17)

turn on the fixed sun gear (21) and increase the

torque from the annulus gear (8) to the planetary

carrier (13). The planetary carrier (13) moves at a

reduced speed in the running direction of the engine.Rear Planetary Gear Set

The annulus gear (11) turns at a reduced speed

due to the mechanical connection to the front plane-

tary carrier (15). The sun gear (23) is held against

the housing by the engaged multiple-disc holding

clutch B2 (6), by the locked freewheel F2 (24) during

acceleration and by the engaged multiple-disc clutch

K3 (12) during deceleration. The planetary gears (19)

turn on the fixed sun gear (23) and increase the

torque from the annulus gear (11) to the planetary

carrier (15). The planetary carrier (15) moves at a

reduced speed in the running direction of the engine.

Fig. 2 First Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

VAAUTOMATIC TRANSMISSION - NAG1 21 - 5

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 882 of 1232

Center Planetary Gear Set

The annulus gear (10) is driven at the same speed

as the rear planetary carrier (15) as a result of a

mechanical connection. The sun gear (22) is held

against the housing by the multiple-disc holding

clutch B2 (6). The planetary pinion gears (18) turn

on the fixed sun gear (22) and increase the torque

from the annulus gear (10) to the planetary carrier

(14). The output shaft (26) connected to the planetary

carrier (14) turns at a reduced speed in the running

direction of the engine.

Fig. 3 First Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - THIRD GEAR RATIO

