clock MERCEDES-BENZ SPRINTER 2005 Service Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 808 of 1232

(24) Remove camshaft sprocket to timing chain tie

straps.

(25) Install guide rail and tighten low pressure

fuel pump drive to 50N´m (37 lbs. ft.).

(26) Install low pressure fuel pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - INSTALLATION).

(27) Install timing chain tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

(28) Install vacuum pump (Refer to 9 - ENGINE/

ENGINE BLOCK/INTERNAL VACUUM PUMP -

INSTALLATION).

(29) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(30) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(31) Connect negative battery cable.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHES.

(32) Start engine and inspect for leaks. Care must

be taken to observe the fuel system warning (Refer to

14 - FUEL SYSTEM - WARNING).

TIMING CHAIN TENSIONER

REMOVAL

(1) Disconnect negative battery cable.

CAUTION: Rotate engine at crankshaft only. DO

NOT rotate the engine with the bolt of the camshaft

sprocket. DO NOT rotate the engine counter clock-

wise.

NOTE: Markings on the camshaft and camshaft

bearing cap must be aligned.

(2) Position piston of number 1 cylinder to ignition

TDC.

(3) Remove intake air scoop.

(4) Remove accessory drive belt and idler pulley

above generator (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

(5) Remove timing chain tensioner (Fig. 85).

