change time MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 266 of 334

Useful information

This Operator's Manual describes all models

as well as standard and optional equipment

of your vehicle that were available at the time

of going to print. Country-specific variations

are possible. Note that your vehicle may not

be equipped with all of the described

functions. This also applies to systems and

functions relevant to safety.

Read the information on qualified specialist

workshops (Y page 26). Where will I find...?

Vehicle tool kit

General notes The vehicle tool kit is in the stowage

compartment in the footwell on the co-

driver's side. For vehicles without a spare

wheel, the Premium tire sealant and the tire

inflation compressor are in the stowage

compartment in the right-hand door sill.

The vehicle tool kit consists of:

R a towing eye

R a lug wrench

R 2o pen-end wrenches

R a screwdriver with Torx ,Phillips and slotted

bits

i Vehicles without a spare wheel are not

equipped with the tools needed to change

a wheel when they leave the factory, e.g. a

jack. In the event of a flat tire, these

vehicles are equipped with a tire sealant

and a tire inflation compressor. Country-

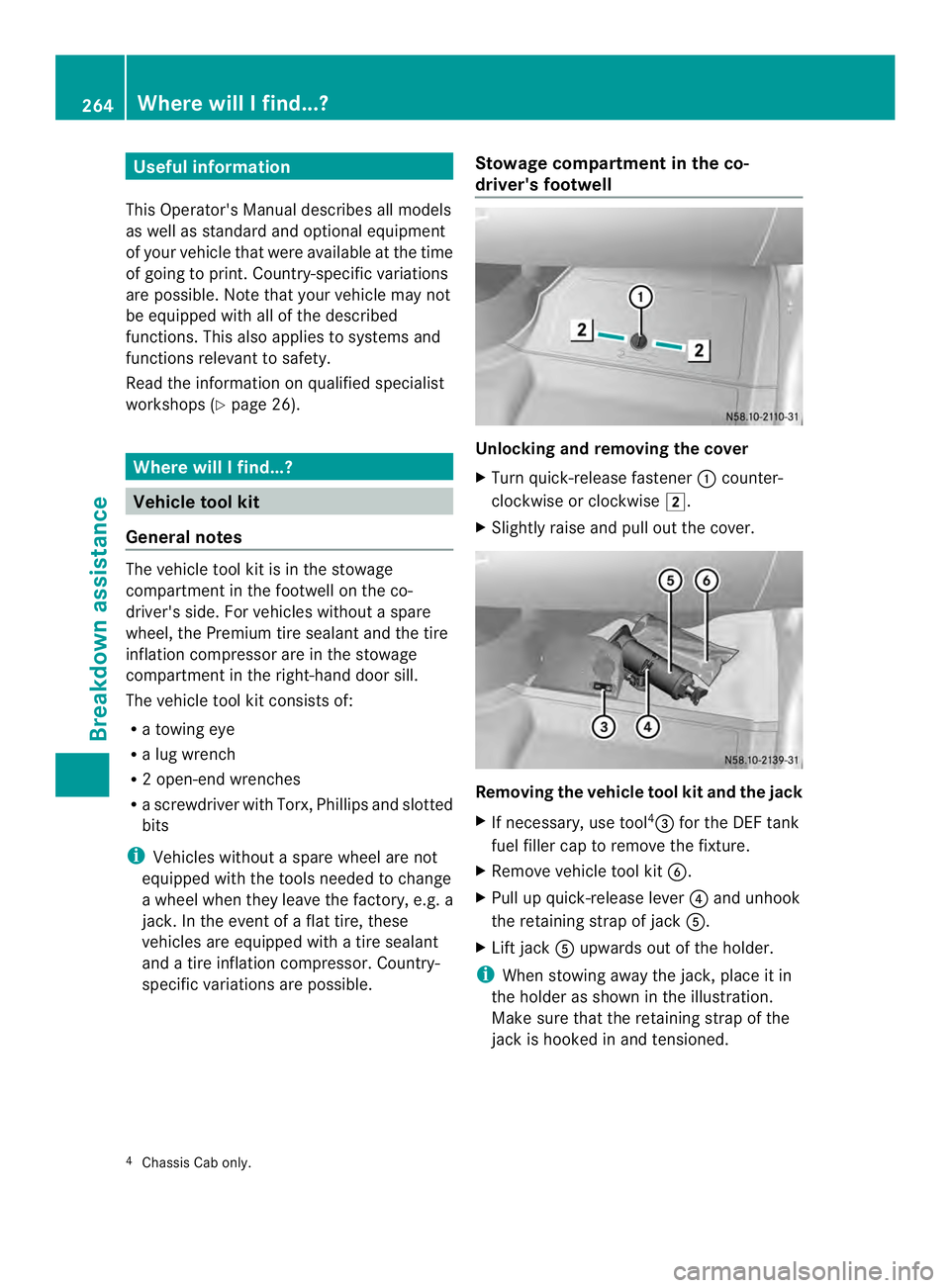

specific variations are possible. Stowage compartment in the co-

driver's footwell Unlocking and removing the cover

X

Turn quick-release fastener 0005counter-

clockwise or clockwise 0009.

