clock MERCEDES-BENZ SPRINTER 2005 Service Manual PDF

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 1021 of 1232

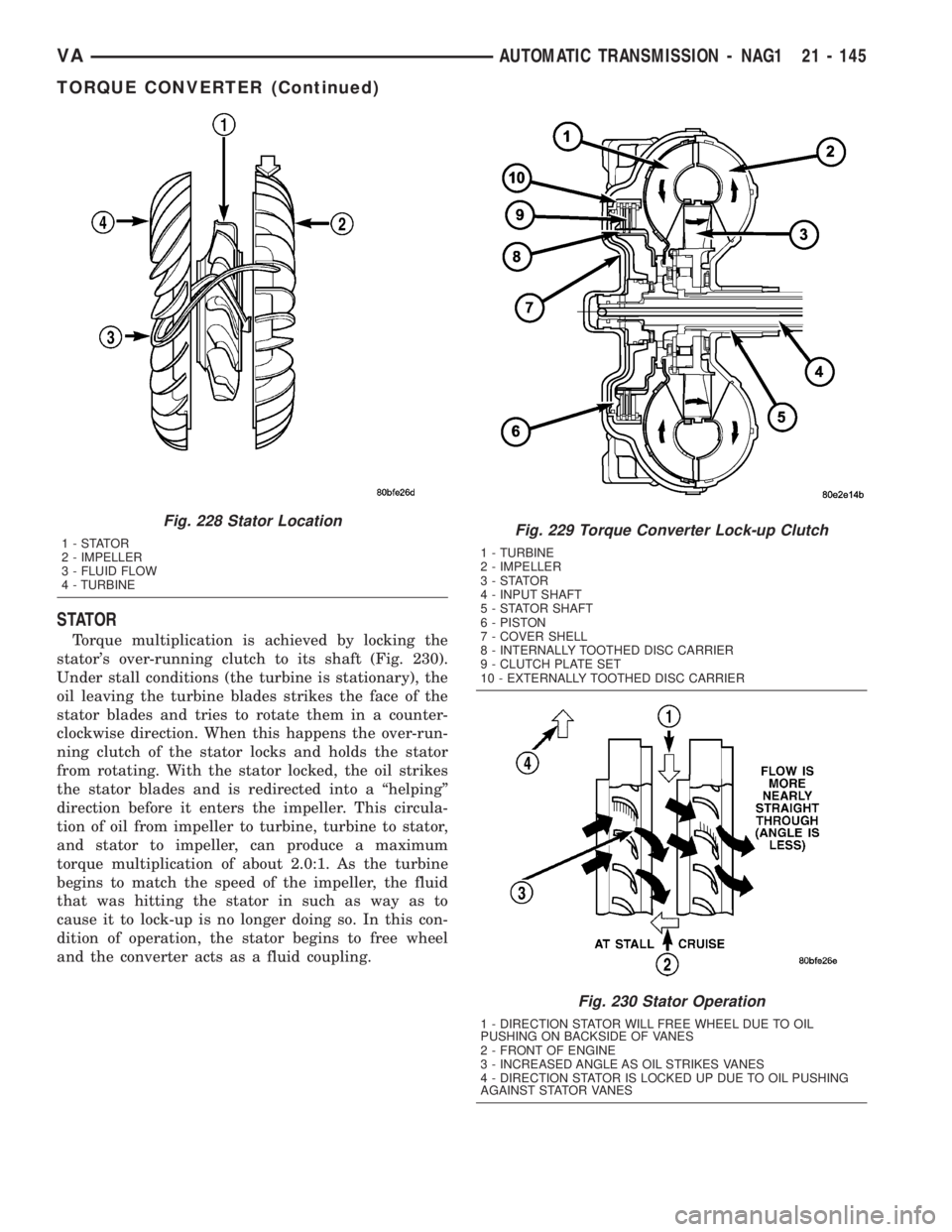

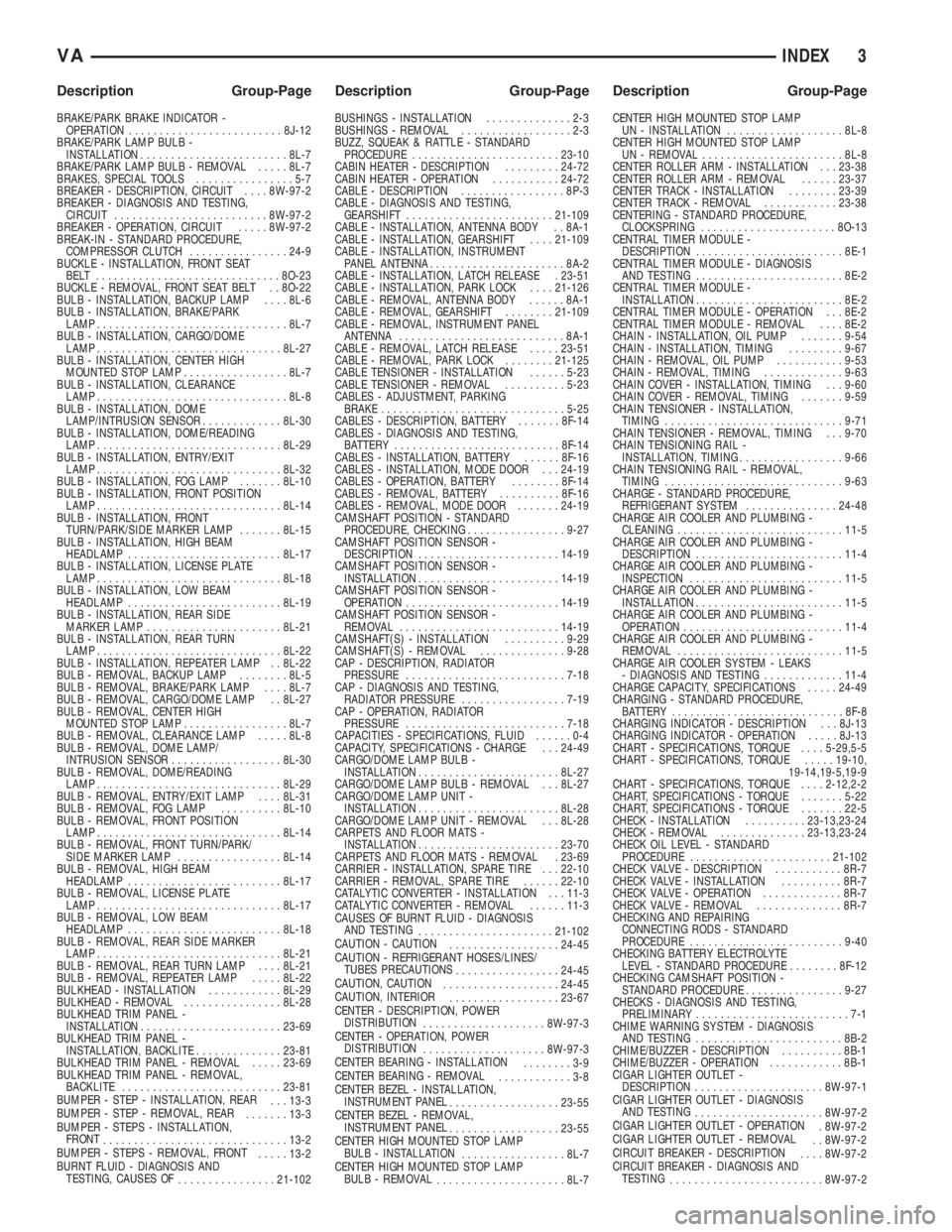

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 230).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-

clockwise direction. When this happens the over-run-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.0:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

Fig. 228 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINEFig. 229 Torque Converter Lock-up Clutch

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

6 - PISTON

7 - COVER SHELL

8 - INTERNALLY TOOTHED DISC CARRIER

9 - CLUTCH PLATE SET

10 - EXTERNALLY TOOTHED DISC CARRIER

Fig. 230 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