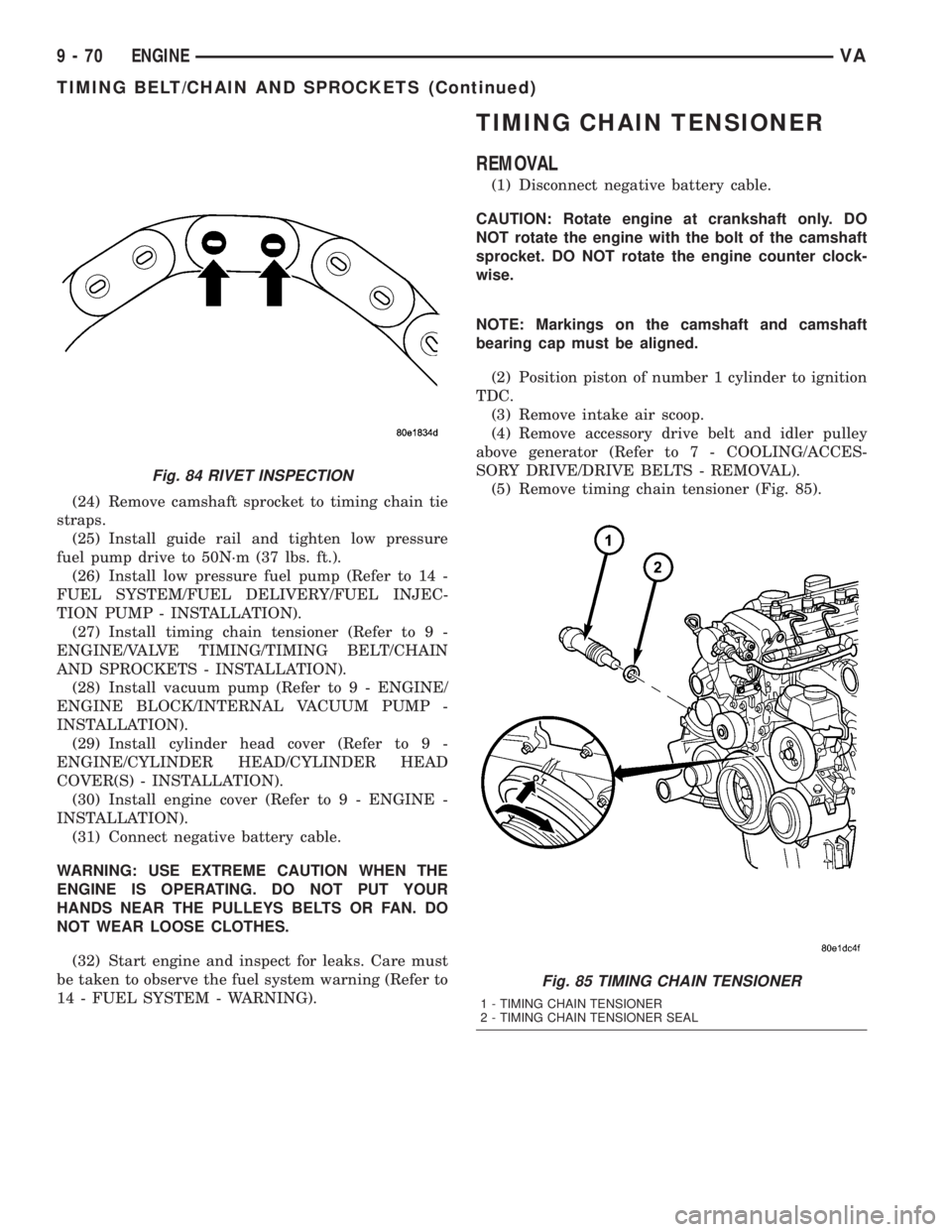

Fig. 84 RIVET INSPECTION

Fig. 85 TIMING CHAIN TENSIONER

1 - TIMING CHAIN TENSIONER

2 - TIMING CHAIN TENSIONER SEAL

9 - 70 ENGINEVA

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 865 of 1232

COLUMN

TABLE OF CONTENTS

page page

COLUMN

SPECIFICATIONS - TORQUE CHART.........5

INTERMEDIATE SHAFT

REMOVAL.............................5

INSTALLATION..........................5

KEY/LOCK CYLINDER

REMOVAL.............................6INSTALLATION..........................7

STEERING WHEEL

REMOVAL.............................7

INSTALLATION..........................7

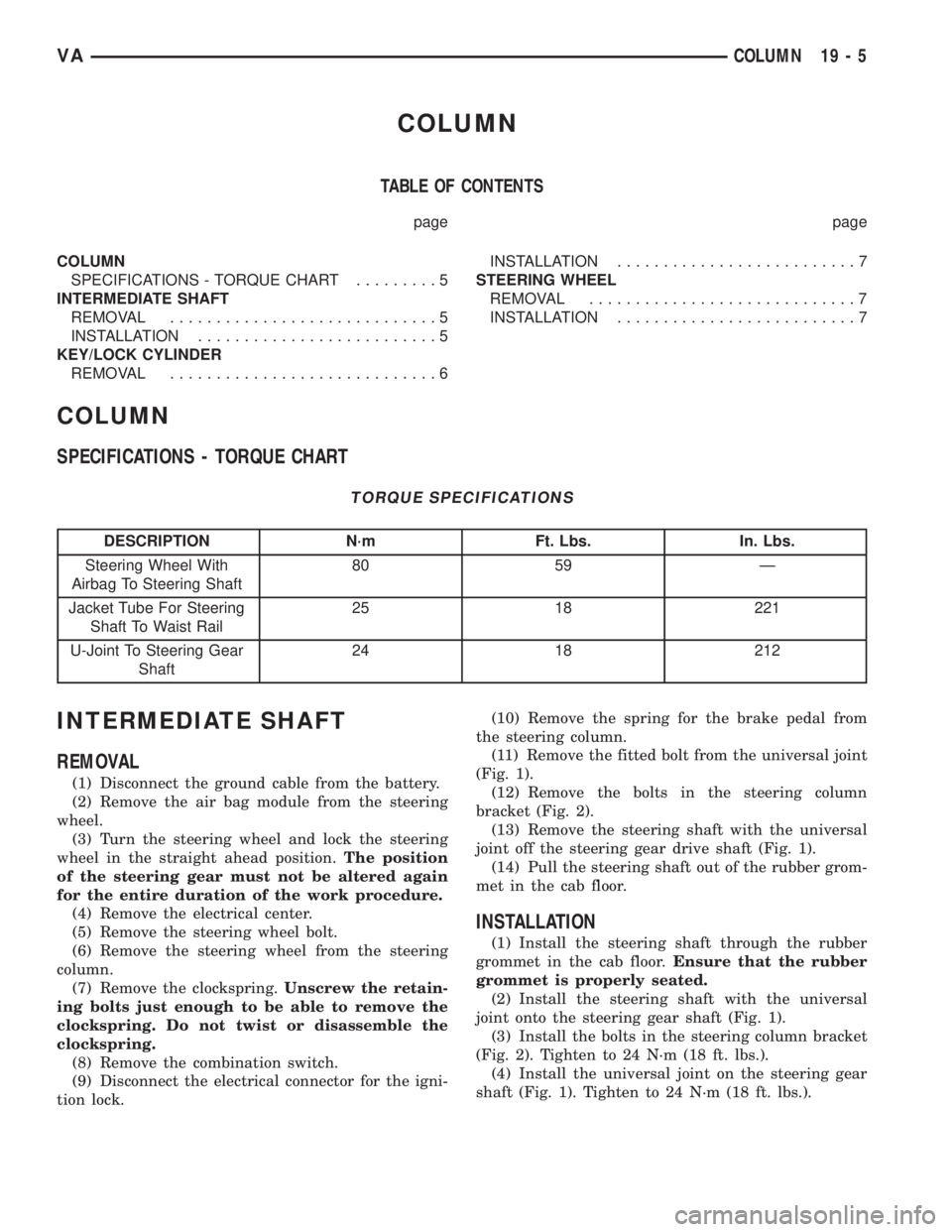

COLUMN

SPECIFICATIONS - TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel With

Airbag To Steering Shaft80 59 Ð

Jacket Tube For Steering

Shaft To Waist Rail25 18 221

U-Joint To Steering Gear

Shaft24 18 212

INTERMEDIATE SHAFT

REMOVAL

(1) Disconnect the ground cable from the battery.

(2) Remove the air bag module from the steering

wheel.

(3) Turn the steering wheel and lock the steering

wheel in the straight ahead position.The position

of the steering gear must not be altered again

for the entire duration of the work procedure.

(4) Remove the electrical center.

(5) Remove the steering wheel bolt.

(6) Remove the steering wheel from the steering

column.

(7) Remove the clockspring.Unscrew the retain-

ing bolts just enough to be able to remove the

clockspring. Do not twist or disassemble the

clockspring.

(8) Remove the combination switch.

(9) Disconnect the electrical connector for the igni-

tion lock.(10) Remove the spring for the brake pedal from

the steering column.

