MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 291 of 1232

washer hose fittings cannot be repaired. If these fittings

are faulty or damaged, they must be replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the

washer system plumbing and fittings to the two

washer nozzles. Whenever routing the washer hose

or a wire harness containing a washer hose, it must

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

WASHER NOZZLE

DESCRIPTION

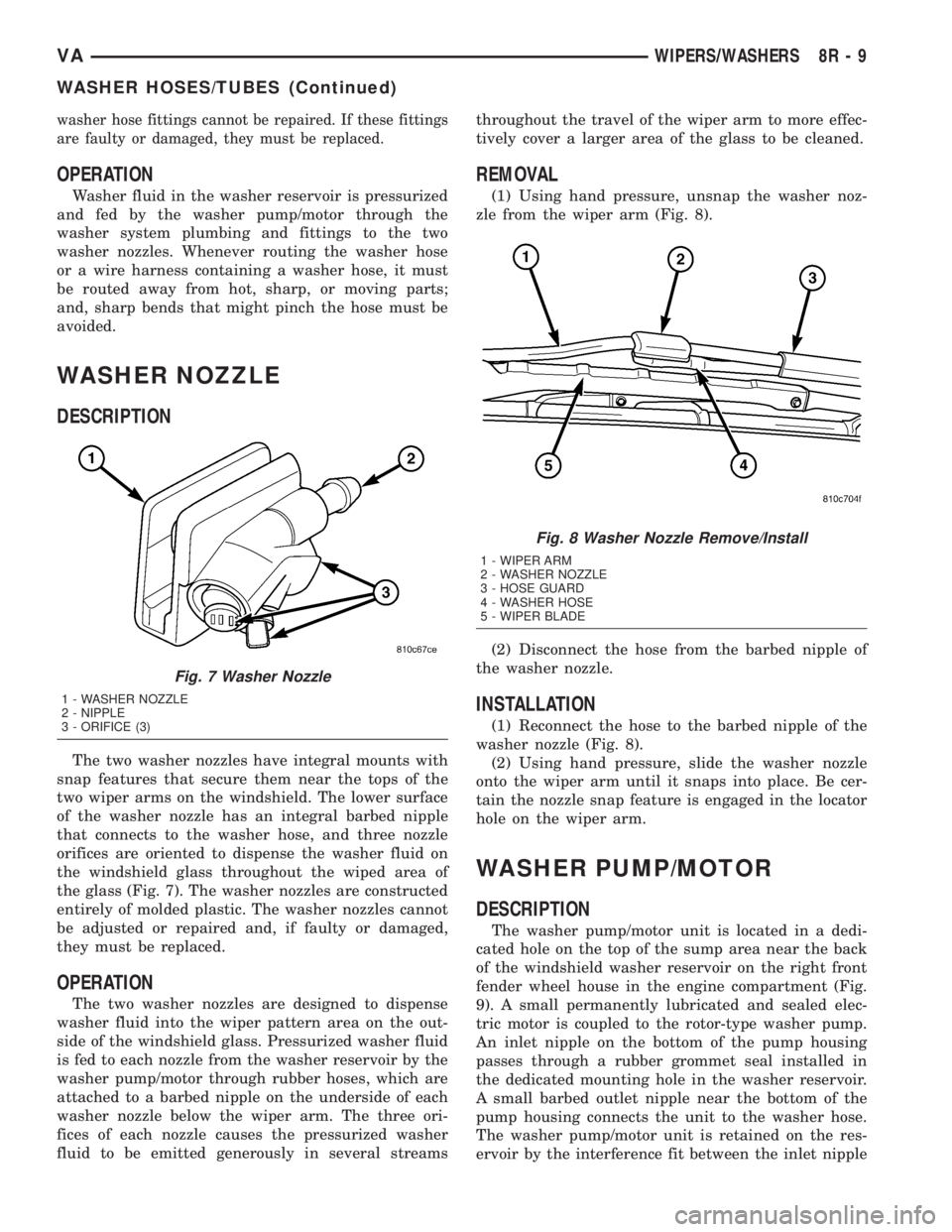

The two washer nozzles have integral mounts with

snap features that secure them near the tops of the

two wiper arms on the windshield. The lower surface

of the washer nozzle has an integral barbed nipple

that connects to the washer hose, and three nozzle

orifices are oriented to dispense the washer fluid on

the windshield glass throughout the wiped area of

the glass (Fig. 7). The washer nozzles are constructed

entirely of molded plastic. The washer nozzles cannot

be adjusted or repaired and, if faulty or damaged,

they must be replaced.

OPERATION

The two washer nozzles are designed to dispense

washer fluid into the wiper pattern area on the out-

side of the windshield glass. Pressurized washer fluid

is fed to each nozzle from the washer reservoir by the

washer pump/motor through rubber hoses, which are

attached to a barbed nipple on the underside of each

washer nozzle below the wiper arm. The three ori-

fices of each nozzle causes the pressurized washer

fluid to be emitted generously in several streamsthroughout the travel of the wiper arm to more effec-

tively cover a larger area of the glass to be cleaned.

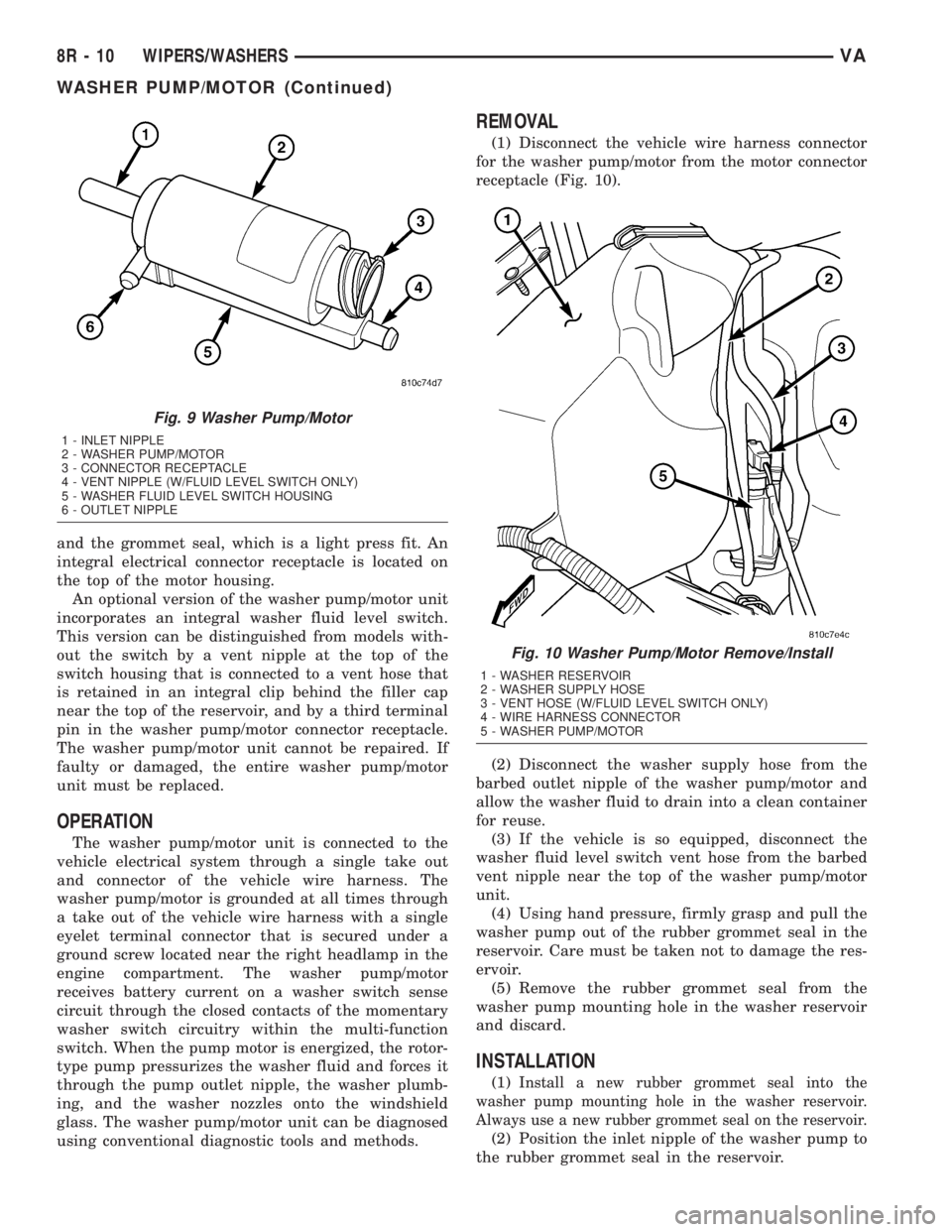

REMOVAL

(1) Using hand pressure, unsnap the washer noz-

zle from the wiper arm (Fig. 8).