X Slightly raise and pull out the cover. Removing the vehicle tool kit and the jack

X

If necessary, use tool 4

0026 for the DEF tank

fuel filler cap to remove the fixture.

X Remove vehicle tool kit 0024.

X Pull up quick-release lever 0025and unhook

the retaining strap of jack 0023.

X Lift jack 0023upwards out of the holder.

i When stowing away the jack, place it in

the holder as shown in the illustration.

Make sure that the retaining strap of the

jack is hooked in and tensioned.

4 Chassis Cab only. 264

Where will I find...?Breakdown assistance

Page 278 of 334

case, the tire is so worn that it mus

tbe

replaced. Selecting, mounting and renewing

tires

R Only mount tires and wheels of the same

type and make.

R Only mount tires of the correct size onto

the wheels.

R Break in new tires at moderate speeds for

the first 65 miles (100 km).

R Do not drive with tires which have too little

tread depth, as this significantly reduces

the traction on wet roads (hydroplaning).

R Replace the tires after 6years at the latest,

regardless of wear. This also applies to the

spare wheel. Operation in winter

General notes

Have your vehicle winterproofed at a qualified

specialist workshop at the onset of winter.

Prior to the onset of winter, ensure that snow

chains are stowed in the vehicle

(Y page 277).

Observe the notes in the "Changing a wheel"

section (Y page 302). Driving with summer tires

At temperatures below 45 ‡(+7 †), summer

tires lose elasticity and therefore traction and

braking power. Change the tires on your

vehicle to M+S tire. Using summer tires at

very cold temperatures could cause tears to

form, thereby damaging the tires

permanently. We cannot accept

responsibility for this type of damage. M+S tires

G

WARNING

Wheel and tire dimensions as well as the type

of tire can vary between the spare wheel and

the wheel to be replaced .When the spare

wheel is installed, driving characteristics may

be severely affected. There is a risk of an

accident.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never install more than one spare wheel

that differs from the wheel to be replaced.

R only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type. G

WARNING

M+S tires with a tire tread depth of less than

000D in (4 mm) are not suitable for use in winter

and do not provide sufficient traction. There

is a risk of an accident.

M+S tires with a tread depth of less than 000D

in (4 mm) must be replaced immediately.

At temperatures below 45 ‡ (+7 †), use

winter tires or all-season tires. Both types of

tire are identified by the M+S marking.

Only winter tires bearing the 0003snowflake

symbol in addition to the M+S marking

provide the best possible grip in wintry road

conditions.

Only these tires will allow driving safety

systems such as ABS and ESP ®

to function

optimally in winter. These tires have been

developed specifically for driving in snow.

For safe driving, use M+S tires of the same

make and tread pattern on all wheels. 276

Operation in winterWheels and tires

Page 283 of 334

X

Read the tire pressure and compare it with

the recommended value on the loading

information table or th etire pressure table

(Y page 278).

X If the tire pressure is too low, increase it to

the recommended value.

X If the tire pressure is too high, release air

by pressing down the metal pin in the valve.

Use the tip of a pen, for example. Then,

chec kthe tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeatt he steps for the other tires. Tire pressure monitor

Important safety notes G

WARNING

Each tire, including the spare (if provided),

should be checked at least once a month

when cold and inflated to the pressure

recommended by the vehicle manufacturer

on the Tire and Loading Information placard

on the driver's door B-pillar or the tire

pressure label on the inside of the fuel filler

flap. If your vehicle has tires of a different size

than the size indicated on the Tire and Loading

Information placard or the tire pressure label,

you should determine the proper tire pressure

for those tires.

As an added safety feature, your vehicle has

been equipped with a tire pressure monitoring

system (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly underinflated tire causes the tire

to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency

and tire tread life, and may affect the vehicle's

handling and stopping ability. Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver's responsibility to maintain correct tire

pressure, even if underinflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

USA only:

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate if the

system is not operating properly. The TPMS

malfunction indicator is combined with the

low tire pressure telltale. When the system

detects a malfunction, the warning lamp will

flash for approximately a minute and then

remain continuously illuminated. This

sequence will be repeated every time the

vehicle is started as long as the malfunction

exists.

When the malfunction indicator is illuminated,

the system may not be able to detect or signal

low tire pressure as intended. TPMS

malfunctions may occur for a variety of

reasons, including the installation of

incompatible replacement or alternate tires

or wheels on the vehicle that prevent the

TPMS from functioning properly. Always

check the TPMS malfunction telltale after

replacing one or more tires or wheels on your

vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to

continue to function properly.

Vehicles with a tire pressure monitor are

equipped with sensors in the wheels that

monitor the tire pressure of all four tires. The

tire pressure monitor monitors the pressure

in all four tires; you set this pressure when

you activate the tire pressure monitor. The

tire pressure monitor warns you when the

pressure drops in one or more of the tires. The

tire pressure monitor only functions if the

corresponding sensors are installed to all

wheels.

