clock MERCEDES-BENZ SPRINTER 2005 Service Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 213 of 1232

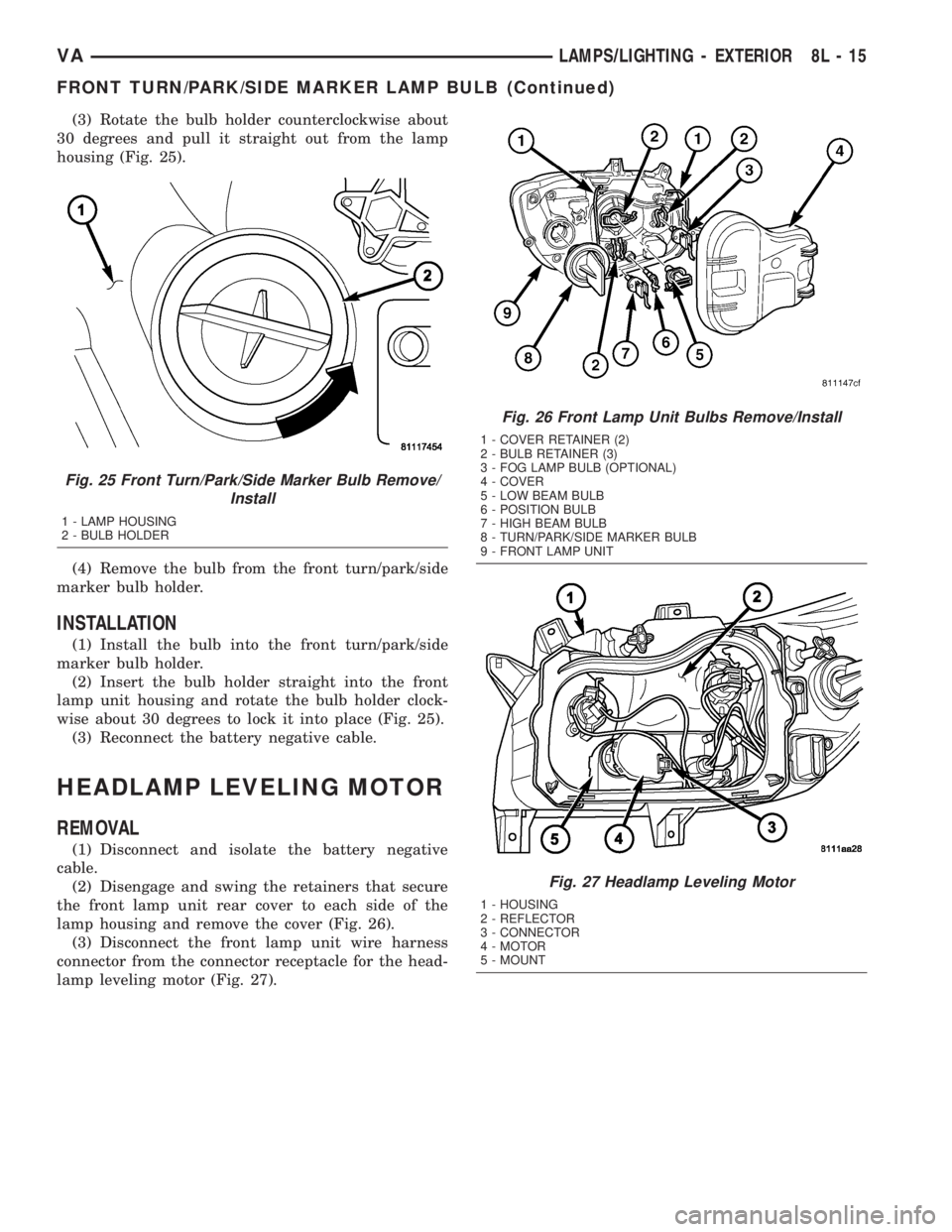

(3) Rotate the bulb holder counterclockwise about

30 degrees and pull it straight out from the lamp

housing (Fig. 25).

(4) Remove the bulb from the front turn/park/side

marker bulb holder.

INSTALLATION

(1) Install the bulb into the front turn/park/side

marker bulb holder.

(2) Insert the bulb holder straight into the front

lamp unit housing and rotate the bulb holder clock-

wise about 30 degrees to lock it into place (Fig. 25).

(3) Reconnect the battery negative cable.