(2) Disconnect the hose from the barbed nipple of

the washer nozzle.

INSTALLATION

(1) Reconnect the hose to the barbed nipple of the

washer nozzle (Fig. 8).

(2) Using hand pressure, slide the washer nozzle

onto the wiper arm until it snaps into place. Be cer-

tain the nozzle snap feature is engaged in the locator

hole on the wiper arm.

WASHER PUMP/MOTOR

DESCRIPTION

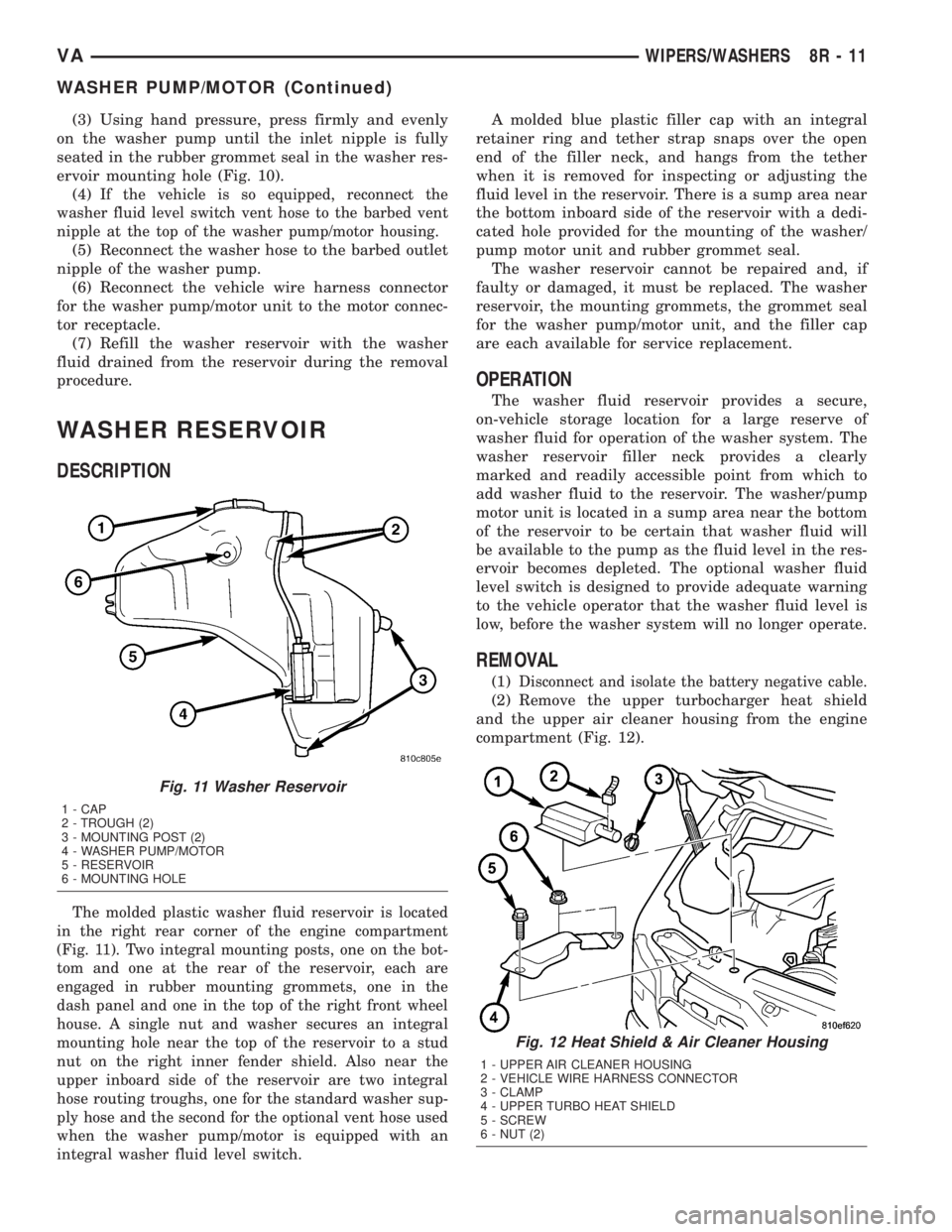

The washer pump/motor unit is located in a dedi-

cated hole on the top of the sump area near the back

of the windshield washer reservoir on the right front

fender wheel house in the engine compartment (Fig.

9). A small permanently lubricated and sealed elec-

tric motor is coupled to the rotor-type washer pump.

An inlet nipple on the bottom of the pump housing

passes through a rubber grommet seal installed in

the dedicated mounting hole in the washer reservoir.

A small barbed outlet nipple near the bottom of the

pump housing connects the unit to the washer hose.

The washer pump/motor unit is retained on the res-

ervoir by the interference fit between the inlet nipple

Fig. 7 Washer Nozzle

1 - WASHER NOZZLE

2 - NIPPLE

3 - ORIFICE (3)

Fig. 8 Washer Nozzle Remove/Install

1 - WIPER ARM

2 - WASHER NOZZLE

3 - HOSE GUARD

4 - WASHER HOSE

5 - WIPER BLADE

VAWIPERS/WASHERS 8R - 9

WASHER HOSES/TUBES (Continued)

Page 292 of 1232

and the grommet seal, which is a light press fit. An

integral electrical connector receptacle is located on

the top of the motor housing.

An optional version of the washer pump/motor unit

incorporates an integral washer fluid level switch.

This version can be distinguished from models with-

out the switch by a vent nipple at the top of the

switch housing that is connected to a vent hose that

is retained in an integral clip behind the filler cap

near the top of the reservoir, and by a third terminal

pin in the washer pump/motor connector receptacle.

The washer pump/motor unit cannot be repaired. If

faulty or damaged, the entire washer pump/motor

unit must be replaced.

OPERATION

The washer pump/motor unit is connected to the

vehicle electrical system through a single take out

and connector of the vehicle wire harness. The

washer pump/motor is grounded at all times through

a take out of the vehicle wire harness with a single

eyelet terminal connector that is secured under a

ground screw located near the right headlamp in the

engine compartment. The washer pump/motor

receives battery current on a washer switch sense

circuit through the closed contacts of the momentary

washer switch circuitry within the multi-function

switch. When the pump motor is energized, the rotor-

type pump pressurizes the washer fluid and forces it

through the pump outlet nipple, the washer plumb-

ing, and the washer nozzles onto the windshield

glass. The washer pump/motor unit can be diagnosed

using conventional diagnostic tools and methods.