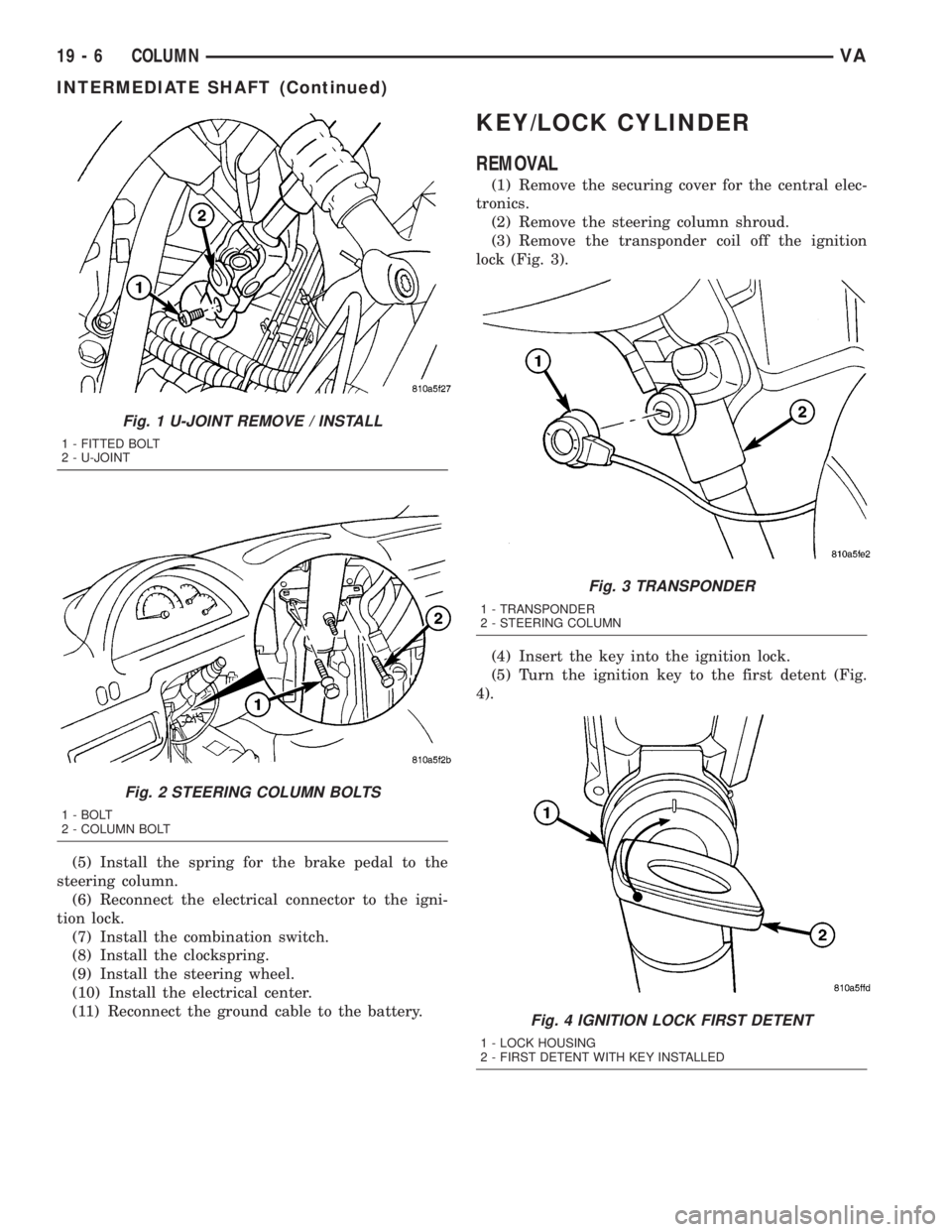

(11) Remove the fitted bolt from the universal joint

(Fig. 1).

(12) Remove the bolts in the steering column

bracket (Fig. 2).

(13) Remove the steering shaft with the universal

joint off the steering gear drive shaft (Fig. 1).

(14) Pull the steering shaft out of the rubber grom-

met in the cab floor.

INSTALLATION

(1) Install the steering shaft through the rubber

grommet in the cab floor.Ensure that the rubber

grommet is properly seated.

(2) Install the steering shaft with the universal

joint onto the steering gear shaft (Fig. 1).

(3) Install the bolts in the steering column bracket

(Fig. 2). Tighten to 24 N´m (18 ft. lbs.).

(4) Install the universal joint on the steering gear

shaft (Fig. 1). Tighten to 24 N´m (18 ft. lbs.).

VACOLUMN 19 - 5

Page 866 of 1232

(5) Install the spring for the brake pedal to the

steering column.

(6) Reconnect the electrical connector to the igni-

tion lock.

(7) Install the combination switch.

(8) Install the clockspring.

(9) Install the steering wheel.

(10) Install the electrical center.

(11) Reconnect the ground cable to the battery.

KEY/LOCK CYLINDER

REMOVAL

(1) Remove the securing cover for the central elec-

tronics.

(2) Remove the steering column shroud.

(3) Remove the transponder coil off the ignition

lock (Fig. 3).

(4) Insert the key into the ignition lock.

(5) Turn the ignition key to the first detent (Fig.

4).

Fig. 1 U-JOINT REMOVE / INSTALL

1 - FITTED BOLT

2 - U-JOINT

Fig. 2 STEERING COLUMN BOLTS

1 - BOLT

2 - COLUMN BOLT

Fig. 3 TRANSPONDER

1 - TRANSPONDER

2 - STEERING COLUMN

Fig. 4 IGNITION LOCK FIRST DETENT

1 - LOCK HOUSING

2 - FIRST DETENT WITH KEY INSTALLED

19 - 6 COLUMNVA

INTERMEDIATE SHAFT (Continued)

Page 904 of 1232

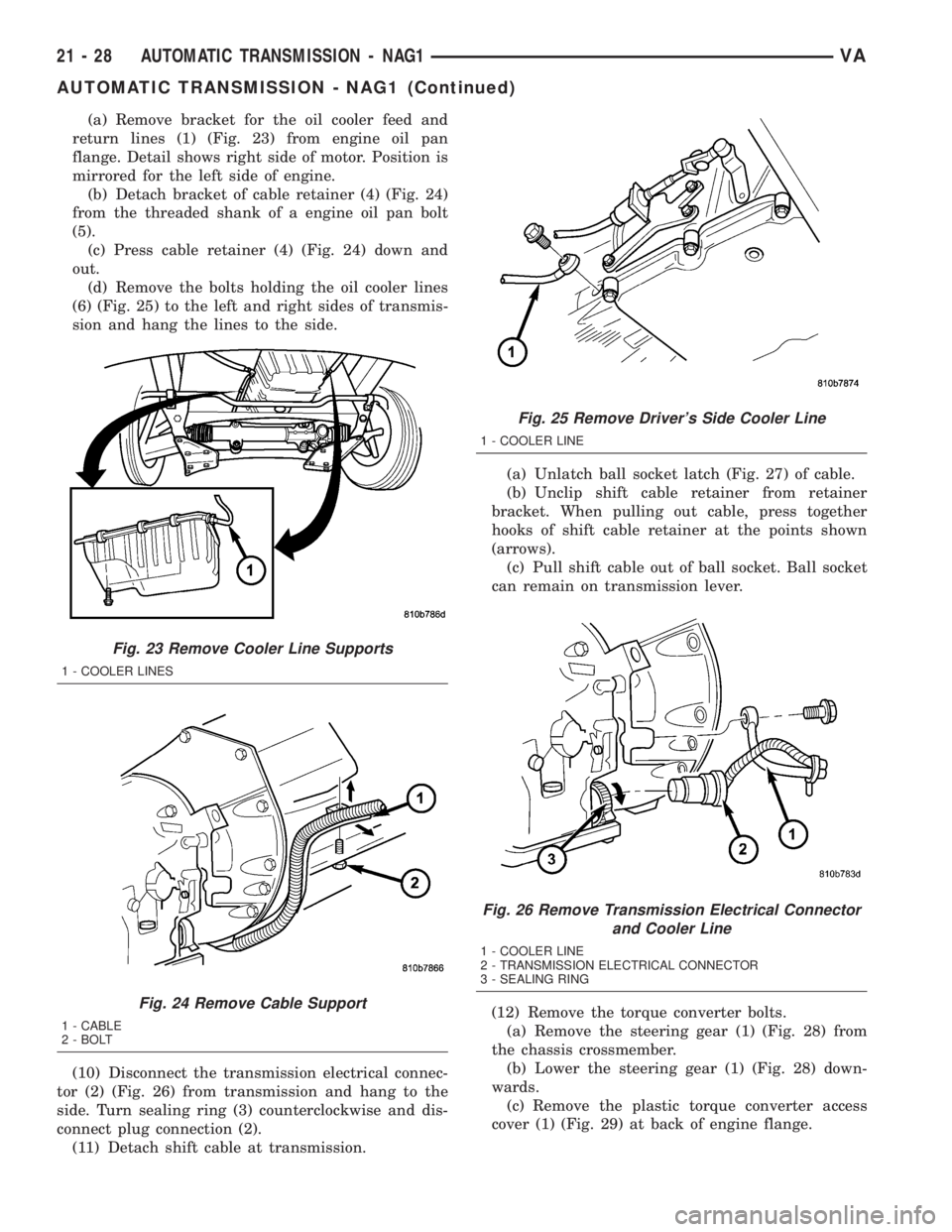

(a) Remove bracket for the oil cooler feed and

return lines (1) (Fig. 23) from engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Detach bracket of cable retainer (4) (Fig. 24)

from the threaded shank of a engine oil pan bolt

(5).

