MERCEDES-BENZ SPRINTER 2020 MY20 with 7” screen

Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2020Pages: 348, PDF Size: 5.84 MB

Page 211 of 348

lation and an

yensuin gconsequences.

Obser vecountr y-specific la ws.

Mak esuret hat thel oad is secur ebefor eevery

jou rney and at regular inter vals during along

journe y.Ad jus tthe load securing as necessar y.

Information on ho wtosecureloads cor rectly can

be obtained from them anufacturer sofload

securing aids or tie downs forl oad-securing, for

ex ample.

When securing loads, obse rvet he following:

R Fill spaces between thel oad and thec argo

compartmen twalls or wheel wells. Forthis

purpose, use rigid load securing aids, suc has

we dges, wooden fixing sorp adding.

R Attach secured and stabilized loads in all

directions.

Use thec argo tie-down points or tie-down

ey es and thel oading rails in thec argo com‐

partmen toronthe load sur face.

Only use tie downs, suc haslashing rods, lock

ro ds or lashing nets and lashing stra ps, which

has been tested in accordance wit hcurrent

st andards (e.g. DI NEN). Alw aysu sethec argo

tie-down points closes ttothe load; pad sharp

edges.

Loads, and heavy loads in particular ,should

preferably be secured using thet ie-down

ey es.

% Yo

uc an obtain tie downs tested in accord‐

ance wit hcurrent standards (e.g. DI NEN)

from an yspecialis tcompan yorfromaq uali‐

fi ed specialis tworks hop.

Note sont he partition

Wi thout apartition ,vehicles that ar eappr ove das

commercial vehicles (N1 ,N2) do no tfulfill ISO

27 956, whi chdescribes thee quipment forp rop‐

erly securing aloa dind elivery vehicles. If the

ve hicle is used totranspo rtgoods, retrofitting the

partition is stro ng lyrecommended ,asprope rly

securing thel oad in vehicles without apartition

will alw aysbeac omplexoperation.

% Yo

um ustn otstor ea nything in thea rea

between theb ackoft he seats and thep arti‐

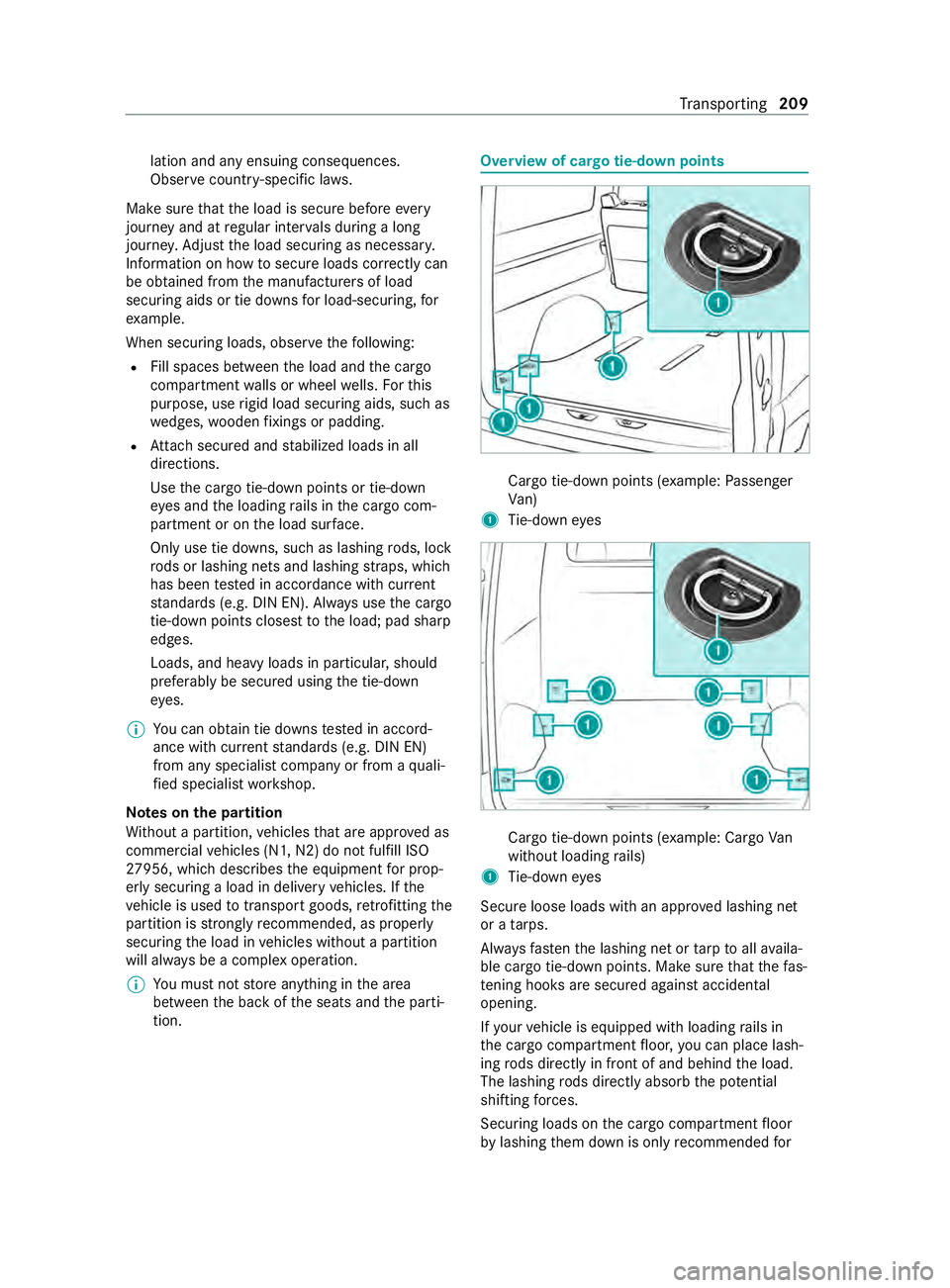

tion. Overvie

wofcargo tie-down points Cargo tie-down points (e

xample:Passenger

Va n)

1 Tie-down eyes Cargo tie-down points (e

xample: Cargo Van

without loadin grails)

1 Tie-down eyes

Secur eloose loads wit hanapprove dlashing net

or atarps.

Alw aysf astent he lashing ne tortarptoa llav aila‐

ble cargo tie-down points .Makes uret hat thef as‐

te ning hoo ksares ecured agains tacciden tal

opening.

If yo ur vehicle is equipped wit hloading rails in

th ec argo compartmen tfloor ,you can place lash‐

ing rods directly in front of and behind thel oad.

The lashing rods directly absorb thep otential

shifting forc es.

Securing loads on thec argo compartmen tfloor

by lashing them down is onl yrecommended for Tr

ansporting 209

Page 212 of 348

light

weight loads. La yanti-slip mats underneath

th el oad tosecur ethe load additionally. Installing and

removing tie-down eyes #

Toinstall: slidethet ie-down eyet hrough a

re cess in thel oading rail close tothel oad

until locking mechanism engages in the

re cess.