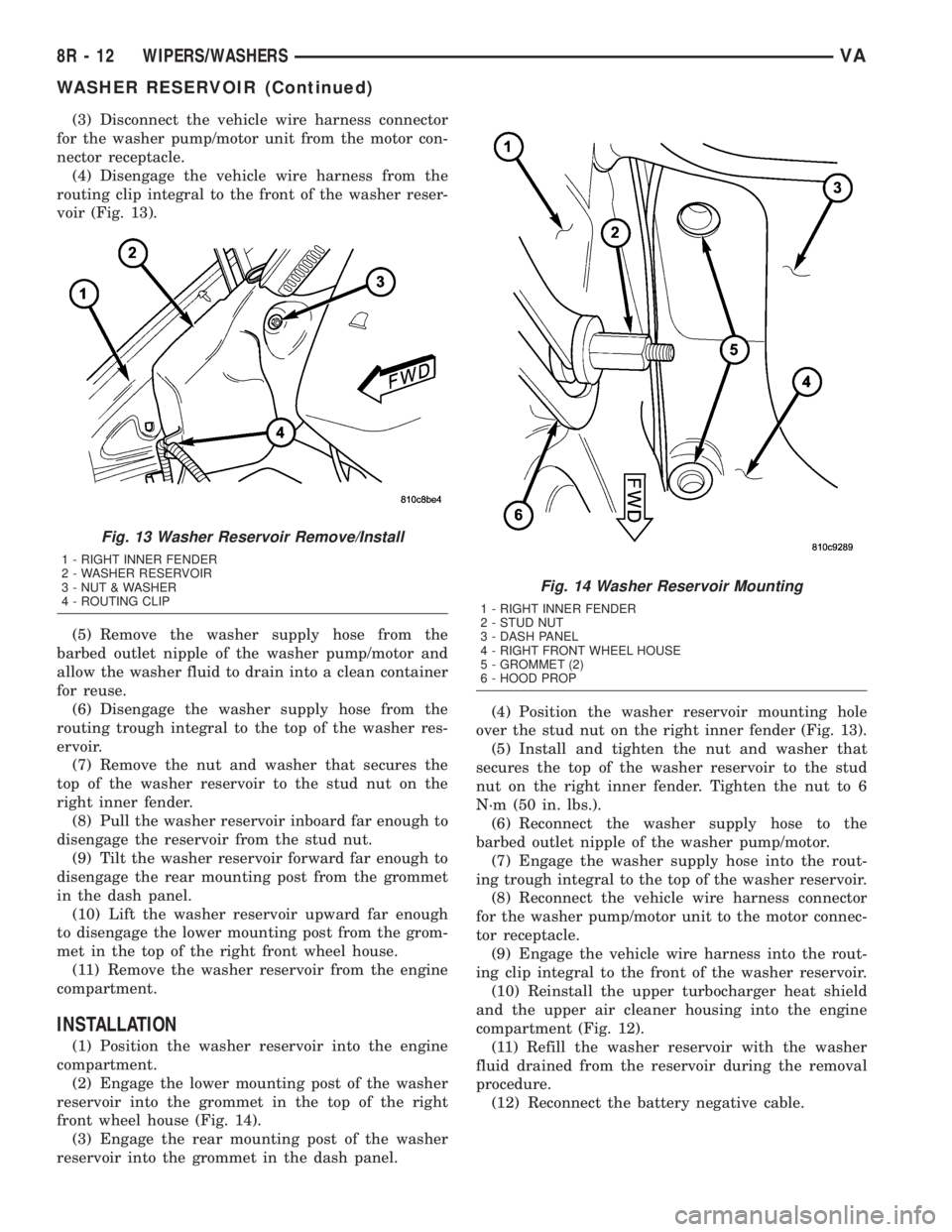

REMOVAL

(1) Disconnect the vehicle wire harness connector

for the washer pump/motor from the motor connector

receptacle (Fig. 10).

(2) Disconnect the washer supply hose from the

barbed outlet nipple of the washer pump/motor and

allow the washer fluid to drain into a clean container

for reuse.

(3) If the vehicle is so equipped, disconnect the

washer fluid level switch vent hose from the barbed

vent nipple near the top of the washer pump/motor

unit.

(4) Using hand pressure, firmly grasp and pull the

washer pump out of the rubber grommet seal in the

reservoir. Care must be taken not to damage the res-

ervoir.

(5) Remove the rubber grommet seal from the

washer pump mounting hole in the washer reservoir

and discard.

INSTALLATION

(1)Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reservoir.

(2) Position the inlet nipple of the washer pump to

the rubber grommet seal in the reservoir.

Fig. 9 Washer Pump/Motor

1 - INLET NIPPLE

2 - WASHER PUMP/MOTOR

3 - CONNECTOR RECEPTACLE

4 - VENT NIPPLE (W/FLUID LEVEL SWITCH ONLY)

5 - WASHER FLUID LEVEL SWITCH HOUSING

6 - OUTLET NIPPLE

Fig. 10 Washer Pump/Motor Remove/Install

1 - WASHER RESERVOIR

2 - WASHER SUPPLY HOSE

3 - VENT HOSE (W/FLUID LEVEL SWITCH ONLY)

4 - WIRE HARNESS CONNECTOR

5 - WASHER PUMP/MOTOR

8R - 10 WIPERS/WASHERSVA

WASHER PUMP/MOTOR (Continued)

Page 293 of 1232

(3) Using hand pressure, press firmly and evenly

on the washer pump until the inlet nipple is fully

seated in the rubber grommet seal in the washer res-

ervoir mounting hole (Fig. 10).

(4)

If the vehicle is so equipped, reconnect the

washer fluid level switch vent hose to the barbed vent

nipple at the top of the washer pump/motor housing.

(5) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.

(6) Reconnect the vehicle wire harness connector

for the washer pump/motor unit to the motor connec-

tor receptacle.

(7) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

WASHER RESERVOIR

DESCRIPTION

The molded plastic washer fluid reservoir is located

in the right rear corner of the engine compartment

(Fig. 11). Two integral mounting posts, one on the bot-

tom and one at the rear of the reservoir, each are

engaged in rubber mounting grommets, one in the

dash panel and one in the top of the right front wheel

house. A single nut and washer secures an integral

mounting hole near the top of the reservoir to a stud

nut on the right inner fender shield. Also near the

upper inboard side of the reservoir are two integral

hose routing troughs, one for the standard washer sup-

ply hose and the second for the optional vent hose used

when the washer pump/motor is equipped with an

integral washer fluid level switch.

A molded blue plastic filler cap with an integral

retainer ring and tether strap snaps over the open

end of the filler neck, and hangs from the tether

when it is removed for inspecting or adjusting the

fluid level in the reservoir. There is a sump area near

the bottom inboard side of the reservoir with a dedi-

cated hole provided for the mounting of the washer/

pump motor unit and rubber grommet seal.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the mounting grommets, the grommet seal

for the washer pump/motor unit, and the filler cap

are each available for service replacement.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The optional washer fluid

level switch is designed to provide adequate warning

to the vehicle operator that the washer fluid level is

low, before the washer system will no longer operate.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the upper turbocharger heat shield

and the upper air cleaner housing from the engine

compartment (Fig. 12).

Fig. 11 Washer Reservoir

1 - CAP

2 - TROUGH (2)

3 - MOUNTING POST (2)

4 - WASHER PUMP/MOTOR

5 - RESERVOIR

6 - MOUNTING HOLE

Fig. 12 Heat Shield & Air Cleaner Housing

1 - UPPER AIR CLEANER HOUSING

2 - VEHICLE WIRE HARNESS CONNECTOR

3 - CLAMP

4 - UPPER TURBO HEAT SHIELD

5 - SCREW

6 - NUT (2)

VAWIPERS/WASHERS 8R - 11

WASHER PUMP/MOTOR (Continued)

Page 294 of 1232

(3) Disconnect the vehicle wire harness connector

for the washer pump/motor unit from the motor con-

nector receptacle.

(4) Disengage the vehicle wire harness from the

routing clip integral to the front of the washer reser-

voir (Fig. 13).