VAAUTOMATIC TRANSMISSION - NAG1 21 - 145

TORQUE CONVERTER (Continued)

Page 1148 of 1232

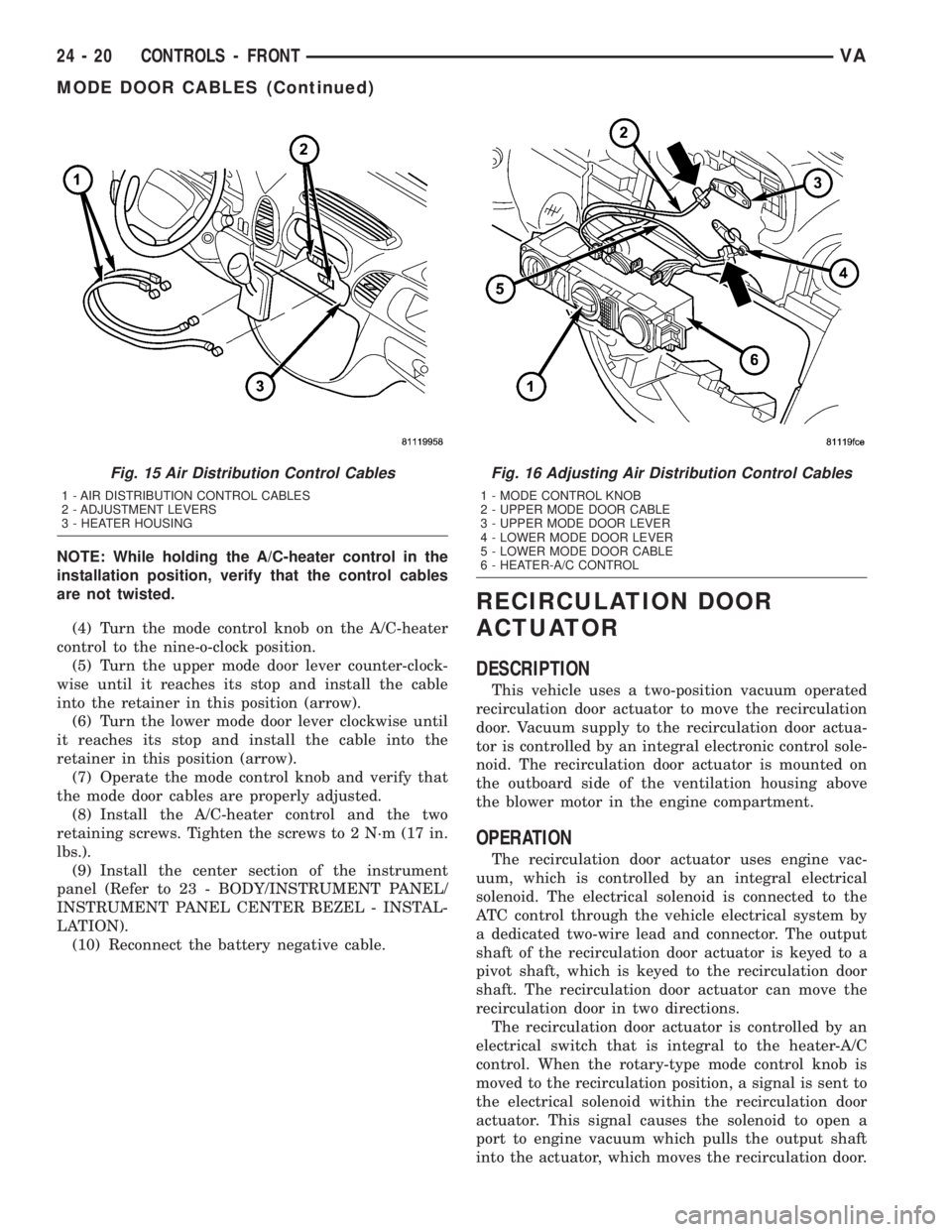

NOTE: While holding the A/C-heater control in the

installation position, verify that the control cables

are not twisted.

(4) Turn the mode control knob on the A/C-heater

control to the nine-o-clock position.

(5) Turn the upper mode door lever counter-clock-

wise until it reaches its stop and install the cable

into the retainer in this position (arrow).

(6) Turn the lower mode door lever clockwise until

it reaches its stop and install the cable into the

retainer in this position (arrow).

(7) Operate the mode control knob and verify that

the mode door cables are properly adjusted.

(8) Install the A/C-heater control and the two

retaining screws. Tighten the screws to 2 N´m (17 in.

lbs.).