% Whe

nyou pull locking mechanism up and out

of ther ecess, thet ie-down eyeisa bleto

mo vewithin thel oading rail. Mak esuret hat

locking mechanism is alw ayse ngaged in a

re cess. #

Che ckthet ie-down eyef or firm seating. #

Toremo ve: pull lo cking mechanism up and

pull thet ie-down eyet ow ards thel ocking

mechanism and out of thel oading rail

th ro ugh arecess. Car

rier sy stems Information abou

tthe roof rack &

WARNING Risk of inju rydue tothem axi‐

mum roof load being exceeded

When youp laceal oad on ther oof as well as

all outer and inner attachments, thev ehicle's

center of gr avity will rise and thef amiliar driv‐

ing characteristic saswell asthes teering and

braking characteristic swillch ange. When

drivin garound bends, thev ehicle will tilt

mor eheavily and ma yreact mor esluggishly

to steering mo vements.

If yo ue xceed them aximum roof load, the

driving characteristics, as well as thes teering

and braking, will be greatl yimp aired. #

Nevere xceed them aximum roof load

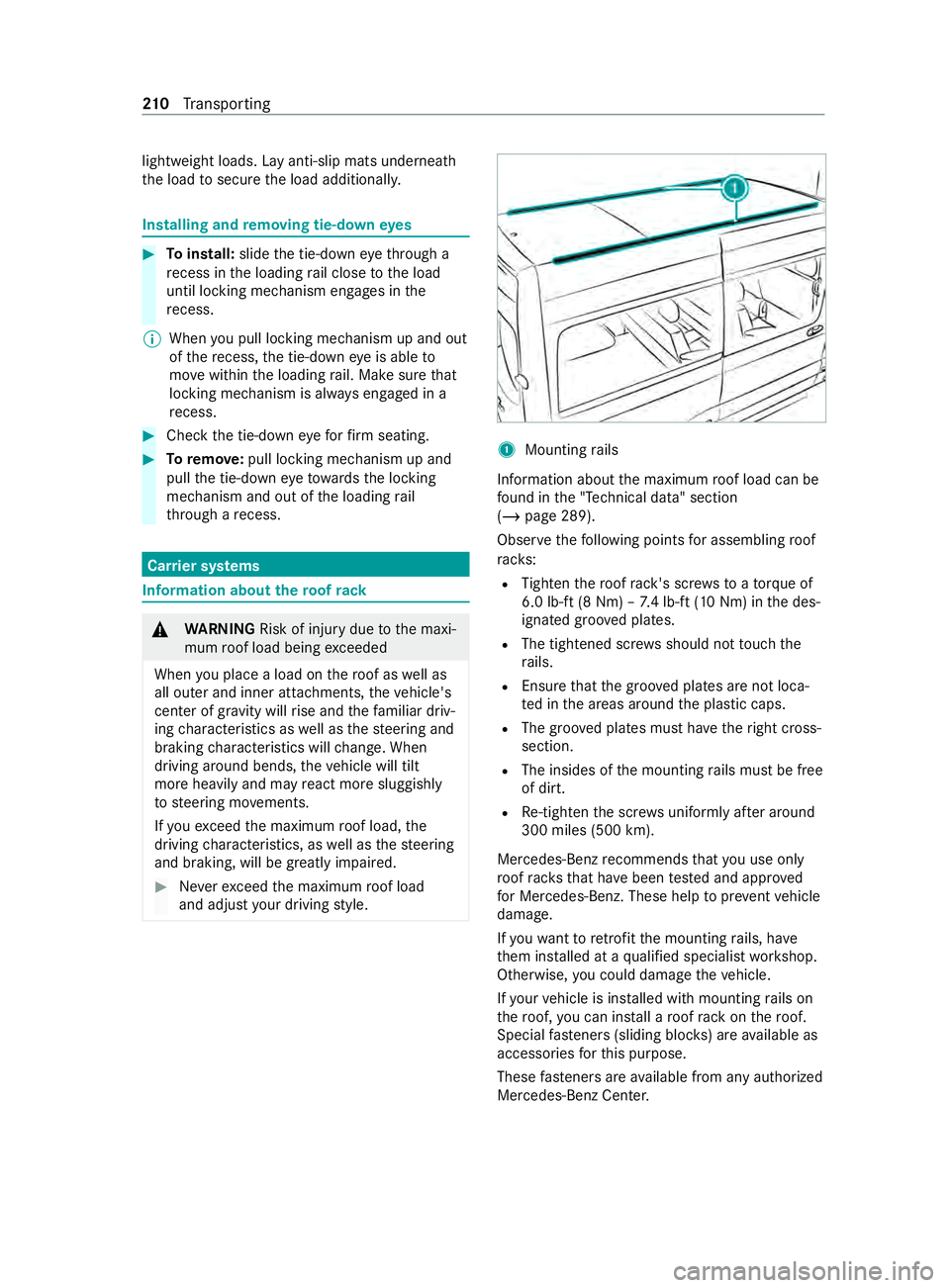

and adjus tyour driving style. 1

Mountin grails

Informatio nabout them aximum roof load can be

fo und in the" Tech nical data" section

(/ page289).

Obser vethef ollowing points fora ssembling roof

ra ck s:

R Tighten ther oof rack 's scr ewstoat orque of

6.0 lb-f t(8N m)–7.4 lb-f t(10 Nm) in thed es‐

ignated groo vedp lates.

R The tightened scr ewsshould no ttouc hthe

ra ils.

R Ensur ethat theg roove dplates ar enotloca‐

te dint he areas around thep lastic caps.

R The groo vedp lates mus thave ther ight cross-

sectio n.

R The insides of them ounting rails mus tbefree

of dirt.

R Re-tigh tent he scr ewsu niformly af tera round

300 mile s(500 km).

Mercedes-Benz recommends that youu se on ly

ro of rack st hat ha vebeen tested and appr oved

fo rM ercedes-Benz. These help topreve ntvehicle

damage.

If yo uw ant toretrofit them ounting rails, ha ve

th em ins talled at aqualified specialis tworks hop.

Otherwise, youc oul dd amag ethe vehicle.

If yo ur vehicle is ins talled wit hmountin grails on

th er oof, youc an install aroof rack on ther oof.

Special fastener s(sliding bloc ks)a re available as

accesso ries fort his purpose.