(c) Press cable retainer (4) (Fig. 24) down and

out.

(d) Remove the bolts holding the oil cooler lines

(6) (Fig. 25) to the left and right sides of transmis-

sion and hang the lines to the side.

(10) Disconnect the transmission electrical connec-

tor (2) (Fig. 26) from transmission and hang to the

side. Turn sealing ring (3) counterclockwise and dis-

connect plug connection (2).

(11) Detach shift cable at transmission.(a) Unlatch ball socket latch (Fig. 27) of cable.

(b) Unclip shift cable retainer from retainer

bracket. When pulling out cable, press together

hooks of shift cable retainer at the points shown

(arrows).

(c) Pull shift cable out of ball socket. Ball socket

can remain on transmission lever.

(12) Remove the torque converter bolts.

(a) Remove the steering gear (1) (Fig. 28) from

the chassis crossmember.

(b) Lower the steering gear (1) (Fig. 28) down-

wards.

(c) Remove the plastic torque converter access

cover (1) (Fig. 29) at back of engine flange.

Fig. 23 Remove Cooler Line Supports

1 - COOLER LINES

Fig. 24 Remove Cable Support

1 - CABLE

2 - BOLT

Fig. 25 Remove Driver's Side Cooler Line

1 - COOLER LINE

Fig. 26 Remove Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

21 - 28 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 920 of 1232

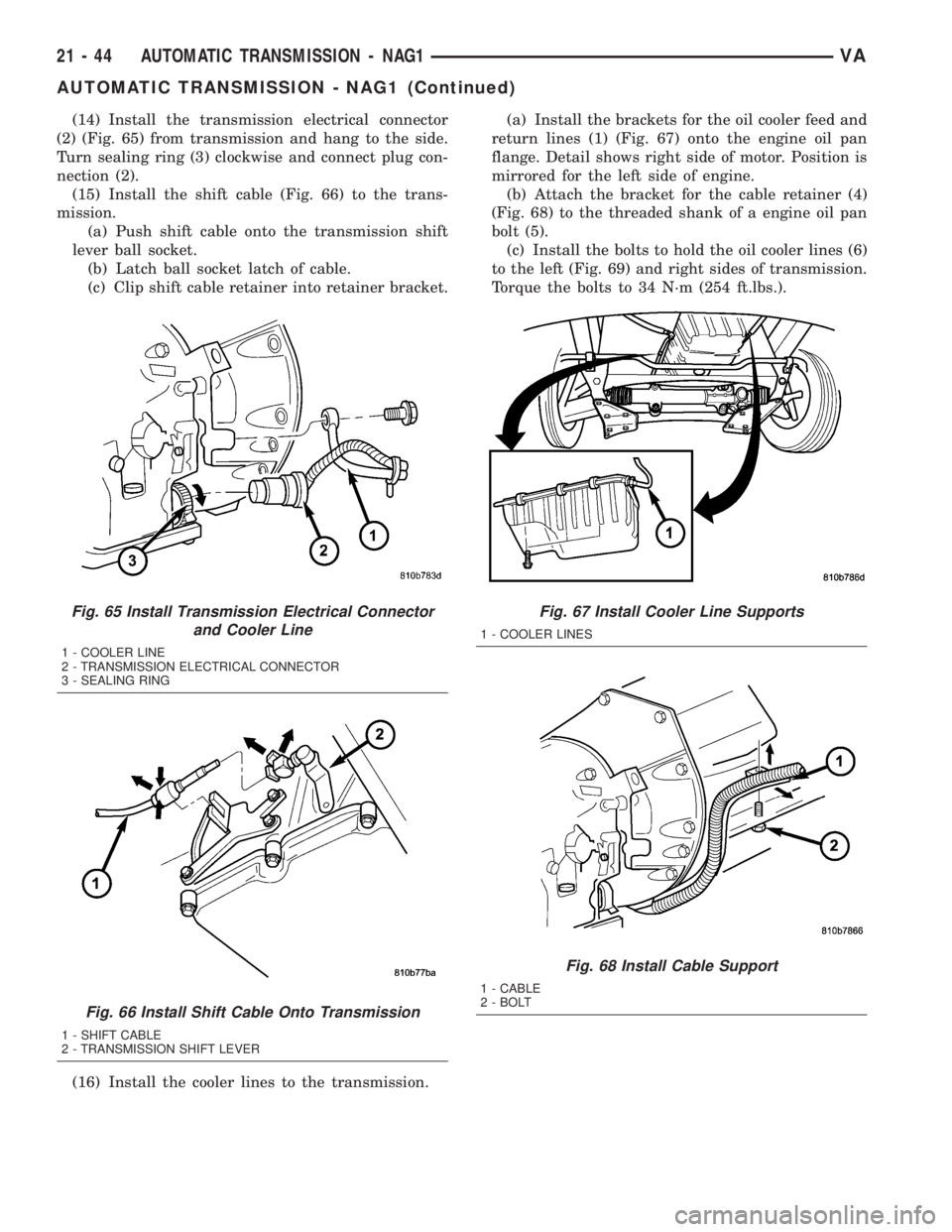

(14) Install the transmission electrical connector

(2) (Fig. 65) from transmission and hang to the side.

Turn sealing ring (3) clockwise and connect plug con-

nection (2).

(15) Install the shift cable (Fig. 66) to the trans-

mission.

(a) Push shift cable onto the transmission shift

lever ball socket.

(b) Latch ball socket latch of cable.

(c) Clip shift cable retainer into retainer bracket.

(16) Install the cooler lines to the transmission.(a) Install the brackets for the oil cooler feed and

return lines (1) (Fig. 67) onto the engine oil pan

flange. Detail shows right side of motor. Position is

mirrored for the left side of engine.

(b) Attach the bracket for the cable retainer (4)

(Fig. 68) to the threaded shank of a engine oil pan

bolt (5).

(c) Install the bolts to hold the oil cooler lines (6)

to the left (Fig. 69) and right sides of transmission.

Torque the bolts to 34 N´m (254 ft.lbs.).

