MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 311 of 1232

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD.................Left Hand Drive Vehicles

RHD ...............Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX . . . Manual Transmissions-Front Wheel Drive

AT....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export....... Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . Vehicles Built For Sale In

North America

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies gage of wire, and color.

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

WIRING DIAGRAM INFORMATION (Continued)

Page 312 of 1232

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

resistance in these circuits use a meter with a 10 -

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle's

electrical system can cause damage to the equip-

ment and provide false readings.

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONVA

WIRING DIAGRAM INFORMATION (Continued)

Page 313 of 1232

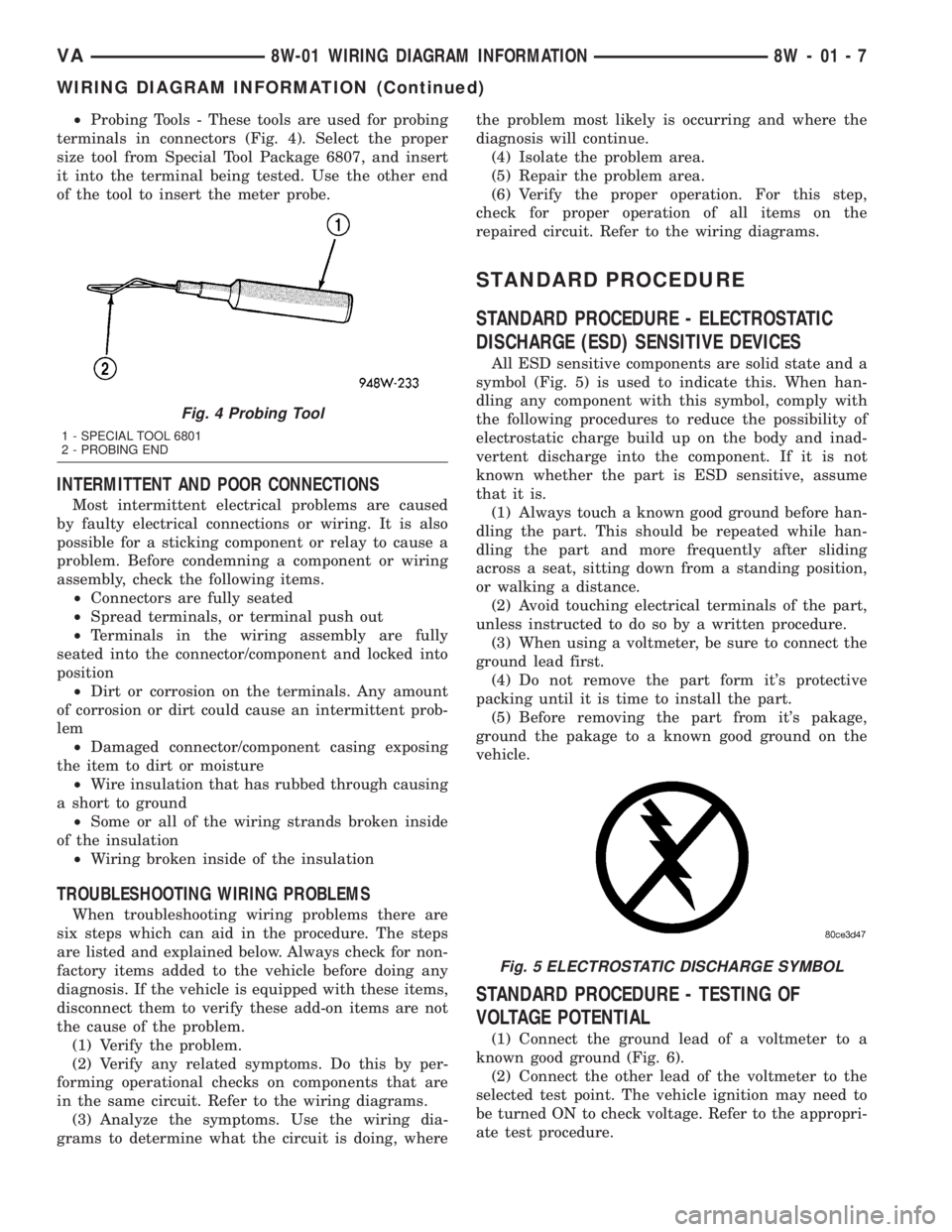

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 4). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly, check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked into

position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt or moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation

²Wiring broken inside of the insulation

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, wherethe problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem area.

(6) Verify the proper operation. For this step,

check for proper operation of all items on the

repaired circuit. Refer to the wiring diagrams.

STANDARD PROCEDURE

STANDARD PROCEDURE - ELECTROSTATIC

DISCHARGE (ESD) SENSITIVE DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 5) is used to indicate this. When han-

dling any component with this symbol, comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.

(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part form it's protective

packing until it is time to install the part.

(5) Before removing the part from it's pakage,

ground the pakage to a known good ground on the

vehicle.