These fastener sareavailable from an yauthorized

Mercedes-Ben zCenter. 210

Transporting

Page 213 of 348

Using the interior

roof car rier sy stem &

WARNING Risk of inju rydue tounse‐

cured loads

When yous ecur eorl oosen aload, thel oad

ma yfall down and injur evehicle occupants. #

When securing or loosening aload, do

no ts tand unde rthe load. *

NO

TERisk of damag etothe belt stra ps

and slider Excessiv

epoint loading on theb elt stra ps and

slider smaycause theb elt stra ps totear or cause

thes lider stob reak of ffro mt herack

ra il. #

Distribut ethe load evenly. When doing

so, ensur ethat theo verall cen terof

gr av ity of thel oad is alw aysasc loseto

th ec enter as possible and between the

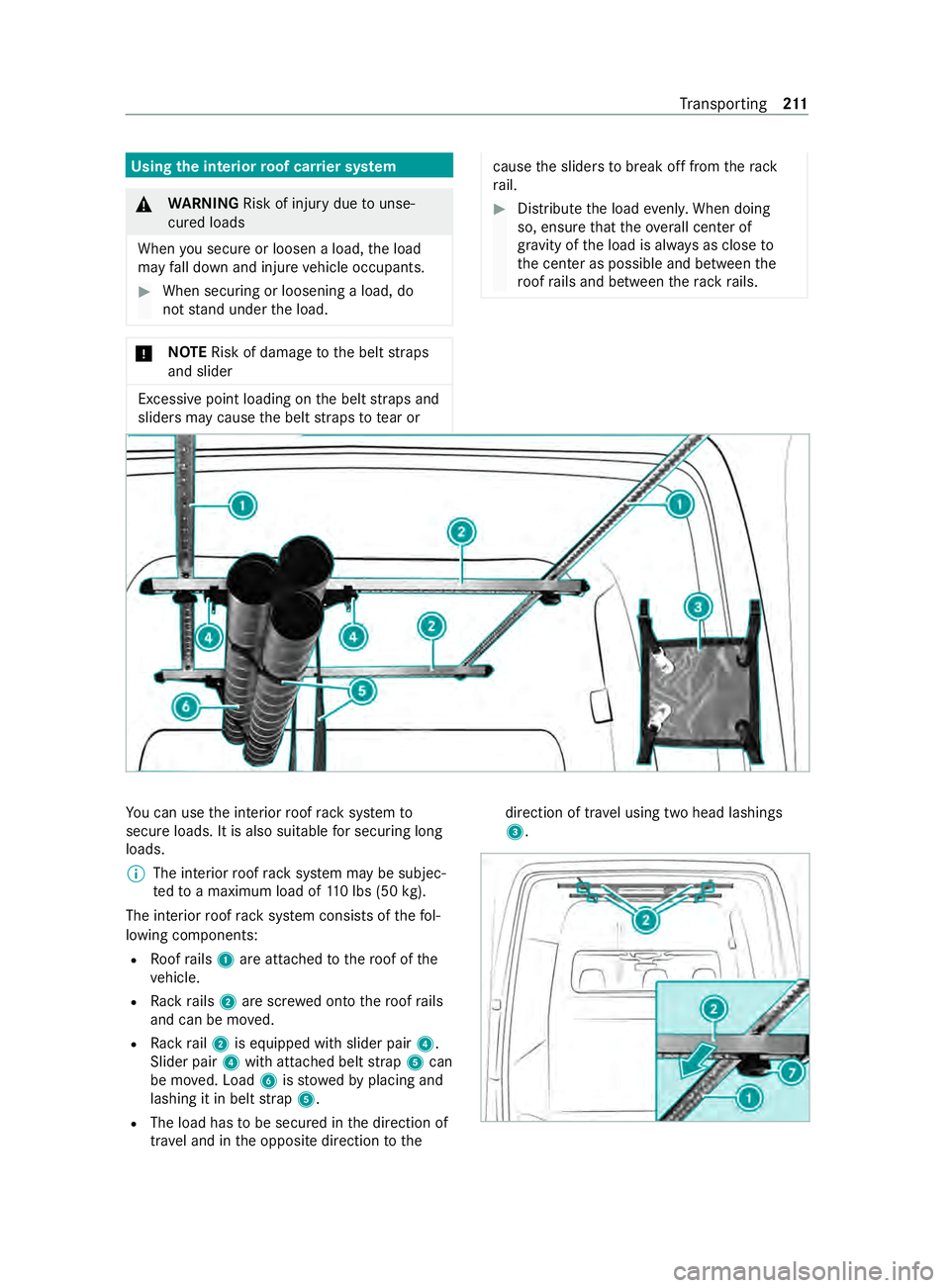

ro of rails and between ther ackr ails. Yo

uc an use thei nterior roof rack system to

secur eloads. It is also suitable fors ecuring long

loads.

% The interior

roof rack system ma ybesubjec‐

te dtoam aximum load of 110l bs (50 kg).

The interior roof rack system consists of thef ol‐

lowing components:

R Roofrails 1 area ttached tother oof of the

ve hicle.

R Rack rails 2 ares crew ed ont othe roof rails

and can be mo ved.

R Rack rail2 is equipped wit hslider pair 4.

Slider pair 4witha ttached belt strap 5can

be mo ved. Load 6isstowe dbyp lacing and

lashing it in belt strap 5.

R The load has tobe secured in thed irection of

tra vela nd in theo pposit edirection tothe direction of tra

velu sing tw ohead lashings

3. Tr

ansporting 211

Page 214 of 348

#

Tomo vether ackr ails: unscr ewstar knobs

7 coun ter-clockwise until they ares lightly

loose. #

Sliderackr ail 2 along roof rail1 tothe

desired position. #

Screw star knobs 7tight clo ckwise. #

Chec kthat ther ackr ail is seated securely.

Moving thes liders &

WARNING Risk of inju rydue toinade‐

qu atel ysecured loads

If th es lider of thei nterior roof rack system is

no te ngaged proper ly,t he load ma ycome

loose, fall down and injur epeople, for

ins tance when they enter or load and unload

th ec argo compartment. #

Alwayse ngag ethe slider properly. %

Ring

8of slider 4mus talway sbeatan

angle of 90° torack rail2,sot hat slider 4

is engaged proper ly. #

When ther ing of thes lider is at an angle

of 90° tother ackr ail: pullring 8of slider

4 down an dsimul taneously mo veslider 4

to thed esired position. #

Release ring 8 atthed esired position. #

Moveslider 4slightl yfurther along on rack

ra il2 until slider 4engages automaticall y. #

When ther ing of thes lider is pa rallel to

th er ackr ail: moveslider 4tothed esired

position. #

Position ring 8 of slider 4at an angle of

90° torack rail2.