Fig. 65 Install Transmission Electrical Connector

and Cooler Line

1 - COOLER LINE

2 - TRANSMISSION ELECTRICAL CONNECTOR

3 - SEALING RING

Fig. 66 Install Shift Cable Onto Transmission

1 - SHIFT CABLE

2 - TRANSMISSION SHIFT LEVER

Fig. 67 Install Cooler Line Supports

1 - COOLER LINES

Fig. 68 Install Cable Support

1 - CABLE

2 - BOLT

21 - 44 AUTOMATIC TRANSMISSION - NAG1VA

AUTOMATIC TRANSMISSION - NAG1 (Continued)

Page 968 of 1232

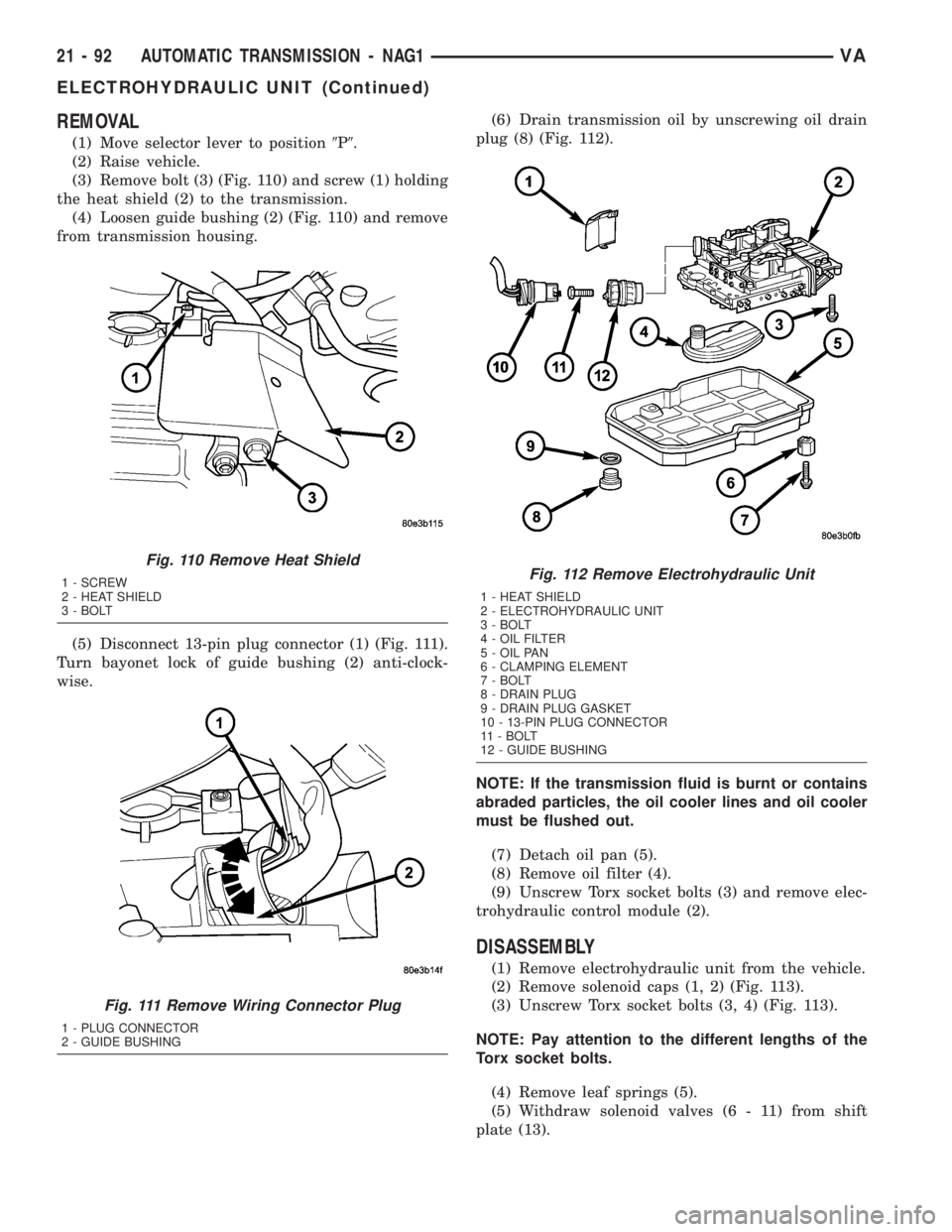

REMOVAL

(1) Move selector lever to position9P9.

(2) Raise vehicle.

(3) Remove bolt (3) (Fig. 110) and screw (1) holding

the heat shield (2) to the transmission.

(4) Loosen guide bushing (2) (Fig. 110) and remove

from transmission housing.

(5) Disconnect 13-pin plug connector (1) (Fig. 111).

Turn bayonet lock of guide bushing (2) anti-clock-

wise.(6) Drain transmission oil by unscrewing oil drain

plug (8) (Fig. 112).

NOTE: If the transmission fluid is burnt or contains

abraded particles, the oil cooler lines and oil cooler

must be flushed out.

(7) Detach oil pan (5).

(8) Remove oil filter (4).

(9) Unscrew Torx socket bolts (3) and remove elec-

trohydraulic control module (2).

DISASSEMBLY

(1) Remove electrohydraulic unit from the vehicle.

(2) Remove solenoid caps (1, 2) (Fig. 113).

(3) Unscrew Torx socket bolts (3, 4) (Fig. 113).

NOTE: Pay attention to the different lengths of the

Torx socket bolts.

(4) Remove leaf springs (5).

(5) Withdraw solenoid valves (6 - 11) from shift

plate (13).

Fig. 110 Remove Heat Shield

1 - SCREW

2 - HEAT SHIELD

3 - BOLT

Fig. 111 Remove Wiring Connector Plug

1 - PLUG CONNECTOR

2 - GUIDE BUSHING

Fig. 112 Remove Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

21 - 92 AUTOMATIC TRANSMISSION - NAG1VA

ELECTROHYDRAULIC UNIT (Continued)