HEADLAMP LEVELING MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

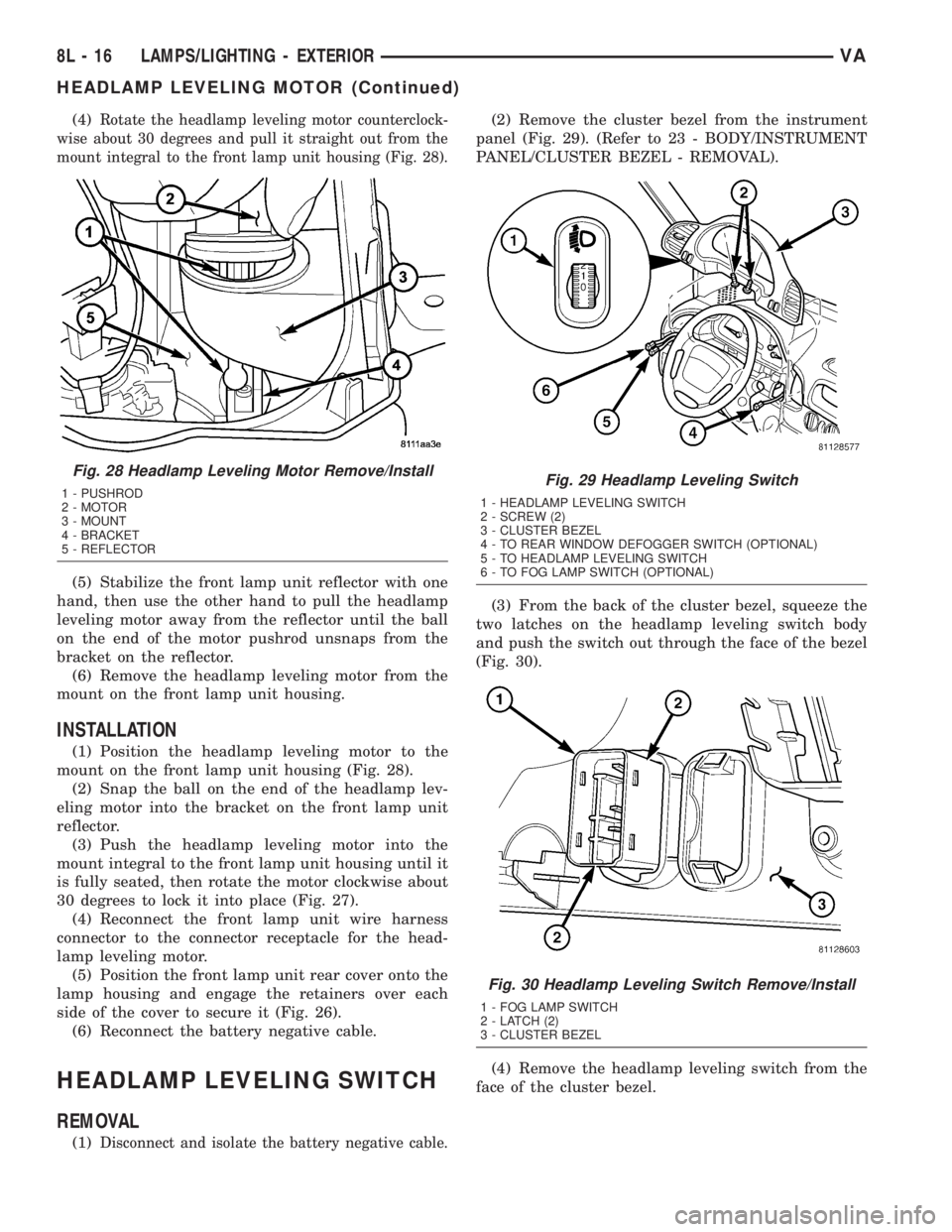

(2) Disengage and swing the retainers that secure

the front lamp unit rear cover to each side of the

lamp housing and remove the cover (Fig. 26).

(3) Disconnect the front lamp unit wire harness

connector from the connector receptacle for the head-

lamp leveling motor (Fig. 27).

Fig. 25 Front Turn/Park/Side Marker Bulb Remove/

Install

1 - LAMP HOUSING

2 - BULB HOLDER

Fig. 26 Front Lamp Unit Bulbs Remove/Install

1 - COVER RETAINER (2)

2 - BULB RETAINER (3)

3 - FOG LAMP BULB (OPTIONAL)

4 - COVER

5 - LOW BEAM BULB

6 - POSITION BULB

7 - HIGH BEAM BULB

8 - TURN/PARK/SIDE MARKER BULB

9 - FRONT LAMP UNIT

Fig. 27 Headlamp Leveling Motor

1 - HOUSING

2 - REFLECTOR

3 - CONNECTOR

4 - MOTOR

5 - MOUNT

VALAMPS/LIGHTING - EXTERIOR 8L - 15

FRONT TURN/PARK/SIDE MARKER LAMP BULB (Continued)

Page 214 of 1232

(4)Rotate the headlamp leveling motor counterclock-

wise about 30 degrees and pull it straight out from the

mount integral to the front lamp unit housing (Fig. 28).

(5) Stabilize the front lamp unit reflector with one

hand, then use the other hand to pull the headlamp

leveling motor away from the reflector until the ball

on the end of the motor pushrod unsnaps from the

bracket on the reflector.

(6) Remove the headlamp leveling motor from the

mount on the front lamp unit housing.

INSTALLATION

(1) Position the headlamp leveling motor to the

mount on the front lamp unit housing (Fig. 28).

(2) Snap the ball on the end of the headlamp lev-

eling motor into the bracket on the front lamp unit

reflector.

(3) Push the headlamp leveling motor into the

mount integral to the front lamp unit housing until it

is fully seated, then rotate the motor clockwise about

30 degrees to lock it into place (Fig. 27).

(4) Reconnect the front lamp unit wire harness

connector to the connector receptacle for the head-

lamp leveling motor.

(5) Position the front lamp unit rear cover onto the

lamp housing and engage the retainers over each

side of the cover to secure it (Fig. 26).

(6) Reconnect the battery negative cable.

HEADLAMP LEVELING SWITCH

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the cluster bezel from the instrument

panel (Fig. 29). (Refer to 23 - BODY/INSTRUMENT

PANEL/CLUSTER BEZEL - REMOVAL).

(3) From the back of the cluster bezel, squeeze the

two latches on the headlamp leveling switch body

and push the switch out through the face of the bezel

(Fig. 30).

(4) Remove the headlamp leveling switch from the

face of the cluster bezel.

Fig. 28 Headlamp Leveling Motor Remove/Install

1 - PUSHROD

2 - MOTOR

3 - MOUNT

4 - BRACKET

5 - REFLECTORFig. 29 Headlamp Leveling Switch

1 - HEADLAMP LEVELING SWITCH

2 - SCREW (2)

3 - CLUSTER BEZEL

4 - TO REAR WINDOW DEFOGGER SWITCH (OPTIONAL)

5 - TO HEADLAMP LEVELING SWITCH

6 - TO FOG LAMP SWITCH (OPTIONAL)

Fig. 30 Headlamp Leveling Switch Remove/Install

1 - FOG LAMP SWITCH

2 - LATCH (2)

3 - CLUSTER BEZEL

8L - 16 LAMPS/LIGHTING - EXTERIORVA

HEADLAMP LEVELING MOTOR (Continued)

