sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 663 of 1146

33B-1

ELECTRONIC

CONTROL

SUSPENSION

CONTENTSM33AA-B

CIRCUIT DIAGRAM

22SPECIAL TOOLS........................................................................3

................................................................

DAMPING FORCE CHANGEOVERSPECIFICATIONS....................................................................2

ACTUATOR................................................................................20General Specifications.......................................................2

ECS CONTROL UNIT................................................................21Service Specifications.......................................................3

ECS INDICATOR LIGHT............................................................20STEERING ANGULAR VELOCITYa .

ECS SWITCH............................................................................

19

G SENSOR................................................................................

19

POSITION DETECTION SWITCH............................................20

SERVICE ADJUSTMENT PROCEDURES

............................

12

On-Vehicle Inspection........................................................12

SENSOR*....................................................................................-IY

STOP LIGHT SWITCH............................................................20

THROTTLE POSITION SENSOR

............................................20

TROUBLESHOOTING............................................................4

VEHICLE SPEED SENSOR....................................................

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(I)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, aiir bagmodule, clock spring, interconnecting wiring.Other SRS-related components (that may have 1:o be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP

Ei2B -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 666 of 1146

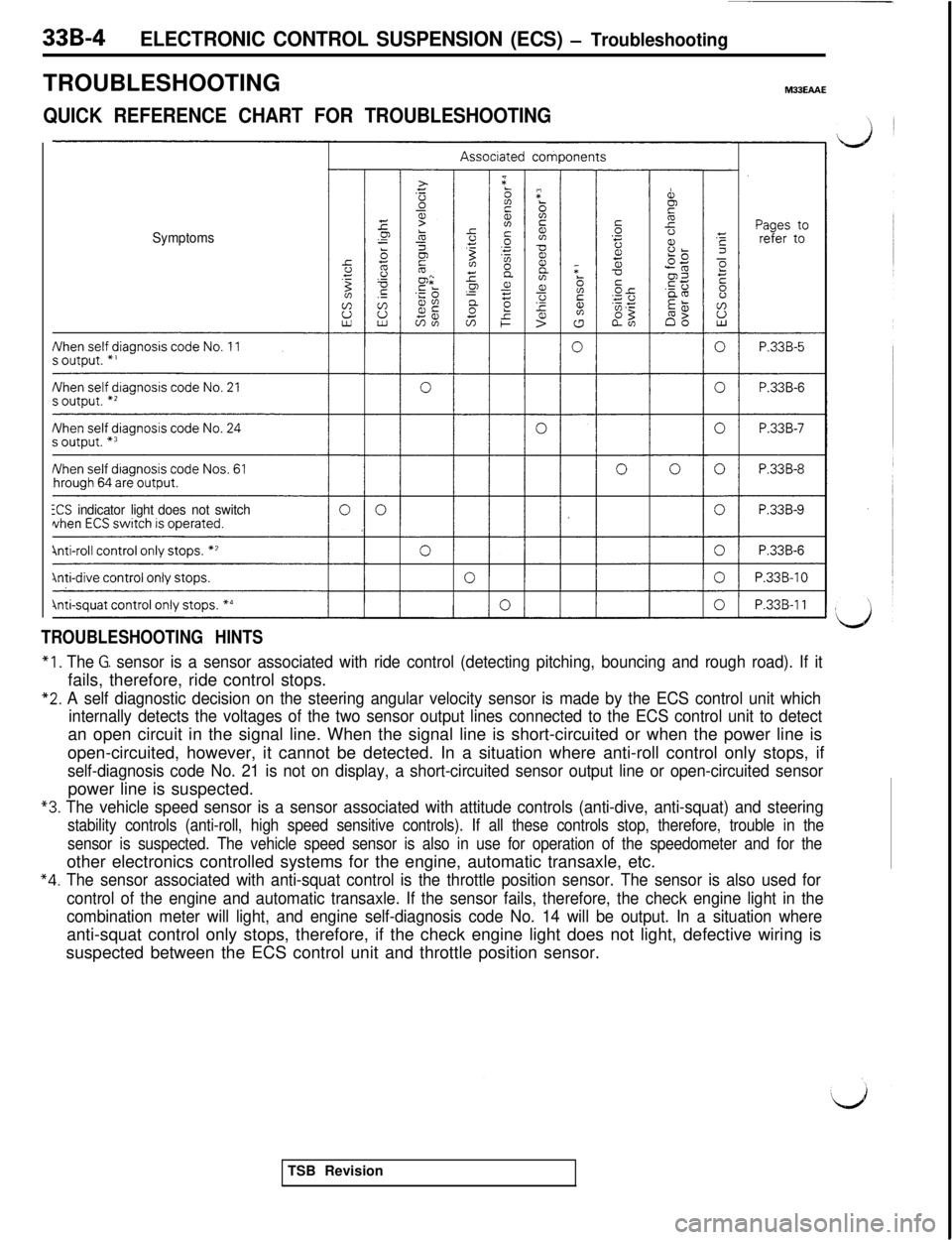

33B-4ELECTRONIC CONTROL SUSPENSION (ECS) - TroubleshootingTROUBLESHOOTING

M33EAAE

QUICK REFERENCE CHART FOR TROUBLESHOOTING

SymptomsXS

indicator lightdoes not switch

TROUBLESHOOTING HINTS

“1. The G. sensor is a sensor associated with ride control (detecting pitching, bouncing and rough road). If itfails, therefore, ride control stops.

“2. A self diagnostic decision on the steering angular velocity sensor is made by the ECS control unit which

internally detects the voltages of the two sensor output lines connected to the ECS control unit to detectan open circuit in the signal line. When the signal line is short-circuited or when the power line is

open-circuited, however, it cannot be detected. In a situation where anti-roll control only stops, if

self-diagnosis code No. 21 is not on display, a short-circuited sensor output line or open-circuited sensorpower line is suspected.

“3. The vehicle speed sensor is a sensor associated with attitude controls (anti-dive, anti-squat) and steering

stability controls (anti-roll, high speed sensitive controls). If all these controls stop, therefore, trouble in the

sensor is suspected. The vehicle speed sensor is also in use for operation of the speedometer and for theother electronics controlled systems for the engine, automatic transaxle, etc.

“4. The sensor associated with anti-squat control is the throttle position sensor. The sensor is also used for

control of the engine and automatic transaxle. If the sensor fails, therefore, the check engine light in the

combination meter will light, and engine self-diagnosis code No. 14 will be output. In a situation whereanti-squat control only stops, therefore, if the check engine light does not light, defective wiring is

suspected between the ECS control unit and throttle position sensor.