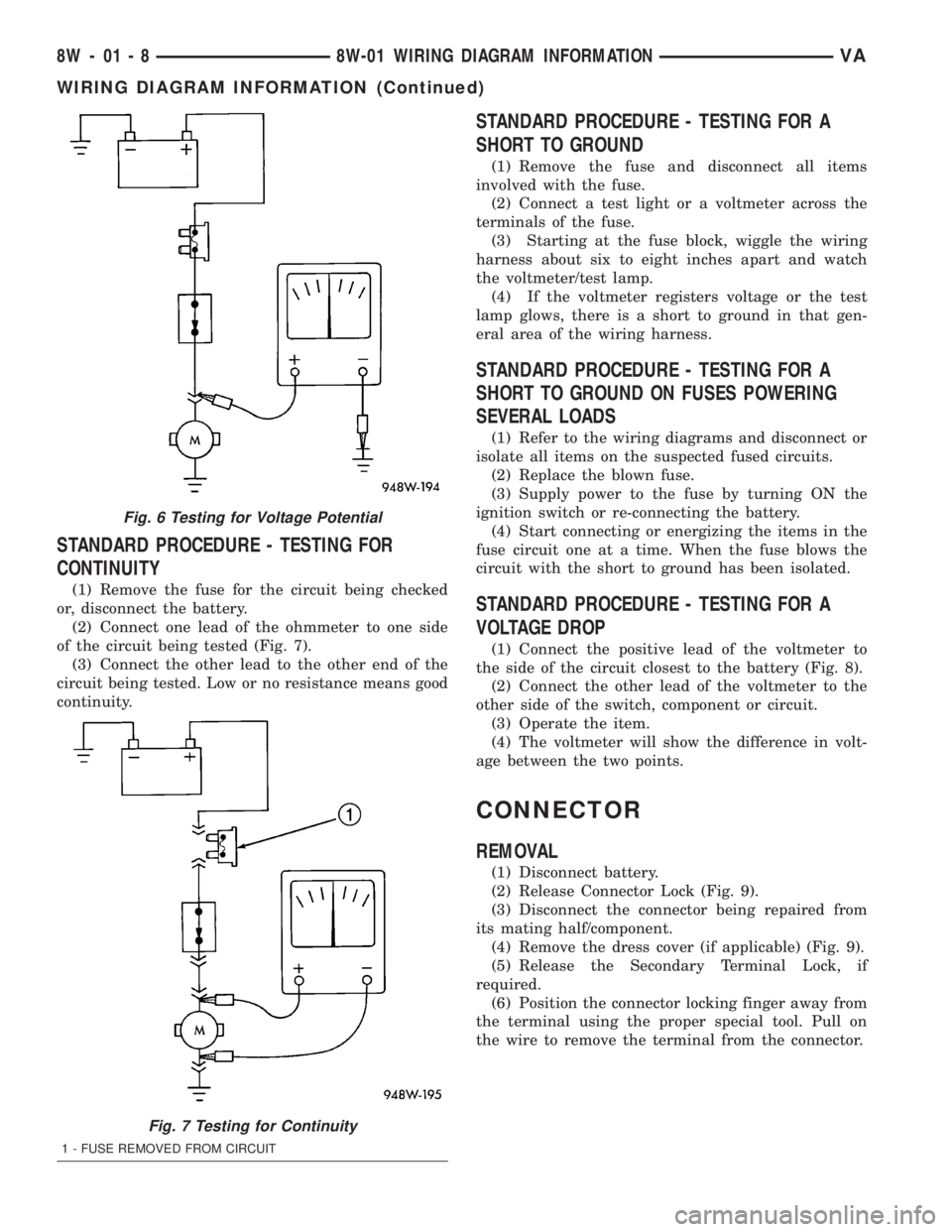

STANDARD PROCEDURE - TESTING OF

VOLTAGE POTENTIAL

(1) Connect the ground lead of a voltmeter to a

known good ground (Fig. 6).

(2) Connect the other lead of the voltmeter to the

selected test point. The vehicle ignition may need to

be turned ON to check voltage. Refer to the appropri-

ate test procedure.

Fig. 4 Probing Tool

1 - SPECIAL TOOL 6801

2 - PROBING END

Fig. 5 ELECTROSTATIC DISCHARGE SYMBOL

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 314 of 1232

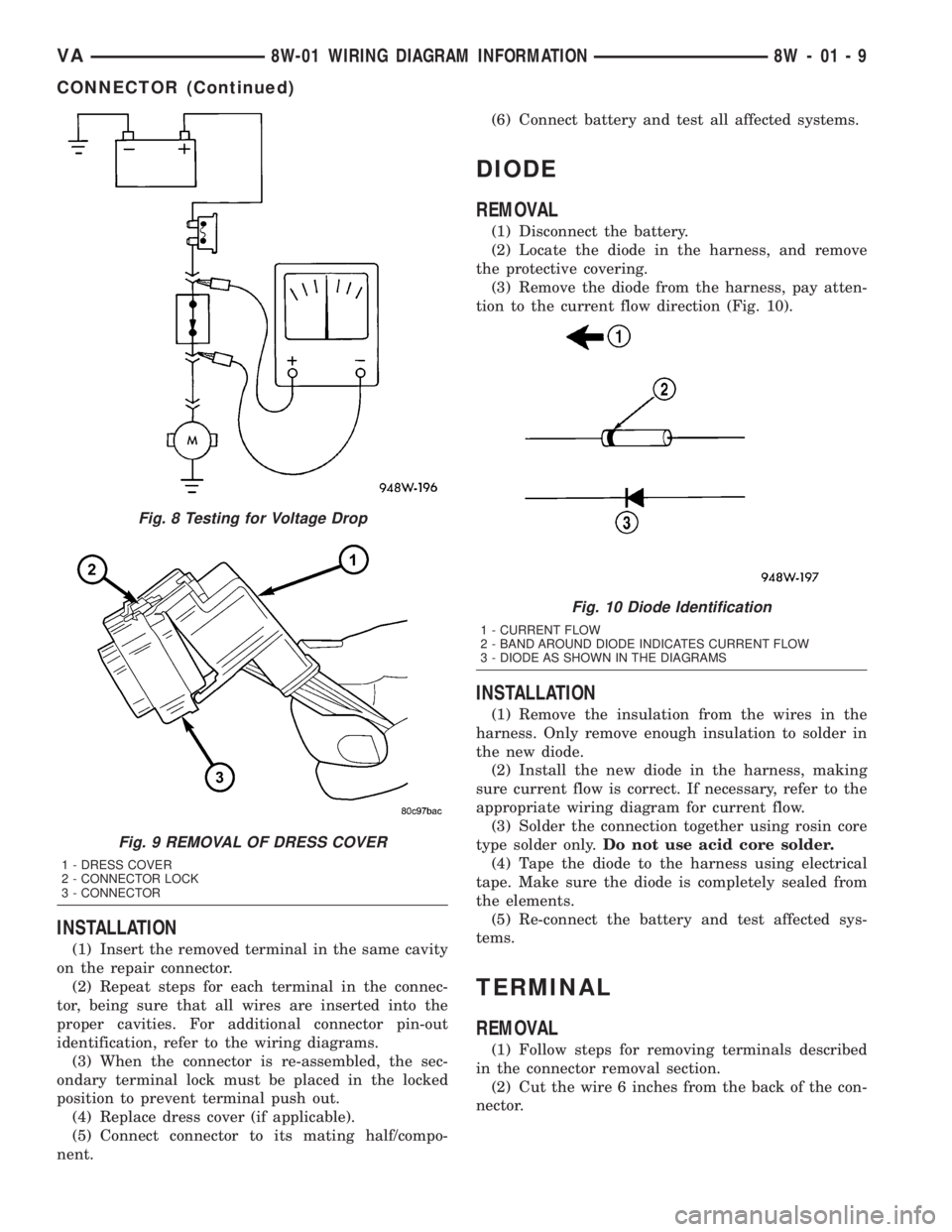

STANDARD PROCEDURE - TESTING FOR

CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 7).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

STANDARD PROCEDURE - TESTING FOR A

SHORT TO GROUND ON FUSES POWERING

SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting or energizing the items in the

fuse circuit one at a time. When the fuse blows the

circuit with the short to ground has been isolated.

