MERCEDES-BENZ V-CLASS MPV 2021 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2021, Model line: V-CLASS MPV, Model: MERCEDES-BENZ V-CLASS MPV 2021Pages: 337, PDF Size: 9.88 MB

Page 261 of 337

The use of wheel spacers or brake dust

shields is not permitted and

results in the

in va lidation of theve hicle's general ope rating

pe rm it.

R Ve

hicles with a tyre pressure monitoring

sy stem: allfitted wheels mu stbe equipped

with functioning sensors forth e tyre pressure

monitoring sy stem.

R Attemp eratures below 10°C use winter tyres

or all-season tyres with the M+S marking on

all wheels.

Wi nter tyres bearing the004D snowflake sym‐

bol in addition tothe M+S marking pr ovide

th e best possible grip in wintry road condi‐

tions.

R For M+S tyres, only use tyres with the same

tread.

R Obser vethe maximum permissible speed for

th e M+S tyres fitted.

If th is is below theve hicle's maximum per‐

missible speed, this must be indicated in an

appropriate label in the driver's field of vision.

R Run in new tyres at moderate speeds forthe

fi rs t10 0 km.

R Replace the tyres af ter six years at the latest,

re ga rdless of wear.

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Also obser vethefo llowing fur ther related sub‐

jects:

R Notes on tyre pressure (/ page 250)

R Tyre pressure table (/ page 251)

R Notes on the emer gency spa rewheel

(/ page 265) Note

s onchanging wheels &

WARNING Risk of injury thro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels can

se verely impair the driving characteristics.

The disk brakes or wheel suspension compo‐

nents may also be damaged. #

Only inter change the front and rear

wheels if the wheels and tyres ha vethe

same dimensions. Inter

changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nder thege neral ope rating pe rmit in valid.

On vehicles with the same front and rear wheel

size, you can inter change the wheels every 5,000

to 10,000 km depending on thewe ar. Ensure the

direction of rotation is maintained forth e wheels.

It is imperative toobser vethe instructions and

saf ety no tes on "Changing a wheel" when doing

so. Size categories of wheels

The de

term ined vehicle speed is displa yed in the

instrument clus ter and is impor tant for control‐

ling the driving saf ety sy stems and driving sys‐

te ms. The display accuracy of the speedome ter

and the odome ter is legally prescribed. De term in‐

ing the speed is dependent on the tyre size or the

ro lling circumference of the tyres. The rim diame‐

te r is alw ays specified in inches.

Fo rth is reason, theve hicle contro l units can be

coded forth efo llowing wheel size categories: Wheel size category 1

19

5/65 R 16 C

205/65 R 16 C

225/60 R 16 C

225/55 R 17 C

225/55 R 17XL

24 5/45 R 18XL Wheel size category 2

225/55 R

17XL

235/55 R 17XL

24 5/55 R 17XL

24 5/45 R 18XL

24 5/50 R 18XL

24 5/45 R 19XL %

Mercedes-Benz

recommends that youstay

within a wheel size category when changing a

tyre. In this wa y,yo uav oid recoding the con‐

trol units. 258

Wheels and tyres

Page 262 of 337

Due

tothe legally prescribed accuracy of the

speedome ter and odome ter displa ys,th efo llow‐

ing tyres are not permitte dfo rta xis and hire cars:

R Wheel size catego ry 1

- 195/65 R16C

R Wheel size category 2

- 225/55 R17XL

- 245/45 R18XL

If th e wheel size category changes, you must

ha ve your vehicle's contro l unitsrecoded at a

qu alified specialist workshop. Information on

the direction of the tyres'

ro tation Ty

res with a specified direction of rotation ha ve

additional benefits, e.g. if there is a risk of aqua‐

planing. You will on lyga in these benefits if the

cor rect direction of rotation is obser ved.

An ar row on the side wall of the tyre indicates its

cor rect direction of rotation.