You should always adjust the tire pressure

according to the vehicle load. Restart the tire

pressure monitor if you change the tire

pressure. Tire pressure

281Wheels and tires Z

Page 298 of 334

Do not drive any further. Contact a qualified

specialis tworkshop. G

WARNING

The tire sealant is harmful and causes

irritation. It must not come into contact with

your skin, eyes or clothing or be swallowed.

Do not inhale TIREFIT fumes. Keep tire sealant

away from children. There is a risk of injury.

If you come into contact with the tire sealant,

observe the following:

R Rinse off the tire sealant from your skin

immediately with water.

R If the tire sealant comes into contact with

your eyes, immediately rinse them

thoroughly with clean water.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately.

R Immediately change out of clothing which

has come into contact with tire sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

In addition, observe the manufacturer's

safety instructions on the sticker on the tire

inflation compressor and on the sticker on the

tire sealant bottle.

The tire sealant is water-soluble. If tire sealant

escapes, you can wash it off with water.

i Have the tire sealant replaced every

8y ears at a qualified specialist workshop.

! The tire inflation compressor should only

be connected to the 12 V socket in the

center console. You may otherwise

damage the vehicle's electrics.

! Do not operate the tire inflation

compressor for longer than 20 minutes at

a time without a break. The tire inflation

compressor may otherwise overheat.

The tire inflation compressor can be

operated again once it has cooled down. H

Environmental note

Have the used tire sealant bottle disposed of

professionally, e.g. at aqualified specialist

workshop.

X Prepare the vehicle as described

(Y page 295).

X If possible, remove the foreign object that

has pierced the tire, e.g .the screw or the

nail.

It is beneficial to the sealing process if the

foreign body that has pierced the tire is

removed.

X Remove the Premium tire sealant, the

accompanying

"max 50 mph"("max80 km/h") sticker and

the tire inflation compressor from the

stowage compartmentint he right-hand

doorway (Y page 264).

X Affix the sticker within the driver's field of

vision. Tire inflation compressor

0005

Switch

0006 Angled connecting piece

0026 Tire inflation compressor hose

0025 Flap

0023 Pressure gauge with pressure release

screw

0024 Connector with cable

X Open flap 0025on the tire inflation

compressor.

X Pull connector 0024and hose 0026with

pressure gauge 0023from the housing. 296

Flat tireWheels and tires

Page 304 of 334

and/or valve tool, warning triangle and

warning lamps in the vehicle.

X Pull away immediately.

This enables the tire sealan tto distribute

inside the tire and create a more effective

seal.

X After driving for approximately 3 minutes,

stop the vehicle at a suitable location, e.g.

at a car park or gas station.

X Check the tire pressure again.

The tire pressure must be at least

300 kPa (3.0 bar/43.5 psi). G

WARNING

If the required tire pressure is not reached

after driving for a short period, the tire is too

badly damaged. The tire sealant cannot repair

the tire in this instance. Damaged tires and a

tire pressure that is too low can significantly

impair the vehicle's braking and driving

characteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i The Mercedes-Benz Service24h

telephone numbers can be found on a

sticker in the driver's door entrance area

and in the vehicle Maintenance Booklet.

i If you check the tire pressure with the tire

inflation compressor, connect angled valve

adapter 0006on tire inflation compressor

hose 0026directly to the tire valve. The tire

pressure will increase when you switch the

tire inflation compressor on. You can

reduce the tire pressure by opening the

pressure release screw on pressure gauge

0023.

If the tire pressure is still at least 300 kPa

(3.0 bar/43.5 psi):

X If possible, inflate the tire to the

recommended tire pressure (Y page 278).

X Drive to the nearest qualified specialist

workshop as soon as possible and have the

tire and tire sealant 0019replaced. Changing wheels

Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions.

The wheel brakes or suspension components

may also be damaged. There is a risk of

accident.

Rotate front and rear wheels only if the wheels

and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are

located in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the

electronic components.

Only have tires changed at a qualified

specialist workshop.

Always observe the instructions and safety

notes in the "Mounting awheel" section

(Y page 303).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires

in the center.

If your vehicle's tire configuration allows, you

can rotate the wheels according to the

intervals in the tire manufacturer's warranty

book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do

not change the direction of rotation.

Clean the contac tsurface softhe wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and