(9) Install the center section of the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(10) Reconnect the battery negative cable.

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

This vehicle uses a two-position vacuum operated

recirculation door actuator to move the recirculation

door. Vacuum supply to the recirculation door actua-

tor is controlled by an integral electronic control sole-

noid. The recirculation door actuator is mounted on

the outboard side of the ventilation housing above

the blower motor in the engine compartment.

OPERATION

The recirculation door actuator uses engine vac-

uum, which is controlled by an integral electrical

solenoid. The electrical solenoid is connected to the

ATC control through the vehicle electrical system by

a dedicated two-wire lead and connector. The output

shaft of the recirculation door actuator is keyed to a

pivot shaft, which is keyed to the recirculation door

shaft. The recirculation door actuator can move the

recirculation door in two directions.

The recirculation door actuator is controlled by an

electrical switch that is integral to the heater-A/C

control. When the rotary-type mode control knob is

moved to the recirculation position, a signal is sent to

the electrical solenoid within the recirculation door

actuator. This signal causes the solenoid to open a

port to engine vacuum which pulls the output shaft

into the actuator, which moves the recirculation door.

Fig. 15 Air Distribution Control Cables

1 - AIR DISTRIBUTION CONTROL CABLES

2 - ADJUSTMENT LEVERS

3 - HEATER HOUSING

Fig. 16 Adjusting Air Distribution Control Cables

1 - MODE CONTROL KNOB

2 - UPPER MODE DOOR CABLE

3 - UPPER MODE DOOR LEVER

4 - LOWER MODE DOOR LEVER

5 - LOWER MODE DOOR CABLE

6 - HEATER-A/C CONTROL

24 - 20 CONTROLS - FRONTVA

MODE DOOR CABLES (Continued)

Page 1167 of 1232

DISTRIBUTION - REAR

TABLE OF CONTENTS

page page

AIR FILTER

REMOVAL.............................39

INSTALLATION.........................39

BLOWER MOTOR

REMOVAL.............................39INSTALLATION.........................40

REAR A/C HOUSING

REMOVAL.............................40

INSTALLATION.........................41

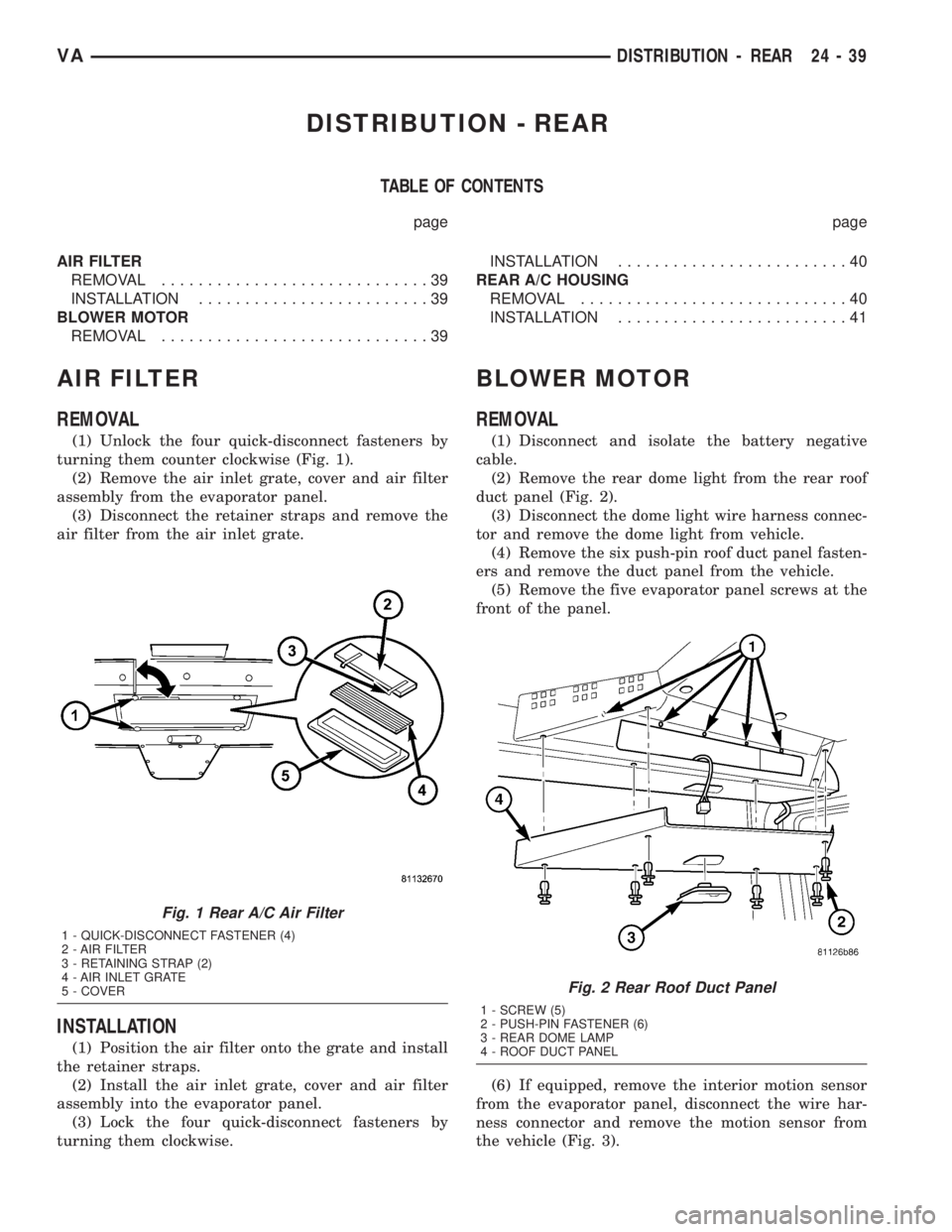

AIR FILTER

REMOVAL

(1) Unlock the four quick-disconnect fasteners by

turning them counter clockwise (Fig. 1).

(2) Remove the air inlet grate, cover and air filter

assembly from the evaporator panel.

(3) Disconnect the retainer straps and remove the

air filter from the air inlet grate.

INSTALLATION

(1) Position the air filter onto the grate and install

the retainer straps.