Yo u may also fit a spa rewheel against the direc‐

tion of rotation. Obser vethe time restriction on

use as well as the speed limitation specified on

th e spare wheel. Information on

storing wheels Obser

vethefo llowing when storing wheels:

R Wheels that ha vebeen remo ved should be

st ored in a cool, dry and, if possible, dark

place.

R Protect the tyres from oil, grease and fuel. Preparing

theve hicle for a wheel change Requ

irements

R The tyre-change tool kit is available.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Appl yth e parking brake. #

Movethe front wheels tothest ra ight-ahead

position. #

Vehicles with manual transmission:

engage firs t or reve rsege ar 005E. #

Vehicles with automatic transmission:

shift the transmission toposition 005D. #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

On le velte rrain: place choc ks orother suita‐

ble objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed. #

On slight inclines: placechoc ks orother

suitable objects under the wheels on the

front and rear axles opposite the wheel tobe

ch anged. #

If included in theve hicle equipment, take the

tyre-change tool kit out of theve hicle tool kit

(/ page 247). #

If included in theve hicle equipment, remo ve

th e spare wheel from the spare wheel brac ket

( / page 265). #

If necessar y,remo vethe wheel co ver. #

Using the wheel wrench, loosen the wheel

nuts/bolts on the wheel you wish tochange

by about one full turn. Do not unscr ewthe

wheel bolts/nuts comple tely. #

Raise theve hicle (/ page 259). Ra

ising theve hicle when changing a wheel &

WARNING Risk of injury from incorrect

positioning of the jack

If yo u do not position the jack cor rectly at the

appropriate jacking point of theve hicle, the

jack could tip wi th theve hicle raised. #

Only position the jack at the appropriate

jacking point of theve hicle. The base of

th e jack must be positioned vertically

under the jacking point of theve hicle. &

WARNING Risk of injury fromvehicle tip‐

ping

On slopes, the jack could tip with theve hicle

ra ised. Wheels and tyres

259

Page 263 of 337

#

Neverch ange a wheel on a slope. #

Consult a qualified specialist workshop. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at the

appropriate jack support point of theve hicle,

th e jack could tip over with theve hicle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. Re

quirements:

R There are no persons in theve hicle.

R The vehicle is prepared forch anging a wheel

(/ page 259).

Impor tant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle. If the jack is used incor‐

re ctl y,it could tip over while theve hicle is

ra ised.

R The jack is designed only toraise theve hicle

fo r a short time while a wheel is being

ch anged and is not suitable for car rying out

maintenance workunder theve hicle.

R Avoid changing a wheel on uphill and downhill

slopes.

R The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load bearing and non-slip unde rlay.

R The base of the jack is positioned vertically

under the jack support point.

Saf ety instructions while theve hicle is raised:

R Do not put your hands or feet under theve hi‐

cle.

R Do not lie underneath theve hicle.

R Do not start theve hicle and do not release

th e parking brake.

R Do not open or close any doors. Jacking points

1(rubber stoppers) are located

behind the front wheel ar ches and in front of the

re ar wheel ar ches. #

Place jack 2beneath cor responding jack

support point 1. #

Turn handwheel 3until the plate of jack 2

sits securely on jack support point 1. #

Ensure that the base of jack 2is positioned

ve rtically under jacking point 1. #

Assemble adap ter4 and ratchet 5from

th eve hicle tool kit. #

Place adap ter4 and ratchet 5onthe he xa‐

gon nut of jack 2sothat the lettering

AU F/UP is visible. #

Turn ratchet wrench 5intheAU F/UP direc‐

tion until the tyre is raised a maximum of

3 cm off the ground.

When doing so, jack 2may mo vetoone of

th e side support sur faces. Re

moving a wheel Re

quirements:

R The vehicle is raised (/ page 259).