TSB Revision

Page 667 of 1146

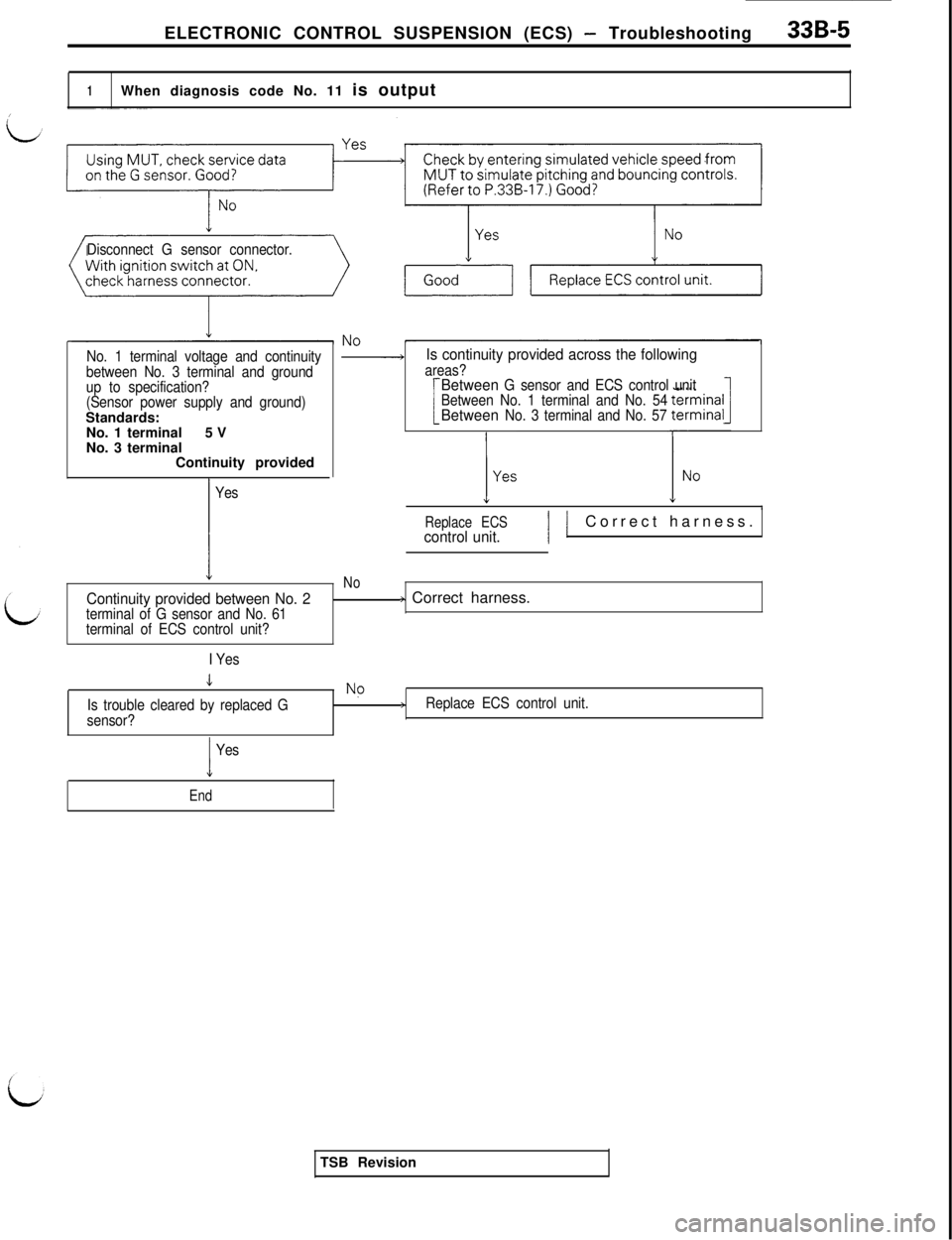

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting33B-5

1When diagnosis code No. 11 is output

Disconnect G sensor connector.

No. 1 terminal voltage and continuity

between No. 3 terminal and ground

up to specification?

(Sensor power supply and ground)Standards:

No. 1 terminal5 V

No. 3 terminal

Continuity provided

IYes.-

-1Is continuity provided across the following

areas?

!

BetweenG sensor and ECS control unit

Between No. 1 terminal and No. 54

BetweenNo. 3 terminal and No. 57

,

Replace ECScontrol unit.Correct harness.

LNo

Continuity provided between No. 2) Correct harness.

terminal of G sensor and No. 61

terminal of ECS control unit?

I Yes

4N?Is trouble cleared by replaced G

sensor?bReplace ECS control unit.