(2) Install the air inlet grate, cover and air filter

assembly into the evaporator panel.

(3) Lock the four quick-disconnect fasteners by

turning them clockwise.

BLOWER MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear dome light from the rear roof

duct panel (Fig. 2).

(3) Disconnect the dome light wire harness connec-

tor and remove the dome light from vehicle.

(4) Remove the six push-pin roof duct panel fasten-

ers and remove the duct panel from the vehicle.

(5) Remove the five evaporator panel screws at the

front of the panel.

(6) If equipped, remove the interior motion sensor

from the evaporator panel, disconnect the wire har-

ness connector and remove the motion sensor from

the vehicle (Fig. 3).

Fig. 1 Rear A/C Air Filter

1 - QUICK-DISCONNECT FASTENER (4)

2 - AIR FILTER

3 - RETAINING STRAP (2)

4 - AIR INLET GRATE

5 - COVER

Fig. 2 Rear Roof Duct Panel

1 - SCREW (5)

2 - PUSH-PIN FASTENER (6)

3 - REAR DOME LAMP

4 - ROOF DUCT PANEL

VADISTRIBUTION - REAR 24 - 39

Page 1174 of 1232

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

ready. The refrigerant system should not be left open

to the atmosphere any longer than necessary. Cap or

plug all lines and fittings as soon as they are opened

to prevent the entrance of dirt and moisture. All lines

and components in parts stock should be capped or

sealed until they are to be installed.

All tools, including the refrigerant recycling equip-

ment, the manifold gauge set, and test hoses should

be kept clean and dry. All tools and equipment must

be designed for R-134a refrigerant.

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM LEAKS

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

If the air conditioning system is not cooling prop-

erly, determine if the refrigerant system is fully-

charged. (Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND TESTING -

A/C PERFORMANCE)

An electronic leak detector designed for R-134a

refrigerant is recommended for locating and confirm-

ing refrigerant system leaks. Refer to the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

An oily residue on or near refrigerant system lines,

connector fittings, components, or component seals

can indicate the general location of a possible refrig-

erant leak. However, the exact leak location should

be confirmed with an electronic leak detector prior to

component repair or replacement.

To detect a leak in the refrigerant system, perform

one of the following procedures:

SYSTEM EMPTY

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(2) Connect and dispense 0.283 kilograms (0.625

pounds or 10 ounces) of R-134a refrigerant into the

evacuated refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

CHARGE)

(3) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.(4) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-

tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(5) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run with the air conditioning system

turned on for five minutes.

(3) With the engine not running, use a electronic

R-134a leak detector and search for leaks. Because

R-134a refrigerant is heavier than air, the leak detec-

tor probe should be moved slowly along the bottom

side of all refrigerant lines, connector fittings and

components.

(4) To inspect the evaporator coil for leaks, insert

the electronic leak detector probe into the center

instrument panel outlet. Set the blower motor switch

to the lowest speed position, the A/C button in the

On position, and select the Recirculation Mode.

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: EYE PROTECTION MUST BE WORN

WHEN SERVICING AN AIR CONDITIONING REFRIG-

ERANT SYSTEM. TURN OFF (ROTATE CLOCKWISE)

ALL VALVES ON THE EQUIPMENT BEING USED,

BEFORE CONNECTING TO OR DISCONNECTING

FROM THE REFRIGERANT SYSTEM. FAILURE TO

OBSERVE THESE WARNINGS MAY RESULT IN PER-

SONAL INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

24 - 46 PLUMBINGVA

PLUMBING (Continued)