reactivate the tire pressure monitor if

necessary. 302

Changing wheelsWheels and tires

Page 305 of 334

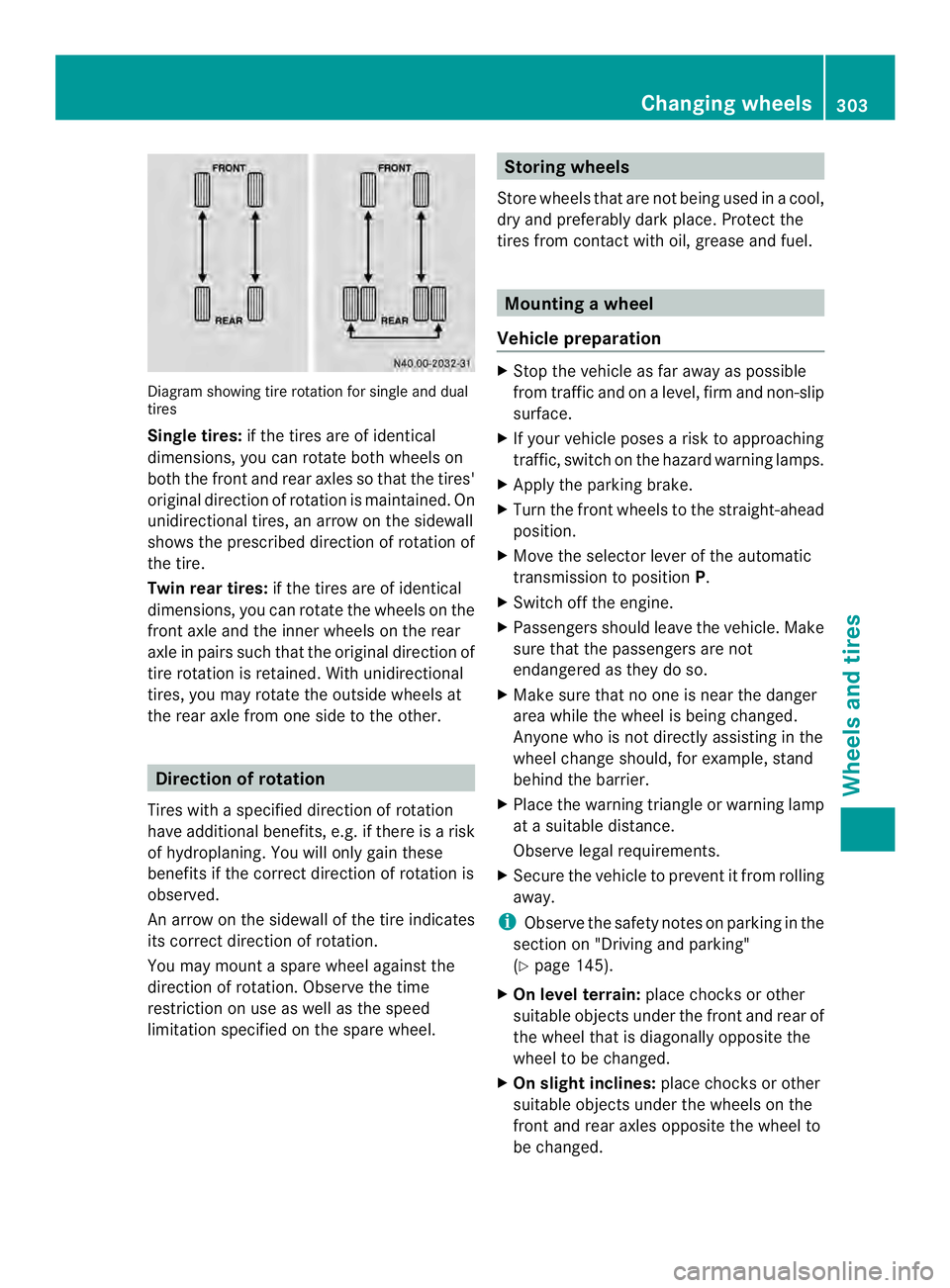

Diagra

mshowing tire rotation for single and dual

tires

Single tires: if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On

unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed

limitation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting

awheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If you rvehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake.

X Turn the fron twheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not

endangered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed.

Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 145).

X On level terrain: place chocks or other

suitable objects under the front and rear of

the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed. Changing wheels

303Wheels and tires Z

Page 306 of 334

X

Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 264).

X Remove the spare wheel from the spare

wheel bracket (Y page 309). Observe the

safety notes in the "Spare wheel" section

(Y page 308).