STANDARD PROCEDURE - TESTING FOR A

VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 8).

(2) Connect the other lead of the voltmeter to the

other side of the switch, component or circuit.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

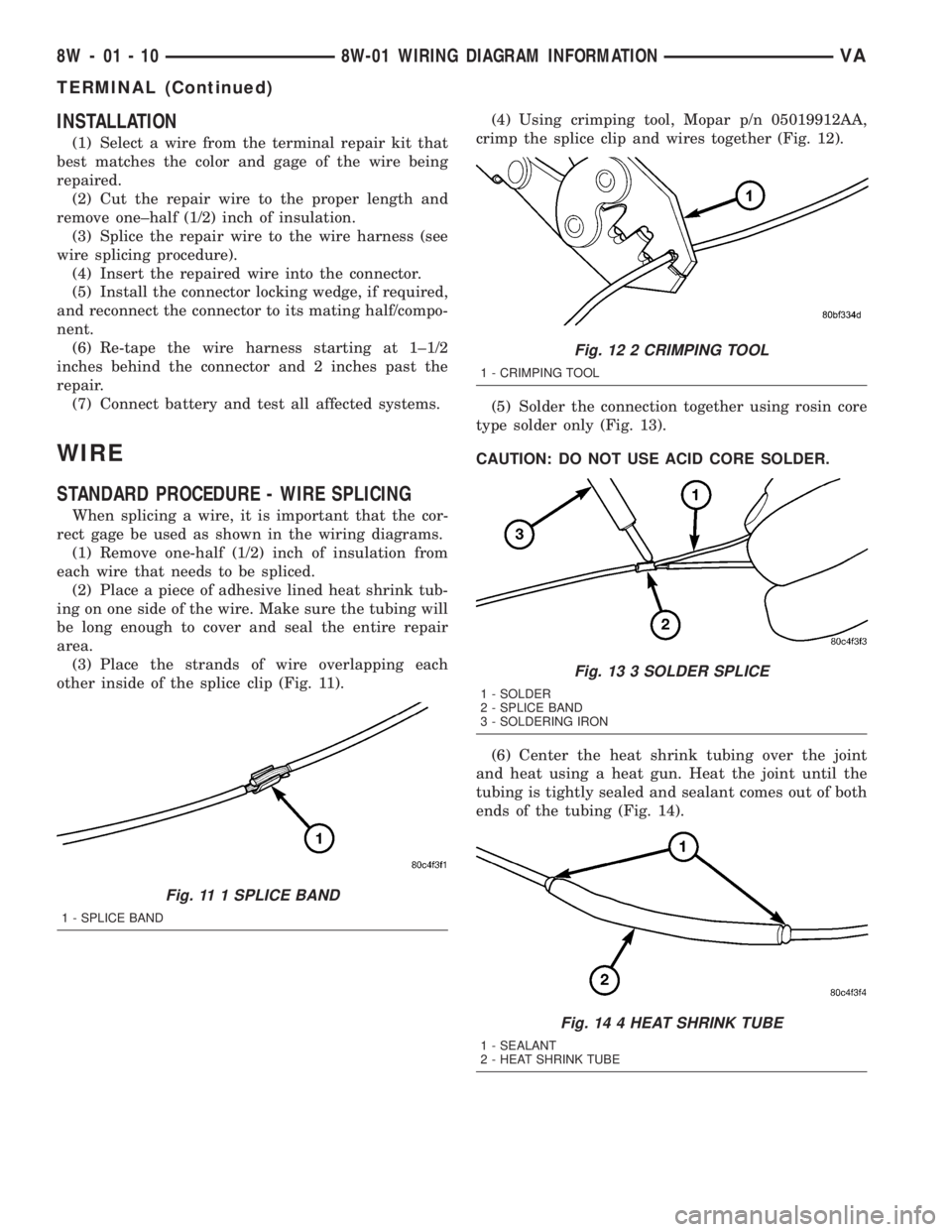

CONNECTOR

REMOVAL

(1) Disconnect battery.

(2) Release Connector Lock (Fig. 9).

(3) Disconnect the connector being repaired from

its mating half/component.

(4) Remove the dress cover (if applicable) (Fig. 9).

(5) Release the Secondary Terminal Lock, if

required.

(6) Position the connector locking finger away from

the terminal using the proper special tool. Pull on

the wire to remove the terminal from the connector.

Fig. 6 Testing for Voltage Potential

Fig. 7 Testing for Continuity

1 - FUSE REMOVED FROM CIRCUIT

8W - 01 - 8 8W-01 WIRING DIAGRAM INFORMATIONVA

WIRING DIAGRAM INFORMATION (Continued)

Page 315 of 1232

INSTALLATION

(1) Insert the removed terminal in the same cavity

on the repair connector.

(2) Repeat steps for each terminal in the connec-

tor, being sure that all wires are inserted into the

proper cavities. For additional connector pin-out

identification, refer to the wiring diagrams.

(3) When the connector is re-assembled, the sec-

ondary terminal lock must be placed in the locked

position to prevent terminal push out.

(4) Replace dress cover (if applicable).

(5) Connect connector to its mating half/compo-

nent.(6) Connect battery and test all affected systems.

DIODE

REMOVAL

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 10).

INSTALLATION

(1) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(2) Install the new diode in the harness, making

sure current flow is correct. If necessary, refer to the

appropriate wiring diagram for current flow.