(5) Remove the washer supply hose from the

barbed outlet nipple of the washer pump/motor and

allow the washer fluid to drain into a clean container

for reuse.

(6) Disengage the washer supply hose from the

routing trough integral to the top of the washer res-

ervoir.

(7) Remove the nut and washer that secures the

top of the washer reservoir to the stud nut on the

right inner fender.

(8) Pull the washer reservoir inboard far enough to

disengage the reservoir from the stud nut.

(9) Tilt the washer reservoir forward far enough to

disengage the rear mounting post from the grommet

in the dash panel.

(10) Lift the washer reservoir upward far enough

to disengage the lower mounting post from the grom-

met in the top of the right front wheel house.

(11) Remove the washer reservoir from the engine

compartment.

INSTALLATION

(1) Position the washer reservoir into the engine

compartment.

(2) Engage the lower mounting post of the washer

reservoir into the grommet in the top of the right

front wheel house (Fig. 14).

(3) Engage the rear mounting post of the washer

reservoir into the grommet in the dash panel.(4) Position the washer reservoir mounting hole

over the stud nut on the right inner fender (Fig. 13).

(5) Install and tighten the nut and washer that

secures the top of the washer reservoir to the stud

nut on the right inner fender. Tighten the nut to 6

N´m (50 in. lbs.).

(6) Reconnect the washer supply hose to the

barbed outlet nipple of the washer pump/motor.

(7) Engage the washer supply hose into the rout-

ing trough integral to the top of the washer reservoir.

(8) Reconnect the vehicle wire harness connector

for the washer pump/motor unit to the motor connec-

tor receptacle.

(9) Engage the vehicle wire harness into the rout-

ing clip integral to the front of the washer reservoir.

(10) Reinstall the upper turbocharger heat shield

and the upper air cleaner housing into the engine

compartment (Fig. 12).

(11) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(12) Reconnect the battery negative cable.

Fig. 13 Washer Reservoir Remove/Install

1 - RIGHT INNER FENDER

2 - WASHER RESERVOIR

3 - NUT & WASHER

4 - ROUTING CLIP

Fig. 14 Washer Reservoir Mounting

1 - RIGHT INNER FENDER

2 - STUD NUT

3 - DASH PANEL

4 - RIGHT FRONT WHEEL HOUSE

5 - GROMMET (2)

6 - HOOD PROP

8R - 12 WIPERS/WASHERSVA

WASHER RESERVOIR (Continued)

Page 295 of 1232

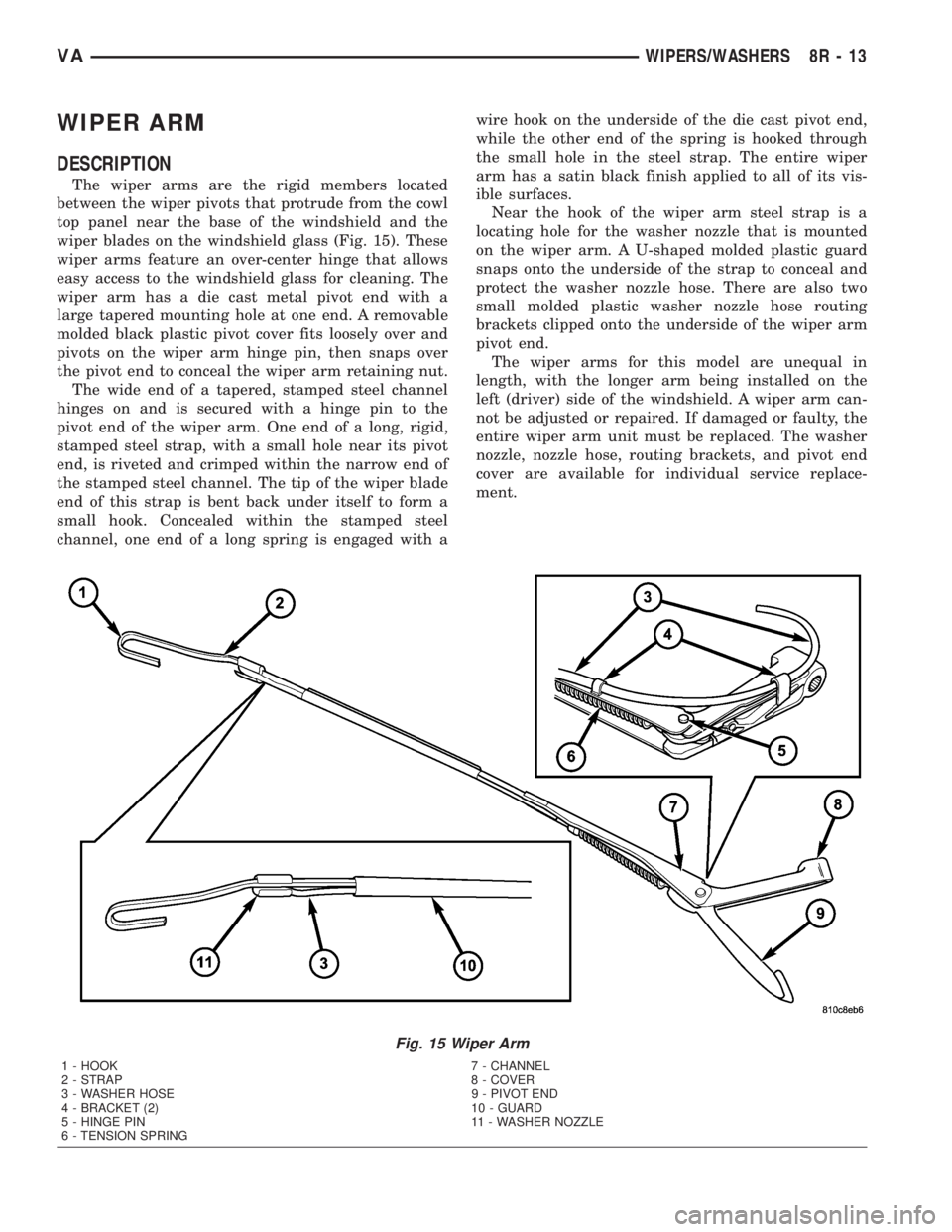

WIPER ARM

DESCRIPTION

The wiper arms are the rigid members located

between the wiper pivots that protrude from the cowl

top panel near the base of the windshield and the

wiper blades on the windshield glass (Fig. 15). These

wiper arms feature an over-center hinge that allows

easy access to the windshield glass for cleaning. The

wiper arm has a die cast metal pivot end with a

large tapered mounting hole at one end. A removable

molded black plastic pivot cover fits loosely over and

pivots on the wiper arm hinge pin, then snaps over

the pivot end to conceal the wiper arm retaining nut.

The wide end of a tapered, stamped steel channel

hinges on and is secured with a hinge pin to the

pivot end of the wiper arm. One end of a long, rigid,

stamped steel strap, with a small hole near its pivot

end, is riveted and crimped within the narrow end of

the stamped steel channel. The tip of the wiper blade

end of this strap is bent back under itself to form a

small hook. Concealed within the stamped steel

channel, one end of a long spring is engaged with awire hook on the underside of the die cast pivot end,

while the other end of the spring is hooked through

the small hole in the steel strap. The entire wiper

arm has a satin black finish applied to all of its vis-

ible surfaces.

Near the hook of the wiper arm steel strap is a

locating hole for the washer nozzle that is mounted

on the wiper arm. A U-shaped molded plastic guard

snaps onto the underside of the strap to conceal and

protect the washer nozzle hose. There are also two

small molded plastic washer nozzle hose routing

brackets clipped onto the underside of the wiper arm

pivot end.