Page 1213 of 1232

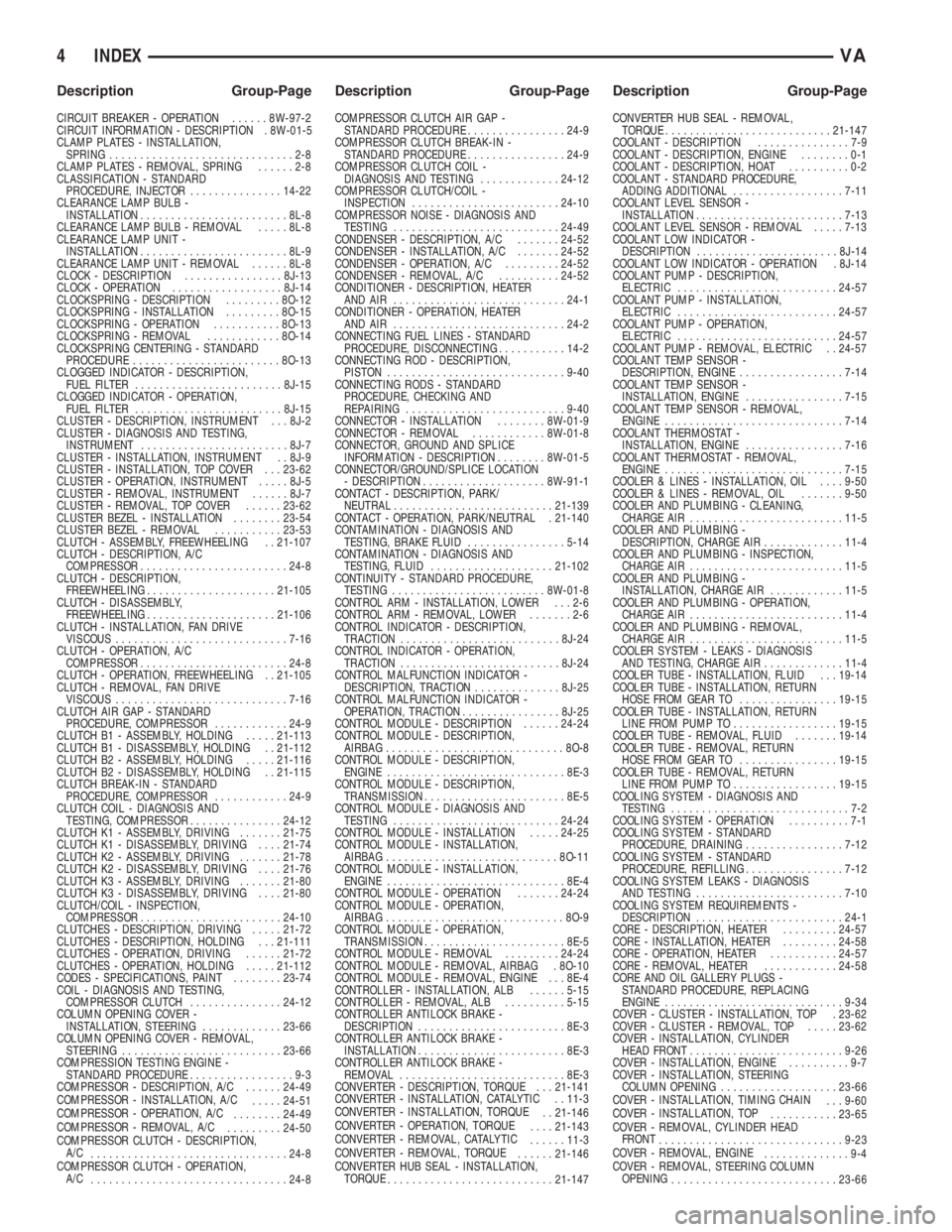

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-12

BRAKE/PARK LAMP BULB -

INSTALLATION........................8L-7

BRAKE/PARK LAMP BULB - REMOVAL.....8L-7

BRAKES, SPECIAL TOOLS................5-7

BREAKER - DESCRIPTION, CIRCUIT....8W-97-2

BREAKER - DIAGNOSIS AND TESTING,

CIRCUIT.........................8W-97-2

BREAKER - OPERATION, CIRCUIT.....8W-97-2

BREAK-IN - STANDARD PROCEDURE,

COMPRESSOR CLUTCH................24-9

BUCKLE - INSTALLATION, FRONT SEAT

BELT ..............................8O-23

BUCKLE - REMOVAL, FRONT SEAT BELT . . 8O-22

BULB - INSTALLATION, BACKUP LAMP....8L-6

BULB - INSTALLATION, BRAKE/PARK

LAMP...............................8L-7

BULB - INSTALLATION, CARGO/DOME

LAMP..............................8L-27

BULB - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP.................8L-7

BULB - INSTALLATION, CLEARANCE

LAMP...............................8L-8

BULB - INSTALLATION, DOME

LAMP/INTRUSION SENSOR.............8L-30

BULB - INSTALLATION, DOME/READING

LAMP..............................8L-29

BULB - INSTALLATION, ENTRY/EXIT

LAMP..............................8L-32

BULB - INSTALLATION, FOG LAMP.......8L-10

BULB - INSTALLATION, FRONT POSITION

LAMP..............................8L-14

BULB - INSTALLATION, FRONT

TURN/PARK/SIDE MARKER LAMP.......8L-15

BULB - INSTALLATION, HIGH BEAM

HEADLAMP.........................8L-17

BULB - INSTALLATION, LICENSE PLATE

LAMP..............................8L-18

BULB - INSTALLATION, LOW BEAM

HEADLAMP.........................8L-19

BULB - INSTALLATION, REAR SIDE

MARKER LAMP......................8L-21

BULB - INSTALLATION, REAR TURN

LAMP..............................8L-22

BULB - INSTALLATION, REPEATER LAMP . . 8L-22

BULB - REMOVAL, BACKUP LAMP........8L-5

BULB - REMOVAL, BRAKE/PARK LAMP....8L-7

BULB - REMOVAL, CARGO/DOME LAMP . . 8L-27

BULB - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP.................8L-7

BULB - REMOVAL, CLEARANCE LAMP.....8L-8

BULB - REMOVAL, DOME LAMP/

INTRUSION SENSOR..................8L-30

BULB - REMOVAL, DOME/READING

LAMP..............................8L-29

BULB - REMOVAL, ENTRY/EXIT LAMP....8L-31

BULB - REMOVAL, FOG LAMP..........8L-10

BULB - REMOVAL, FRONT POSITION

LAMP..............................8L-14

BULB - REMOVAL, FRONT TURN/PARK/

SIDE MARKER LAMP.................8L-14

BULB - REMOVAL, HIGH BEAM

HEADLAMP.........................8L-17

BULB - REMOVAL, LICENSE PLATE

LAMP..............................8L-17

BULB - REMOVAL, LOW BEAM

HEADLAMP.........................8L-18

BULB - REMOVAL, REAR SIDE MARKER

LAMP..............................8L-21

BULB - REMOVAL, REAR TURN LAMP....8L-21

BULB - REMOVAL, REPEATER LAMP.....8L-22

BULKHEAD - INSTALLATION............8L-29

BULKHEAD - REMOVAL................8L-28

BULKHEAD TRIM PANEL -

INSTALLATION.......................23-69

BULKHEAD TRIM PANEL -

INSTALLATION, BACKLITE..............23-81

BULKHEAD TRIM PANEL - REMOVAL.....23-69

BULKHEAD TRIM PANEL - REMOVAL,

BACKLITE..........................23-81

BUMPER - STEP - INSTALLATION, REAR

. . . 13-3

BUMPER - STEP - REMOVAL, REAR

.......13-3

BUMPER - STEPS - INSTALLATION,

FRONT

..............................13-2

BUMPER - STEPS - REMOVAL, FRONT

.....13-2

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF

................21-102BUSHINGS - INSTALLATION..............2-3

BUSHINGS - REMOVAL..................2-3

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE........................23-10

CABIN HEATER - DESCRIPTION.........24-72

CABIN HEATER - OPERATION...........24-72

CABLE - DESCRIPTION.................8P-3

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT........................21-109