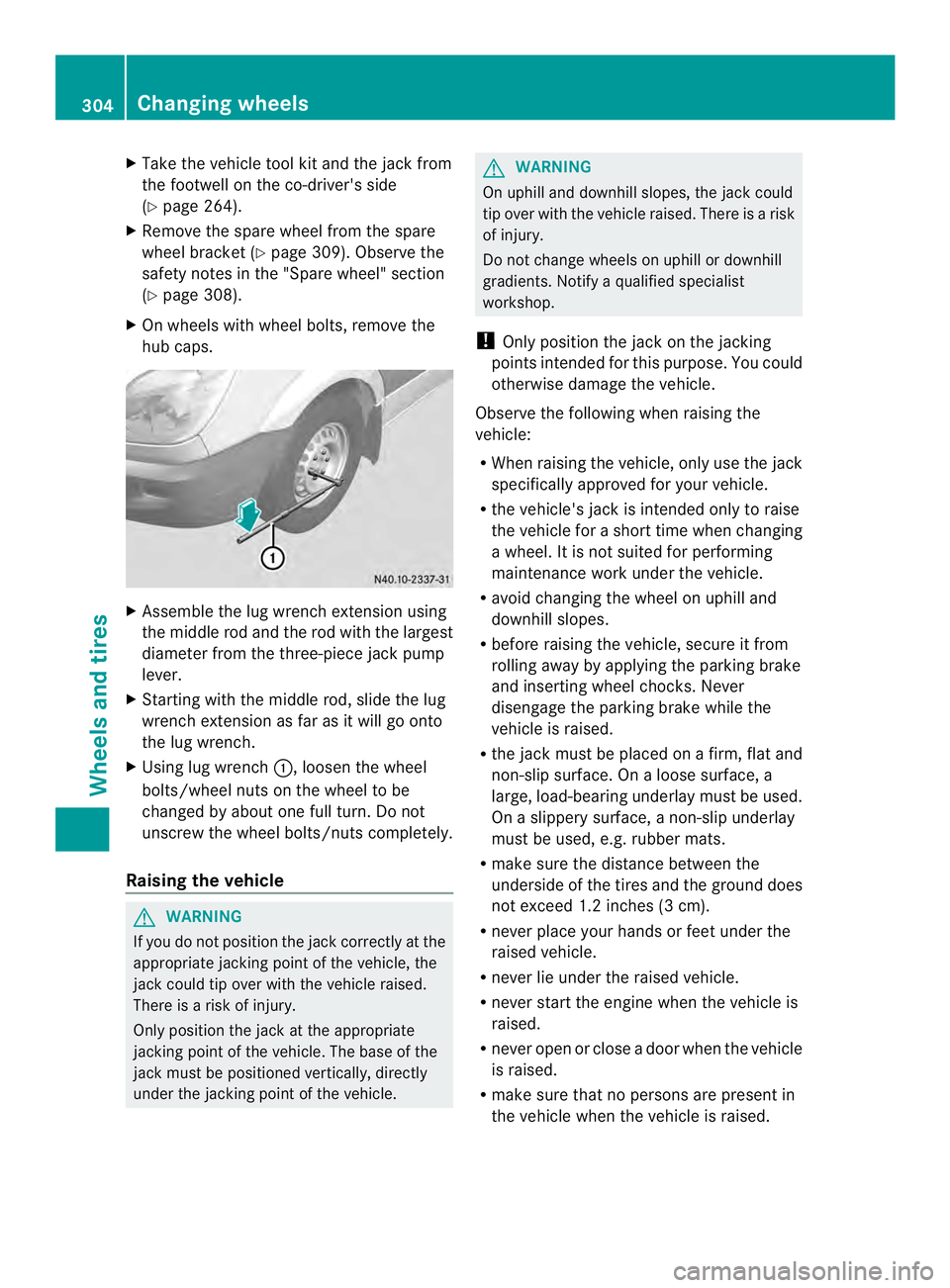

X On wheels with wheel bolts, remove the

hub caps. X

Assemble the lug wrench extension using

the middle rod and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0005, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist

workshop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the

vehicle:

R When raising the vehicle, only use the jack

specifically approved for your vehicle.

R the vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R make sure the distance between the

underside of the tires and the ground does

not exceed 1.2 inches (3 cm).

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door when the vehicle

is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised. 304

Changing wheelsWheels and tires

Page 311 of 334

R

only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correc twheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting awheel"

(Y page 303).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 278).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6years at the latest,

regardless of wear. This also applies to the

spare wheel.

i If you have mounted a spare wheel, the

tire pressure monitor (Y page 281) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