The wiper arms for this model are unequal in

length, with the longer arm being installed on the

left (driver) side of the windshield. A wiper arm can-

not be adjusted or repaired. If damaged or faulty, the

entire wiper arm unit must be replaced. The washer

nozzle, nozzle hose, routing brackets, and pivot end

cover are available for individual service replace-

ment.

Fig. 15 Wiper Arm

1 - HOOK 7 - CHANNEL

2 - STRAP 8 - COVER

3 - WASHER HOSE 9 - PIVOT END

4 - BRACKET (2) 10 - GUARD

5 - HINGE PIN 11 - WASHER NOZZLE

6 - TENSION SPRING

VAWIPERS/WASHERS 8R - 13

Page 296 of 1232

OPERATION

The wiper arms are designed to mechanically

transmit the motion from the wiper pivots to the

wiper blades. The wiper arm must be properly

indexed to the wiper pivot in order to maintain the

proper wiper blade travel on the glass. The tapered

mounting hole in the wiper arm pivot end interlocks

with the serrations on the outer circumference of the

wiper pivot shaft, allowing positive engagement and

finite adjustment of this connection. The mounting

nut locks the wiper arm to the threaded end of the

wiper pivot shaft. The spring-loaded wiper arm hinge

controls the down-force applied through the tip of the

wiper arm to the wiper blade on the glass. The hook

formation on the tip of the wiper arm provides a cra-

dle for securing and latching the wiper blade pivot

block to the wiper arm.

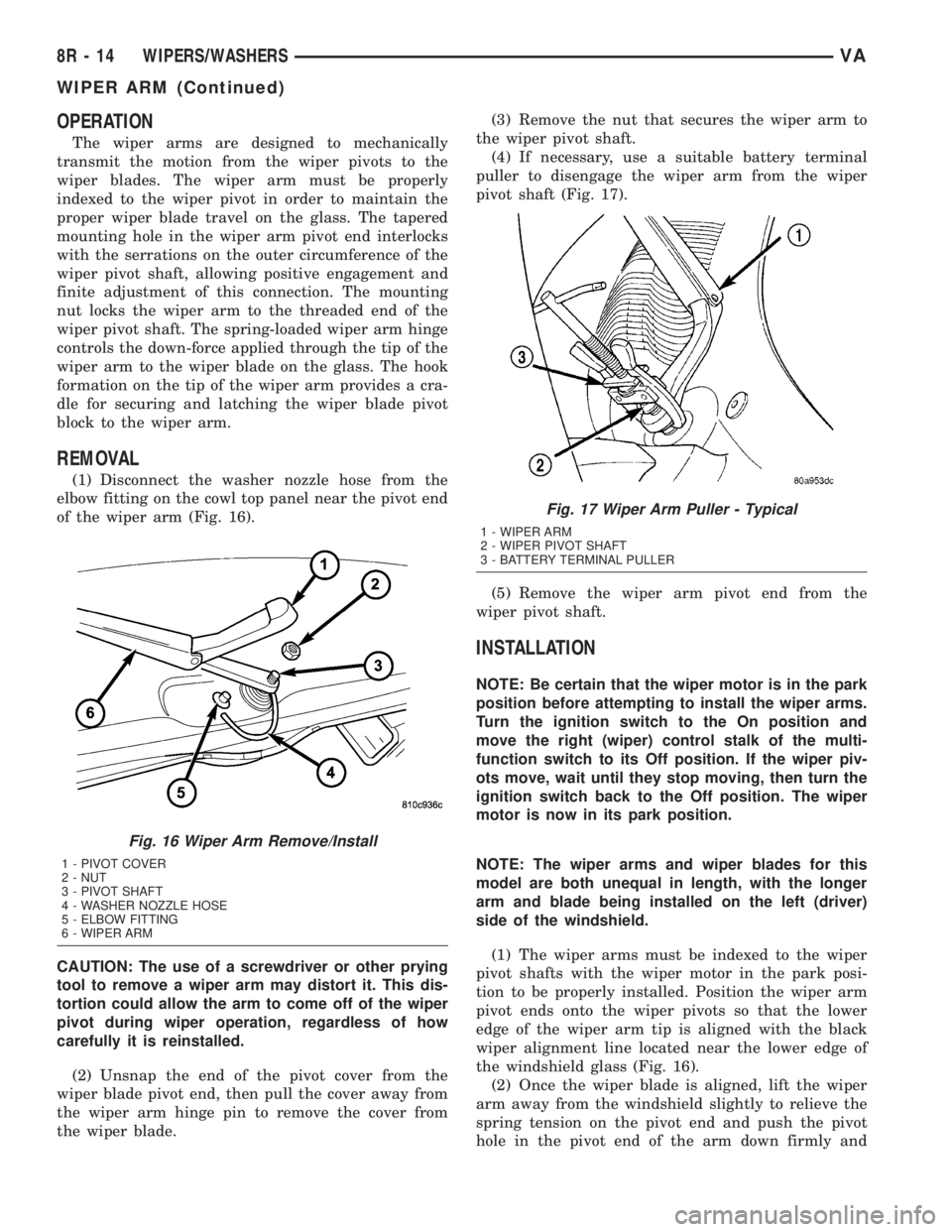

REMOVAL

(1) Disconnect the washer nozzle hose from the

elbow fitting on the cowl top panel near the pivot end

of the wiper arm (Fig. 16).

CAUTION: The use of a screwdriver or other prying

tool to remove a wiper arm may distort it. This dis-

tortion could allow the arm to come off of the wiper

pivot during wiper operation, regardless of how

carefully it is reinstalled.

(2) Unsnap the end of the pivot cover from the

wiper blade pivot end, then pull the cover away from

the wiper arm hinge pin to remove the cover from

the wiper blade.(3) Remove the nut that secures the wiper arm to

the wiper pivot shaft.

(4) If necessary, use a suitable battery terminal

puller to disengage the wiper arm from the wiper

pivot shaft (Fig. 17).

(5) Remove the wiper arm pivot end from the

wiper pivot shaft.

INSTALLATION

NOTE: Be certain that the wiper motor is in the park

position before attempting to install the wiper arms.

Turn the ignition switch to the On position and

move the right (wiper) control stalk of the multi-

function switch to its Off position. If the wiper piv-

ots move, wait until they stop moving, then turn the

ignition switch back to the Off position. The wiper

motor is now in its park position.

NOTE: The wiper arms and wiper blades for this

model are both unequal in length, with the longer

arm and blade being installed on the left (driver)

side of the windshield.

(1) The wiper arms must be indexed to the wiper

pivot shafts with the wiper motor in the park posi-

tion to be properly installed. Position the wiper arm

pivot ends onto the wiper pivots so that the lower

edge of the wiper arm tip is aligned with the black

wiper alignment line located near the lower edge of

the windshield glass (Fig. 16).

(2) Once the wiper blade is aligned, lift the wiper

arm away from the windshield slightly to relieve the

spring tension on the pivot end and push the pivot

hole in the pivot end of the arm down firmly and

Fig. 16 Wiper Arm Remove/Install

1 - PIVOT COVER

2 - NUT

3 - PIVOT SHAFT

4 - WASHER NOZZLE HOSE

5 - ELBOW FITTING

6 - WIPER ARM

Fig. 17 Wiper Arm Puller - Typical

1 - WIPER ARM

2 - WIPER PIVOT SHAFT

3 - BATTERY TERMINAL PULLER

8R - 14 WIPERS/WASHERSVA

WIPER ARM (Continued)

Page 297 of 1232

evenly over the wiper pivot shaft. Gently lower the

wiper arm until the wiper blade rests on the glass.

(3) Install and tighten the nut that secures the

wiper arm to the wiper pivot shaft. Tighten the nut

to 24 N´m (18 ft. lbs.).

(4) Wet the windshield glass, then operate the wip-

ers. Move the right (wiper) control stalk of the multi-

function switch to the Off position, then check for the

correct wiper arm position and readjust as required.