(3) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(4) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(5) Re-connect the battery and test affected sys-

tems.

TERMINAL

REMOVAL

(1) Follow steps for removing terminals described

in the connector removal section.

(2) Cut the wire 6 inches from the back of the con-

nector.

Fig. 8 Testing for Voltage Drop

Fig. 9 REMOVAL OF DRESS COVER

1 - DRESS COVER

2 - CONNECTOR LOCK

3 - CONNECTOR

Fig. 10 Diode Identification

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

VA8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 9

CONNECTOR (Continued)

Page 316 of 1232

INSTALLATION

(1) Select a wire from the terminal repair kit that

best matches the color and gage of the wire being

repaired.

(2) Cut the repair wire to the proper length and

remove one±half (1/2) inch of insulation.

(3) Splice the repair wire to the wire harness (see

wire splicing procedure).

(4) Insert the repaired wire into the connector.

(5) Install the connector locking wedge, if required,

and reconnect the connector to its mating half/compo-

nent.

(6) Re-tape the wire harness starting at 1±1/2

inches behind the connector and 2 inches past the

repair.

(7) Connect battery and test all affected systems.

WIRE

STANDARD PROCEDURE - WIRE SPLICING

When splicing a wire, it is important that the cor-

rect gage be used as shown in the wiring diagrams.

(1) Remove one-half (1/2) inch of insulation from

each wire that needs to be spliced.

(2) Place a piece of adhesive lined heat shrink tub-

ing on one side of the wire. Make sure the tubing will

be long enough to cover and seal the entire repair

area.

(3) Place the strands of wire overlapping each

other inside of the splice clip (Fig. 11).(4) Using crimping tool, Mopar p/n 05019912AA,

crimp the splice clip and wires together (Fig. 12).

(5) Solder the connection together using rosin core

type solder only (Fig. 13).

CAUTION: DO NOT USE ACID CORE SOLDER.

(6) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing (Fig. 14).

Fig. 11 1 SPLICE BAND

1 - SPLICE BAND

Fig. 12 2 CRIMPING TOOL

1 - CRIMPING TOOL

Fig. 13 3 SOLDER SPLICE

1 - SOLDER

2 - SPLICE BAND

3 - SOLDERING IRON

Fig. 14 4 HEAT SHRINK TUBE

1 - SEALANT

2 - HEAT SHRINK TUBE

8W - 01 - 10 8W-01 WIRING DIAGRAM INFORMATIONVA

TERMINAL (Continued)