CABLE - INSTALLATION, ANTENNA BODY . . 8A-1

CABLE - INSTALLATION, GEARSHIFT....21-109

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-2

CABLE - INSTALLATION, LATCH RELEASE . 23-51

CABLE - INSTALLATION, PARK LOCK....21-126

CABLE - REMOVAL, ANTENNA BODY......8A-1

CABLE - REMOVAL, GEARSHIFT........21-109

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-1

CABLE - REMOVAL, LATCH RELEASE.....23-51

CABLE - REMOVAL, PARK LOCK........21-125

CABLE TENSIONER - INSTALLATION......5-23

CABLE TENSIONER - REMOVAL..........5-23

CABLES - ADJUSTMENT, PARKING

BRAKE..............................5-25

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-14

CABLES - INSTALLATION, BATTERY......8F-16

CABLES - INSTALLATION, MODE DOOR . . . 24-19

CABLES - OPERATION, BATTERY........8F-14

CABLES - REMOVAL, BATTERY..........8F-16

CABLES - REMOVAL, MODE DOOR.......24-19

CAMSHAFT POSITION - STANDARD

PROCEDURE, CHECKING................9-27

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-19

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-19

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-19

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-19

CAMSHAFT(S) - INSTALLATION..........9-29

CAMSHAFT(S) - REMOVAL..............9-28

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-18

CAP - DIAGNOSIS AND TESTING,

RADIATOR PRESSURE.................7-19

CAP - OPERATION, RADIATOR

PRESSURE..........................7-18

CAPACITIES - SPECIFICATIONS, FLUID......0-4

CAPACITY, SPECIFICATIONS - CHARGE . . . 24-49

CARGO/DOME LAMP BULB -

INSTALLATION.......................8L-27

CARGO/DOME LAMP BULB - REMOVAL . . . 8L-27

CARGO/DOME LAMP UNIT -

INSTALLATION.......................8L-28

CARGO/DOME LAMP UNIT - REMOVAL . . . 8L-28

CARPETS AND FLOOR MATS -

INSTALLATION.......................23-70

CARPETS AND FLOOR MATS - REMOVAL . 23-69

CARRIER - INSTALLATION, SPARE TIRE . . . 22-10

CARRIER - REMOVAL, SPARE TIRE......22-10

CATALYTIC CONVERTER - INSTALLATION . . . 11-3

CATALYTIC CONVERTER - REMOVAL......11-3

CAUSES OF BURNT FLUID - DIAGNOSIS

AND TESTING

......................21-102

CAUTION - CAUTION

..................24-45

CAUTION - REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS

.................24-45

CAUTION, CAUTION

...................24-45

CAUTION, INTERIOR

..................23-67

CENTER - DESCRIPTION, POWER

DISTRIBUTION

....................8W-97-3

CENTER - OPERATION, POWER

DISTRIBUTION

....................8W-97-3

CENTER BEARING - INSTALLATION

........3-9

CENTER BEARING - REMOVAL

............3-8

CENTER BEZEL - INSTALLATION,

INSTRUMENT PANEL

..................23-55

CENTER BEZEL - REMOVAL,

INSTRUMENT PANEL

..................23-55

CENTER HIGH MOUNTED STOP LAMP

BULB - INSTALLATION

.................8L-7

CENTER HIGH MOUNTED STOP LAMP

BULB - REMOVAL

.....................8L-7CENTER HIGH MOUNTED STOP LAMP

UN - INSTALLATION...................8L-8

CENTER HIGH MOUNTED STOP LAMP

UN - REMOVAL.......................8L-8

CENTER ROLLER ARM - INSTALLATION . . . 23-38

CENTER ROLLER ARM - REMOVAL......23-37

CENTER TRACK - INSTALLATION........23-39

CENTER TRACK - REMOVAL............23-38

CENTERING - STANDARD PROCEDURE,

CLOCKSPRING......................8O-13

CENTRAL TIMER MODULE -

DESCRIPTION........................8E-1

CENTRAL TIMER MODULE - DIAGNOSIS

AND TESTING........................8E-2

CENTRAL TIMER MODULE -

INSTALLATION........................8E-2

CENTRAL TIMER MODULE - OPERATION . . . 8E-2

CENTRAL TIMER MODULE - REMOVAL....8E-2

CHAIN - INSTALLATION, OIL PUMP.......9-54

CHAIN - INSTALLATION, TIMING.........9-67

CHAIN - REMOVAL, OIL PUMP...........9-53

CHAIN - REMOVAL, TIMING.............9-63

CHAIN COVER - INSTALLATION, TIMING . . . 9-60

CHAIN COVER - REMOVAL, TIMING.......9-59

CHAIN TENSIONER - INSTALLATION,

TIMING.............................9-71

CHAIN TENSIONER - REMOVAL, TIMING . . . 9-70

CHAIN TENSIONING RAIL -

INSTALLATION, TIMING.................9-66

CHAIN TENSIONING RAIL - REMOVAL,

TIMING.............................9-63

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-48

CHARGE AIR COOLER AND PLUMBING -

CLEANING...........................11-5

CHARGE AIR COOLER AND PLUMBING -

DESCRIPTION........................11-4

CHARGE AIR COOLER AND PLUMBING -

INSPECTION.........................11-5

CHARGE AIR COOLER AND PLUMBING -

INSTALLATION........................11-5

CHARGE AIR COOLER AND PLUMBING -

OPERATION..........................11-4

CHARGE AIR COOLER AND PLUMBING -

REMOVAL...........................11-5

CHARGE AIR COOLER SYSTEM - LEAKS

- DIAGNOSIS AND TESTING.............11-4

CHARGE CAPACITY, SPECIFICATIONS.....24-49

CHARGING - STANDARD PROCEDURE,

BATTERY............................8F-8

CHARGING INDICATOR - DESCRIPTION . . . 8J-13

CHARGING INDICATOR - OPERATION.....8J-13

CHART - SPECIFICATIONS, TORQUE....5-29,5-5

CHART - SPECIFICATIONS, TORQUE.....19-10,

19-14,19-5,19-9

CHART - SPECIFICATIONS, TORQUE....2-12,2-2

CHART, SPECIFICATIONS - TORQUE.......5-22

CHART, SPECIFICATIONS - TORQUE.......22-5

CHECK - INSTALLATION..........23-13,23-24

CHECK - REMOVAL..............23-13,23-24

CHECK OIL LEVEL - STANDARD

PROCEDURE.......................21-102

CHECK VALVE - DESCRIPTION...........8R-7

CHECK VALVE - INSTALLATION..........8R-7

CHECK VALVE - OPERATION.............8R-7

CHECK VALVE - REMOVAL..............8R-7

CHECKING AND REPAIRING

CONNECTING RODS - STANDARD

PROCEDURE.........................9-40

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-12

CHECKING CAMSHAFT POSITION -

STANDARD PROCEDURE................9-27

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY.........................7-1