(5) Engage the pivot cover with the wiper arm

hinge pin, then push the pivot end of the cover down

firmly and evenly until it snaps over the wiper blade

pivot end.

(6) Reconnect the washer nozzle hose to the elbow

fitting on the cowl top panel near the pivot end of the

wiper arm.

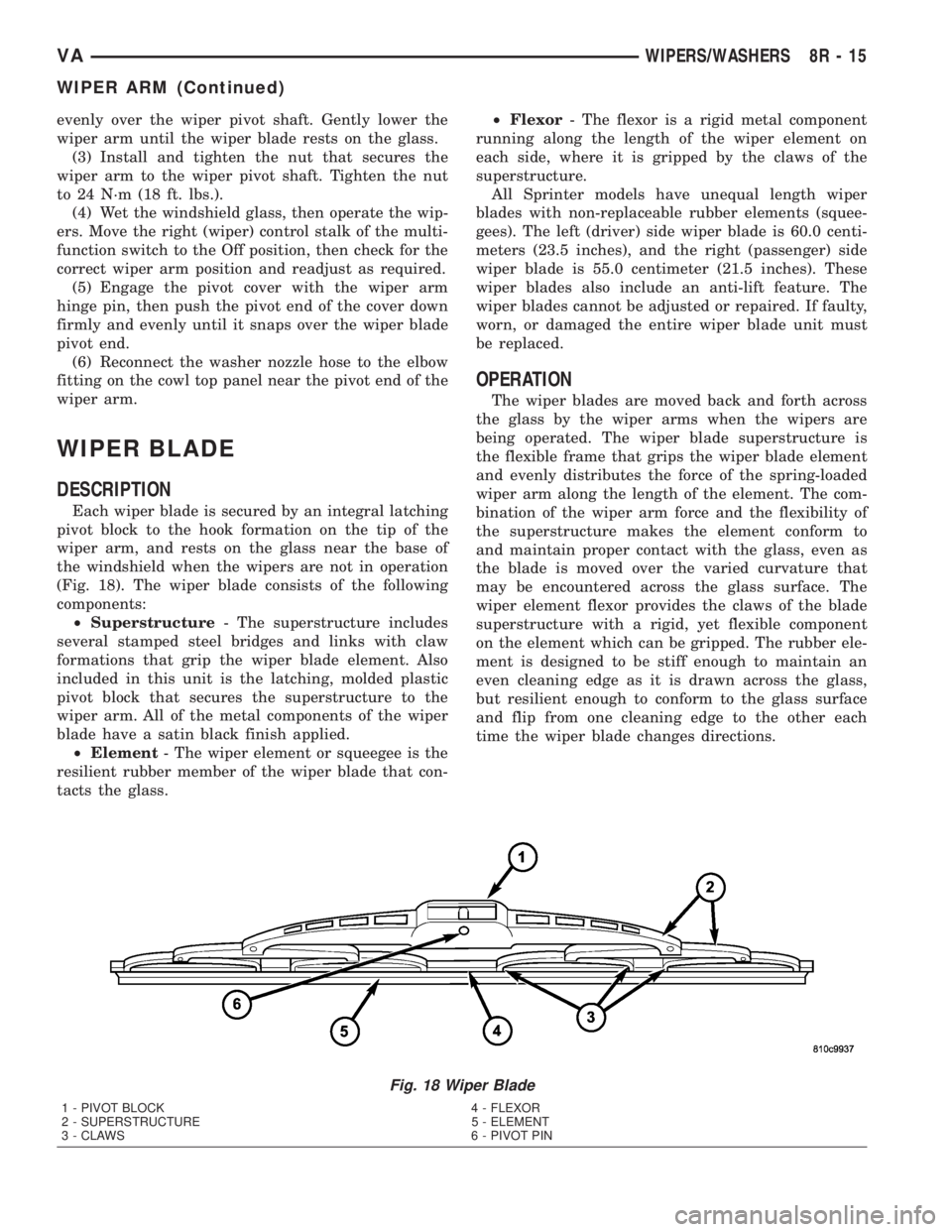

WIPER BLADE

DESCRIPTION

Each wiper blade is secured by an integral latching

pivot block to the hook formation on the tip of the

wiper arm, and rests on the glass near the base of

the windshield when the wipers are not in operation

(Fig. 18). The wiper blade consists of the following

components:

²Superstructure- The superstructure includes

several stamped steel bridges and links with claw

formations that grip the wiper blade element. Also

included in this unit is the latching, molded plastic

pivot block that secures the superstructure to the

wiper arm. All of the metal components of the wiper

blade have a satin black finish applied.

²Element- The wiper element or squeegee is the

resilient rubber member of the wiper blade that con-

tacts the glass.²Flexor- The flexor is a rigid metal component

running along the length of the wiper element on

each side, where it is gripped by the claws of the

superstructure.

All Sprinter models have unequal length wiper

blades with non-replaceable rubber elements (squee-

gees). The left (driver) side wiper blade is 60.0 centi-

meters (23.5 inches), and the right (passenger) side

wiper blade is 55.0 centimeter (21.5 inches). These

wiper blades also include an anti-lift feature. The

wiper blades cannot be adjusted or repaired. If faulty,

worn, or damaged the entire wiper blade unit must

be replaced.

OPERATION

The wiper blades are moved back and forth across

the glass by the wiper arms when the wipers are

being operated. The wiper blade superstructure is

the flexible frame that grips the wiper blade element

and evenly distributes the force of the spring-loaded

wiper arm along the length of the element. The com-

bination of the wiper arm force and the flexibility of

the superstructure makes the element conform to

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature that

may be encountered across the glass surface. The

wiper element flexor provides the claws of the blade

superstructure with a rigid, yet flexible component

on the element which can be gripped. The rubber ele-

ment is designed to be stiff enough to maintain an

even cleaning edge as it is drawn across the glass,

but resilient enough to conform to the glass surface

and flip from one cleaning edge to the other each

time the wiper blade changes directions.

Fig. 18 Wiper Blade

1 - PIVOT BLOCK 4 - FLEXOR

2 - SUPERSTRUCTURE 5 - ELEMENT

3 - CLAWS 6 - PIVOT PIN

VAWIPERS/WASHERS 8R - 15

WIPER ARM (Continued)