Page 217 of 1232

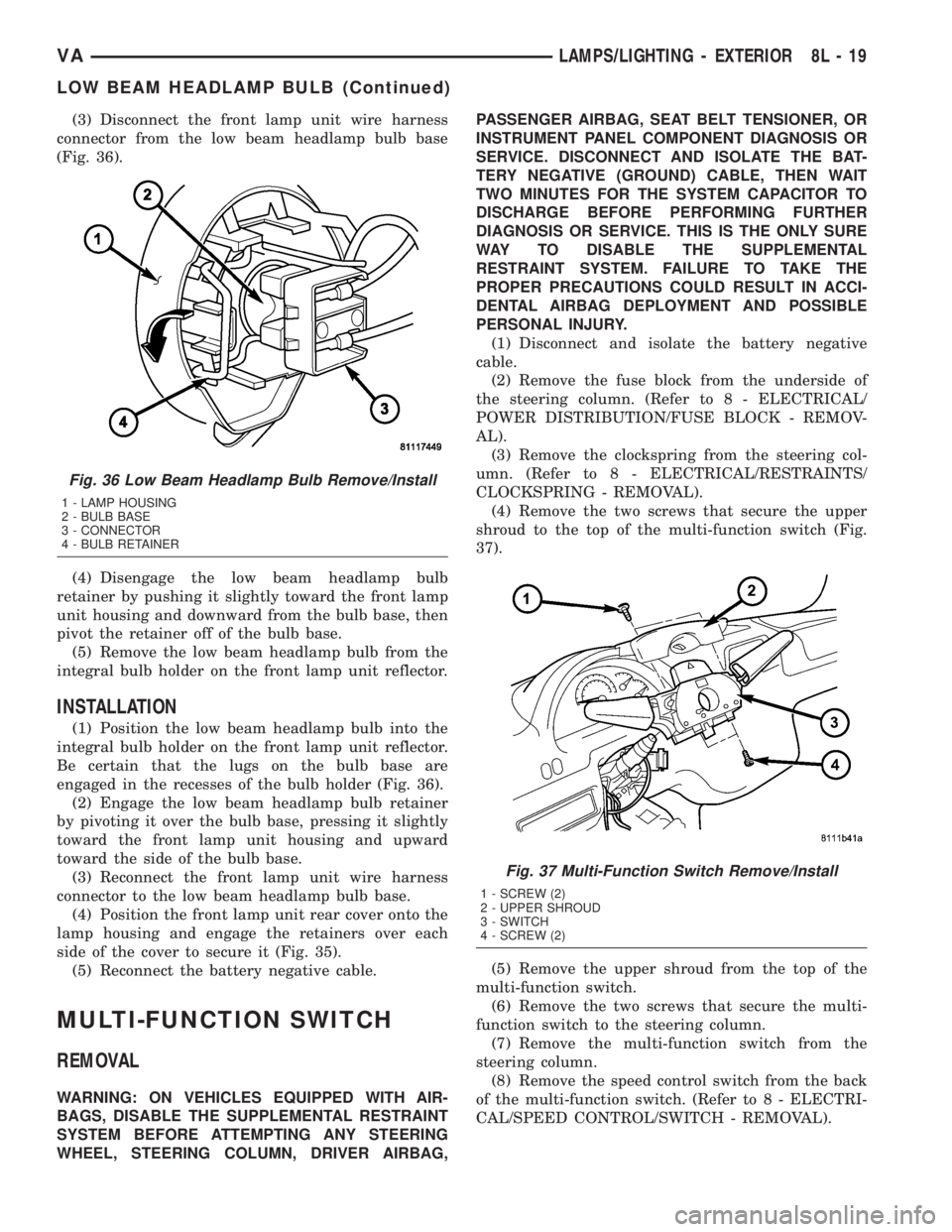

(3) Disconnect the front lamp unit wire harness

connector from the low beam headlamp bulb base

(Fig. 36).

(4) Disengage the low beam headlamp bulb

retainer by pushing it slightly toward the front lamp

unit housing and downward from the bulb base, then

pivot the retainer off of the bulb base.

(5) Remove the low beam headlamp bulb from the

integral bulb holder on the front lamp unit reflector.

INSTALLATION

(1) Position the low beam headlamp bulb into the

integral bulb holder on the front lamp unit reflector.

Be certain that the lugs on the bulb base are

engaged in the recesses of the bulb holder (Fig. 36).

(2) Engage the low beam headlamp bulb retainer

by pivoting it over the bulb base, pressing it slightly

toward the front lamp unit housing and upward

toward the side of the bulb base.

(3) Reconnect the front lamp unit wire harness

connector to the low beam headlamp bulb base.

(4) Position the front lamp unit rear cover onto the

lamp housing and engage the retainers over each

side of the cover to secure it (Fig. 35).

(5) Reconnect the battery negative cable.

MULTI-FUNCTION SWITCH

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse block from the underside of

the steering column. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/FUSE BLOCK - REMOV-

AL).

(3) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

(4) Remove the two screws that secure the upper

shroud to the top of the multi-function switch (Fig.

37).

(5) Remove the upper shroud from the top of the

multi-function switch.

(6) Remove the two screws that secure the multi-

function switch to the steering column.

(7) Remove the multi-function switch from the

steering column.

(8) Remove the speed control switch from the back

of the multi-function switch. (Refer to 8 - ELECTRI-

CAL/SPEED CONTROL/SWITCH - REMOVAL).

Fig. 36 Low Beam Headlamp Bulb Remove/Install

1 - LAMP HOUSING

2 - BULB BASE

3 - CONNECTOR

4 - BULB RETAINER

Fig. 37 Multi-Function Switch Remove/Install

1 - SCREW (2)

2 - UPPER SHROUD

3 - SWITCH

4 - SCREW (2)

VALAMPS/LIGHTING - EXTERIOR 8L - 19

LOW BEAM HEADLAMP BULB (Continued)

Page 218 of 1232

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Reinstall the speed control switch onto the

back of the multi-function switch. (Refer to 8 - ELEC-

TRICAL/SPEED CONTROL/SWITCH - INSTALLA-

TION).

(2) Position the multi-function switch onto the

steering column (Fig. 37).

(3) Install and tighten the two screws that secure

the multi-function switch to the steering column.

(4) Position the upper shroud onto the top of the

multi-function switch.

(5) Install and tighten the two screws that secure

the upper shroud to the top of the multi-function

switch.

(6) Reinstall the clockspring onto the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - INSTALLATION).

(7) Reinstall the fuse block onto the underside of

the steering column. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/FUSE BLOCK - INSTAL-

LATION).

(8) Reconnect the battery negative cable.