Page 317 of 1232

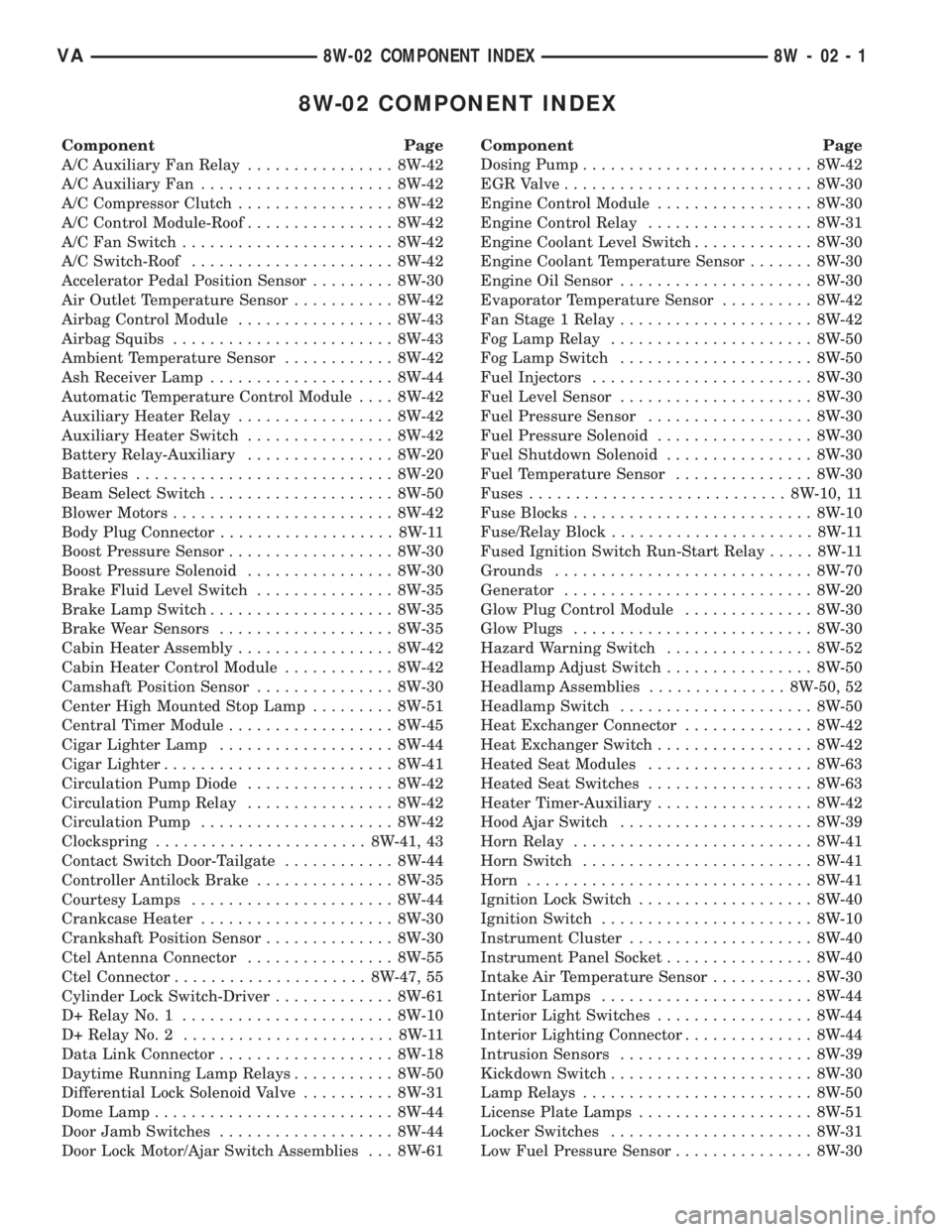

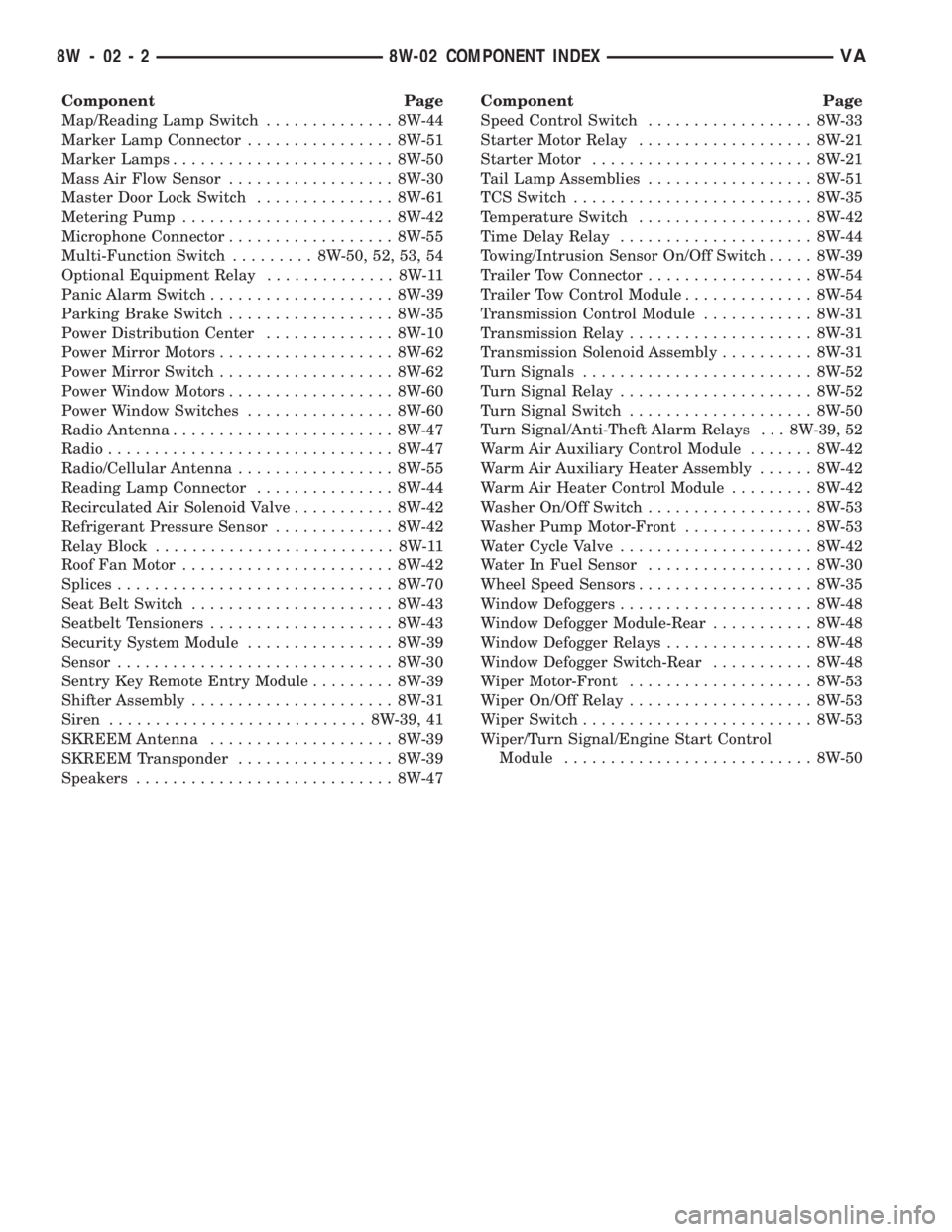

8W-02 COMPONENT INDEX

Component Page

A/C Auxiliary Fan Relay................ 8W-42

A/C Auxiliary Fan..................... 8W-42

A/C Compressor Clutch................. 8W-42

A/C Control Module-Roof................ 8W-42

A/C Fan Switch....................... 8W-42

A/C Switch-Roof...................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Air Outlet Temperature Sensor........... 8W-42

Airbag Control Module................. 8W-43

Airbag Squibs........................ 8W-43

Ambient Temperature Sensor............ 8W-42

Ash Receiver Lamp.................... 8W-44

Automatic Temperature Control Module.... 8W-42

Auxiliary Heater Relay................. 8W-42

Auxiliary Heater Switch................ 8W-42

Battery Relay-Auxiliary................ 8W-20

Batteries............................ 8W-20

Beam Select Switch.................... 8W-50

Blower Motors........................ 8W-42

Body Plug Connector................... 8W-11

Boost Pressure Sensor.................. 8W-30

Boost Pressure Solenoid................ 8W-30

Brake Fluid Level Switch............... 8W-35

Brake Lamp Switch.................... 8W-35

Brake Wear Sensors................... 8W-35

Cabin Heater Assembly................. 8W-42

Cabin Heater Control Module............ 8W-42

Camshaft Position Sensor............... 8W-30

Center High Mounted Stop Lamp......... 8W-51

Central Timer Module.................. 8W-45

Cigar Lighter Lamp................... 8W-44

Cigar Lighter......................... 8W-41

Circulation Pump Diode................ 8W-42

Circulation Pump Relay................ 8W-42

Circulation Pump..................... 8W-42

Clockspring....................... 8W-41, 43

Contact Switch Door-Tailgate............ 8W-44

Controller Antilock Brake............... 8W-35

Courtesy Lamps...................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Ctel Antenna Connector................ 8W-55

Ctel Connector..................... 8W-47, 55

Cylinder Lock Switch-Driver............. 8W-61

D+ Relay No. 1....................... 8W-10

D+ Relay No. 2....................... 8W-11

Data Link Connector................... 8W-18

Daytime Running Lamp Relays........... 8W-50

Differential Lock Solenoid Valve.......... 8W-31

Dome Lamp.......................... 8W-44

Door Jamb Switches................... 8W-44

Door Lock Motor/Ajar Switch Assemblies . . . 8W-61Component Page

Dosing Pump......................... 8W-42

EGR Valve........................... 8W-30

Engine Control Module................. 8W-30

Engine Control Relay.................. 8W-31

Engine Coolant Level Switch............. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Sensor..................... 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fan Stage 1 Relay..................... 8W-42