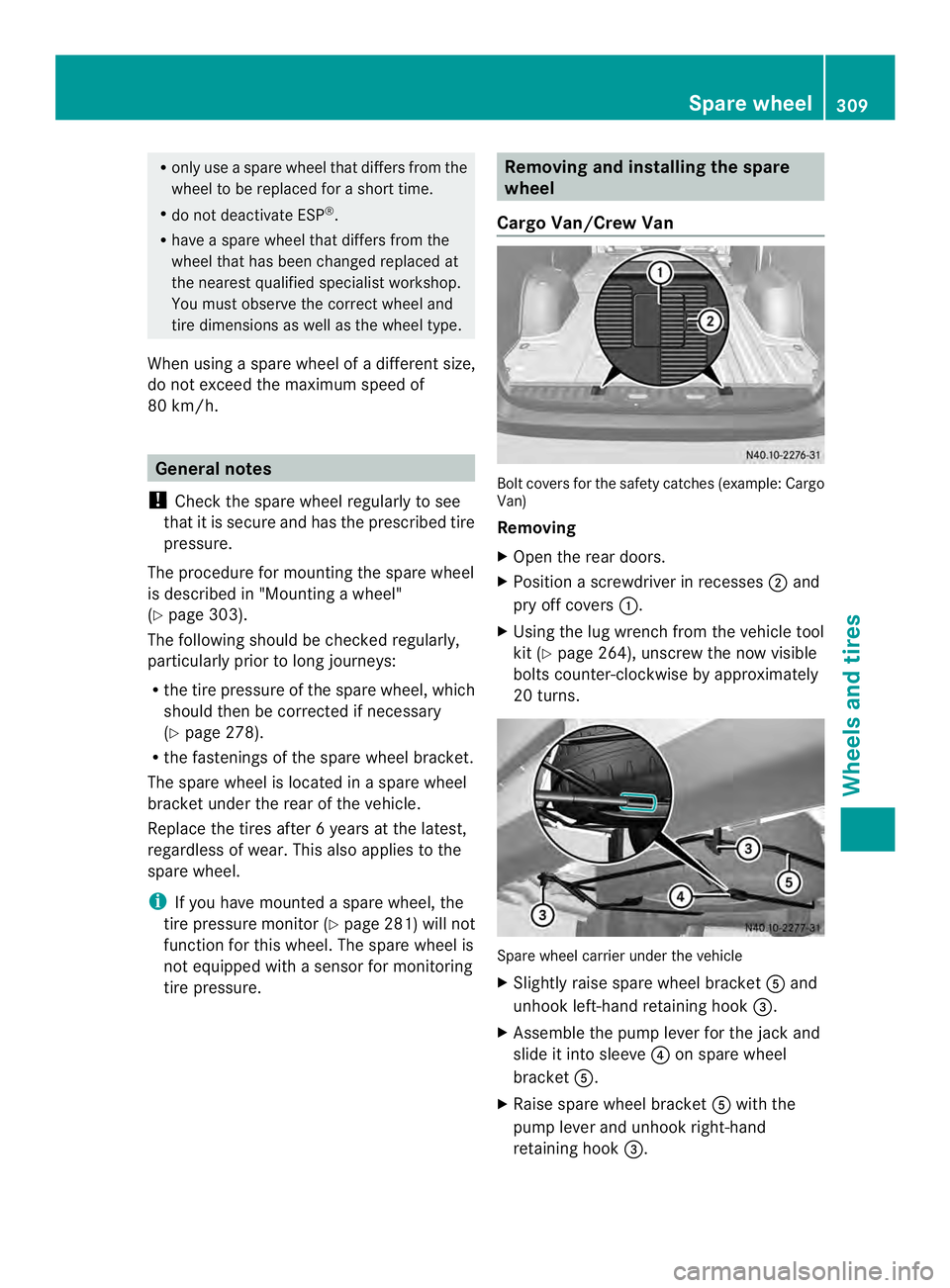

Cargo Van/Crew Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X

Open the rear doors.

X Position a screwdriver in recesses 0006and

pry off covers 0005.

X Using the lug wrench from the vehicle tool

kit (Y page 264), unscrew the now visible

bolts counter-clockwise by approximately

20 turns. Spare wheel carrier under the vehicle

X

Slightly raise spare wheel bracket 0023and

unhook left-hand retaining hook 0026.

X Assemble the pump lever for the jack and

slide it into sleeve 0025on spare wheel

bracket 0023.