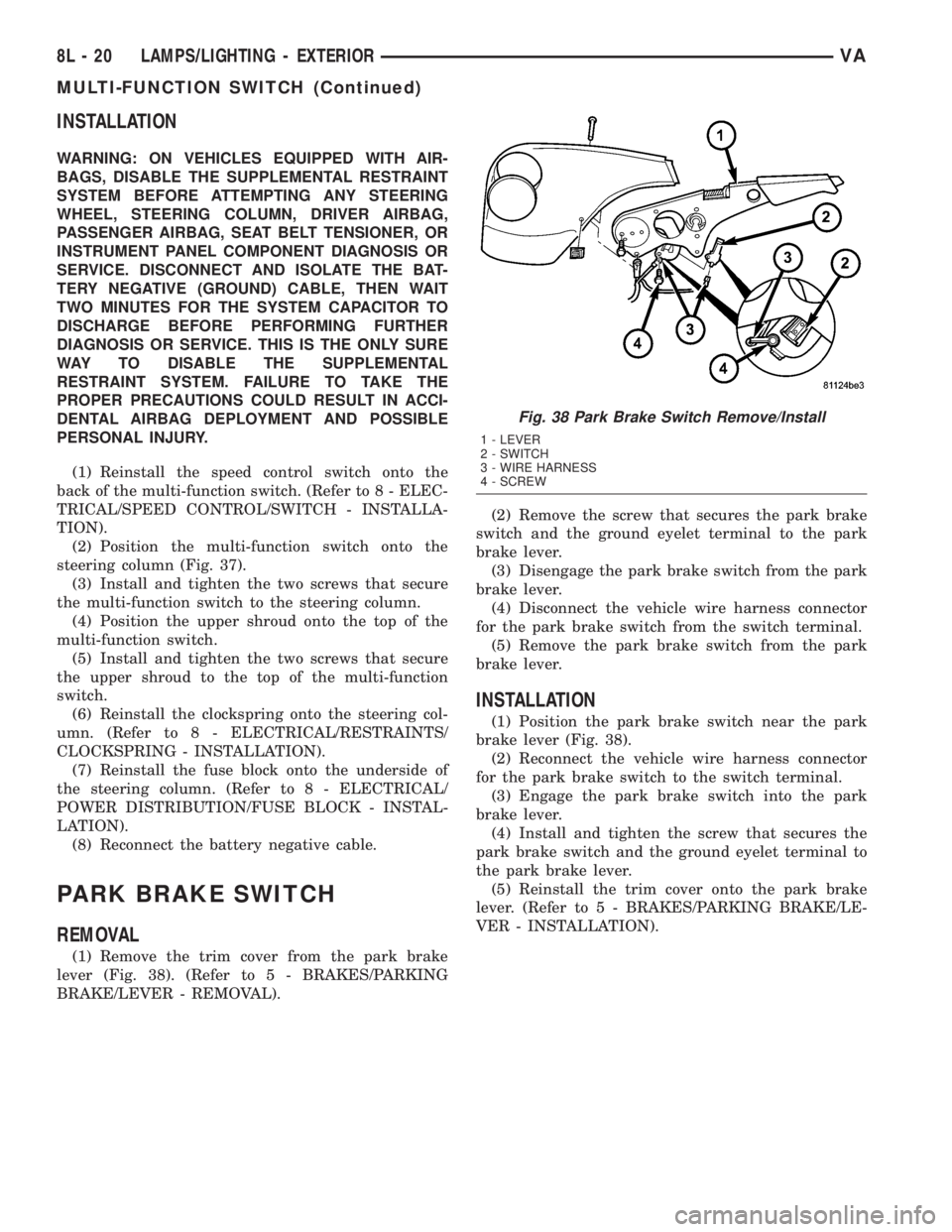

PARK BRAKE SWITCH

REMOVAL

(1) Remove the trim cover from the park brake

lever (Fig. 38). (Refer to 5 - BRAKES/PARKING

BRAKE/LEVER - REMOVAL).(2) Remove the screw that secures the park brake

switch and the ground eyelet terminal to the park

brake lever.

(3) Disengage the park brake switch from the park

brake lever.

(4) Disconnect the vehicle wire harness connector

for the park brake switch from the switch terminal.

(5) Remove the park brake switch from the park

brake lever.

INSTALLATION

(1) Position the park brake switch near the park

brake lever (Fig. 38).

(2) Reconnect the vehicle wire harness connector

for the park brake switch to the switch terminal.

(3) Engage the park brake switch into the park

brake lever.

(4) Install and tighten the screw that secures the

park brake switch and the ground eyelet terminal to

the park brake lever.

(5) Reinstall the trim cover onto the park brake

lever. (Refer to 5 - BRAKES/PARKING BRAKE/LE-

VER - INSTALLATION).

Fig. 38 Park Brake Switch Remove/Install

1 - LEVER

2 - SWITCH

3 - WIRE HARNESS

4 - SCREW

8L - 20 LAMPS/LIGHTING - EXTERIORVA

MULTI-FUNCTION SWITCH (Continued)