Fog Lamp Relay...................... 8W-50

Fog Lamp Switch..................... 8W-50

Fuel Injectors........................ 8W-30

Fuel Level Sensor..................... 8W-30

Fuel Pressure Sensor.................. 8W-30

Fuel Pressure Solenoid................. 8W-30

Fuel Shutdown Solenoid................ 8W-30

Fuel Temperature Sensor............... 8W-30

Fuses............................ 8W-10, 11

Fuse Blocks.......................... 8W-10

Fuse/Relay Block...................... 8W-11

Fused Ignition Switch Run-Start Relay..... 8W-11

Grounds............................ 8W-70

Generator........................... 8W-20

Glow Plug Control Module.............. 8W-30

Glow Plugs.......................... 8W-30

Hazard Warning Switch................ 8W-52

Headlamp Adjust Switch................ 8W-50

Headlamp Assemblies............... 8W-50, 52

Headlamp Switch..................... 8W-50

Heat Exchanger Connector.............. 8W-42

Heat Exchanger Switch................. 8W-42

Heated Seat Modules.................. 8W-63

Heated Seat Switches.................. 8W-63

Heater Timer-Auxiliary................. 8W-42

Hood Ajar Switch..................... 8W-39

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn............................... 8W-41

Ignition Lock Switch................... 8W-40

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Instrument Panel Socket................ 8W-40

Intake Air Temperature Sensor........... 8W-30

Interior Lamps....................... 8W-44

Interior Light Switches................. 8W-44

Interior Lighting Connector.............. 8W-44

Intrusion Sensors..................... 8W-39

Kickdown Switch...................... 8W-30

Lamp Relays......................... 8W-50

License Plate Lamps................... 8W-51

Locker Switches...................... 8W-31

Low Fuel Pressure Sensor............... 8W-30

VA8W-02 COMPONENT INDEX 8W - 02 - 1

Page 318 of 1232

Component Page

Map/Reading Lamp Switch.............. 8W-44

Marker Lamp Connector................ 8W-51

Marker Lamps........................ 8W-50

Mass Air Flow Sensor.................. 8W-30

Master Door Lock Switch............... 8W-61

Metering Pump....................... 8W-42

Microphone Connector.................. 8W-55

Multi-Function Switch......... 8W-50, 52, 53, 54

Optional Equipment Relay.............. 8W-11

Panic Alarm Switch.................... 8W-39

Parking Brake Switch.................. 8W-35

Power Distribution Center.............. 8W-10

Power Mirror Motors................... 8W-62

Power Mirror Switch................... 8W-62

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Radio Antenna........................ 8W-47

Radio............................... 8W-47

Radio/Cellular Antenna................. 8W-55

Reading Lamp Connector............... 8W-44

Recirculated Air Solenoid Valve........... 8W-42

Refrigerant Pressure Sensor............. 8W-42

Relay Block.......................... 8W-11

Roof Fan Motor....................... 8W-42

Splices.............................. 8W-70

Seat Belt Switch...................... 8W-43

Seatbelt Tensioners.................... 8W-43

Security System Module................ 8W-39

Sensor.............................. 8W-30

Sentry Key Remote Entry Module......... 8W-39

Shifter Assembly...................... 8W-31

Siren............................ 8W-39, 41

SKREEM Antenna.................... 8W-39

SKREEM Transponder................. 8W-39

Speakers............................ 8W-47Component Page

Speed Control Switch.................. 8W-33

Starter Motor Relay................... 8W-21

Starter Motor........................ 8W-21

Tail Lamp Assemblies.................. 8W-51

TCS Switch.......................... 8W-35

Temperature Switch................... 8W-42

Time Delay Relay..................... 8W-44

Towing/Intrusion Sensor On/Off Switch..... 8W-39

Trailer Tow Connector.................. 8W-54

Trailer Tow Control Module.............. 8W-54

Transmission Control Module............ 8W-31

Transmission Relay.................... 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signals......................... 8W-52

Turn Signal Relay..................... 8W-52

Turn Signal Switch.................... 8W-50

Turn Signal/Anti-Theft Alarm Relays . . . 8W-39, 52

Warm Air Auxiliary Control Module....... 8W-42

Warm Air Auxiliary Heater Assembly...... 8W-42

Warm Air Heater Control Module......... 8W-42

Washer On/Off Switch.................. 8W-53

Washer Pump Motor-Front.............. 8W-53

Water Cycle Valve..................... 8W-42

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Window Defoggers..................... 8W-48