When changing a wheel, avoid applying any force

to the brake discs since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on a

dirty sur face. #

Unscr ewthe wheel bolts. #

Remo vethe wheel. 260

Wheels and tyres

Page 264 of 337

Fi

tting a new wheel Re

quirements

R The wheel is remo ved (/ page 260). &

WARNING Risk of accident from losing a

wheel

Oiled or greased wheel bolts can cause the

wheel bolts tocome loose, as too can dam‐

aged wheel bolts or wheel hub thre ads. #

Never oil or grease theth re ads. #

Intheeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. &

WARNING Risk of injury from tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Obser vethe information on thech oice of

tyres (/ page 256). #

Obser vethe instructions and saf ety no tes on

ch anging a wheel (/ page 256).#

For saf etyre asons, only use wheel bolts or

wheel nuts which ha vebeen appr ovedby

Mercedes-Benz and forth e wheel in question. #

Clean the wheel and wheel hub contact sur fa‐

ces. Lo

weri ngtheve hicle af ter a wheel change &

WARNING Risk of accident due toincor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed torque. #

Ensu rethat the wheel bolts or wheel

nuts are tightened tothe prescribed

tightening torque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Contact a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. Re

quirements:

R The new wheel has been fitted (/ page 261). #

Place the adap ter and thera tchet on the hex‐

agon head nut of the jack such that the letter‐

ing AB/DOWN is visible. #

Tolowe r the vehicle: turnthera tchet of the

jack anti-clo ckwise. #

Steel wheels: tightenth e wheel bolts or

wheel nuts evenly in a crosswise pattern in

th e sequence indicated (1 to5 ) and to a

maximum of 200 Nm. #

Light-alloy wheels: tightenthe wheel bolts

or wheel nuts evenly in a crosswise pattern in

th e sequence indicated (1 to5 ) and to a

maximum of 180 Nm. #

Che ckthe tyre pressure of the newly fitted

wheel and adjust it if necessa ry.

Ve hicles with the tyre pressure monitor sys‐

te m: allfitted wheels mu stbe equipped with

functioning sensors. #

Retighten the wheel bolts tothe specified

tightening torque af terth eve hicle has been

driven 50 km.

% When using a wheel or spare wheel with a

new or newly painted disk wheel, ha

vethe

wheel bolts or wheel nuts retightened again

af te r appro ximately 1,000 to5,000 km.

Obser vethe specified tightening torque. Infor

mation on wheel and tyre combinations

Gene ral no tes

Information on tyres, wheels and permissible

combinations can be obtained at a qualified spe‐

cialist workshop.