Page 228 of 1232

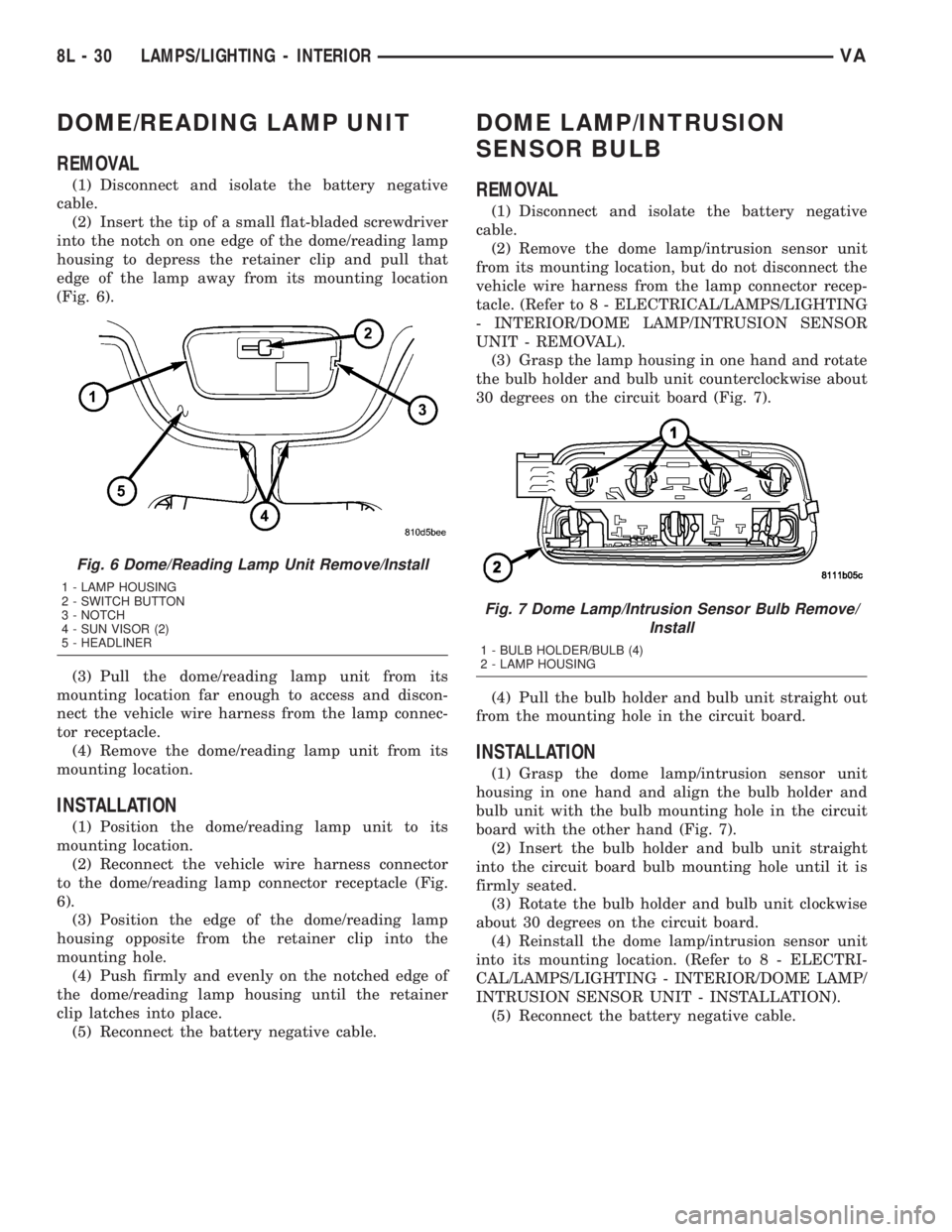

DOME/READING LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the tip of a small flat-bladed screwdriver

into the notch on one edge of the dome/reading lamp

housing to depress the retainer clip and pull that

edge of the lamp away from its mounting location

(Fig. 6).

(3) Pull the dome/reading lamp unit from its

mounting location far enough to access and discon-

nect the vehicle wire harness from the lamp connec-

tor receptacle.

(4) Remove the dome/reading lamp unit from its

mounting location.

INSTALLATION

(1) Position the dome/reading lamp unit to its

mounting location.

(2) Reconnect the vehicle wire harness connector

to the dome/reading lamp connector receptacle (Fig.

6).

(3) Position the edge of the dome/reading lamp

housing opposite from the retainer clip into the

mounting hole.

(4) Push firmly and evenly on the notched edge of

the dome/reading lamp housing until the retainer

clip latches into place.

(5) Reconnect the battery negative cable.

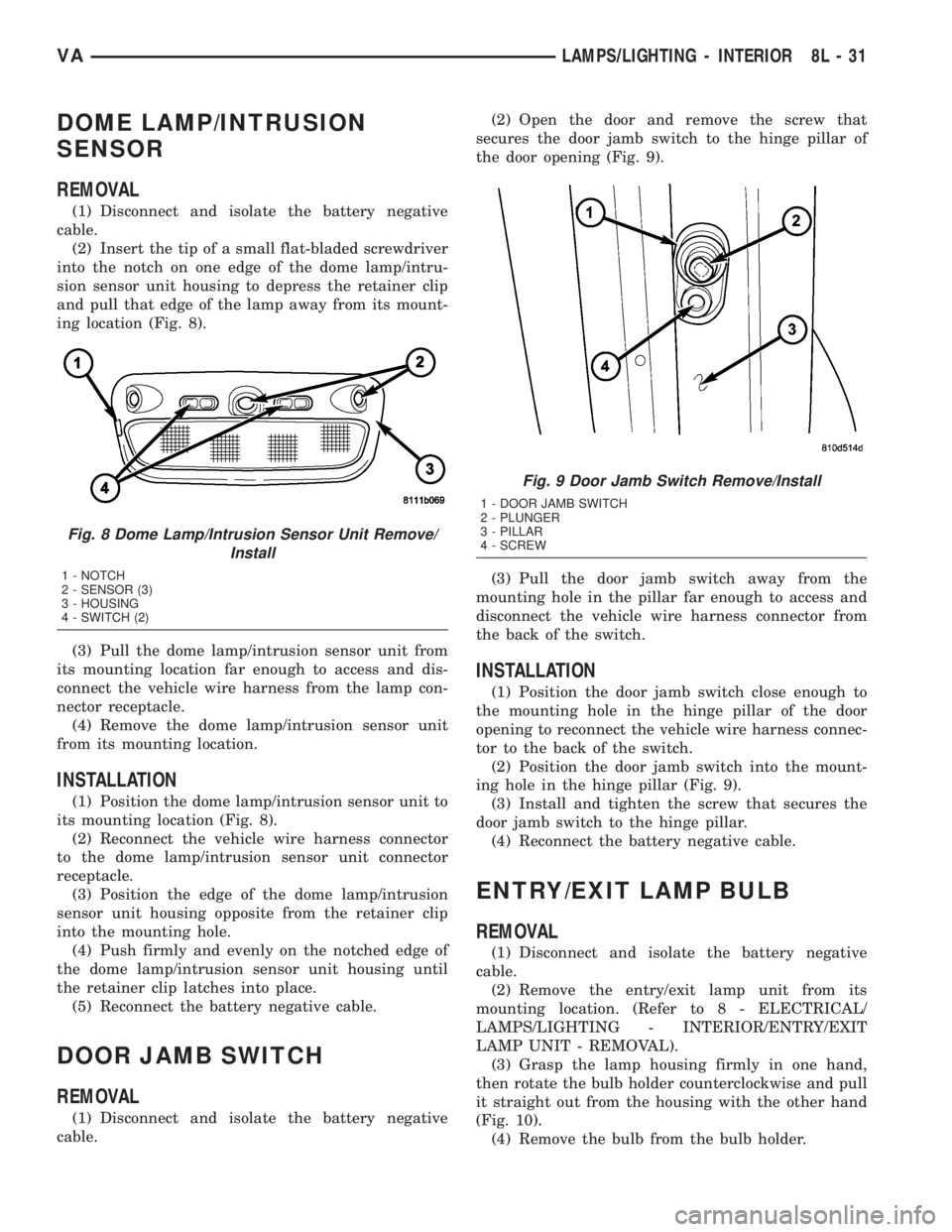

DOME LAMP/INTRUSION

SENSOR BULB

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the dome lamp/intrusion sensor unit

from its mounting location, but do not disconnect the

vehicle wire harness from the lamp connector recep-

tacle. (Refer to 8 - ELECTRICAL/LAMPS/LIGHTING

- INTERIOR/DOME LAMP/INTRUSION SENSOR

UNIT - REMOVAL).