Window Defogger Module-Rear........... 8W-48

Window Defogger Relays................ 8W-48

Window Defogger Switch-Rear........... 8W-48

Wiper Motor-Front.................... 8W-53

Wiper On/Off Relay.................... 8W-53

Wiper Switch......................... 8W-53

Wiper/Turn Signal/Engine Start Control

Module........................... 8W-50

8W - 02 - 2 8W-02 COMPONENT INDEXVA

Page 319 of 1232

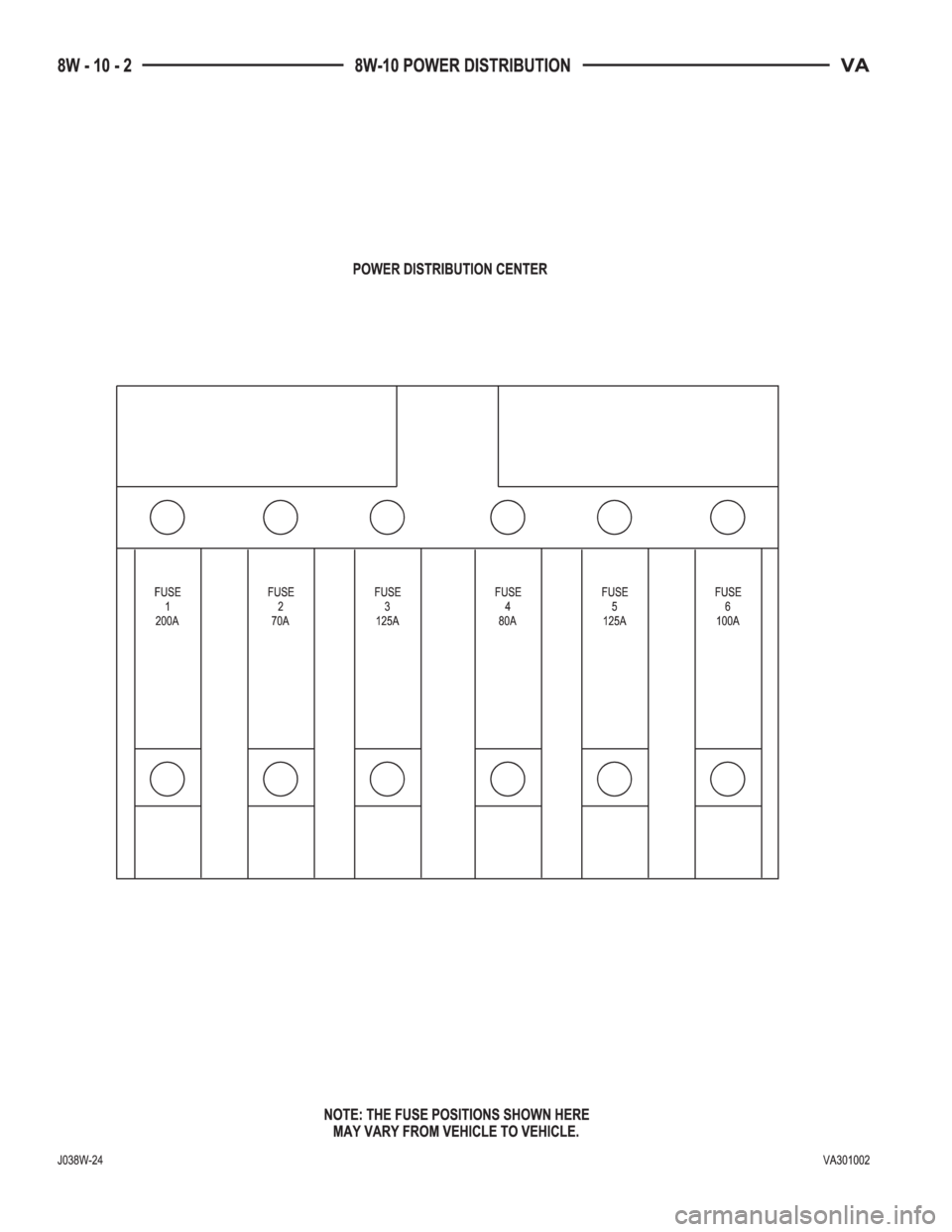

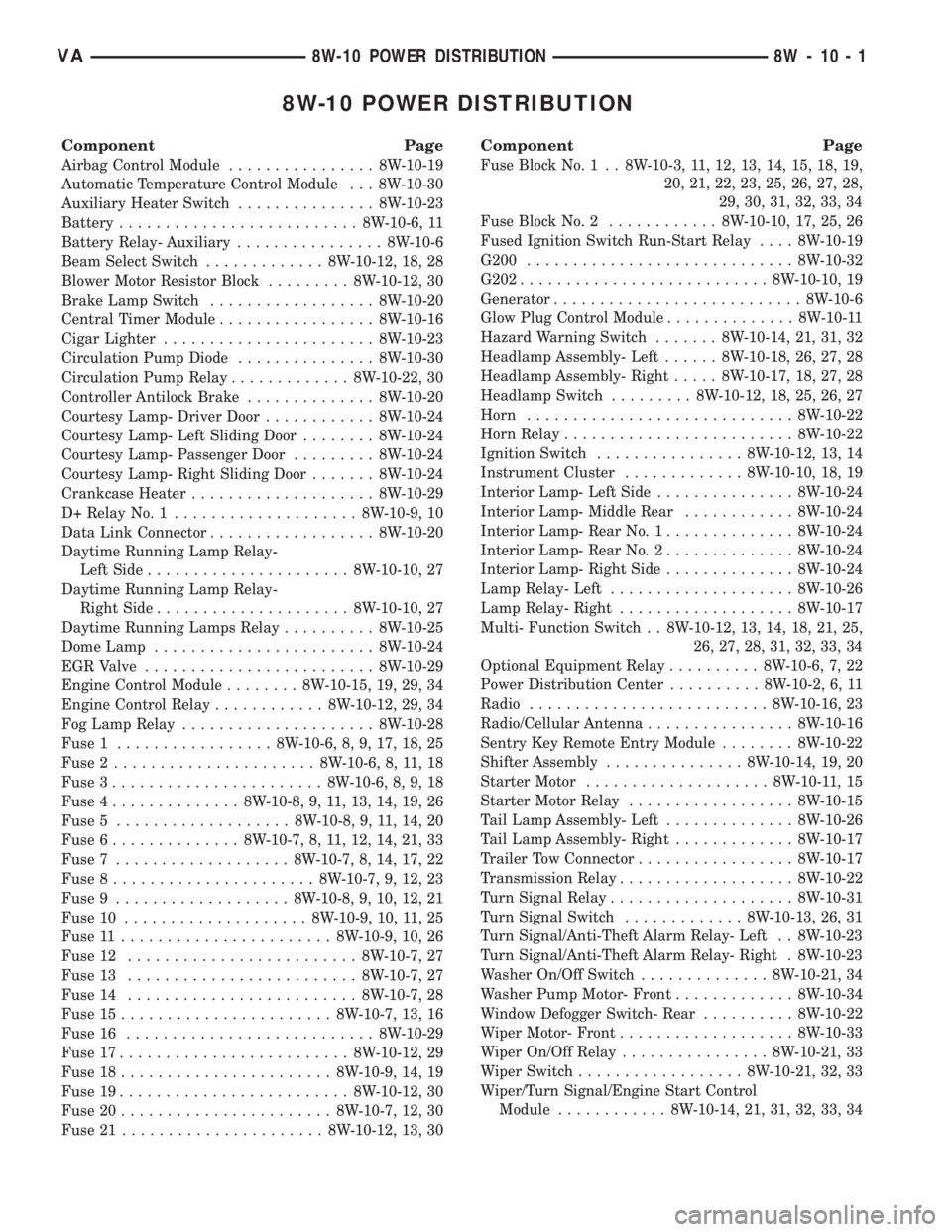

8W-10 POWER DISTRIBUTION

Component Page

Airbag Control Module................ 8W-10-19

Automatic Temperature Control Module . . . 8W-10-30

Auxiliary Heater Switch............... 8W-10-23

Battery.......................... 8W-10-6, 11

Battery Relay- Auxiliary................ 8W-10-6

Beam Select Switch............. 8W-10-12, 18, 28

Blower Motor Resistor Block......... 8W-10-12, 30

Brake Lamp Switch.................. 8W-10-20

Central Timer Module................. 8W-10-16

Cigar Lighter....................... 8W-10-23

Circulation Pump Diode............... 8W-10-30

Circulation Pump Relay............. 8W-10-22, 30

Controller Antilock Brake.............. 8W-10-20

Courtesy Lamp- Driver Door............ 8W-10-24

Courtesy Lamp- Left Sliding Door........ 8W-10-24

Courtesy Lamp- Passenger Door......... 8W-10-24

Courtesy Lamp- Right Sliding Door....... 8W-10-24

Crankcase Heater.................... 8W-10-29

D+ Relay No. 1.................... 8W-10-9, 10

Data Link Connector.................. 8W-10-20

Daytime Running Lamp Relay-

Left Side...................... 8W-10-10, 27

Daytime Running Lamp Relay-

Right Side..................... 8W-10-10, 27

Daytime Running Lamps Relay.......... 8W-10-25

Dome Lamp........................ 8W-10-24

EGR Valve......................... 8W-10-29

Engine Control Module........ 8W-10-15, 19, 29, 34

Engine Control Relay............ 8W-10-12, 29, 34

Fog Lamp Relay..................... 8W-10-28

Fuse 1................. 8W-10-6, 8, 9, 17, 18, 25

Fuse 2...................... 8W-10-6, 8, 11, 18

Fuse 3....................... 8W-10-6, 8, 9, 18

Fuse 4.............. 8W-10-8, 9, 11, 13, 14, 19, 26

Fuse 5................... 8W-10-8, 9, 11, 14, 20

Fuse 6.............. 8W-10-7, 8, 11, 12, 14, 21, 33

Fuse 7................... 8W-10-7, 8, 14, 17, 22

Fuse 8...................... 8W-10-7, 9, 12, 23

Fuse 9................... 8W-10-8, 9, 10, 12, 21

Fuse 10.................... 8W-10-9, 10, 11, 25

Fuse 11....................... 8W-10-9, 10, 26

Fuse 12......................... 8W-10-7, 27

Fuse 13......................... 8W-10-7, 27

Fuse 14......................... 8W-10-7, 28

Fuse 15....................... 8W-10-7, 13, 16

Fuse 16........................... 8W-10-29