The smaller the cross-section of a tyre of a spe‐

cific wheel size, thewo rseth e driving comfort on

poor road sur faces. Ride and damp ing comfort

are reduced and therisk increases that when you

drive over obs tacles, damage towheels and tyres

may result. Wheels and tyres

261

Page 265 of 337

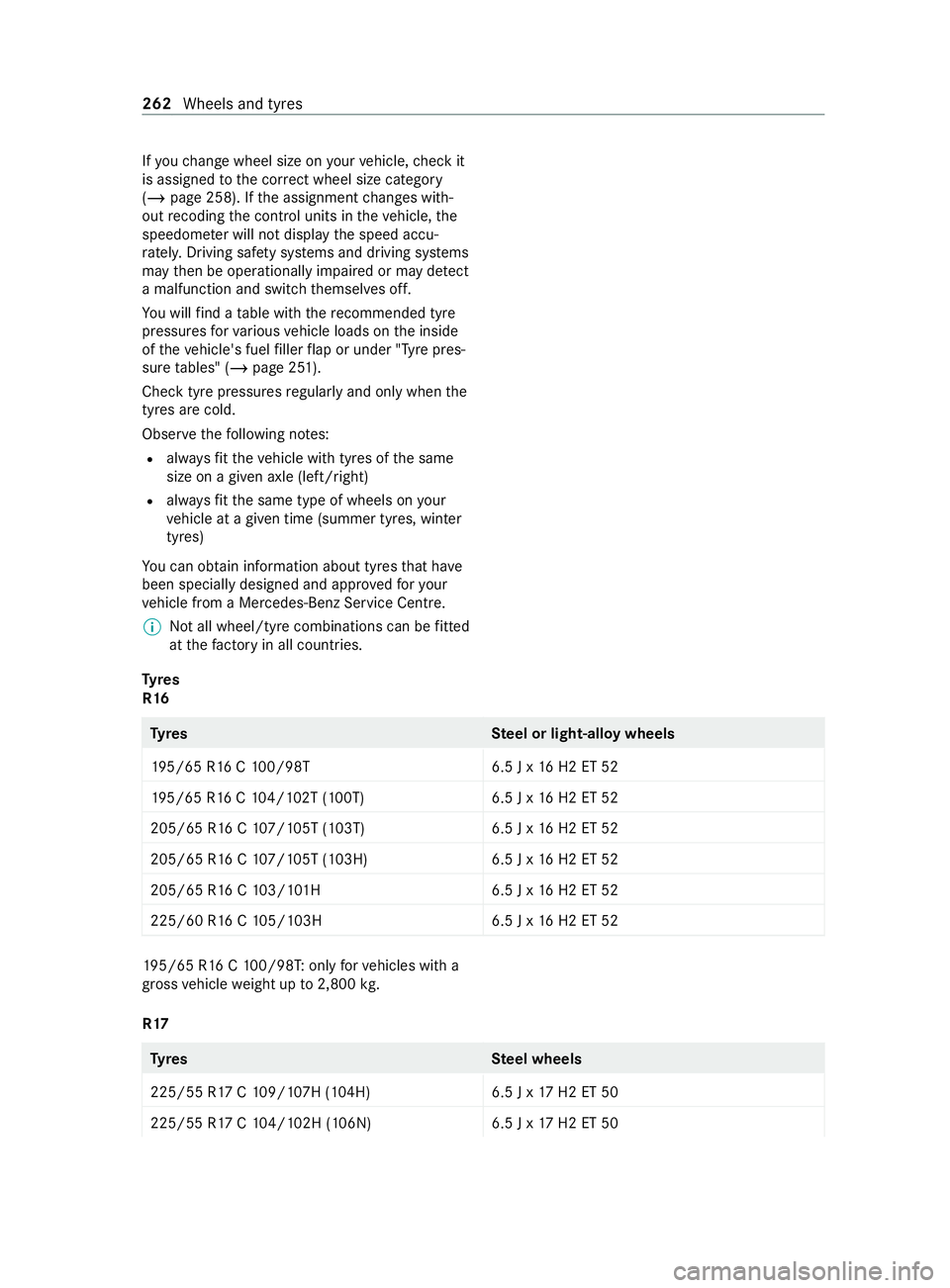

If

yo uch ange wheel size on your vehicle, check it

is assigned tothe cor rect wheel size catego ry

( / page 258). If the assignment changes with‐

out recoding the cont rol units in theve hicle, the

speedome ter will not display the speed accu‐

ra tely. Driving saf ety sy stems and driving sy stems

may then be operationally impaired or may de tect

a malfunction and switch themselves off.

Yo u will find a table with there commended tyre

pressures forva rious vehicle loads on the inside

of theve hicle's fuel filler flap or under "Tyre pres‐

sure tables" (/ page 251).

Check tyre pressures regularly and only when the

tyres are cold.

Obser vethefo llowing no tes:

R alwaysfit th eve hicle with tyres of the same

size on a given axle (left/right)

R alwaysfit th e same type of wheels on your

ve hicle at a given time (summer tyres, winter

tyres)

Yo u can obtain information about tyres that ha ve

been specially designed and appr ovedfo ryo ur

ve hicle from a Mercedes-Benz Service Centre.

% Not all wheel/tyre combinations can be

fitted

at thefa ctory in all countries.

Ty res

R16 Ty

resS teel or light-alloy wheels

19 5/65 R16 C 100/98T 6.5 J x16H2 ET 52

19 5/65 R16 C 104/102T (100T) 6.5 J x16H2 ET 52

205/65 R16 C 107/105T (103T) 6.5 J x16H2 ET 52

205/65 R16 C 107/105T (103H) 6.5 J x16H2 ET 52

205/65 R16 C 103/1 01H6 .5 J x16H2 ET 52

225/60 R16 C 105/103H 6.5 J x16H2 ET 52 19

5/65 R16 C 100/98T: only forve hicles with a

gross vehicle weight up to2,800 kg.