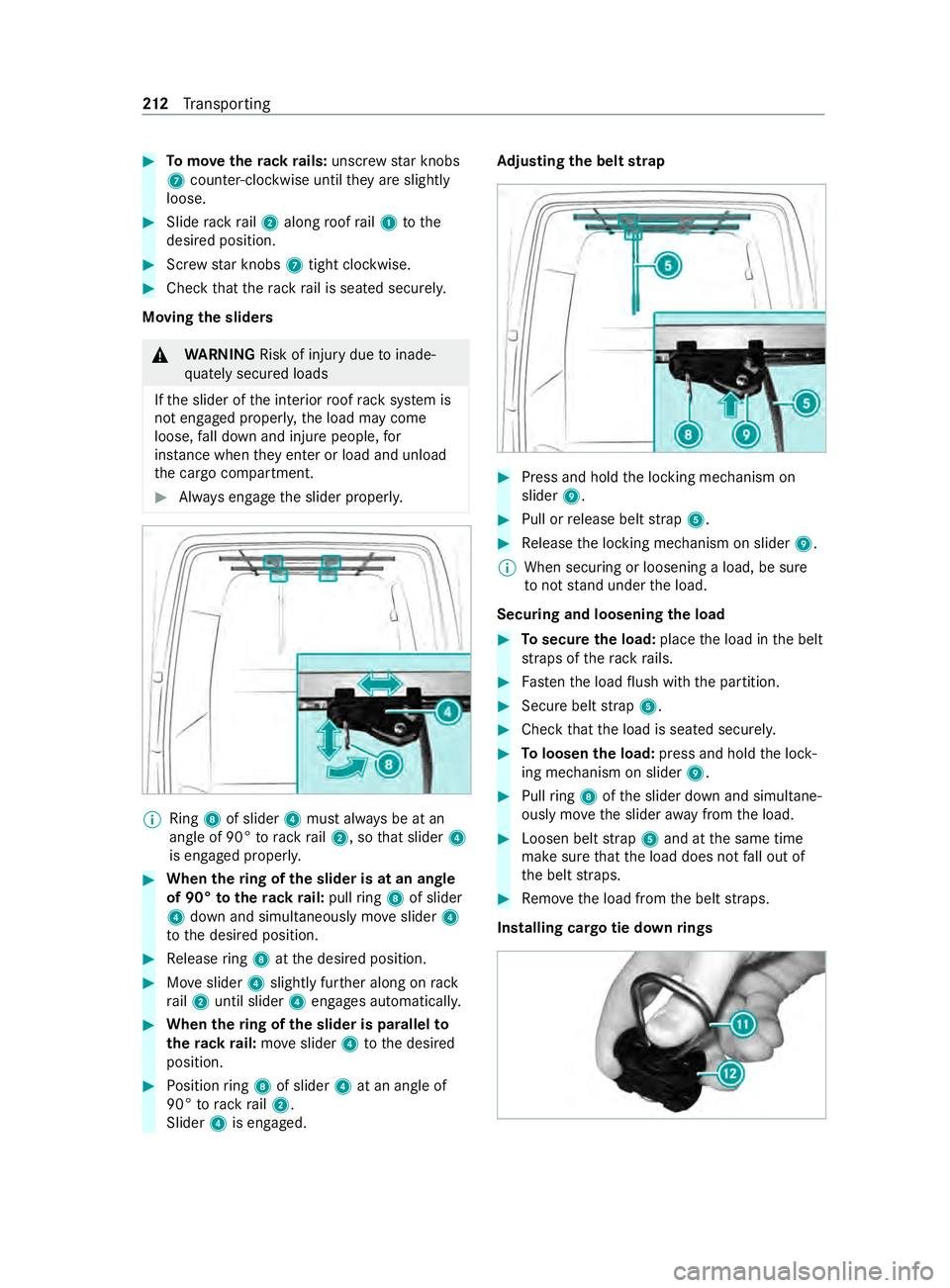

Slider 4is engaged. Ad

justin gthe belt strap #

Press and hold thel ocking mechanism on

slider 9. #

Pull or release belt strap 5. #

Release thel ocking mechanism on slider 9.

% When securing or loosening

aload, be sure

to nots tand unde rthe load.

Securing and loosening thel oad #

Tosecur ethe load: placethel oad in theb elt

st ra ps of ther ackr ails. #

Fasten thel oad flush wit hthe partition. #

Secur ebelt strap 5. #

Chec kthat thel oad is seated securel y. #

Toloosen thel oad: press and hold thel ock‐

ing mechanism on slider 9. #

Pull ring 8 ofthes lider down and simultane‐

ously mo vethes lider away from thel oad. #

Loosen belt strap 5and at thes ame time

mak esuret hat thel oad does no tfall out of

th eb elt stra ps. #

Remo vethel oad from theb elt stra ps.

Installing cargo tie down rings 212

Transporting

Page 215 of 348

#

Turn ther ing of carg otie-down ring B unti lit

is pa rallel tothel ongitudinal axis of cargo tie-

down ring C. #

Holdcargo tie-down ring C between the

inde xfinger an dmiddlefinger an dplace your

th umb thro ugh ther ing of carg otie-down ring

B and ont othe centra lpressur epoint. #

Use your thumb topush thel ocking pin down

as farasitw illg o. #

Push cargo tie-down ring C nea rthe load

th ro ugh then otch es on rack rail2 and mo ve

it appr oximately 0.5 in (1 2mm). #

Remo veyour thumb from thep ressur epoint

and slide cargo tie-down ring C unti lit

engages. #

Turn ther ing of carg otie-down ring B unti lit

is pe rpendicular tothel ongitudinal axis of

cargo tie-down ring C.

Cargo tie-down ring C is secu red.

Re moving cargo tie down rings #

Turn ther ing of carg otie-down ring B unti lit

is pa rallel tothel ongitudinal axis of cargo tie-

down ring C. #

Grip cargo tie-down ring C as described

ab ove unde rins talling and use your thumb to

push thel ocking pin down as farasitw illg o. #

Slide cargo tie-down ring C and pull it down

and ou tthrough then otch es of rack rail2.