CHIME WARNING SYSTEM - DIAGNOSIS

AND TESTING........................8B-2

CHIME/BUZZER - DESCRIPTION..........8B-1

CHIME/BUZZER - OPERATION............8B-1

CIGAR LIGHTER OUTLET -

DESCRIPTION.....................8W-97-1

CIGAR LIGHTER OUTLET - DIAGNOSIS

AND TESTING

.....................8W-97-2

CIGAR LIGHTER OUTLET - OPERATION

. 8W-97-2

CIGAR LIGHTER OUTLET - REMOVAL

. . 8W-97-2

CIRCUIT BREAKER - DESCRIPTION

....8W-97-2

CIRCUIT BREAKER - DIAGNOSIS AND

TESTING

.........................8W-97-2

VAINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 1214 of 1232

CIRCUIT BREAKER - OPERATION......8W-97-2

CIRCUIT INFORMATION - DESCRIPTION . 8W-01-5

CLAMP PLATES - INSTALLATION,

SPRING..............................2-8

CLAMP PLATES - REMOVAL, SPRING......2-8

CLASSIFICATION - STANDARD

PROCEDURE, INJECTOR...............14-22

CLEARANCE LAMP BULB -

INSTALLATION........................8L-8

CLEARANCE LAMP BULB - REMOVAL.....8L-8

CLEARANCE LAMP UNIT -

INSTALLATION........................8L-9

CLEARANCE LAMP UNIT - REMOVAL......8L-8

CLOCK - DESCRIPTION................8J-13

CLOCK - OPERATION..................8J-14

CLOCKSPRING - DESCRIPTION.........8O-12

CLOCKSPRING - INSTALLATION.........8O-15

CLOCKSPRING - OPERATION...........8O-13

CLOCKSPRING - REMOVAL............8O-14

CLOCKSPRING CENTERING - STANDARD

PROCEDURE........................8O-13

CLOGGED INDICATOR - DESCRIPTION,

FUEL FILTER........................8J-15

CLOGGED INDICATOR - OPERATION,

FUEL FILTER........................8J-15

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-2

CLUSTER - DIAGNOSIS AND TESTING,

INSTRUMENT........................8J-7

CLUSTER - INSTALLATION, INSTRUMENT . . 8J-9

CLUSTER - INSTALLATION, TOP COVER . . . 23-62

CLUSTER - OPERATION, INSTRUMENT.....8J-5

CLUSTER - REMOVAL, INSTRUMENT......8J-7

CLUSTER - REMOVAL, TOP COVER......23-62

CLUSTER BEZEL - INSTALLATION........23-54

CLUSTER BEZEL - REMOVAL...........23-53

CLUTCH - ASSEMBLY, FREEWHEELING . . 21-107

CLUTCH - DESCRIPTION, A/C

COMPRESSOR........................24-8

CLUTCH - DESCRIPTION,

FREEWHEELING.....................21-105

CLUTCH - DISASSEMBLY,

FREEWHEELING.....................21-106

CLUTCH - INSTALLATION, FAN DRIVE

VISCOUS............................7-16

CLUTCH - OPERATION, A/C

COMPRESSOR........................24-8

CLUTCH - OPERATION, FREEWHEELING . . 21-105

CLUTCH - REMOVAL, FAN DRIVE

VISCOUS............................7-16

CLUTCH AIR GAP - STANDARD

PROCEDURE, COMPRESSOR............24-9

CLUTCH B1 - ASSEMBLY, HOLDING.....21-113

CLUTCH B1 - DISASSEMBLY, HOLDING . . 21-112

CLUTCH B2 - ASSEMBLY, HOLDING.....21-116

CLUTCH B2 - DISASSEMBLY, HOLDING . . 21-115

CLUTCH BREAK-IN - STANDARD

PROCEDURE, COMPRESSOR............24-9

CLUTCH COIL - DIAGNOSIS AND

TESTING, COMPRESSOR...............24-12

CLUTCH K1 - ASSEMBLY, DRIVING.......21-75

CLUTCH K1 - DISASSEMBLY, DRIVING....21-74

CLUTCH K2 - ASSEMBLY, DRIVING.......21-78

CLUTCH K2 - DISASSEMBLY, DRIVING....21-76

CLUTCH K3 - ASSEMBLY, DRIVING.......21-80

CLUTCH K3 - DISASSEMBLY, DRIVING....21-80

CLUTCH/COIL - INSPECTION,

COMPRESSOR.......................24-10

CLUTCHES - DESCRIPTION, DRIVING.....21-72

CLUTCHES - DESCRIPTION, HOLDING . . . 21-111

CLUTCHES - OPERATION, DRIVING......21-72

CLUTCHES - OPERATION, HOLDING.....21-112

CODES - SPECIFICATIONS, PAINT........23-74

COIL - DIAGNOSIS AND TESTING,

COMPRESSOR CLUTCH...............24-12

COLUMN OPENING COVER -

INSTALLATION, STEERING.............23-66

COLUMN OPENING COVER - REMOVAL,

STEERING..........................23-66

COMPRESSION TESTING ENGINE -

STANDARD PROCEDURE.................9-3

COMPRESSOR - DESCRIPTION, A/C......24-49

COMPRESSOR - INSTALLATION, A/C

.....24-51

COMPRESSOR - OPERATION, A/C

........24-49

COMPRESSOR - REMOVAL, A/C

.........24-50

COMPRESSOR CLUTCH - DESCRIPTION,

A/C

................................24-8

COMPRESSOR CLUTCH - OPERATION,

A/C

................................24-8COMPRESSOR CLUTCH AIR GAP -

STANDARD PROCEDURE................24-9

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE................24-9

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-12

COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-10

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING...........................24-49