R17 Ty

resS teel wheels

225/55 R17 C 109/1 07H (104H) 6.5 J x17H2 ET 50

225/55 R17 C 104/102H (106N) 6.5 J x17H2 ET 50 262

Wheels and tyres

Page 266 of 337

Ty

resS teel wheels

225/55 R17 C 109/1 07T (104T) 6.5 J x17H2 ET 50

225/55 R17 XL 101V 6.5 J x17H2 ET 50

225/55 R17 XL 101H 6.5 J x17H2 ET 50

235/55 R17 XL 103W/V 6.5 J x17H2 ET 50 R17

Ty

resL ight-alloy wheels

225/55 R17 C 109/1 07H (104H) 7 J x17H2 ET 51

225/55 R17 C 104/102H (106N) 7 J x17H2 ET 51

225/55 R17 C 109/1 07T (104T) 7 J x17H2 ET 51

225/55 R17 XL 101V 7 J x17H2 ET 51

225/55 R17 XL 101H 7 J x17H2 ET 51

235/55 R17 XL 103W/V 7 J x17H2 ET 51 R18

Ty

resL ight-alloy wheels

24 5/45 R18 XL 100W 7.5 J x 18H2 ET 52

24 5/45 R18 XL 100V 7.5 J x 18H2 ET 52 24

5/45 R18 XL 100W: only forve hicles with a

permissible gross weight up to3,10 0kg and a

permissible axle load of 1,550 kgon there ar

axle. Not forve hicles with a gross vehicle weight

up to3,200 kg. 24

5/45 R18 XL 100V: only forve hicles with a

permissible gross weight up to3,10 0kg and a

permissible axle load of 1,550 kgon there ar

axle. Not forve hicles with a gross vehicle weight

up to3,200 kg.

R19 Ty

resL ight-alloy wheels

24 5/45 R19 XL 102Y 8 J x19H2 ET 52 24

5/45 R19 XL 102Y: only forve hicles with a

permissible gross weight up to3,200 kgand a

permissible axle load of 1,650 kgon there ar

axle. Use of sn ow chains is not permit ted.

Obser vethe no tes under "Snow chains". The

following additional wheel/tyre combinations

apply tovehicles with 4MATIC. Wheels and tyres

263

Page 267 of 337

R17

Ty

resS teel wheels

225/55 R17 C 109/1 07H (104H) 6.5 J x17H2 ET 50

225/55 R17 C 104/102H (106N) 6.5 J x17H2 ET 50

225/55 R17 C 109/1 07T (104T) 6.5 J x17H2 ET 50

225/55 R17 XL 101H/V1 26 .5 J x17H2 ET 50

235/55 R17 XL 103W/V 6.5 J x17H2 ET 50 R17

Ty

resL ight-alloy wheels

225/55 R17 C 109/1 07H (104H) 7 J x17H2 ET 51

225/55 R17 C 104/102H (106N) 7 J x17H2 ET 51

225/55 R17 C 109/1 07T (104T) 7 J x17H2 ET 51

225/55 R17 XL 101H/V 7 J x17H2 ET 51

235/55 R17 XL 103W/V 7 J x17H2 ET 51 225/55 R17 XL

101H/V: only forve hicles with a

permissible gross weight up to3,10 0kg and a permissible axle load of

1,550 kgon there ar

axle.

R18 Ty

resL ight-alloy wheels

24 5/45 R18 XL 100W 7.5 J x 18H2 ET 52

24 5/45 R18 XL 100V 7.5 J x 18H2 ET 52 24

5/45 R18 XL 100W: only forve hicles with a

permissible gross weight up to3,10 0kg and a

permissible axle load of 1,550 kgon there ar

axle. Not forve hicles with a gross vehicle weight

up to3,200 kg. 24

5/45 R18 XL 100V: only forve hicles with a

permissible gross weight up to3,10 0kg and a

permissible axle load of 1,550 kgon there ar

axle. Not forve hicles with a gross vehicle weight

up to3,200 kg.