Page 298 of 1232

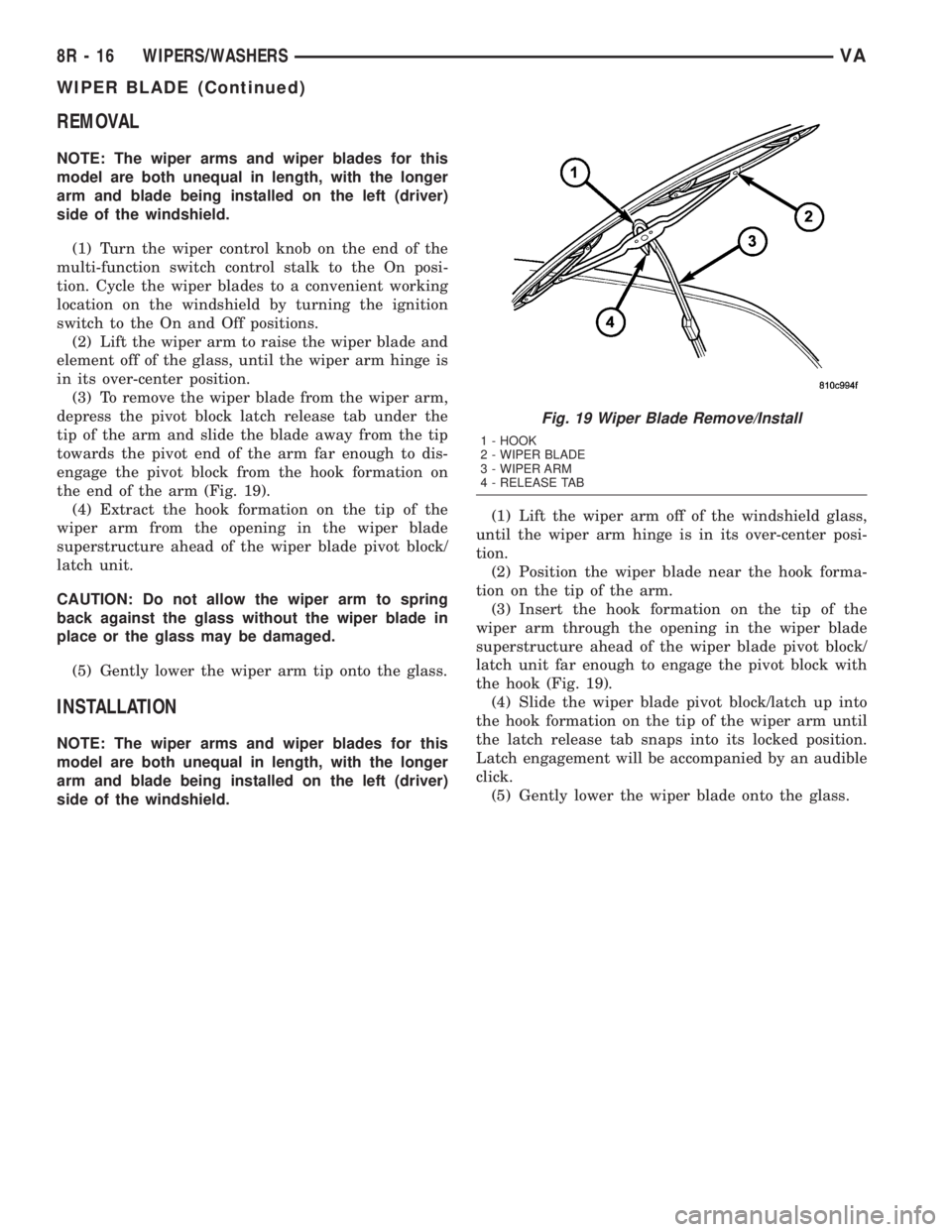

REMOVAL

NOTE: The wiper arms and wiper blades for this

model are both unequal in length, with the longer

arm and blade being installed on the left (driver)

side of the windshield.

(1) Turn the wiper control knob on the end of the

multi-function switch control stalk to the On posi-

tion. Cycle the wiper blades to a convenient working

location on the windshield by turning the ignition

switch to the On and Off positions.

(2) Lift the wiper arm to raise the wiper blade and

element off of the glass, until the wiper arm hinge is

in its over-center position.

(3) To remove the wiper blade from the wiper arm,

depress the pivot block latch release tab under the

tip of the arm and slide the blade away from the tip

towards the pivot end of the arm far enough to dis-

engage the pivot block from the hook formation on

the end of the arm (Fig. 19).

(4) Extract the hook formation on the tip of the

wiper arm from the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.

(5) Gently lower the wiper arm tip onto the glass.

INSTALLATION

NOTE: The wiper arms and wiper blades for this

model are both unequal in length, with the longer

arm and blade being installed on the left (driver)

side of the windshield.(1) Lift the wiper arm off of the windshield glass,

until the wiper arm hinge is in its over-center posi-

tion.

(2) Position the wiper blade near the hook forma-

tion on the tip of the arm.

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block with

the hook (Fig. 19).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

Fig. 19 Wiper Blade Remove/Install

1 - HOOK

2 - WIPER BLADE

3 - WIPER ARM

4 - RELEASE TAB

8R - 16 WIPERS/WASHERSVA

WIPER BLADE (Continued)

Page 299 of 1232

WIPER LINKAGE

DESCRIPTION

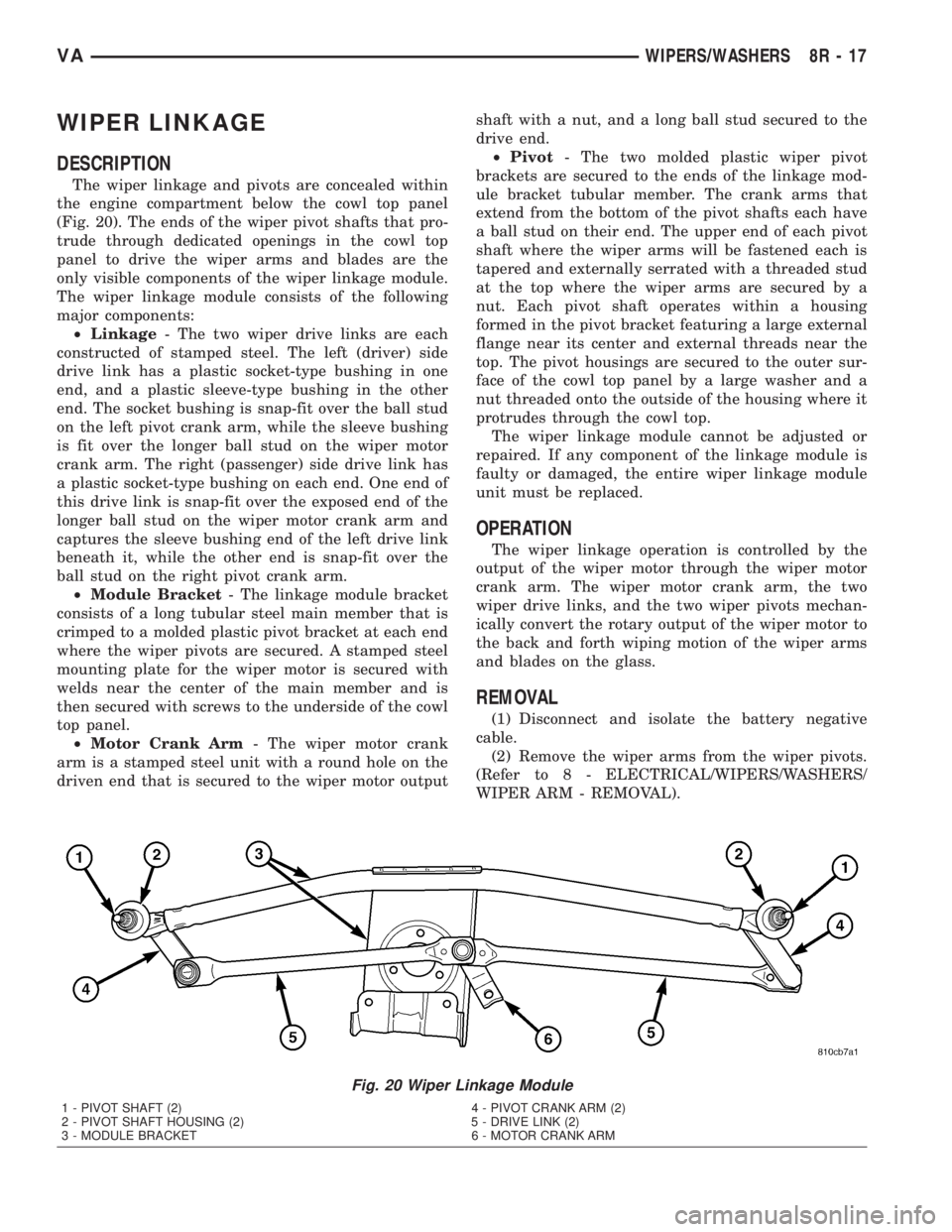

The wiper linkage and pivots are concealed within

the engine compartment below the cowl top panel

(Fig. 20). The ends of the wiper pivot shafts that pro-

trude through dedicated openings in the cowl top

panel to drive the wiper arms and blades are the

only visible components of the wiper linkage module.