C - FIRST GEAR RATIO F - FIXED PARTS

21 - 6 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 883 of 1232

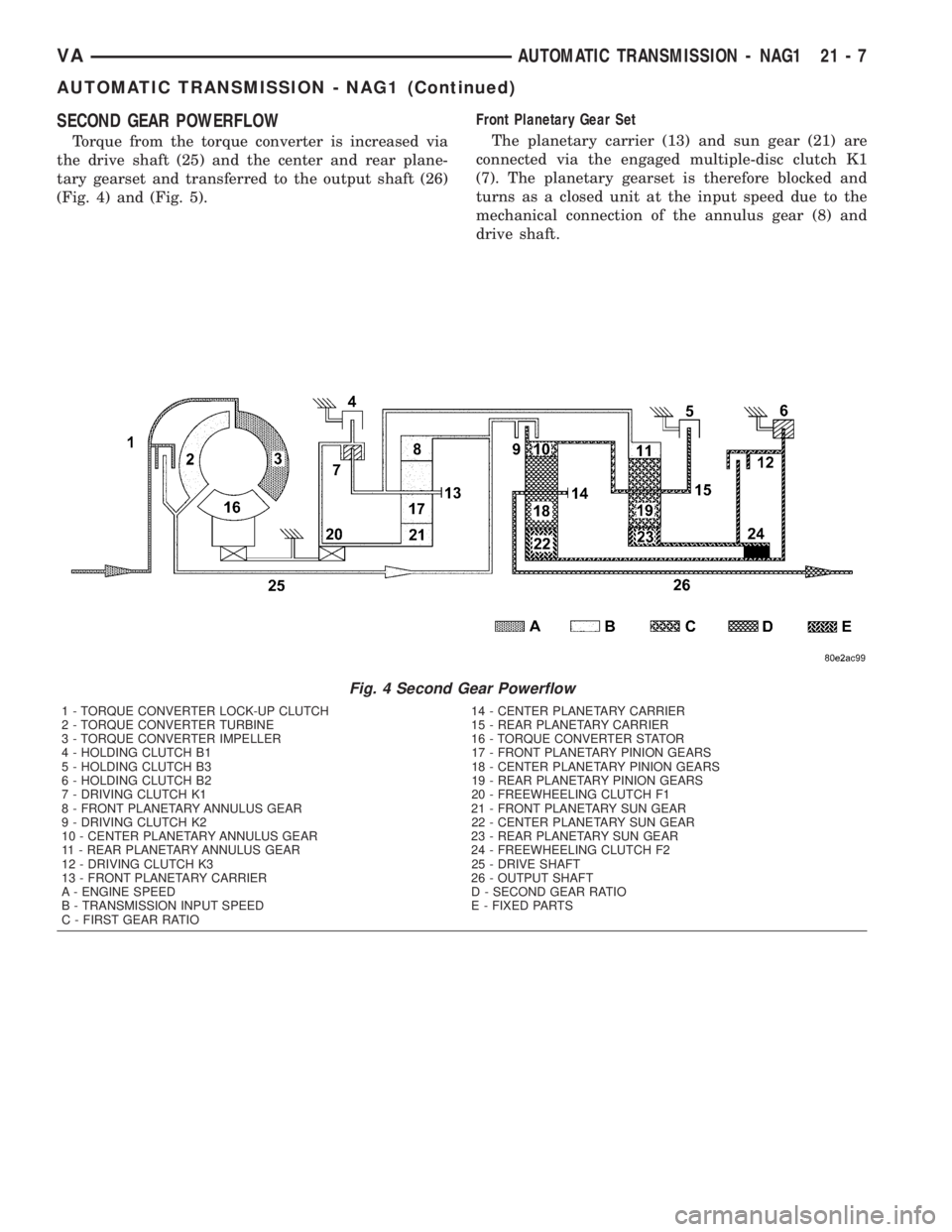

SECOND GEAR POWERFLOW

Torque from the torque converter is increased via

the drive shaft (25) and the center and rear plane-

tary gearset and transferred to the output shaft (26)

(Fig. 4) and (Fig. 5).Front Planetary Gear Set

The planetary carrier (13) and sun gear (21) are

connected via the engaged multiple-disc clutch K1

(7). The planetary gearset is therefore blocked and

turns as a closed unit at the input speed due to the

mechanical connection of the annulus gear (8) and

drive shaft.