R19 Ty

resL ight-alloy wheels

24 5/45 R19 XL 102Y 8 J x19H2 ET 52 24

5/45 R19 XL 102Y: only forve hicles with a

permissible gross weight up to3,200 kgand a

permissible axle load of 1,650 kgon there ar

axle. Use of sn ow chains is not permit ted.

Obser vethe no tes under "Snow chains". 264

Wheels and tyres

Page 268 of 337

Spare wheel

Note

s onthe emer gency spare wheel and

spare wheel Spare wheel:

wheel and tyre dimensions as well

as the type of tyre cor respond totheot her fitted

wheels.

A fitted spa rewheel changes the driving charac‐

te rist ics and bears risks. &

WARNING Risk of accident due toincor‐

re ct wheel and tyre dimensions

Driving with th e spare wheel fitted can

se verely impair theve hicle's driving charac‐

te rist ics.

To avo idrisks, obser vethefo llowing points: #

Drive carefully #

Neverfit more than one spare wheel

which is dif fere nt from the wheel tobe

re placed. #

Only use the spare wheel for a short

period of time. #

Change a spare wheel which is of a dif‐

fere nt size at the nearest qualified spe‐

cialist workshop. Be sure topay atten‐

tion tothe cor rect wheel and tyre

dimensions as well as the tyre type. R

When using a spare wheel (which is dif fere nt

from the wheel tobe replaced) a top speed of

80 km/h must not be exceeded.

R The tyre pressure of the spare wheel must be

ch ecked before starting a journey

(/ page 251).

R Have the emer gency spa rewheel replaced by

a qu alified specialist workshop.

The following should be checkedre gular ly, partic‐

ularly prior tolong journe ys:

R the secure positioning of the spare tyre

R the tyre pressure of the spare wheel (adjust

th e tyre pressure if necessary) (/ page 251)

R thefast enings of the spare wheel brac ket

The spare wheel is located in a spare wheel

brac ket under there ar of theve hicle.

Re place the tyres af ter six years at the latest,

re ga rdless of wear. This also applies tothe spare

wheel.

% If

yo u ha vefitted a spa rewheel, the tyre

pressure monitor will not function forth is wheel. The spare wheel is not equipped with

a sensor

for monitoring tyre pressu re. Fi

tting/ removing the spare wheel Re

moving the spare wheel under the rear of

th eve hicle #

Take the wheel wrench and auxiliary tool for

th e spare wheel lif ter out of theve hicle tool

kit (/ page247). #

Carefully prise off co ver cap 1with a suita‐

ble tool, e.g. a scr ewdriver. Be careful not to

damage the paintwork or the co vering cap

when doing so. #

Push auxilia rytool 2 thro ugh the opening

into the winch guide. #

Attach wheel wrench 3toauxiliary tool 2

fo rth e spare wheel lif ter. #

Turn wheel wrench 3inthe direction of

ar row 5until youfe el resis tance or until the

friction clutch of the winch overwinds.