Fuse 17......................... 8W-10-12, 29

Fuse 18....................... 8W-10-9, 14, 19

Fuse 19......................... 8W-10-12, 30

Fuse 20....................... 8W-10-7, 12, 30

Fuse 21...................... 8W-10-12, 13, 30

Component Page

Fuse Block No. 1 . . 8W-10-3, 11, 12, 13, 14, 15, 18, 19,

20, 21, 22, 23, 25, 26, 27, 28,

29, 30, 31, 32, 33, 34

Fuse Block No. 2............ 8W-10-10, 17, 25, 26

Fused Ignition Switch Run-Start Relay.... 8W-10-19

G200............................. 8W-10-32

G202........................... 8W-10-10, 19

Generator........................... 8W-10-6

Glow Plug Control Module.............. 8W-10-11

Hazard Warning Switch....... 8W-10-14, 21, 31, 32

Headlamp Assembly- Left...... 8W-10-18, 26, 27, 28

Headlamp Assembly- Right..... 8W-10-17, 18, 27, 28

Headlamp Switch......... 8W-10-12, 18, 25, 26, 27

Horn............................. 8W-10-22

Horn Relay......................... 8W-10-22

Ignition Switch................ 8W-10-12, 13, 14

Instrument Cluster............. 8W-10-10, 18, 19

Interior Lamp- Left Side............... 8W-10-24

Interior Lamp- Middle Rear............ 8W-10-24

Interior Lamp- Rear No. 1.............. 8W-10-24

Interior Lamp- Rear No. 2.............. 8W-10-24

Interior Lamp- Right Side.............. 8W-10-24

Lamp Relay- Left.................... 8W-10-26

Lamp Relay- Right................... 8W-10-17

Multi- Function Switch . . 8W-10-12, 13, 14, 18, 21, 25,

26, 27, 28, 31, 32, 33, 34

Optional Equipment Relay.......... 8W-10-6, 7, 22

Power Distribution Center.......... 8W-10-2, 6, 11

Radio.......................... 8W-10-16, 23

Radio/Cellular Antenna................ 8W-10-16

Sentry Key Remote Entry Module........ 8W-10-22

Shifter Assembly............... 8W-10-14, 19, 20

Starter Motor.................... 8W-10-11, 15

Starter Motor Relay.................. 8W-10-15

Tail Lamp Assembly- Left.............. 8W-10-26

Tail Lamp Assembly- Right............. 8W-10-17

Trailer Tow Connector................. 8W-10-17

Transmission Relay................... 8W-10-22

Turn Signal Relay.................... 8W-10-31

Turn Signal Switch............. 8W-10-13, 26, 31

Turn Signal/Anti-Theft Alarm Relay- Left . . 8W-10-23

Turn Signal/Anti-Theft Alarm Relay- Right . 8W-10-23

Washer On/Off Switch.............. 8W-10-21, 34

Washer Pump Motor- Front............. 8W-10-34

Window Defogger Switch- Rear.......... 8W-10-22

Wiper Motor- Front................... 8W-10-33

Wiper On/Off Relay................ 8W-10-21, 33

Wiper Switch.................. 8W-10-21, 32, 33

Wiper/Turn Signal/Engine Start Control

Module............ 8W-10-14, 21, 31, 32, 33, 34

VA8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 320 of 1232