At tachin gthe hea dlashing &

WARNING Risk of inju rydue toincor‐

re ctly secu redl oads

When theh ook sont he head lashing are

attached tother ing soft he sliders, thes lid‐

er sc ould come loose. The load ma ycome

loose, fall down and injur epeople, for

ins tance when they enter or load and unload

th ec argo compartment. #

Onlyattach theh ook sont he head lash‐

ing tother ing soft he cargo tie-down

ri ngs. %

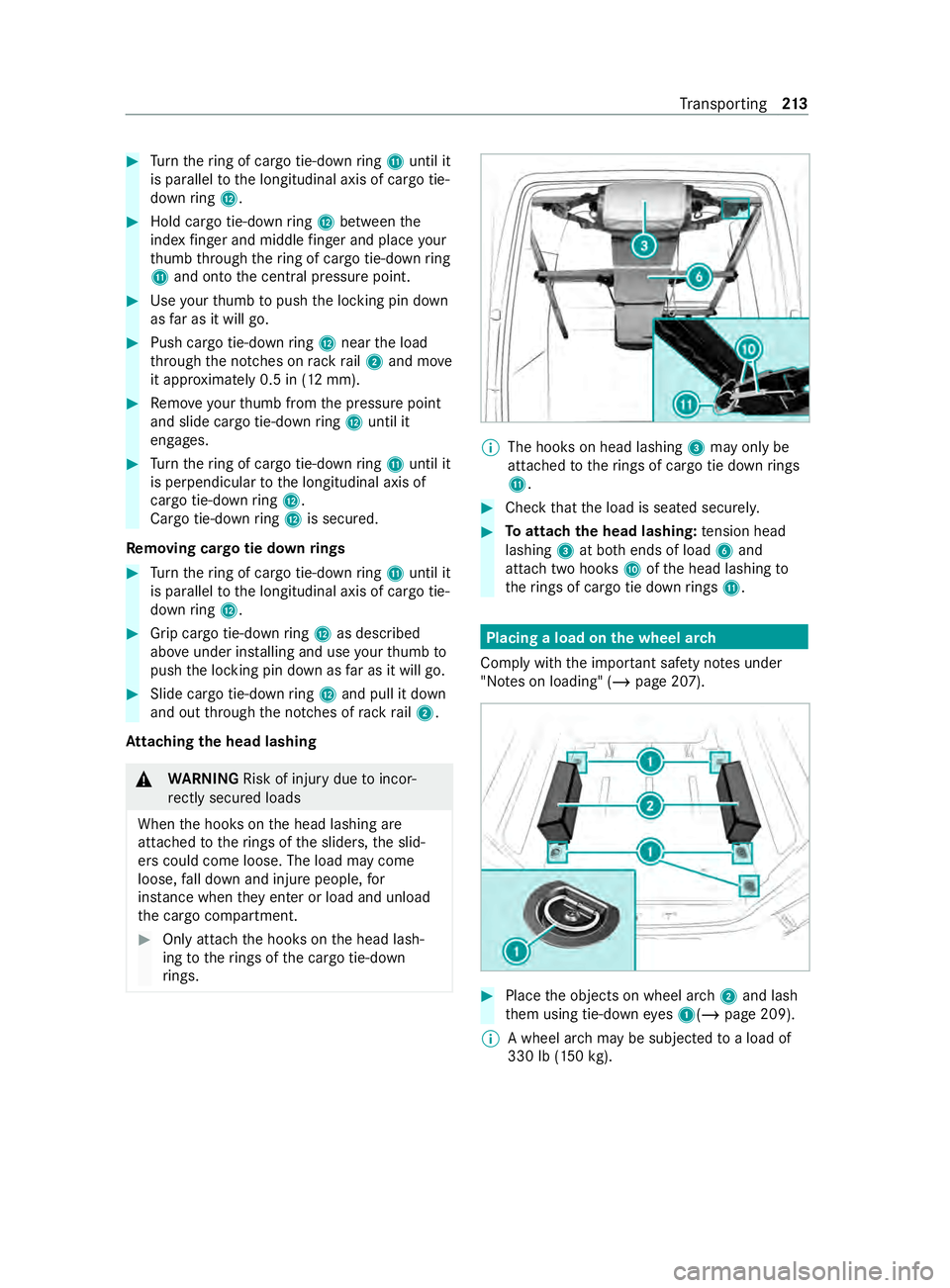

The hoo

kson head lashing 3mayonlybe

attached tother ing sofc argo tie down rings

B. #

Chec kthat thel oad is seated securel y. #

Toattac hthe hea dlashing: tensio nhead

lashing 3at bo thends of load 6and

attac htwo hooks Aoftheh ead lashing to

th er ing sofc argo tie down rings B. Placing

aloa dont he wheel ar ch

Compl ywitht he impor tant sa fety no tesu nder

"No tesonl oading" (/ page207). #

Place theo bject sonw heel ar ch2 and lash

th em using tie-down eyes 1(/ page209).

% Aw

heel ar chma ybes ubjected toaload of

33 0lb( 150k g). Tr

ansporting 213

Page 216 of 348

ASS

YSTP LUSs ervice in terv al display Fu

nction of theA SSYSTP LUSs ervice in terv al

display The ASS

YSTP LUSs ervice inter vald ispla yont he

instrument display prov ides informatio nonthe

re maining time or dis tance be fore then ext

service due date.

Yo uc an hide this service messag ebyusingthe

bac kbutton on thel eft-hand side of thes teering

wheel.

Yo uc an obtain fur ther information concerning

th es ervicing of your vehicle from aqualified spe‐

cialis tworks hop, e.g. an authorized Mercedes-

Benz Center. Displaying

thes ervice du edate On-boa

rdcomputer:

4 Service 5

ASSYSTP LUS

The next service due dat eisdisplayed. #

Toexitth ed ispla y:press theb ackb utton on

th el eft-hand side of thes teering wheel.

Bear in mind thef ollowing related topic:

R Operating theo n-boar dcom‐

puter(/ page175) Ca

rrying out maintenance workregular ly *

NO

TEPrematur ewear thro ugh failur eto

obser veservice due dates Service

workwhic hisn otcar ried out at the

ri ght time or incomple tely can lea dto

inc reased wear and damag etothevehicle. #

Alwayso bser vethep rescribed service

inter vals. #

Alwaysh ave thep rescribed service

wo rkcar ried out at aqualified specialist

wo rkshop. Special service

requ irements The prescribed service inter

valisb ased on nor‐

mal vehicle use. Maintenance workwill need to

be per form ed mor eoften than presc ribed if the

ve hicle is operated under arduous conditions or

increased loads. Examples of arduous operating conditions:

R Regular city driving wit hfrequ ent intermedi‐

at es tops

R Mainly short-dis tance driving

R Frequent operation in mountainous terrain or

on poor road sur faces

R Whe nthe engine is of tenl eftidling forl ong

periods

R Operation in particula rlyd usty conditions

and/o rifair-reci rculation mod eisfrequ ently

used

In these or similar operating conditions, ha vethe

interior air filter ,engin eair cleaner ,engin eoil and

oil filter etc. changed mor efrequ ently .Ifthevehi‐

cle is subjected tohigher loads, thet ires mus tbe

ch eckedm oref requ entl y.Yo uc an obtain fur ther

information at aqualified specialis tworks hop. Batter

ydisconnection periods The ASS

YSTP LUSs ervice in terv al displa ycan

onl ycalculat ethe service due dat ewhen the

batter yisconnected. #

Notedown thes ervice due dat edispla yedon

th eI nstrument Displa ybefor edisconnecting

th eb atter y(/pag e214). Engine compartment

Opening and closing

theh ood &

WARNING Risk of accident if thee ngine

hood is unlatched while driving

An unloc kede ngin ehood ma yopen up when

th ev ehicle is in motion and bloc kyour vie w. #

Neveru nlatc hthe engine hood while

driving. #

Befor eevery trip, ensur ethat thee ngine

hood is latched. &

WARNING Danger of bu rnsw hen open‐

ing theh ood

If yo uo pen theh ood when thee ngine has

ove rheated or during afireint he engine com‐

partment, youc oul dc om eintoc ontact wi th

ho tg ases or other escaping operating fluids. #

Befor eopening theh ood, allo wthe

engine tocool down. 214

Maintenance and care

Page 217 of 348

#

Inthee vent of afireint he engine com‐

partment, keep theh ood closed and call

th ef ires ervice. &

WARNING Risk of inju rydue tomoving

parts

Cer tainc omponents in thee ngine compart‐

ment ma ycontinue tomo veor suddenly

mo veagain even af tert he ignition has been

switched off, e.g. thec ooler fan.

Ma kesur eoft hefollowing befor eperform ing

ta sk sint he engine compartment: #

Switc hthe ignition off. #

Nevertouc hthe danger zone sur round‐

ing movin gcomponent parts ,e.g.t he

ro tatio na reaoft hefan. #

Remo vejewe lrya nd watches. #

Keep items of clo thing and hair away

from moving parts. &

WARNING Risk of inju ryfrom touching

component parts unde rvoltage

The ignition sy stem and thef uel injection sys‐

te mw orku nde rhigh voltage. If yout ouch

component parts whic hareunde rvoltage,

yo uc oul drecei vean electric shoc k. #

Nevertouc hcomponent parts of the

ignition sy stem or thef uel injection sys‐

te mw hen thei gnition is switched on. Liv

ec omponents of thef uel injection sy stem

include thei njec tors,for example.