X Raise spare wheel bracket 0023with the

pump lever and unhook right-hand

retaining hook 0026. Spare wheel

309Wheels and tires Z

Page 323 of 334

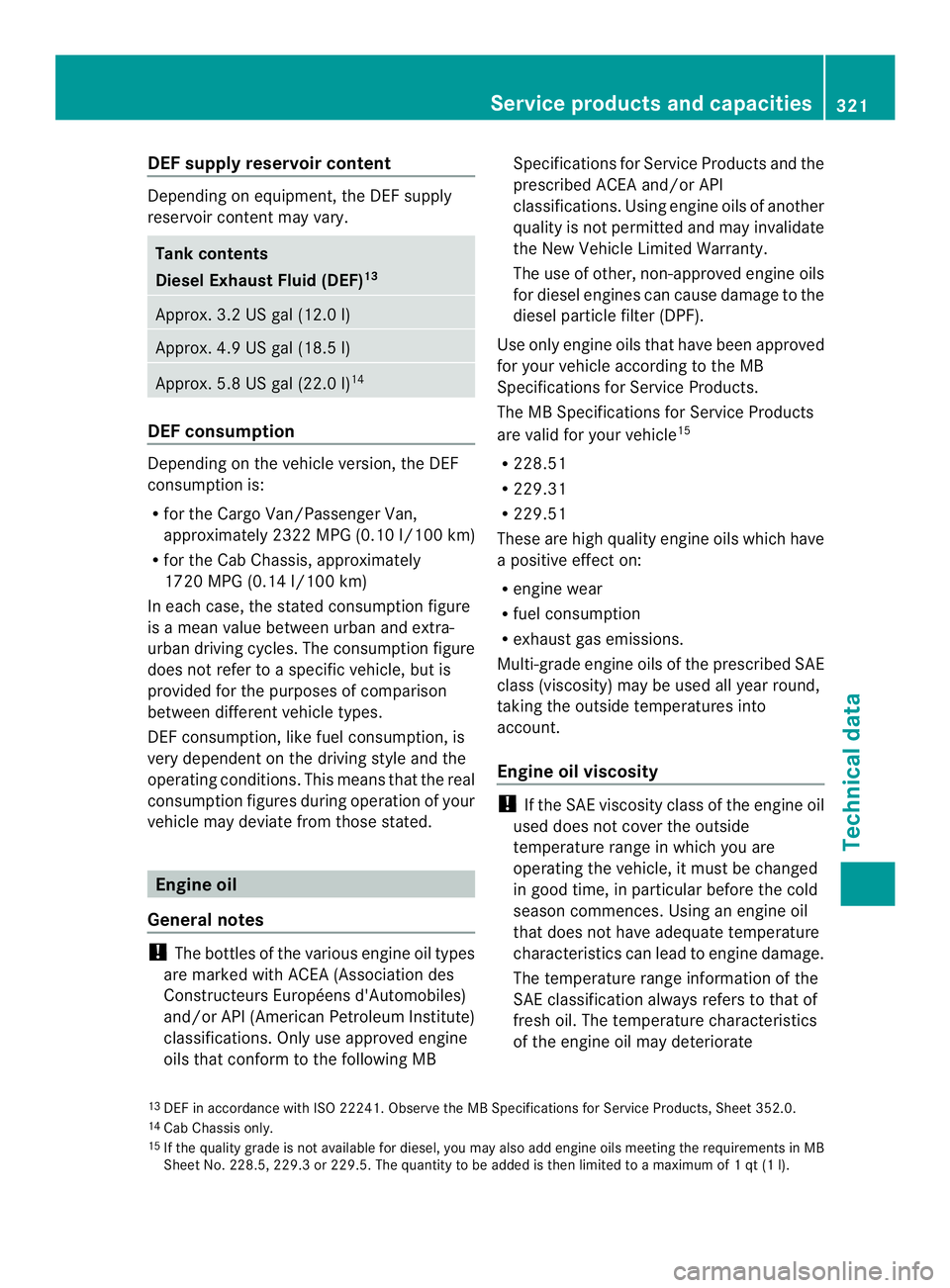

DEF supply reservoir content

Depending on equipment, th

eDEF supply

reservoir content may vary. Tank contents

Diesel Exhaus

tFluid (DEF) 13 Approx. 3.2 US gal (12.0 l)

Approx. 4.9 US gal (18.5 l)

Approx. 5.8 US gal (22.0 l)

14DEF consumption

Depending on the vehicle version, the DEF

consumption is:

R for the Cargo Van/Passenger Van,

approximately 2322 MPG (0.10 l/100 km)

R for the Cab Chassis, approximately

1720 MPG (0.14 l/100 km)

In each case, the stated consumption figure

is a mea nvalue between urban and extra-

urban driving cycles. The consumption figure

does no trefer to a specific vehicle, but is

provided for the purposes of comparison

between differen tvehicle types.

DEFc onsumption, like fuel consumption, is

very dependent on the driving style and the

operating conditions. This means that the real

consumption figures during operation of your

vehicle may deviate from those stated. Engine oil

General notes !

The bottles of the various engine oil types

are marked with ACEA (Association des

Constructeurs Européens d'Automobiles)

and/or API (American Petroleum Institute)

classifications. Only use approved engine

oils that conform to the following MB Specifications for Service Products and the

prescribed ACEA and/or API

classifications. Using engine oils of another

quality is not permitted and may invalidate

the New Vehicle Limited Warranty.

The use of other, non-approved engine oils

for diesel engines can cause damage to the

diesel particle filter (DPF).

Use only engine oils that have been approved

for your vehicle according to the MB

Specifications for Service Products.

The MB Specifications for Service Products

are valid for your vehicle 15

R 228.51

R 229.31

R 229.51

These are high quality engine oils which have

a positive effect on:

R engine wear

R fuel consumption

R exhaust gas emissions.

Multi-grade engine oils of the prescribed SAE

class (viscosity) may be used all year round,

taking the outside temperatures into

account.

Engine oil viscosity !

If the SAE viscosity class of the engine oil

used does not cover the outside

temperature range in which you are

operating the vehicle, it must be changed

in good time, in particular before the cold

season commences. Using an engine oil

that does not have adequate temperature

characteristics can lead to engine damage.

The temperature range information of the

SAE classification always refers to that of

fresh oil. The temperature characteristics

of the engine oil may deteriorate

13 DEF in accordance with ISO 22241. Observe the MB Specifications for Service Products, Sheet 352.0.

14 Cab Chassis only.

15 If the quality grade is not available for diesel, you may also add engine oils meeting the requirements in MB

Sheet No. 228.5, 229.3 or 229.5. The quantity to be added is then limited to a maximum of 1 qt (1 l). Service products and capacities

321Technical data Z

Page 324 of 334

significantly due to aging in use, especially

at low outside temperatures.

We recommend that you change the engine

oil before the cold season commences. Use

an approved engine oil of the specified SAE

class.