Fig. 4 Second Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - FIXED PARTS

C - FIRST GEAR RATIO

VAAUTOMATIC TRANSMISSION - NAG1 21 - 7

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 884 of 1232

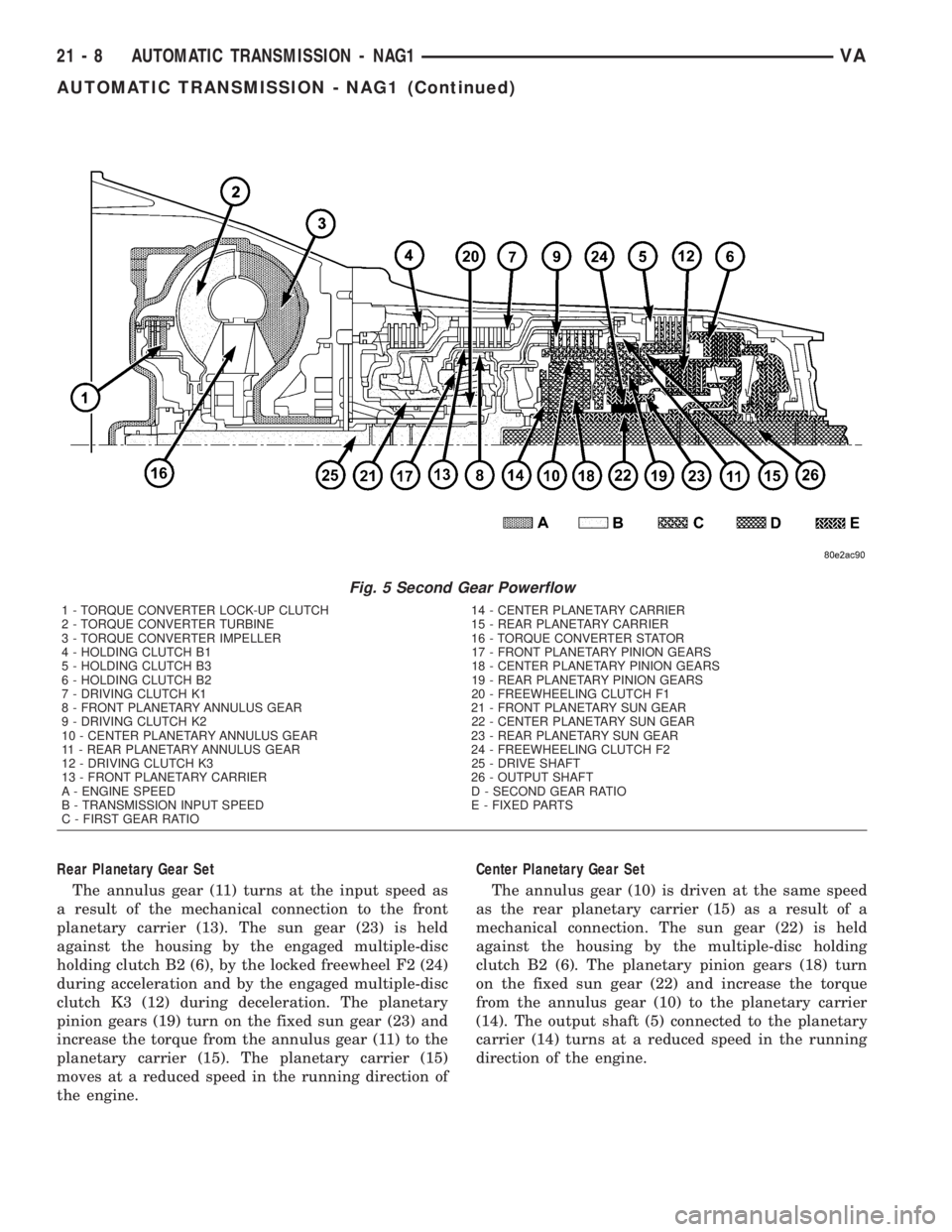

Rear Planetary Gear Set

The annulus gear (11) turns at the input speed as

a result of the mechanical connection to the front

planetary carrier (13). The sun gear (23) is held

against the housing by the engaged multiple-disc

holding clutch B2 (6), by the locked freewheel F2 (24)

during acceleration and by the engaged multiple-disc

clutch K3 (12) during deceleration. The planetary

pinion gears (19) turn on the fixed sun gear (23) and

increase the torque from the annulus gear (11) to the

planetary carrier (15). The planetary carrier (15)

moves at a reduced speed in the running direction of

the engine.Center Planetary Gear Set

The annulus gear (10) is driven at the same speed

as the rear planetary carrier (15) as a result of a

mechanical connection. The sun gear (22) is held

against the housing by the multiple-disc holding

clutch B2 (6). The planetary pinion gears (18) turn

on the fixed sun gear (22) and increase the torque

from the annulus gear (10) to the planetary carrier

(14). The output shaft (5) connected to the planetary

carrier (14) turns at a reduced speed in the running

direction of the engine.

Fig. 5 Second Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED D - SECOND GEAR RATIO