Page 976 of 1232

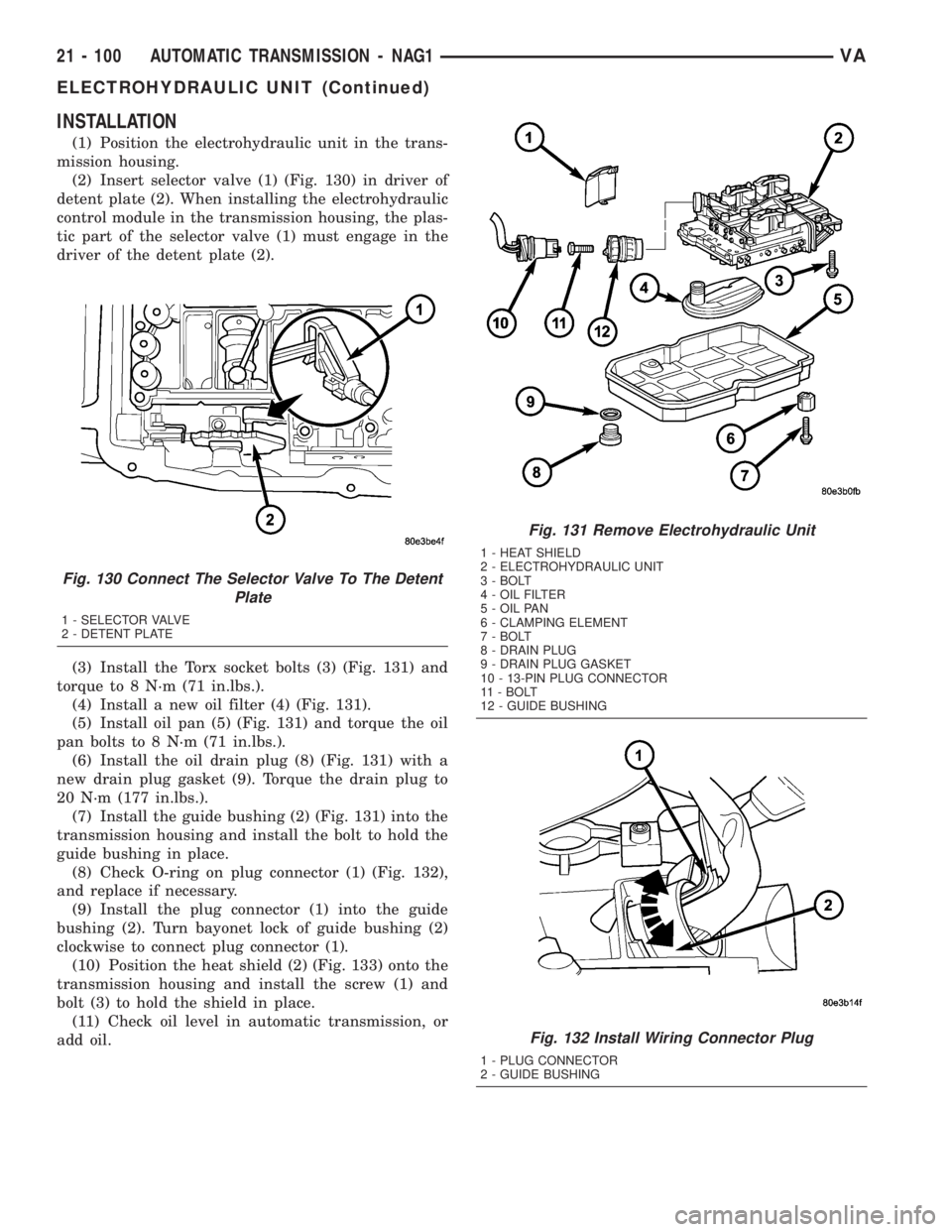

INSTALLATION

(1) Position the electrohydraulic unit in the trans-

mission housing.

(2) Insert selector valve (1) (Fig. 130) in driver of

detent plate (2). When installing the electrohydraulic

control module in the transmission housing, the plas-

tic part of the selector valve (1) must engage in the

driver of the detent plate (2).

(3) Install the Torx socket bolts (3) (Fig. 131) and

torque to 8 N´m (71 in.lbs.).

(4) Install a new oil filter (4) (Fig. 131).

(5) Install oil pan (5) (Fig. 131) and torque the oil

pan bolts to 8 N´m (71 in.lbs.).

(6) Install the oil drain plug (8) (Fig. 131) with a

new drain plug gasket (9). Torque the drain plug to

20 N´m (177 in.lbs.).

(7) Install the guide bushing (2) (Fig. 131) into the

transmission housing and install the bolt to hold the

guide bushing in place.

(8) Check O-ring on plug connector (1) (Fig. 132),

and replace if necessary.

(9) Install the plug connector (1) into the guide

bushing (2). Turn bayonet lock of guide bushing (2)

clockwise to connect plug connector (1).

(10) Position the heat shield (2) (Fig. 133) onto the

transmission housing and install the screw (1) and

bolt (3) to hold the shield in place.

(11) Check oil level in automatic transmission, or

add oil.

Fig. 130 Connect The Selector Valve To The Detent

Plate

1 - SELECTOR VALVE

2 - DETENT PLATE

Fig. 131 Remove Electrohydraulic Unit

1 - HEAT SHIELD

2 - ELECTROHYDRAULIC UNIT

3 - BOLT

4 - OIL FILTER

5 - OIL PAN

6 - CLAMPING ELEMENT

7 - BOLT

8 - DRAIN PLUG

9 - DRAIN PLUG GASKET

10 - 13-PIN PLUG CONNECTOR

11 - BOLT

12 - GUIDE BUSHING

Fig. 132 Install Wiring Connector Plug

1 - PLUG CONNECTOR

2 - GUIDE BUSHING

21 - 100 AUTOMATIC TRANSMISSION - NAG1VA

ELECTROHYDRAULIC UNIT (Continued)