CONDENSER - DESCRIPTION, A/C.......24-52

CONDENSER - INSTALLATION, A/C.......24-52

CONDENSER - OPERATION, A/C.........24-52

CONDENSER - REMOVAL, A/C..........24-52

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-2

CONNECTING FUEL LINES - STANDARD

PROCEDURE, DISCONNECTING...........14-2

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-40

CONNECTING RODS - STANDARD

PROCEDURE, CHECKING AND

REPAIRING..........................9-40

CONNECTOR - INSTALLATION........8W-01-9

CONNECTOR - REMOVAL............8W-01-8

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-5

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONTACT - DESCRIPTION, PARK/

NEUTRAL..........................21-139

CONTACT - OPERATION, PARK/NEUTRAL . 21-140

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-14

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....................21-102

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-8

CONTROL ARM - INSTALLATION, LOWER . . . 2-6

CONTROL ARM - REMOVAL, LOWER.......2-6

CONTROL INDICATOR - DESCRIPTION,

TRACTION..........................8J-24

CONTROL INDICATOR - OPERATION,

TRACTION..........................8J-24

CONTROL MALFUNCTION INDICATOR -

DESCRIPTION, TRACTION..............8J-25

CONTROL MALFUNCTION INDICATOR -

OPERATION, TRACTION................8J-25

CONTROL MODULE - DESCRIPTION......24-24

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-8

CONTROL MODULE - DESCRIPTION,

ENGINE.............................8E-3

CONTROL MODULE - DESCRIPTION,

TRANSMISSION.......................8E-5

CONTROL MODULE - DIAGNOSIS AND

TESTING...........................24-24

CONTROL MODULE - INSTALLATION.....24-25

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-11

CONTROL MODULE - INSTALLATION,

ENGINE.............................8E-4

CONTROL MODULE - OPERATION.......24-24

CONTROL MODULE - OPERATION,

AIRBAG.............................8O-9

CONTROL MODULE - OPERATION,

TRANSMISSION.......................8E-5

CONTROL MODULE - REMOVAL.........24-24

CONTROL MODULE - REMOVAL, AIRBAG . 8O-10

CONTROL MODULE - REMOVAL, ENGINE . . . 8E-4

CONTROLLER - INSTALLATION, ALB......5-15

CONTROLLER - REMOVAL, ALB..........5-15

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-3

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-3

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-3

CONVERTER - DESCRIPTION, TORQUE . . . 21-141

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - INSTALLATION, TORQUE

. . 21-146

CONVERTER - OPERATION, TORQUE

....21-143

CONVERTER - REMOVAL, CATALYTIC

......11-3

CONVERTER - REMOVAL, TORQUE

......21-146

CONVERTER HUB SEAL - INSTALLATION,

TORQUE

...........................21-147CONVERTER HUB SEAL - REMOVAL,

TORQUE...........................21-147

COOLANT - DESCRIPTION...............7-9

COOLANT - DESCRIPTION, ENGINE........0-1

COOLANT - DESCRIPTION, HOAT..........0-2

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL..................7-11

COOLANT LEVEL SENSOR -

INSTALLATION........................7-13

COOLANT LEVEL SENSOR - REMOVAL.....7-13

COOLANT LOW INDICATOR -

DESCRIPTION.......................8J-14

COOLANT LOW INDICATOR - OPERATION . 8J-14

COOLANT PUMP - DESCRIPTION,

ELECTRIC..........................24-57

COOLANT PUMP - INSTALLATION,

ELECTRIC..........................24-57

COOLANT PUMP - OPERATION,

ELECTRIC..........................24-57

COOLANT PUMP - REMOVAL, ELECTRIC . . 24-57

COOLANT TEMP SENSOR -

DESCRIPTION, ENGINE.................7-14

COOLANT TEMP SENSOR -

INSTALLATION, ENGINE................7-15

COOLANT TEMP SENSOR - REMOVAL,

ENGINE.............................7-14

COOLANT THERMOSTAT -

INSTALLATION, ENGINE................7-16

COOLANT THERMOSTAT - REMOVAL,

ENGINE.............................7-15

COOLER & LINES - INSTALLATION, OIL....9-50

COOLER & LINES - REMOVAL, OIL.......9-50

COOLER AND PLUMBING - CLEANING,

CHARGE AIR.........................11-5

COOLER AND PLUMBING -

DESCRIPTION, CHARGE AIR.............11-4

COOLER AND PLUMBING - INSPECTION,

CHARGE AIR.........................11-5

COOLER AND PLUMBING -

INSTALLATION, CHARGE AIR............11-5

COOLER AND PLUMBING - OPERATION,

CHARGE AIR.........................11-4

COOLER AND PLUMBING - REMOVAL,

CHARGE AIR.........................11-5

COOLER SYSTEM - LEAKS - DIAGNOSIS

AND TESTING, CHARGE AIR.............11-4

COOLER TUBE - INSTALLATION, FLUID . . . 19-14

COOLER TUBE - INSTALLATION, RETURN

HOSE FROM GEAR TO................19-15

COOLER TUBE - INSTALLATION, RETURN

LINE FROM PUMP TO.................19-15

COOLER TUBE - REMOVAL, FLUID.......19-14

COOLER TUBE - REMOVAL, RETURN

HOSE FROM GEAR TO................19-15

COOLER TUBE - REMOVAL, RETURN

LINE FROM PUMP TO.................19-15

COOLING SYSTEM - DIAGNOSIS AND

TESTING.............................7-2

COOLING SYSTEM - OPERATION..........7-1

COOLING SYSTEM - STANDARD

PROCEDURE, DRAINING................7-12

COOLING SYSTEM - STANDARD

PROCEDURE, REFILLING................7-12

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING........................7-10

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

CORE - DESCRIPTION, HEATER.........24-57

CORE - INSTALLATION, HEATER.........24-58

CORE - OPERATION, HEATER...........24-57

CORE - REMOVAL, HEATER............24-58

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, REPLACING

ENGINE.............................9-34

COVER - CLUSTER - INSTALLATION, TOP . 23-62

COVER - CLUSTER - REMOVAL, TOP.....23-62

COVER - INSTALLATION, CYLINDER

HEAD FRONT.........................9-26

COVER - INSTALLATION, ENGINE..........9-7

COVER - INSTALLATION, STEERING

COLUMN OPENING...................23-66

COVER - INSTALLATION, TIMING CHAIN

. . . 9-60

COVER - INSTALLATION, TOP

...........23-65

COVER - REMOVAL, CYLINDER HEAD

FRONT

..............................9-23

COVER - REMOVAL, ENGINE

..............9-4

COVER - REMOVAL, STEERING COLUMN

OPENING

...........................23-66

4 INDEXVA

Description Group-Page Description Group-Page Description Group-Page