B - TRANSMISSION INPUT SPEED E - FIXED PARTS

C - FIRST GEAR RATIO

21 - 8 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 885 of 1232

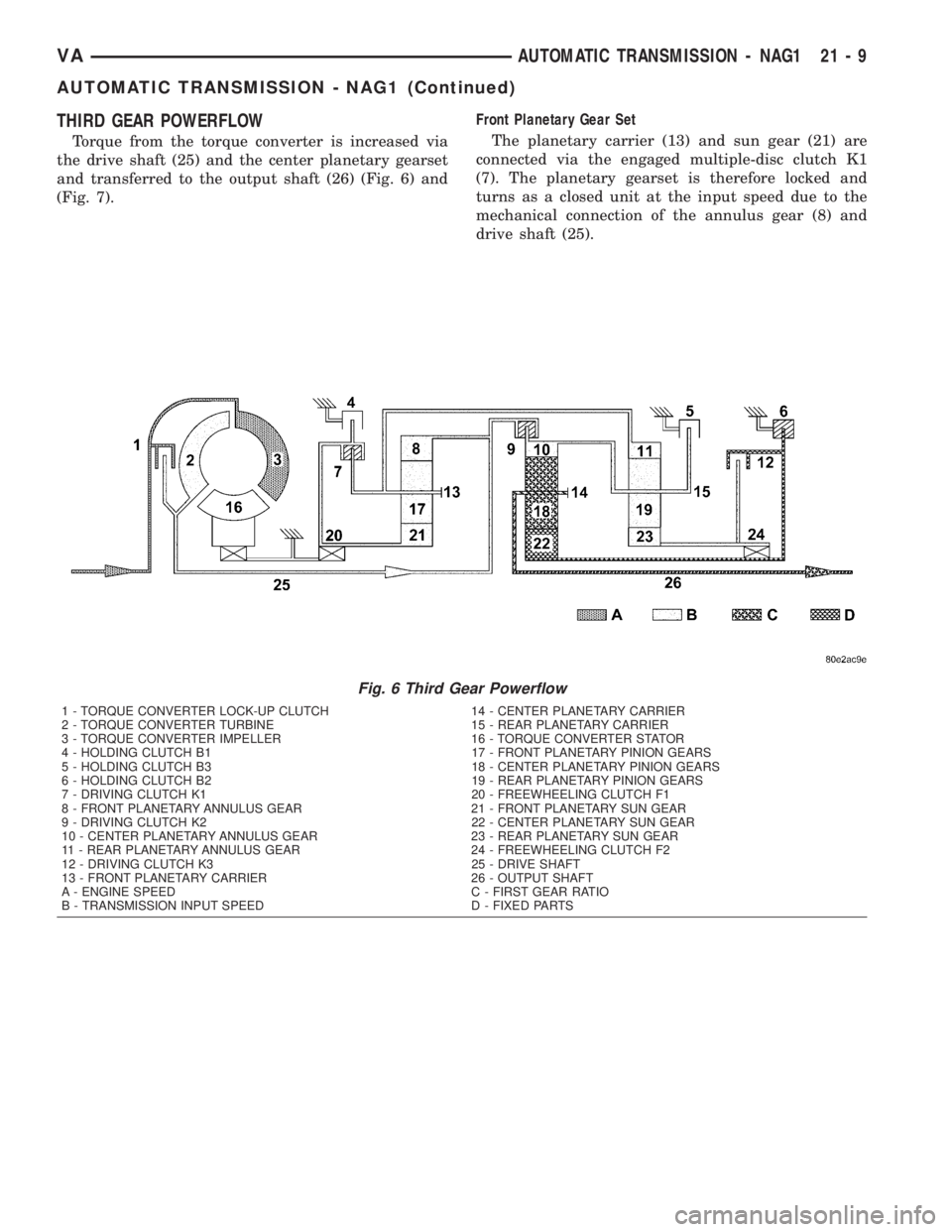

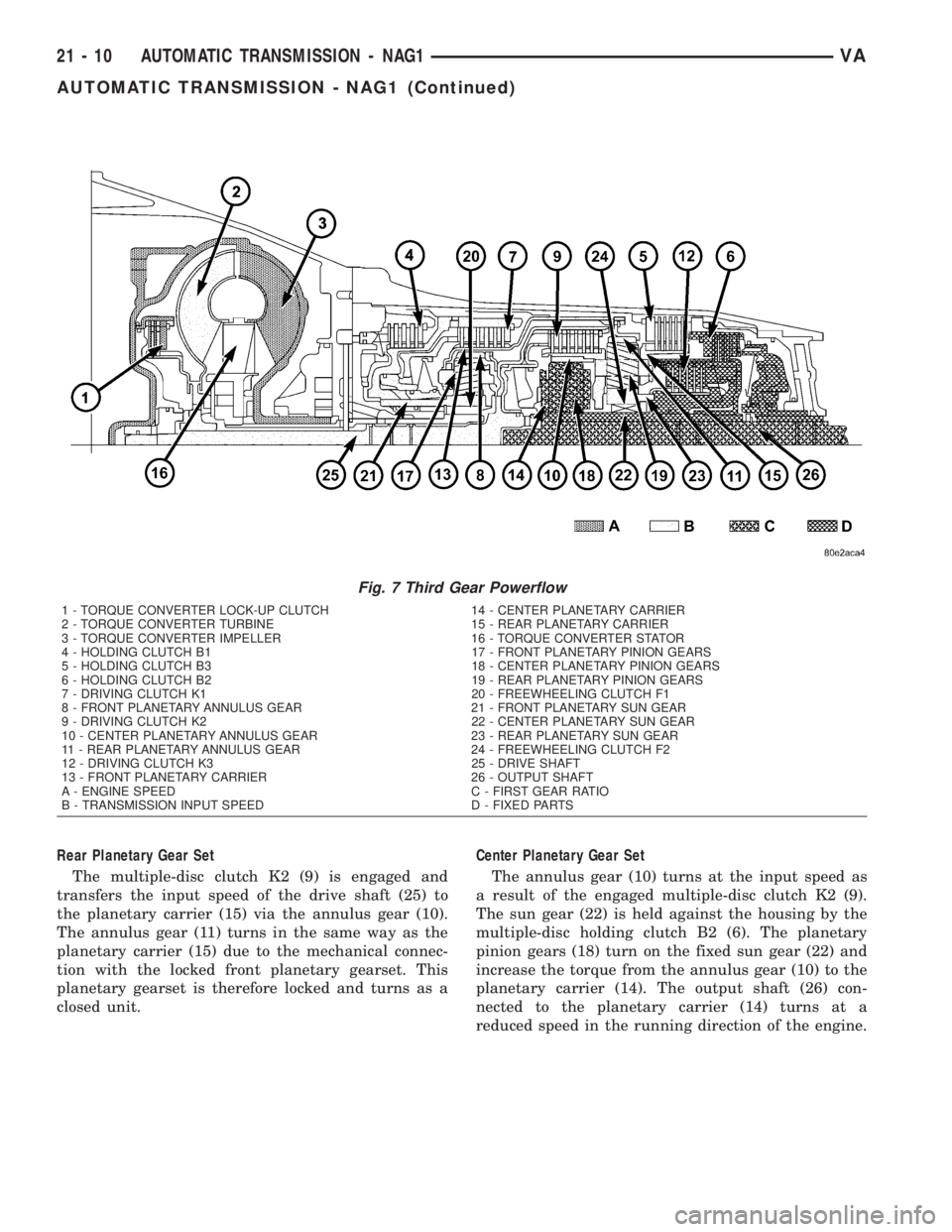

THIRD GEAR POWERFLOW

Torque from the torque converter is increased via

the drive shaft (25) and the center planetary gearset

and transferred to the output shaft (26) (Fig. 6) and

(Fig. 7).Front Planetary Gear Set

The planetary carrier (13) and sun gear (21) are

connected via the engaged multiple-disc clutch K1

(7). The planetary gearset is therefore locked and

turns as a closed unit at the input speed due to the

mechanical connection of the annulus gear (8) and

drive shaft (25).

Fig. 6 Third Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED C - FIRST GEAR RATIO

B - TRANSMISSION INPUT SPEED D - FIXED PARTS

VAAUTOMATIC TRANSMISSION - NAG1 21 - 9

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 886 of 1232

Rear Planetary Gear Set

The multiple-disc clutch K2 (9) is engaged and

transfers the input speed of the drive shaft (25) to

the planetary carrier (15) via the annulus gear (10).

The annulus gear (11) turns in the same way as the

planetary carrier (15) due to the mechanical connec-

tion with the locked front planetary gearset. This

planetary gearset is therefore locked and turns as a

closed unit.Center Planetary Gear Set

The annulus gear (10) turns at the input speed as

a result of the engaged multiple-disc clutch K2 (9).

The sun gear (22) is held against the housing by the

multiple-disc holding clutch B2 (6). The planetary

pinion gears (18) turn on the fixed sun gear (22) and

increase the torque from the annulus gear (10) to the

planetary carrier (14). The output shaft (26) con-

nected to the planetary carrier (14) turns at a

reduced speed in the running direction of the engine.

Fig. 7 Third Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED C - FIRST GEAR RATIO