Liv ec omponent softhe ignition sy stem include

th ef ollowing, fore xamp le:

R Ignitio ncoils

R Spar kplug connec tors

R Diagnostic soc ket &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponents in thee ngine compart‐

ment can be very hot, e.g. thee ngine, the

ra diator and parts of thee xhau stsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. If

yo uh ave tocar ryout an yworkint he engine

compartment, touc ho nlyt he following compo‐

nents:

R Hood

R Engine oil filler openin gcap

R Washer fluid reser voir cap

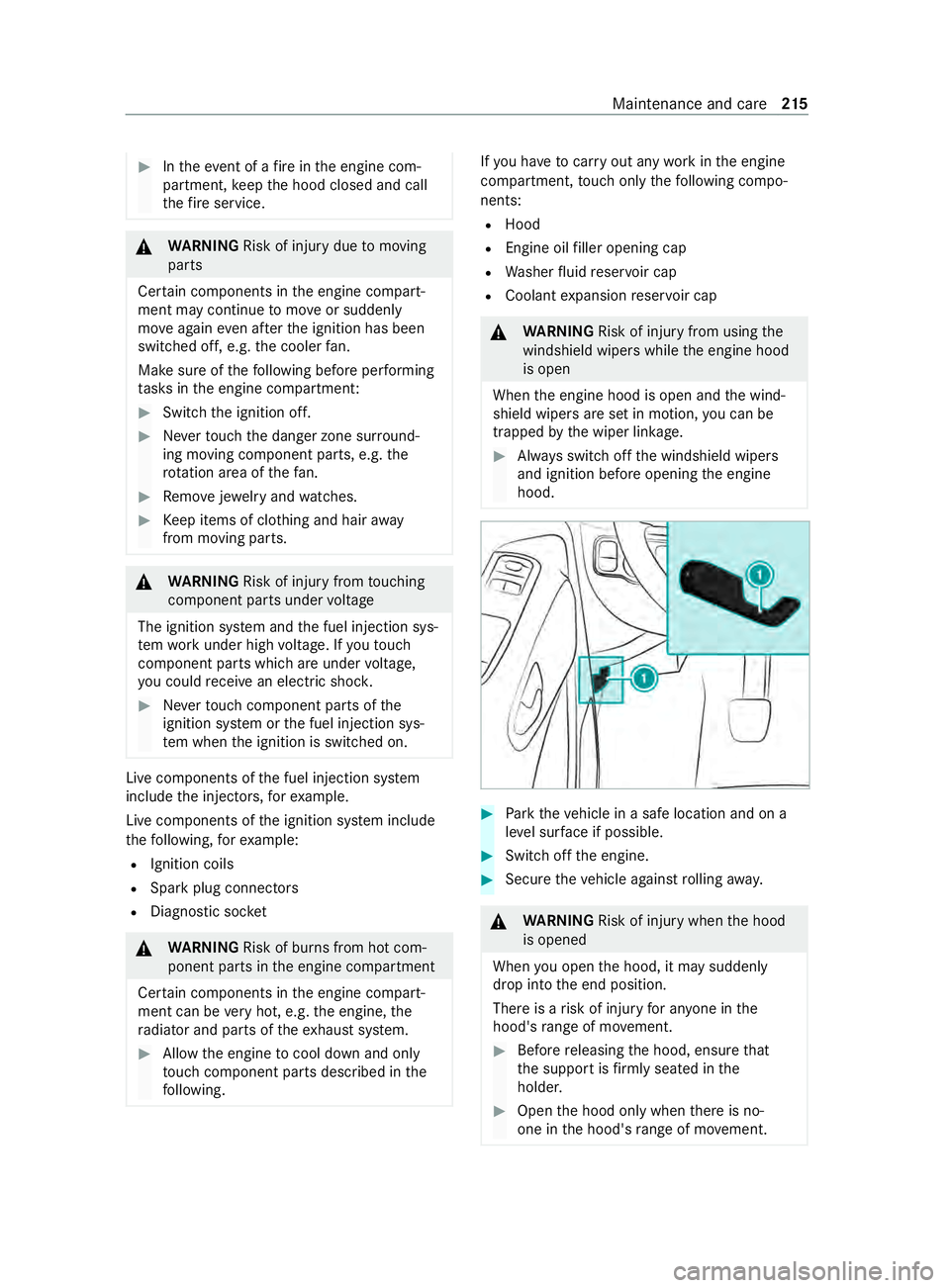

R Coolant expansion reser voir cap &

WARNING Risk of inju ryfrom using the

windshield wiper swhile thee ngine hood

is open

When thee ngine hood is open and thew ind‐

shield wiper saresetinm otion, youc an be

trapped bythew iper linkage. #

Alwayss witc hoffthew indshield wipers

and ignition befor eopening thee ngine

hood. #

Park thev ehicle in asafel ocation and on a

le ve ls urface if possible. #

Switc hoffthee ngine. #

Secur ethe vehicle agains trolling away. &

WARNING Risk of inju rywhen theh ood

is opened

When youo pen theh ood, it ma ysuddenly

drop int othe end position.