(3) Grasp the lamp housing in one hand and rotate

the bulb holder and bulb unit counterclockwise about

30 degrees on the circuit board (Fig. 7).

(4) Pull the bulb holder and bulb unit straight out

from the mounting hole in the circuit board.

INSTALLATION

(1) Grasp the dome lamp/intrusion sensor unit

housing in one hand and align the bulb holder and

bulb unit with the bulb mounting hole in the circuit

board with the other hand (Fig. 7).

(2) Insert the bulb holder and bulb unit straight

into the circuit board bulb mounting hole until it is

firmly seated.

(3) Rotate the bulb holder and bulb unit clockwise

about 30 degrees on the circuit board.

(4) Reinstall the dome lamp/intrusion sensor unit

into its mounting location. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP/

INTRUSION SENSOR UNIT - INSTALLATION).

(5) Reconnect the battery negative cable.

Fig. 6 Dome/Reading Lamp Unit Remove/Install

1 - LAMP HOUSING

2 - SWITCH BUTTON

3 - NOTCH

4 - SUN VISOR (2)

5 - HEADLINER

Fig. 7 Dome Lamp/Intrusion Sensor Bulb Remove/

Install

1 - BULB HOLDER/BULB (4)

2 - LAMP HOUSING

8L - 30 LAMPS/LIGHTING - INTERIORVA

Page 229 of 1232

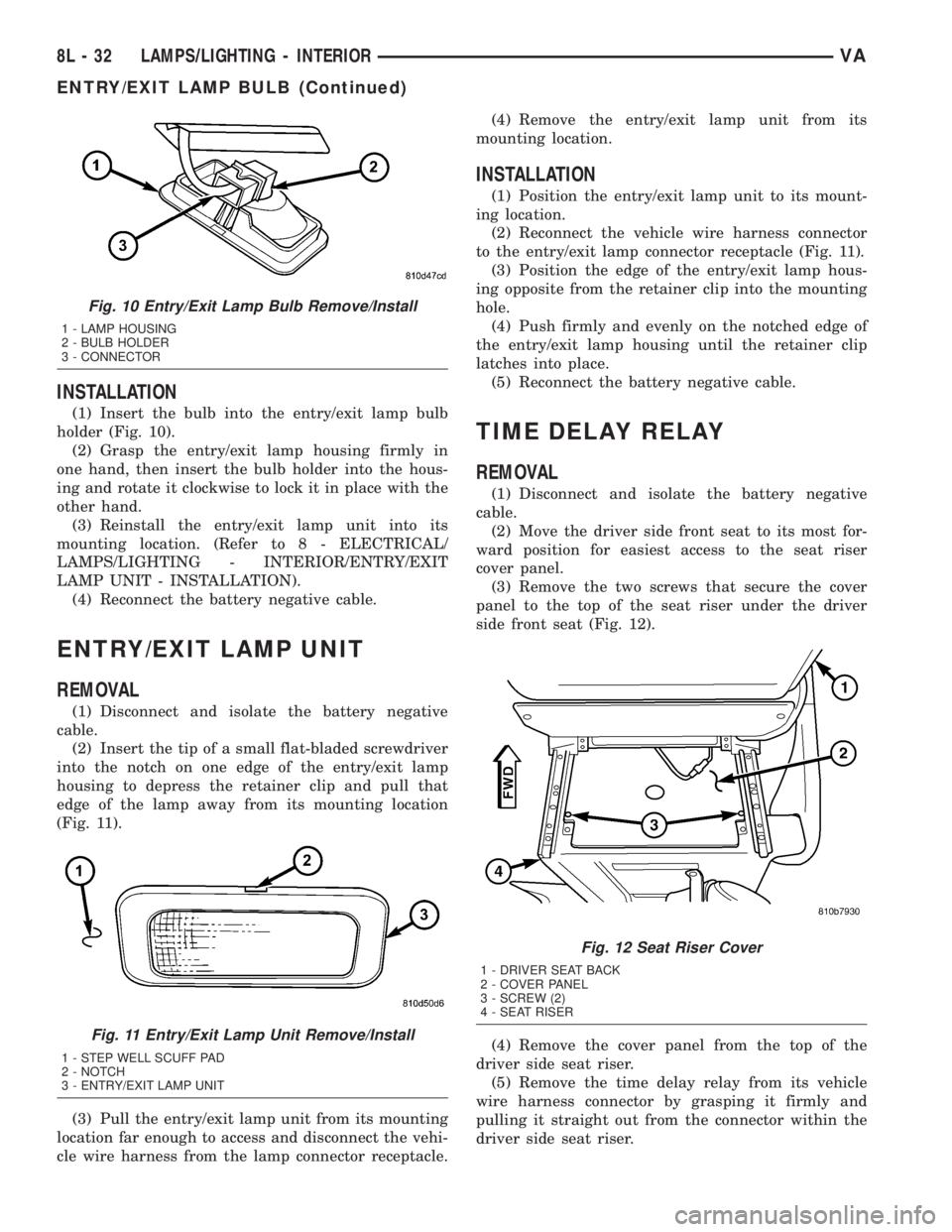

DOME LAMP/INTRUSION

SENSOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the tip of a small flat-bladed screwdriver

into the notch on one edge of the dome lamp/intru-

sion sensor unit housing to depress the retainer clip

and pull that edge of the lamp away from its mount-

ing location (Fig. 8).

(3) Pull the dome lamp/intrusion sensor unit from

its mounting location far enough to access and dis-

connect the vehicle wire harness from the lamp con-

nector receptacle.

(4) Remove the dome lamp/intrusion sensor unit

from its mounting location.

INSTALLATION

(1) Position the dome lamp/intrusion sensor unit to

its mounting location (Fig. 8).

(2) Reconnect the vehicle wire harness connector

to the dome lamp/intrusion sensor unit connector

receptacle.

(3) Position the edge of the dome lamp/intrusion

sensor unit housing opposite from the retainer clip

into the mounting hole.