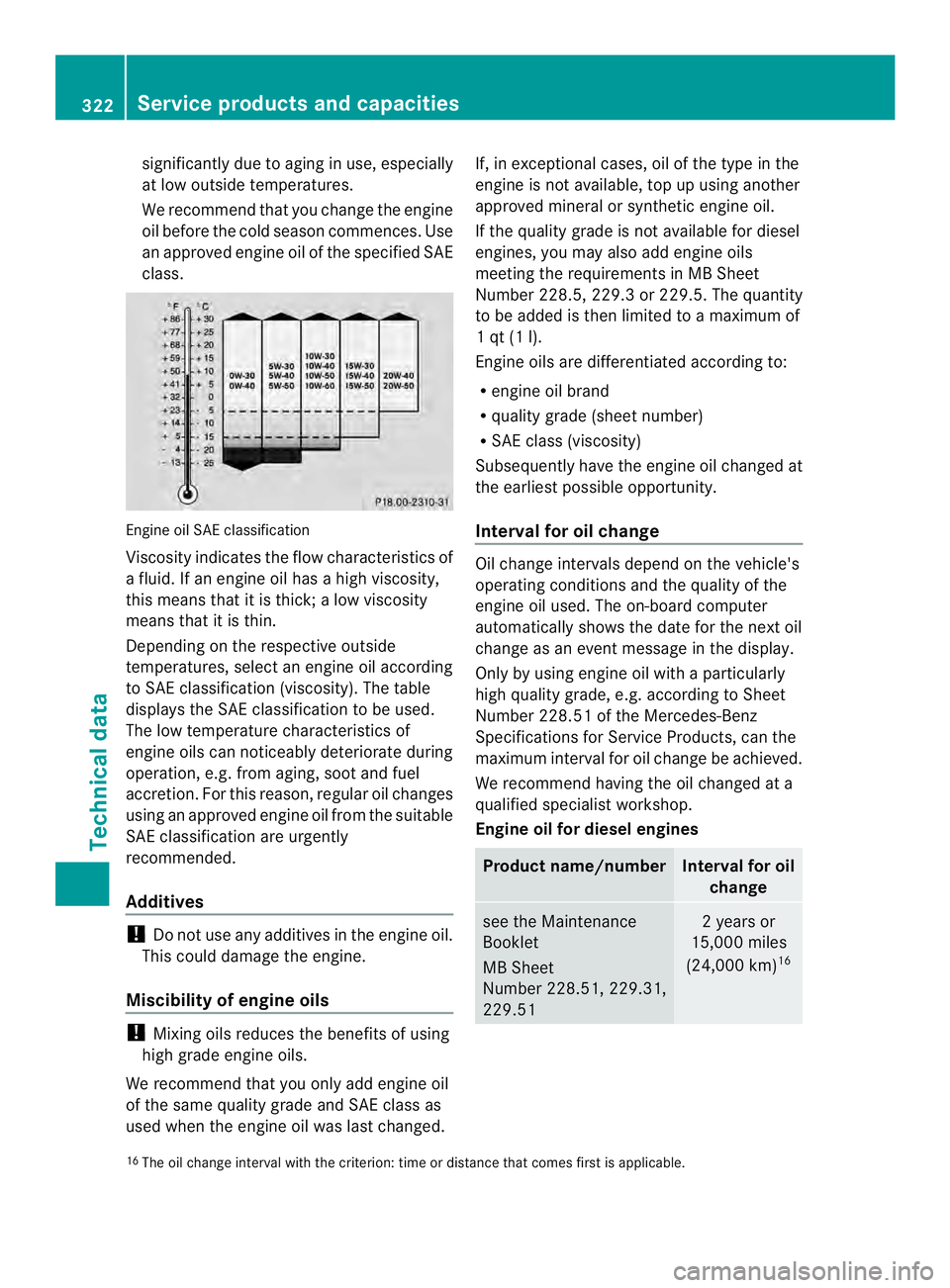

Engine oil SAE classification

Viscosity indicates the flow characteristics of

a fluid. If an engine oil has a high viscosity,

this means that it is thick; a low viscosity

means that it is thin.

Depending on the respective outside

temperatures, select an engine oil according

to SAE classification (viscosity). The table

displays the SAE classification to be used.

The low temperature characteristics of

engine oils can noticeably deteriorate during

operation, e.g. from aging, soot and fuel

accretion. For this reason, regularo il changes

using an approved engine oil fro mthe suitable

SAE classification are urgently

recommended.

Additives !

Do not use any additives in the engine oil.

This could damage the engine.

Miscibility of engine oils !

Mixing oils reduces the benefits of using

high grade engine oils.

We recommend that you only add engine oil

of the same quality grade and SAE class as

used when the engine oil was last changed. If, in exceptional cases, oil of the type in the

engine is not available, top up using another

approved mineral or synthetic engine oil.

If the quality grade is not available for diesel

engines, you may also add engine oils

meeting the requirements in MB Sheet

Number 228.5, 229.3 or 229.5. The quantity

to be added is then limited to a maximum of

1 qt (1 l).

Engine oils are differentiated according to:

R

engine oil brand

R quality grade (sheet number)

R SAE class (viscosity)

Subsequently have the engine oil changed at

the earliest possible opportunity.

Interval for oil change Oil change intervals depend on the vehicle's

operating conditions and the quality of the

engine oil used. The on-board computer

automatically shows the date for the next oil

change as an event message in the display.

Only by using engine oil with a particularly

high quality grade, e.g. according to Sheet

Number 228.51 of the Mercedes-Benz

Specifications for Service Products, can the

maximum interval for oil change be achieved.

We recommend having the oil changed at a

qualified specialist workshop.

Engine oil for diesel engines

Product name/number Interval for oil

change see the Maintenance

Booklet

MB Sheet

Number 228.51, 229.31,

229.51 2y

ears or

15,000 miles

(24,000 km) 16 16

The oil change interval with the criterion: time or distance that comes first is applicable. 322

Service products and capacitiesTechnical data