The spare wheel is lo wered. Wheels and tyres

265

Page 269 of 337

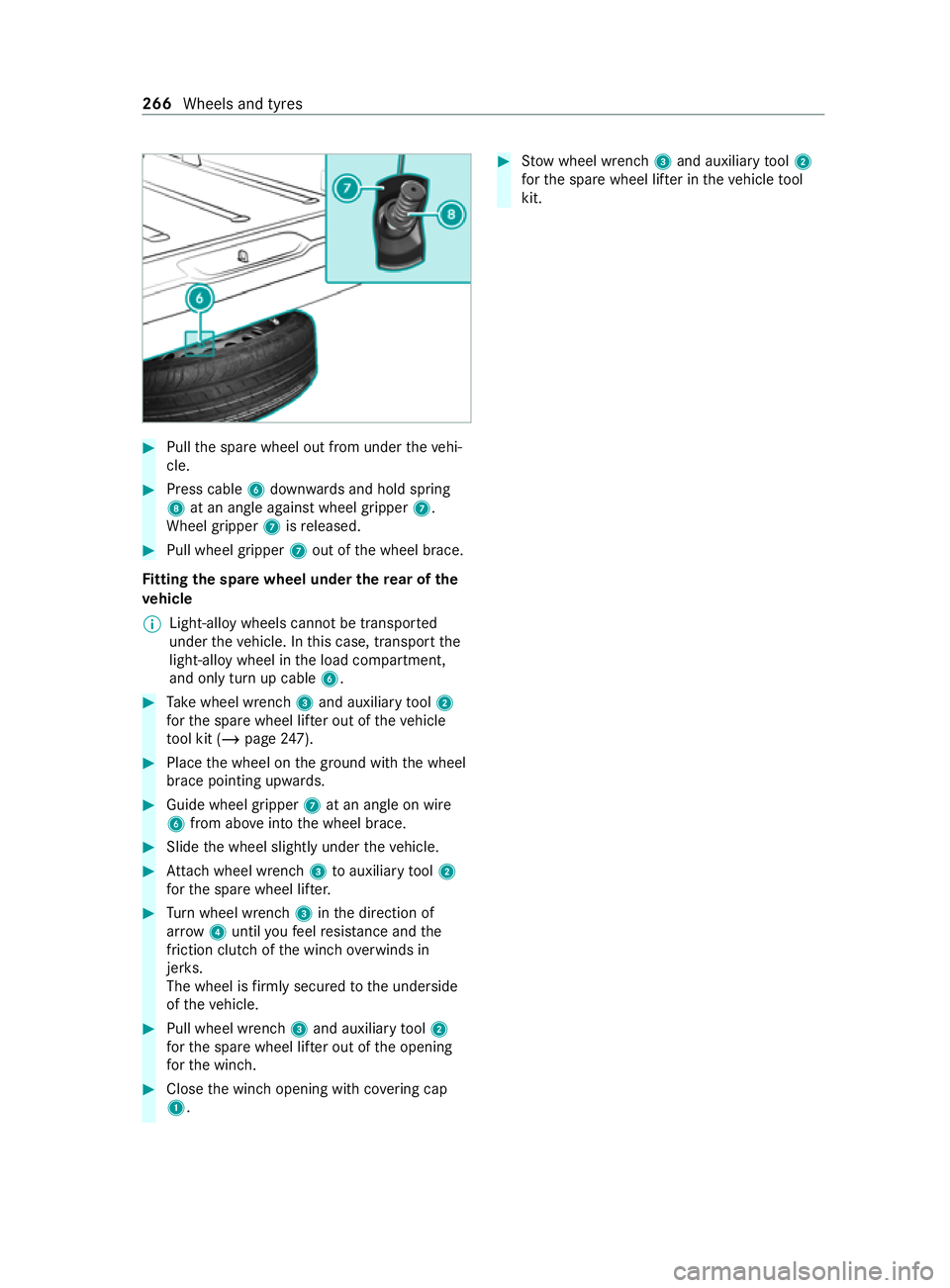

#

Pull the spare wheel out from under theve hi‐

cle. #

Press cable 6down wards and hold spring

8 at an angle against wheel gripper 7.

Wheel gripper 7isreleased. #

Pull wheel gripper 7out of the wheel brace.

Fi tting the spare wheel under the rear of the

ve hicle

% Light-alloy wheels cannot be transpor

ted

under theve hicle. In this case, transpo rtthe

light-alloy wheel in the load compartment,

and only turn up cable 6.#

Take wheel wrench 3and auxiliary tool 2

fo rth e spare wheel lif ter out of theve hicle

to ol kit (/ page247). #

Place the wheel on the ground with the wheel

brace pointing upwards. #

Guide wheel gripper 7at an angle on wire

6 from abo veinto the wheel brace. #

Slide the wheel slightly under theve hicle. #

Attach wheel wrench 3toauxiliary tool 2

fo rth e spare wheel lif ter. #

Turn wheel wrench 3inthe direction of

ar row 4until youfe el resis tance and the

friction clutch of the winch overwinds in

jer ks.