(4) Push firmly and evenly on the notched edge of

the dome lamp/intrusion sensor unit housing until

the retainer clip latches into place.

(5) Reconnect the battery negative cable.

DOOR JAMB SWITCH

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Open the door and remove the screw that

secures the door jamb switch to the hinge pillar of

the door opening (Fig. 9).

(3) Pull the door jamb switch away from the

mounting hole in the pillar far enough to access and

disconnect the vehicle wire harness connector from

the back of the switch.

INSTALLATION

(1) Position the door jamb switch close enough to

the mounting hole in the hinge pillar of the door

opening to reconnect the vehicle wire harness connec-

tor to the back of the switch.

(2) Position the door jamb switch into the mount-

ing hole in the hinge pillar (Fig. 9).

(3) Install and tighten the screw that secures the

door jamb switch to the hinge pillar.

(4) Reconnect the battery negative cable.

ENTRY/EXIT LAMP BULB

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the entry/exit lamp unit from its

mounting location. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/ENTRY/EXIT

LAMP UNIT - REMOVAL).

(3) Grasp the lamp housing firmly in one hand,

then rotate the bulb holder counterclockwise and pull

it straight out from the housing with the other hand

(Fig. 10).

(4) Remove the bulb from the bulb holder.

Fig. 8 Dome Lamp/Intrusion Sensor Unit Remove/

Install

1 - NOTCH

2 - SENSOR (3)

3 - HOUSING

4 - SWITCH (2)

Fig. 9 Door Jamb Switch Remove/Install

1 - DOOR JAMB SWITCH

2 - PLUNGER

3 - PILLAR

4 - SCREW

VALAMPS/LIGHTING - INTERIOR 8L - 31

Page 230 of 1232

INSTALLATION

(1) Insert the bulb into the entry/exit lamp bulb

holder (Fig. 10).

(2) Grasp the entry/exit lamp housing firmly in

one hand, then insert the bulb holder into the hous-

ing and rotate it clockwise to lock it in place with the

other hand.

(3) Reinstall the entry/exit lamp unit into its

mounting location. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/ENTRY/EXIT

LAMP UNIT - INSTALLATION).

(4) Reconnect the battery negative cable.

ENTRY/EXIT LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the tip of a small flat-bladed screwdriver

into the notch on one edge of the entry/exit lamp

housing to depress the retainer clip and pull that

edge of the lamp away from its mounting location

(Fig. 11).

(3) Pull the entry/exit lamp unit from its mounting

location far enough to access and disconnect the vehi-

cle wire harness from the lamp connector receptacle.(4) Remove the entry/exit lamp unit from its

mounting location.

INSTALLATION

(1) Position the entry/exit lamp unit to its mount-

ing location.

(2) Reconnect the vehicle wire harness connector

to the entry/exit lamp connector receptacle (Fig. 11).

(3) Position the edge of the entry/exit lamp hous-

ing opposite from the retainer clip into the mounting

hole.

(4) Push firmly and evenly on the notched edge of

the entry/exit lamp housing until the retainer clip

latches into place.

(5) Reconnect the battery negative cable.

TIME DELAY RELAY

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Move the driver side front seat to its most for-

ward position for easiest access to the seat riser

cover panel.

(3) Remove the two screws that secure the cover

panel to the top of the seat riser under the driver

side front seat (Fig. 12).

(4) Remove the cover panel from the top of the

driver side seat riser.

(5) Remove the time delay relay from its vehicle

wire harness connector by grasping it firmly and

pulling it straight out from the connector within the

driver side seat riser.

Fig. 10 Entry/Exit Lamp Bulb Remove/Install

1 - LAMP HOUSING

2 - BULB HOLDER

3 - CONNECTOR

Fig. 11 Entry/Exit Lamp Unit Remove/Install

1 - STEP WELL SCUFF PAD

2 - NOTCH

3 - ENTRY/EXIT LAMP UNIT

Fig. 12 Seat Riser Cover

1 - DRIVER SEAT BACK

2 - COVER PANEL

3 - SCREW (2)

4 - SEAT RISER

8L - 32 LAMPS/LIGHTING - INTERIORVA

ENTRY/EXIT LAMP BULB (Continued)

Page 239 of 1232

RESTRAINTS

TABLE OF CONTENTS

page page

RESTRAINTS

DESCRIPTION..........................2

OPERATION............................4

WARNING

WARNINGS - RESTRAINT SYSTEM........5

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM...................5

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS.........................6

STANDARD PROCEDURE - SERVICE

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT.........................6

STANDARD PROCEDURE - VERIFICATION

TEST................................7

AIRBAG CONTROL MODULE

DESCRIPTION..........................8

OPERATION............................9

REMOVAL.............................10

INSTALLATION.........................11

CLOCKSPRING

DESCRIPTION.........................12

OPERATION...........................13

STANDARD PROCEDURE - CLOCKSPRING

CENTERING.........................13

REMOVAL.............................14

INSTALLATION.........................15

DRIVER AIRBAG

DESCRIPTION.........................16

OPERATION...........................17

REMOVAL.............................17

INSTALLATION.........................18FRONT SEAT BELT & RETRACTOR

REMOVAL.............................19

INSTALLATION.........................21

FRONT SEAT BELT BUCKLE

REMOVAL.............................22

INSTALLATION.........................23

PASSENGER AIRBAG

DESCRIPTION.........................23

OPERATION...........................24

REMOVAL.............................24

INSTALLATION.........................26

PASSENGER AIRBAG BRACKET

REMOVAL.............................27

INSTALLATION.........................27

REAR SEAT BELT & RETRACTOR

REMOVAL.............................27

INSTALLATION.........................29

REAR SEAT BELT BUCKLE

REMOVAL

REMOVAL - INBOARD..................29

REMOVAL - OUTBOARD................30

INSTALLATION

INSTALLATION - INBOARD..............30

INSTALLATION - OUTBOARD............31

SEAT BELT SWITCH

DESCRIPTION.........................31

OPERATION...........................31

SEAT BELT TENSIONER

DESCRIPTION.........................31

OPERATION...........................32

SEAT BELT TURNING LOOP ADJUSTER

REMOVAL.............................33

INSTALLATION.........................34

VARESTRAINTS 8O - 1

Page 241 of 1232

ACTIVE RESTRAINTS

The active restraints for this model include:

²Front Seat Belts- Both outboard front seating

positions are equipped with three-point seat belt sys-

tems employing a lower B-pillar mounted inertia

latch-type retractors, height-adjustable upper B-pil-

lar mounted turning loops, travelling lower seat belt

anchors secured to the outboard seat tracks, and

travelling end-release seat belt buckles secured to

the inboard seat track. The driver side front seat belt

buckle of all models includes an integral seat belt

switch that detects whether its seat belt has been

fastened.