Page 980 of 1232

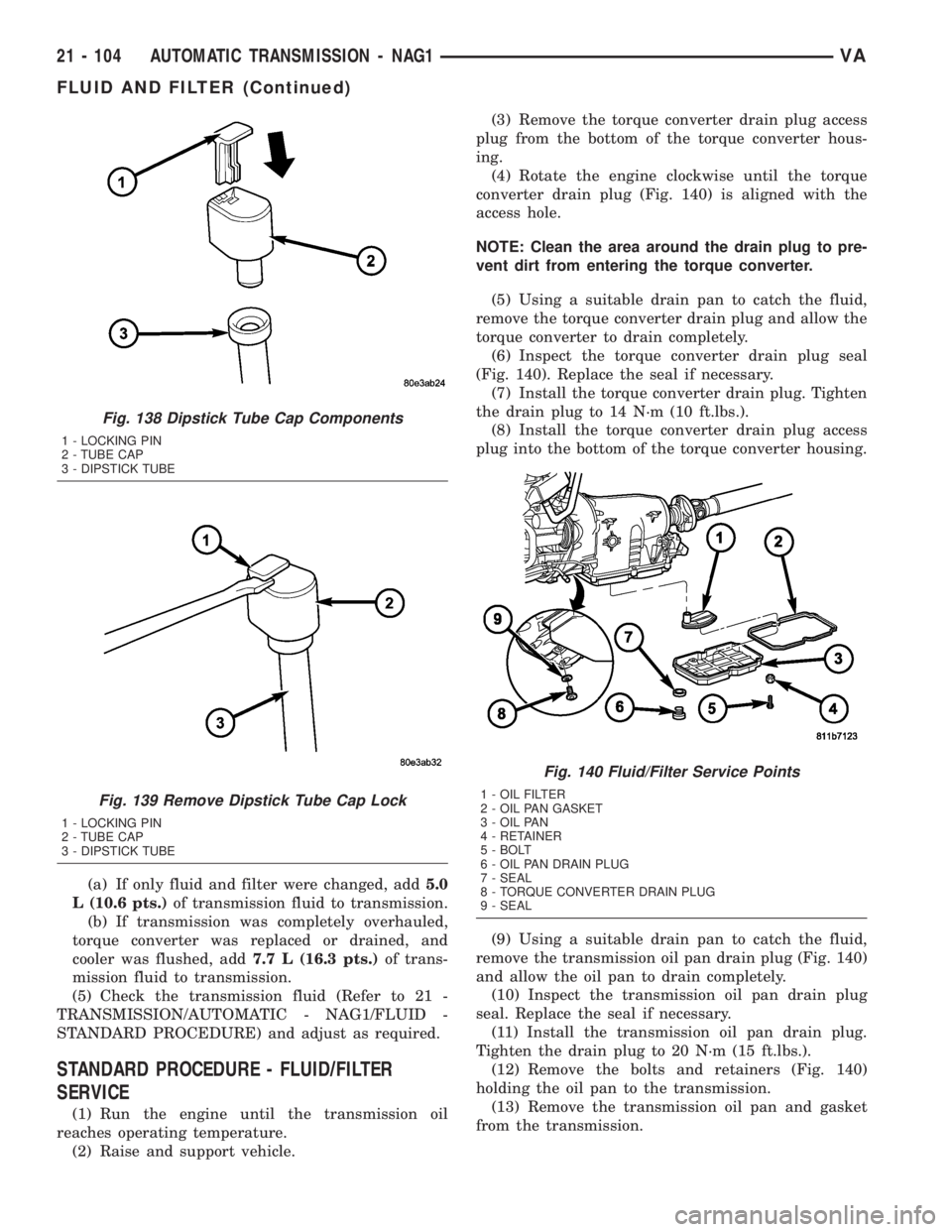

(a) If only fluid and filter were changed, add5.0

L (10.6 pts.)of transmission fluid to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add7.7 L (16.3 pts.)of trans-

mission fluid to transmission.

(5) Check the transmission fluid (Refer to 21 -

TRANSMISSION/AUTOMATIC - NAG1/FLUID -

STANDARD PROCEDURE) and adjust as required.

STANDARD PROCEDURE - FLUID/FILTER

SERVICE

(1) Run the engine until the transmission oil

reaches operating temperature.

(2) Raise and support vehicle.(3) Remove the torque converter drain plug access

plug from the bottom of the torque converter hous-

ing.

(4) Rotate the engine clockwise until the torque

converter drain plug (Fig. 140) is aligned with the

access hole.

NOTE: Clean the area around the drain plug to pre-

vent dirt from entering the torque converter.

(5) Using a suitable drain pan to catch the fluid,

remove the torque converter drain plug and allow the

torque converter to drain completely.

(6) Inspect the torque converter drain plug seal

(Fig. 140). Replace the seal if necessary.

(7) Install the torque converter drain plug. Tighten

the drain plug to 14 N´m (10 ft.lbs.).

(8) Install the torque converter drain plug access

plug into the bottom of the torque converter housing.

(9) Using a suitable drain pan to catch the fluid,

remove the transmission oil pan drain plug (Fig. 140)

and allow the oil pan to drain completely.

(10) Inspect the transmission oil pan drain plug

seal. Replace the seal if necessary.

(11) Install the transmission oil pan drain plug.

Tighten the drain plug to 20 N´m (15 ft.lbs.).

(12) Remove the bolts and retainers (Fig. 140)

holding the oil pan to the transmission.

(13) Remove the transmission oil pan and gasket

from the transmission.

Fig. 138 Dipstick Tube Cap Components

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

Fig. 139 Remove Dipstick Tube Cap Lock

1 - LOCKING PIN

2 - TUBE CAP

3 - DIPSTICK TUBE

Fig. 140 Fluid/Filter Service Points

1 - OIL FILTER

2 - OIL PAN GASKET

3 - OIL PAN

4 - RETAINER

5 - BOLT

6 - OIL PAN DRAIN PLUG

7 - SEAL

8 - TORQUE CONVERTER DRAIN PLUG

9 - SEAL

21 - 104 AUTOMATIC TRANSMISSION - NAG1VA

FLUID AND FILTER (Continued)