The wheel is firm lysecured tothe underside

of theve hicle. #

Pull wheel wrench 3and auxiliary tool 2

fo rth e spare wheel lif ter out of the opening

fo rth e winch. #

Close the winch opening with co vering cap

1. #

Stow wheel wrench 3and auxiliary tool 2

fo rth e spare wheel lif ter in theve hicle tool

kit. 266

Wheels and tyres

Page 270 of 337

Information on

thetech nical data

The tech nical da tawa s de term ined in acco rdance

with EU Directives. The given data only applies to

ve hicles with standard equipment. You can obtain

fur ther information at a qualified specialist work‐

shop.

Only for ce rtain countries: you can find vehicle-

specific vehicle data in the COC documents (CER‐

TIFIC ATE OF CONFORMITY). These documents

are supplied when theve hicle is delivered. On-board electronics

Note

s onworkon the engine electronics *

NO

TEPremature wearthro ugh improper

main tenance Improper maintenance may cause

vehicle

components towe ar more quickly and the

ve hicle's operating permit may be in validated. #

Always ha vewo rkon the engine elec‐

tronics and related components car ried

out at a qualified specialist workshop. Tw

o-w ayradios In

stallation no tesfo r two-w ayradios &

WARNING Risk of accident due to

improper workon two-w ayradios

If two-w ayradios are manipulated or retrofit‐

te d incor rectl y,the electromagnetic radiation

from the two-w ayradios can inter fere with

th eve hicle electronics and jeopardise the

operating saf ety of theve hicle. #

You should ha veall workon electrical

and electronic components car ried out

at a qualified specialist workshop. &

WARNING Risk of accident from incor‐

re ct ope ration of two-w ayradios

If yo u use two- wayra dios in theve hicle

improperly, their electromagnetic radiation

can disrupt theve hicle's electronics. This is

true in thefo llowing situations, in particular:

R The two-w ayradio is not connected toan

ex terior aerial.

R The exterior aerial is fitted inco rrectly or

is not a lo w-reflection aerial. This could jeopardise

the operating saf ety of

th eve hicle. #

Have the lo w-reflection exterior aerial

fi tted at a qualified specialist workshop. #

When operating two-w ayradios in the

ve hicle, alw ays connect them tothe

lo w- reflection exterior aerial. *

NO

TEInva lidation of the operating per‐

mit due tofailure tocomply wi th the

instructions for ins tallation and use The operating permit may be in

validated if the

instructions for ins tallation and use of two-

wa yra dios are not obser ved. #

Only use appr oved frequency bands. #

Obser vethe maximum permissible out‐

put po wer in these frequency bands. #

Only use appr oved aerial positions. Use

Tech nical Specification ISO/TS 21609 (Road

Ve hicles - EMC guidelines for ins tallation of af ter‐

mar ketra dio frequency transmitting equipment)

when retrofitting two-w ayradios. Comply with the

legal requirements for de tach able parts.

If yo ur vehicle has fittings for two-w ayradio

equipment, use the po wer supp lyor aerial con‐

nections intended for use with thefittings.

Obser vethe manufacturer's supplements during

ins tallation.

Tw o-w ayradio transmission output

The maximum transmission outputs (PEAK) at the

base of the aerial must not exceed theva lues in

th efo llowing table:

Fr equency band and maximum transmission

output Fr

equency band Maximum transmis‐

sion output

Sho rtwa ve

3 – 54MHz 10

0 W

4 m waveband

74 – 88 MHz 30 W

2 m waveband

14 4 – 174 MHz 50 W

Tr unked radio sys‐

te m/T etra

380 – 460 MHz 10 W Te

ch nical da ta267