²Rear Seat Belts- All rear seating positions are

equipped with three-point seat belt systems. Each

rear seating position belt employs an integral seat

cushion frame mounted inertia latch-type retractor, a

fixed position upper seat back frame mounted turn-

ing loop, and a fixed lower seat belt anchor secured

to the seat cushion frame. All rear seat belts have

fixed end-release seat belt buckles that are also

secured to the seat cushion frame.

PASSIVE RESTRAINTS

A Next Generation driver airbag is standard facto-

ry-installed safety equipment on this model, while a

passenger side front airbag is optional. This airbag

system is a passive, inflatable, Supplemental

Restraint System (SRS) and vehicles with this equip-

ment can be readily identified by the ªSRS - AIR-

BAGº logo molded into the driver airbag trim cover

in the center of the steering wheel and, if the vehicle

is so equipped, also into the passenger airbag door on

the instrument panel above the glove box (Fig. 2).

Vehicles with the airbag system can also be identified

by the airbag indicator, which will illuminate in the

instrument cluster for about six seconds as a bulb

test each time the ignition switch is turned to the On

position. A pyrotechnic-type seat belt tensioner is

integral to the front seat belt retractor mounted on

the lower B-pillar on the driver side, and to the pas-

senger side retractor of vehicles equipped with the

optional passenger side airbag.

The supplemental restraint system includes the

following major components, which are described in

further detail elsewhere in this service information:

²Airbag Control Module- The Airbag Control

Module (ACM) is located on a mount on the floor

panel within the driver side seat riser, beneath the

driver seat in the passenger compartment.

²Airbag (SRS) Indicator- The airbag indicator

is integral to the ElectroMechanical Instrument Clus-

ter (EMIC), which is located on the instrument panel

in front of the driver.²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The structure of the

lower instrument panel serves as a knee blocker for

the driver.

²Passenger Airbag- The optional passenger air-

bag is located within the instrument panel, behind

the passenger airbag door on the instrument panel

above the glove box on the passenger side of the vehi-

cle.

²Passenger Knee Blocker- The structure of

the glove box door and the lower instrument panel

serve as a knee blocker for the front seat passenger.

²Seat Belt Tensioner- A seat belt tensioner is

integral to the driver side front seat belt retractor

unit, and to the passenger side front seat belt retrac-

tor unit on vehicles equipped with an optional pas-

senger airbag.

The ACM contains a central processing unit and

programming that allows it to communicate on a

serial data bus diagnostic circuit connected to the

16-way Data Link Connector (DLC) located below the

left end of the instrument panel. This method of com-

munication is used for initialization of the ACM and

for diagnosis of the SRS circuits and components

using a DRBIIItscan tool.

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system,

and to the supplemental restraint system compo-

nents through the use of a combination of soldered

Fig. 2 SRS Logo

VARESTRAINTS 8O - 3

RESTRAINTS (Continued)

Page 244 of 1232

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag or seat belt tensioner. When carrying a

non-deployed airbag, the trim cover or airbag cushion

side of the unit should be pointed away from the

body to minimize injury in the event of an accidental

deployment. If the airbag unit is placed on a bench or

any other surface, the trim cover or airbag cushion

side of the unit should be face up to minimize move-

ment in the event of an accidental deployment. When

handling a non-deployed seat belt tensioner, take

proper care to keep fingers out from under the

retractor cover and away from the seat belt webbing

where it exits from the retractor cover. In addition,

the supplemental restraint system should be dis-

armed whenever any steering wheel, steering col-

umn, seat belt tensioner, driver airbag, passenger

airbag, or instrument panel components require diag-

nosis or service. Failure to observe this warning

could result in accidental deployment and possible

personal injury.

All damaged, faulty or non-deployed airbags and

seat belt tensioners which are replaced on vehicles

are to be handled and disposed of properly. If an air-

bag or seat belt tensioner unit is faulty or damaged

and non-deployed, refer to the Hazardous Substance

Control System for proper disposal. Dispose of all

non-deployed and deployed airbags and seat belt ten-

sioners in a manner consistent with state, provincial,

local and federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags and seat belt tensioners must be stored in

their original, special container until they are used

for service. Also, they must be stored in a clean, dry

environment; away from sources of extreme heat,

sparks, and high electrical energy. Always place or

store any airbag on a surface with its trim cover or

airbag cushion side facing up, to minimize movement

in case of an accidental deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring and

the steering wheel must be replaced. The seat belt

tensioners are deployed by the same signal that

deploys the driver and passenger airbags and must

also be replaced if either airbag has been deployed.

These components are not intended for reuse and

will be damaged or weakened as a result of a supple-

mental restraint deployment, which may or may not

be obvious during a visual inspection.

It is also critical that the mounting surfaces and/or

mounting brackets for the Airbag Control Module

(ACM) be closely inspected and restored to their orig-

inal conditions following any vehicle impact damage.

Because the ACM contains the impact sensor that is

used by the supplemental restraint system to moni-

tor or confirm the direction and severity of a vehicle

impact, improper orientation or insecure fastening of

this component may cause airbags not to deploy

when required, or to deploy when not required. All

other vehicle components should be closely inspected

following any supplemental restraint deployment, but

are to be replaced only as required by the extent of

the visible damage incurred.

CLEANUP PROCEDURE

Following a supplemental restraint deployment,

the vehicle interior will contain a powdery residue.

This residue consists primarily of harmless particu-

late by-products of the small pyrotechnic charge that

initiates the propellant used to deploy a supplemen-

tal restraint. However, this residue may also contain

traces of sodium hydroxide powder, a chemical

by-product of the propellant material that is used to

generate the inert gas that inflates the airbag. Since

sodium hydroxide powder can irritate the skin, eyes,

nose, or throat, be certain to wear safety glasses,

rubber gloves, and a long-sleeved shirt during

cleanup (Fig. 3).

8O - 6 RESTRAINTSVA

RESTRAINTS (Continued)