The wiper linkage module consists of the following

major components:

²Linkage- The two wiper drive links are each

constructed of stamped steel. The left (driver) side

drive link has a plastic socket-type bushing in one

end, and a plastic sleeve-type bushing in the other

end. The socket bushing is snap-fit over the ball stud

on the left pivot crank arm, while the sleeve bushing

is fit over the longer ball stud on the wiper motor

crank arm. The right (passenger) side drive link has

a plastic socket-type bushing on each end. One end of

this drive link is snap-fit over the exposed end of the

longer ball stud on the wiper motor crank arm and

captures the sleeve bushing end of the left drive link

beneath it, while the other end is snap-fit over the

ball stud on the right pivot crank arm.

²Module Bracket- The linkage module bracket

consists of a long tubular steel main member that is

crimped to a molded plastic pivot bracket at each end

where the wiper pivots are secured. A stamped steel

mounting plate for the wiper motor is secured with

welds near the center of the main member and is

then secured with screws to the underside of the cowl

top panel.

²Motor Crank Arm- The wiper motor crank

arm is a stamped steel unit with a round hole on the

driven end that is secured to the wiper motor outputshaft with a nut, and a long ball stud secured to the

drive end.

²Pivot- The two molded plastic wiper pivot

brackets are secured to the ends of the linkage mod-

ule bracket tubular member. The crank arms that

extend from the bottom of the pivot shafts each have

a ball stud on their end. The upper end of each pivot

shaft where the wiper arms will be fastened each is

tapered and externally serrated with a threaded stud

at the top where the wiper arms are secured by a

nut. Each pivot shaft operates within a housing

formed in the pivot bracket featuring a large external

flange near its center and external threads near the

top. The pivot housings are secured to the outer sur-

face of the cowl top panel by a large washer and a

nut threaded onto the outside of the housing where it

protrudes through the cowl top.

The wiper linkage module cannot be adjusted or

repaired. If any component of the linkage module is

faulty or damaged, the entire wiper linkage module

unit must be replaced.

OPERATION

The wiper linkage operation is controlled by the

output of the wiper motor through the wiper motor

crank arm. The wiper motor crank arm, the two

wiper drive links, and the two wiper pivots mechan-

ically convert the rotary output of the wiper motor to

the back and forth wiping motion of the wiper arms

and blades on the glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the wiper arms from the wiper pivots.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ARM - REMOVAL).

Fig. 20 Wiper Linkage Module

1 - PIVOT SHAFT (2) 4 - PIVOT CRANK ARM (2)

2 - PIVOT SHAFT HOUSING (2) 5 - DRIVE LINK (2)

3 - MODULE BRACKET 6 - MOTOR CRANK ARM

VAWIPERS/WASHERS 8R - 17

Page 300 of 1232

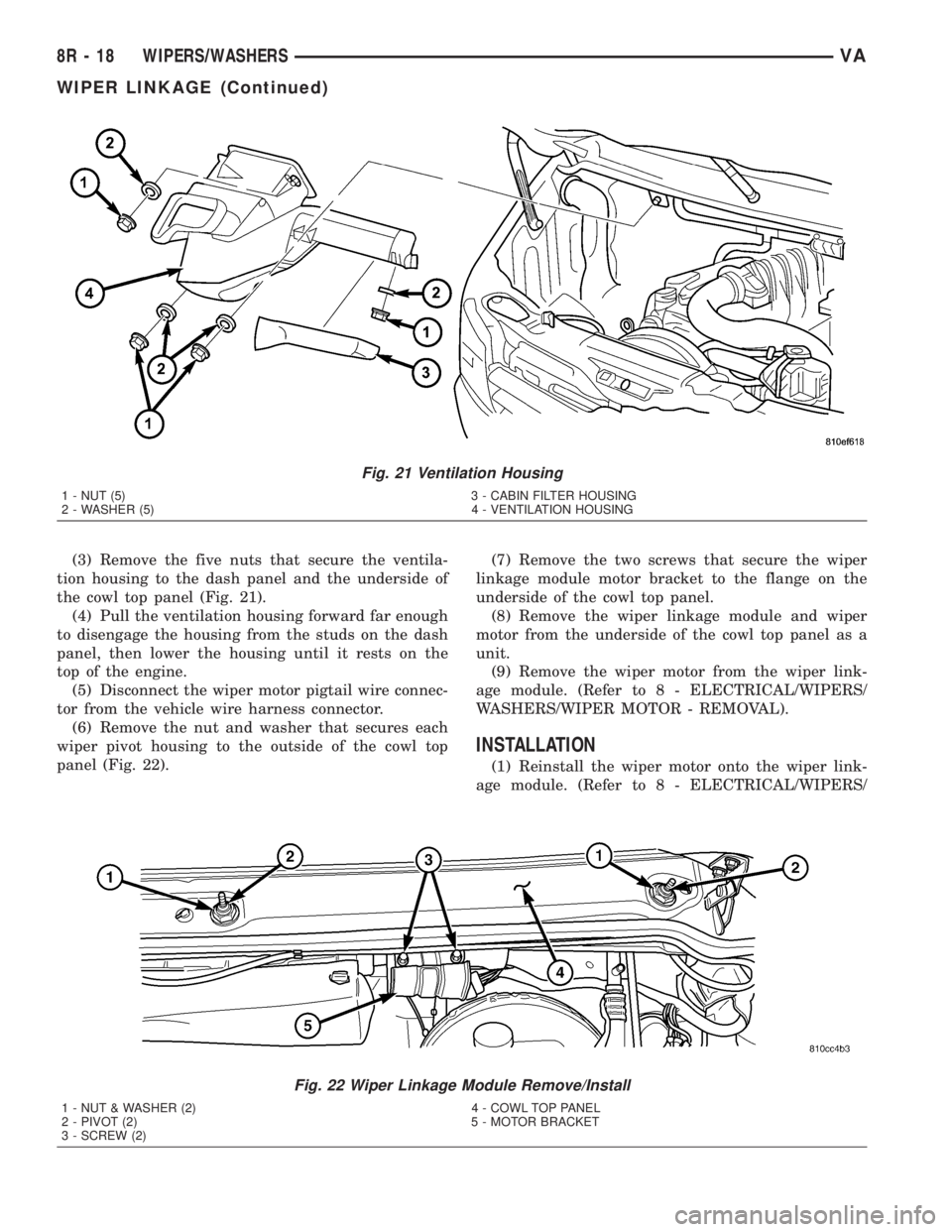

(3) Remove the five nuts that secure the ventila-

tion housing to the dash panel and the underside of

the cowl top panel (Fig. 21).

(4) Pull the ventilation housing forward far enough

to disengage the housing from the studs on the dash

panel, then lower the housing until it rests on the

top of the engine.

(5) Disconnect the wiper motor pigtail wire connec-

tor from the vehicle wire harness connector.

(6) Remove the nut and washer that secures each

wiper pivot housing to the outside of the cowl top

panel (Fig. 22).(7) Remove the two screws that secure the wiper

linkage module motor bracket to the flange on the

underside of the cowl top panel.

(8) Remove the wiper linkage module and wiper

motor from the underside of the cowl top panel as a

unit.

(9) Remove the wiper motor from the wiper link-

age module. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MOTOR - REMOVAL).

INSTALLATION

(1) Reinstall the wiper motor onto the wiper link-

age module. (Refer to 8 - ELECTRICAL/WIPERS/

Fig. 21 Ventilation Housing

1 - NUT (5) 3 - CABIN FILTER HOUSING

2 - WASHER (5) 4 - VENTILATION HOUSING

Fig. 22 Wiper Linkage Module Remove/Install

1 - NUT & WASHER (2) 4 - COWL TOP PANEL

2 - PIVOT (2) 5 - MOTOR BRACKET

3 - SCREW (2)

8R - 18 WIPERS/WASHERSVA

WIPER LINKAGE (Continued)