B - TRANSMISSION INPUT SPEED D - FIXED PARTS

21 - 10 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 887 of 1232

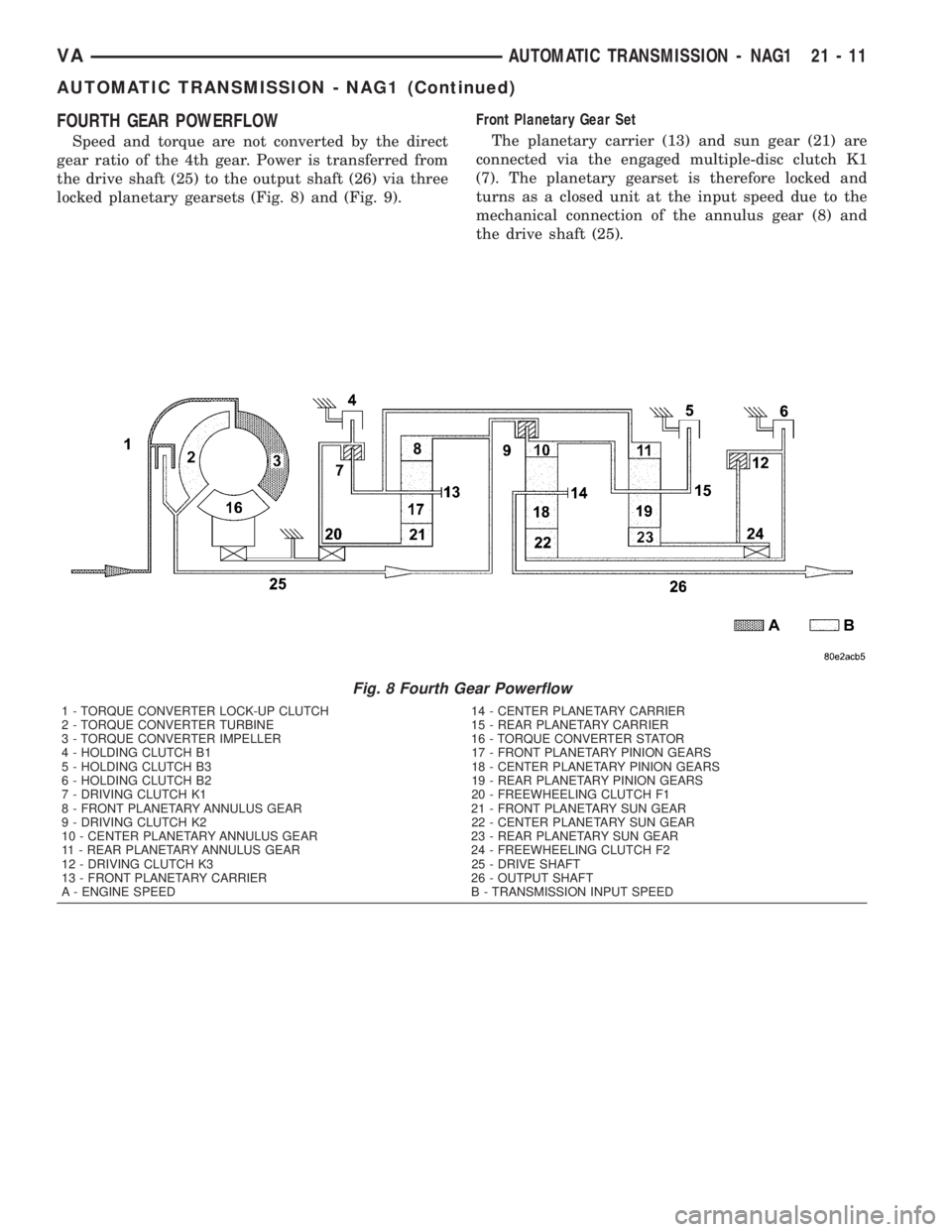

FOURTH GEAR POWERFLOW

Speed and torque are not converted by the direct

gear ratio of the 4th gear. Power is transferred from

the drive shaft (25) to the output shaft (26) via three

locked planetary gearsets (Fig. 8) and (Fig. 9).Front Planetary Gear Set

The planetary carrier (13) and sun gear (21) are

connected via the engaged multiple-disc clutch K1

(7). The planetary gearset is therefore locked and

turns as a closed unit at the input speed due to the

mechanical connection of the annulus gear (8) and

the drive shaft (25).

Fig. 8 Fourth Gear Powerflow

1 - TORQUE CONVERTER LOCK-UP CLUTCH 14 - CENTER PLANETARY CARRIER

2 - TORQUE CONVERTER TURBINE 15 - REAR PLANETARY CARRIER

3 - TORQUE CONVERTER IMPELLER 16 - TORQUE CONVERTER STATOR

4 - HOLDING CLUTCH B1 17 - FRONT PLANETARY PINION GEARS

5 - HOLDING CLUTCH B3 18 - CENTER PLANETARY PINION GEARS

6 - HOLDING CLUTCH B2 19 - REAR PLANETARY PINION GEARS

7 - DRIVING CLUTCH K1 20 - FREEWHEELING CLUTCH F1

8 - FRONT PLANETARY ANNULUS GEAR 21 - FRONT PLANETARY SUN GEAR

9 - DRIVING CLUTCH K2 22 - CENTER PLANETARY SUN GEAR

10 - CENTER PLANETARY ANNULUS GEAR 23 - REAR PLANETARY SUN GEAR

11 - REAR PLANETARY ANNULUS GEAR 24 - FREEWHEELING CLUTCH F2

12 - DRIVING CLUTCH K3 25 - DRIVE SHAFT

13 - FRONT PLANETARY CARRIER 26 - OUTPUT SHAFT

A - ENGINE SPEED B - TRANSMISSION INPUT SPEED

VAAUTOMATIC TRANSMISSION - NAG1 21 - 11

AUTOMATIC TRANSMISSION - NAG1 (Continued)