Page 1018 of 1232

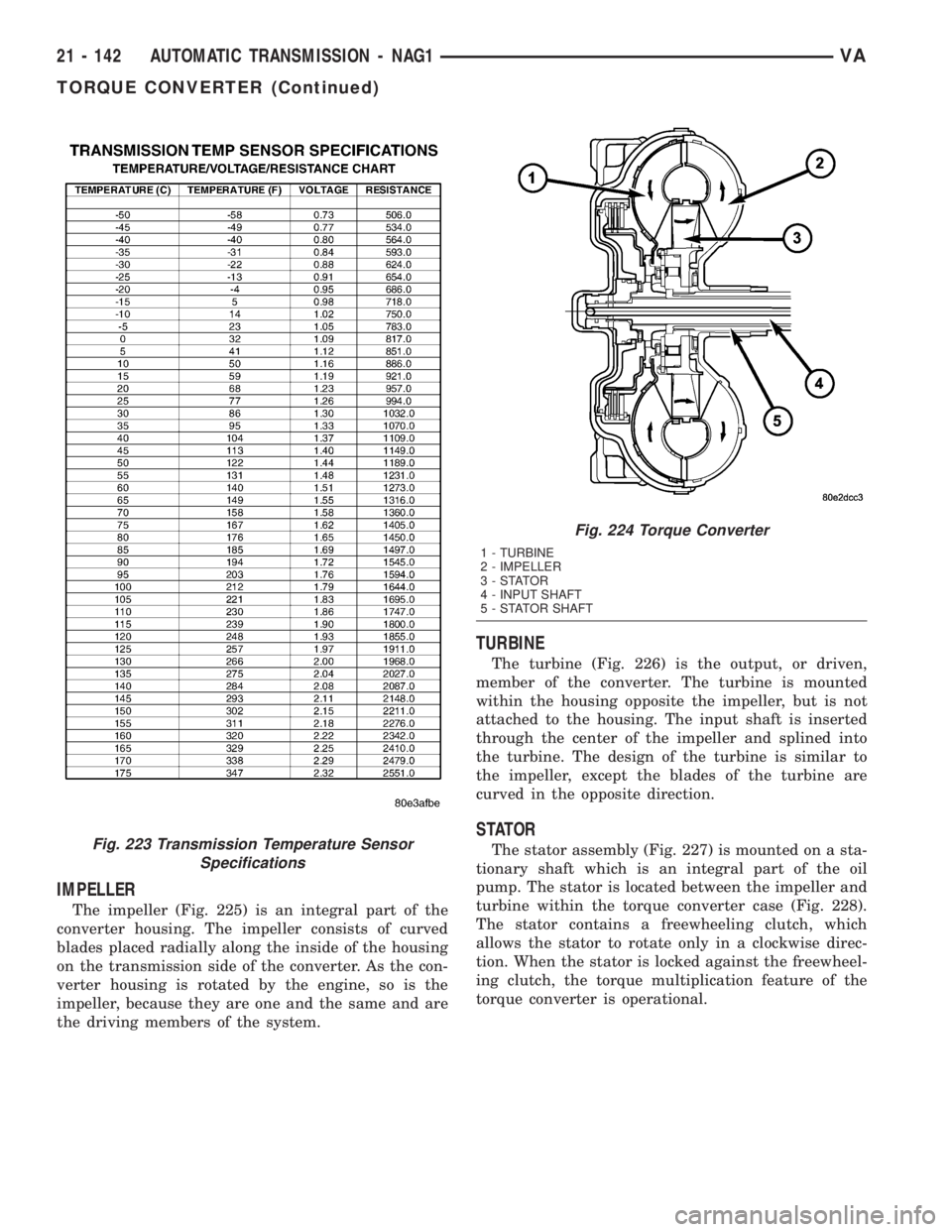

IMPELLER

The impeller (Fig. 225) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

TURBINE

The turbine (Fig. 226) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

STATOR

The stator assembly (Fig. 227) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 228).

The stator contains a freewheeling clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the freewheel-

ing clutch, the torque multiplication feature of the

torque converter is operational.Fig. 223 Transmission Temperature Sensor

Specifications

Fig. 224 Torque Converter

1 - TURBINE

2 - IMPELLER

3-STATOR

4 - INPUT SHAFT

5 - STATOR SHAFT

21 - 142 AUTOMATIC TRANSMISSION - NAG1VA

TORQUE CONVERTER (Continued)

Page 1020 of 1232

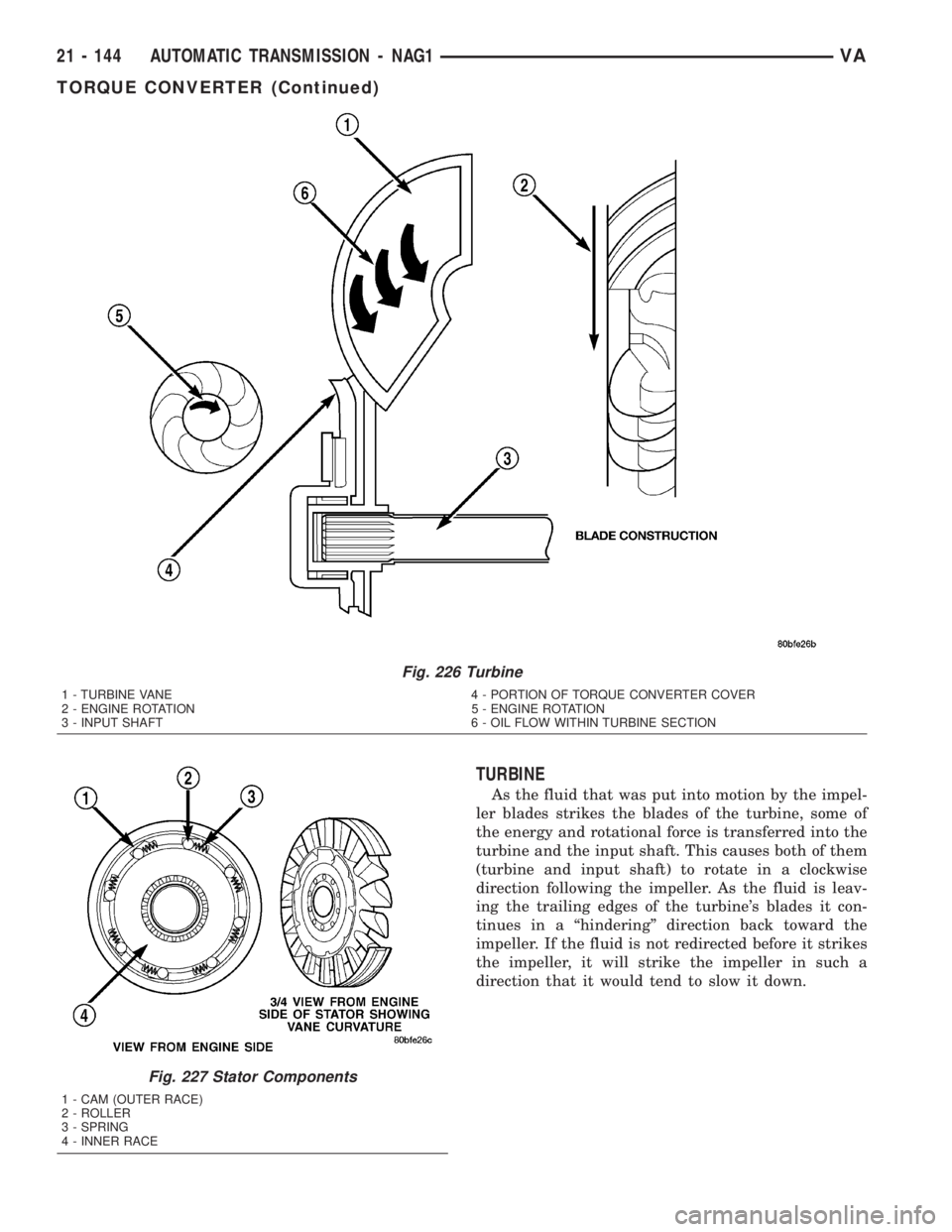

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

Fig. 226 Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

Fig. 227 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

21 - 144 AUTOMATIC TRANSMISSION - NAG1VA

TORQUE CONVERTER (Continued)