Ther eisar isk of injur yfor an yone in the

hood's rang eofm ovement. #

Befor ereleasing theh ood, ensur ethat

th es uppor tisfirmlyseatedint he

holder. #

Open theh ood onl ywhen ther eisn o-

one in theh ood's rang eofm ovement. Maintenance and care

215

Page 218 of 348

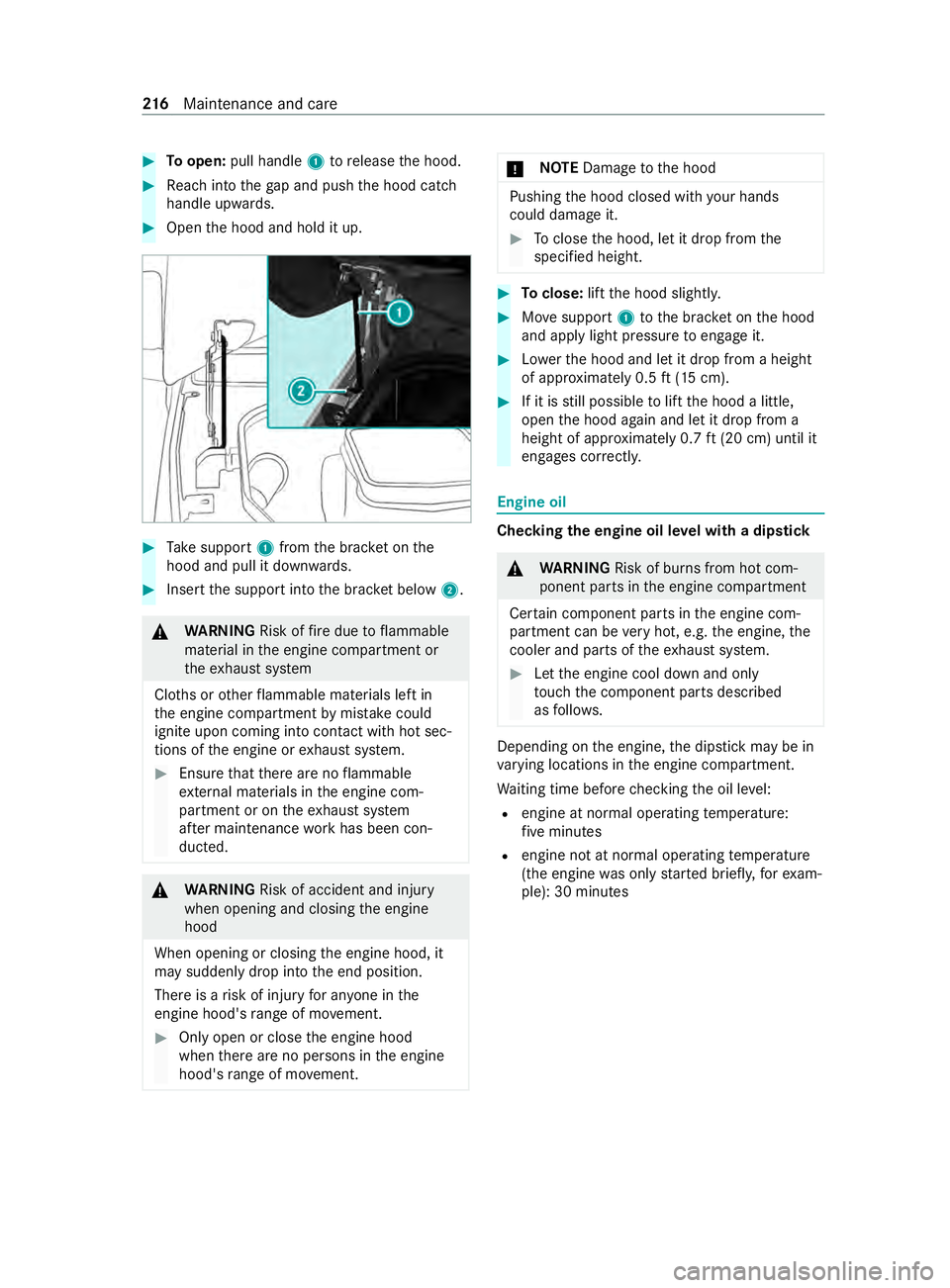

#

Toopen: pull handle 1torelease theh ood. #

Reachi ntot he gapa nd push theh ood catch

handle upwards. #

Open theh ood and hold it up. #

Take support 1from theb rack et on the

hood and pull it down wards. #

Inse rtthes uppor tint ot he brac ketb elow 2. &

WARNING Risk offire due toflammable

material in thee ngine compartmen tor

th ee xhau stsystem

Clo thsoro ther flammable materials lef tin

th ee ngine compartmen tbymista ke could

igni teupon coming int ocontact wi thhots ec‐

tions of thee ngine or exhaus tsyst em. #

Ensur ethat ther ea reno flammable

ex tern al materials in thee ngine com‐

partmen torontheexhaus tsyst em

af te rm aintenance workhas been con‐

ducted. &

WARNING Risk of accident and inju ry

when opening and closing thee ngine

hood

When opening or closing thee ngine hood, it

ma ysuddenl ydropi ntot he end position.

Ther eisar isk of injur yfor an yone in the

engine hood's rang eofm ovement. #

Only open or close thee ngine hood

when ther ea reno persons in thee ngine

hood's rang eofm ovement. *

NO

TEDama getotheh ood Pushing

theh ood closed wit hyour hands

could dama geit. #

Toclos ethe hood, le titdropf romt he

specified height. #

Toclose: liftt he hood slightl y. #

Movesupport 1totheb rack et on theh ood

and apply light pressur etoengageit. #

Lowe rthe hood and le titdropf romah eight

of appr oximately 0.5 ft(15c m). #

If it is still possible toliftt he hood alittle,

open theh ood again and le titdropf roma

height of appr oximately 0.7 ft(20 cm) until it

engages cor rectly. Engin

eoil Che

cking thee ngine oil le velw ithad ipst ick &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponent pa rtsint he engine com‐

partment can be very hot, e.g. thee ngine, the

cooler and pa rtsoft heexhaus tsystem. #

Letthe engine cool down and only

to uc ht he component parts described

as follo ws. Depending on

thee ngine, thed ipstic kmaybe in

va rying locations in thee ngine compartment.

Wa itin gtimeb efor echecking theo il le vel:

R engin eatn ormal operatin gtemperature:

fi ve minutes

R engine no tatnormal operating temp erature

(the engine waso nlys tarted briefly ,for exam‐

ple): 30 minutes 216

Maintenance and care

Page 219 of 348

Dip

stick( example) #

Park thev ehicle on an even sur face. #

Remo vedipstick 1and wipe it off. #

Slowl yinser tdipstick 1intot he dipstick

guide tube as farasitw illgoa nd pullito ut

af te rt hree seconds.

R Oil le velO K:theo il le velisb etwe en the

MIN and theM AX mar k.

R Oil le veltoo low: theo il le velisatt he MIN

mar korb elow. #

Ifth eo il le velist oo lo w,add appr ox.

1. 1USq t(1l iter) engine oil. #

Ifth eo il le velist oo high, drain of fexcess

engine oil.

Vi sit aq ualified specialis tworks hop.

Checking thee ngine oil le velw itht he on-

boa rdcompu ter

Re quirements:

R The vehicle is le veld uring them easuring

process.

R The hood is no topen.

R Dependin gonthe driving profile, theo il le vel

can be displa yedo nlya fter ad riving time of

up to30 minutes and onl ywhen thei gnition

is switched on.

On-boar dcomputer:

4 Service 5

Engine Oil Level

Yo uw ills ee one of the following messa geson

th em ultifunction displa y: #

Measuring Engine Oil Level...:m easurement

of theo il le veln ot ye tpossible. Repeat the

qu erya fter drivin gfor am aximu mof

30 minutes. #

Engine Oil Level OK andtheb ar showing the

oil le velont he multifunction displa yisgreen

and lies between "MIN" and "MAX": theo il

le ve lisO K. #

Engine Oil Level Drive until the engin eis

warm. :warmupt he engine tooperating tem‐

perature. #

Engine Oil Level Correct Measurement Only

if Vehicl eIsonL evel Ground:p arkt he vehicle

on aleve lsurface. #

Engine Oil Leve lAdd 1,0 liq.gal. andtheb ar

showing theo il le velont he multifunction dis‐

pla yiso rang ea nd lies belo w"MIN": add

1. 1USq t(1l)ofe ngine oil. #

Reduce Engine Oil Level andtheb ar showing

th eo il le velont he multifunction displa yis

orang eand lies abo ve"MAX": drain of fexcess

engine oil.

Vi sit aq ualified specialis tworks hop. #

For Engine Oil Level Switch Ignition On :

switc hont he ignition in order tocheckt he

engine oil le vel. #

Engine Oil Level System Inoperative:t he sen‐

sor is defectiv eornotconnected. Visit a

qu alified specialis tworks hop. #

Engine Oil Level System Currently Unavaila-

ble:c losetheh ood.

% Ve

hicles with col doil le veld ispla ys:theo il

le ve lisa utomaticall ydispla yedont he multi‐

function displa yafter thev ehicle has been

non-operational forane xtende dperiod .Ifit

is no tpossible tomeasu rethee ngine oil

le ve l,ac orresponding messag ewill appear.

Ad ding engin eoil &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponents in thee ngine compart‐

ment can be very hot, e.g. thee ngine, the

ra diator and parts of thee xhau stsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. &

WARNING Danger of bu rnsw hen open‐

ing theh ood

If yo uo pen theh ood when thee ngine has

ove rheated or during afireint he engine com‐

partment, youc oul dc om eintoc ontact wi th

ho tg ases or other escaping operating fluids. Main

tenance and care 217

Page 220 of 348

#

Befor eopening theh ood, allo wthe

engine tocool down. #

Inthee vent of afireint he engine com‐

partment, keep theh ood closed and call

th ef ires ervice. If

yo uh ave tocar ryout an yworkint he engine

compartment, touc ho nlyt he following compo‐

nents:

R Hood

R Engine oil filler openin gcap

R Washer fluid reser voir cap

R Coolant expansion reser voir cap &

WARNING Risk offire and injur yfrom

engine oil

If engine oil comes int ocontact wi thhotc om‐

ponent parts in thee ngine compartment, it

ma yignite. #

Mak esuret hat no engine oil is spilled

next tothef iller opening. #

Allowthe engine tocool of fand thor‐

oughly clean thee ngine oil from compo‐

nent parts befor estartin gt he vehicle. *

NO

TEEngine damag eduetoincor rect oil

fi lter ,incor rect oil or additi ve #

Do no tuse engine oi loranoilfilter with

specifications deviatin gfromt hose

re qu ired fort he prescribed service

inter vals.

Mercedes-Benz recommends using original or

te sted replacement and service parts. #

Do no tchang ethe engine oil or oil filter

in order tosetc hang einter vals longer

th an those prescribed. #

Do no tuse an yadditive. #

Followt he instructions on thes ervice

inter vald ispla yfor changing thee ngine

oil. *

NO

TEDama gecaused byaddin gtoo

muc hengine oil To

om uche ngine oil can damag ethe engine

or thec atalytic con verter. #

Have excess engine oil remo vedata

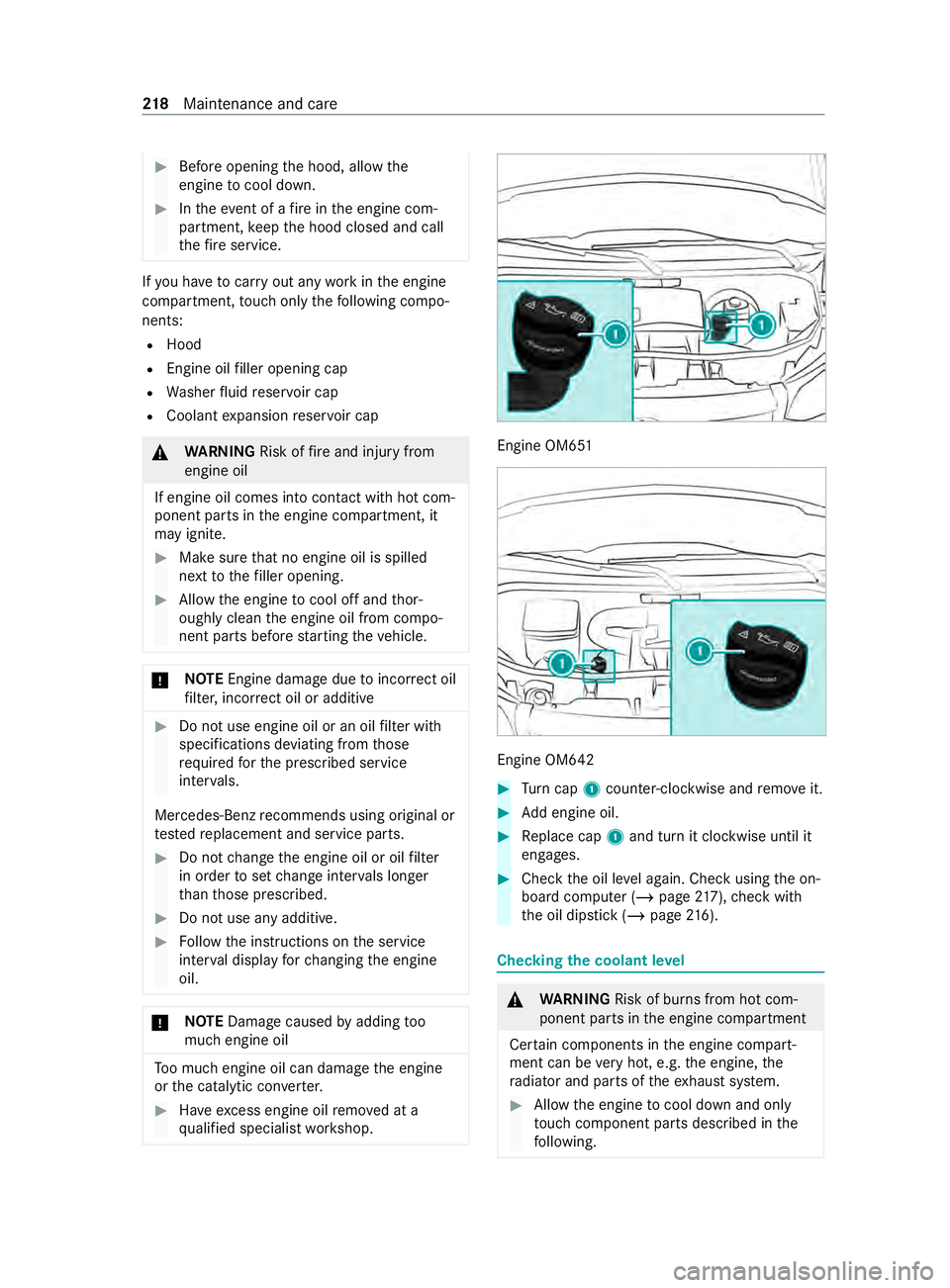

qu alified specialis tworks hop. Engine OM651

Engine OM642

#

Turn cap 1counter-clockwise and remo veit. #

Adde ngin eoil. #

Replace cap 1and tur nitclockwise until it

engages. #

Chec kthe oil le vela ga in. Chec kusing theo n-

boar dcomputer (/ page217),ch eckw ith

th eo il dipstic k(/pag e216). Checking

thec oolant le vel &

WARNING Risk of bu rnsf romh otcom‐

ponent parts in thee ngine compartment

Cer tainc omponents in thee ngine compart‐

ment can be very hot, e.g. thee ngine, the

ra diator and parts of thee xhau stsystem. #

Allowthe engine tocool down and only

to uc hc omponent parts desc ribed in the

fo llowing. 218

Maintenance and care