I

Yes

EndTSB Revision

Page 668 of 1146

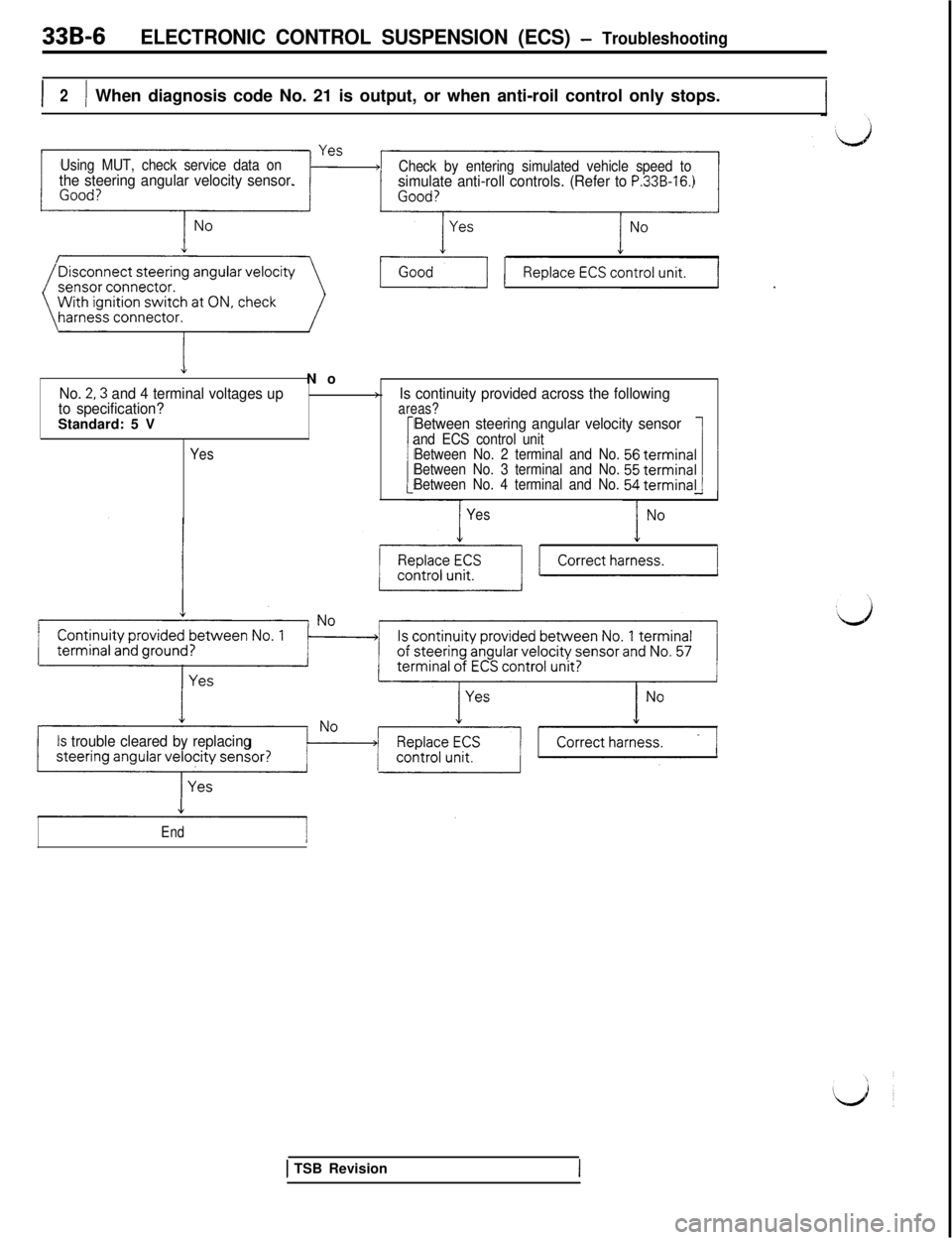

33B-6ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting

I I2When diagnosis code No. 21 is output, or when anti-roil control only stops.

Using MUT, check service data onthe steering angular velocity sensor.Check by entering simulated vehicle speed tosimulate anti-roll controls. (Refer to P.33B-16.)

+No

No. 2,3 and 4 terminal voltages up

to specification?Standard: 5 V

Yes

>Is continuity provided across the followingareas?Between steering angular velocity sensorand ECS control unit

Between No. 2 terminal and No.!Between No. 3 terminal and No.

Between No. 4 terminal and No.

Yes

Is trouble cleared by replacing

End

1 TSB RevisionI

Page 669 of 1146

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting33B-7

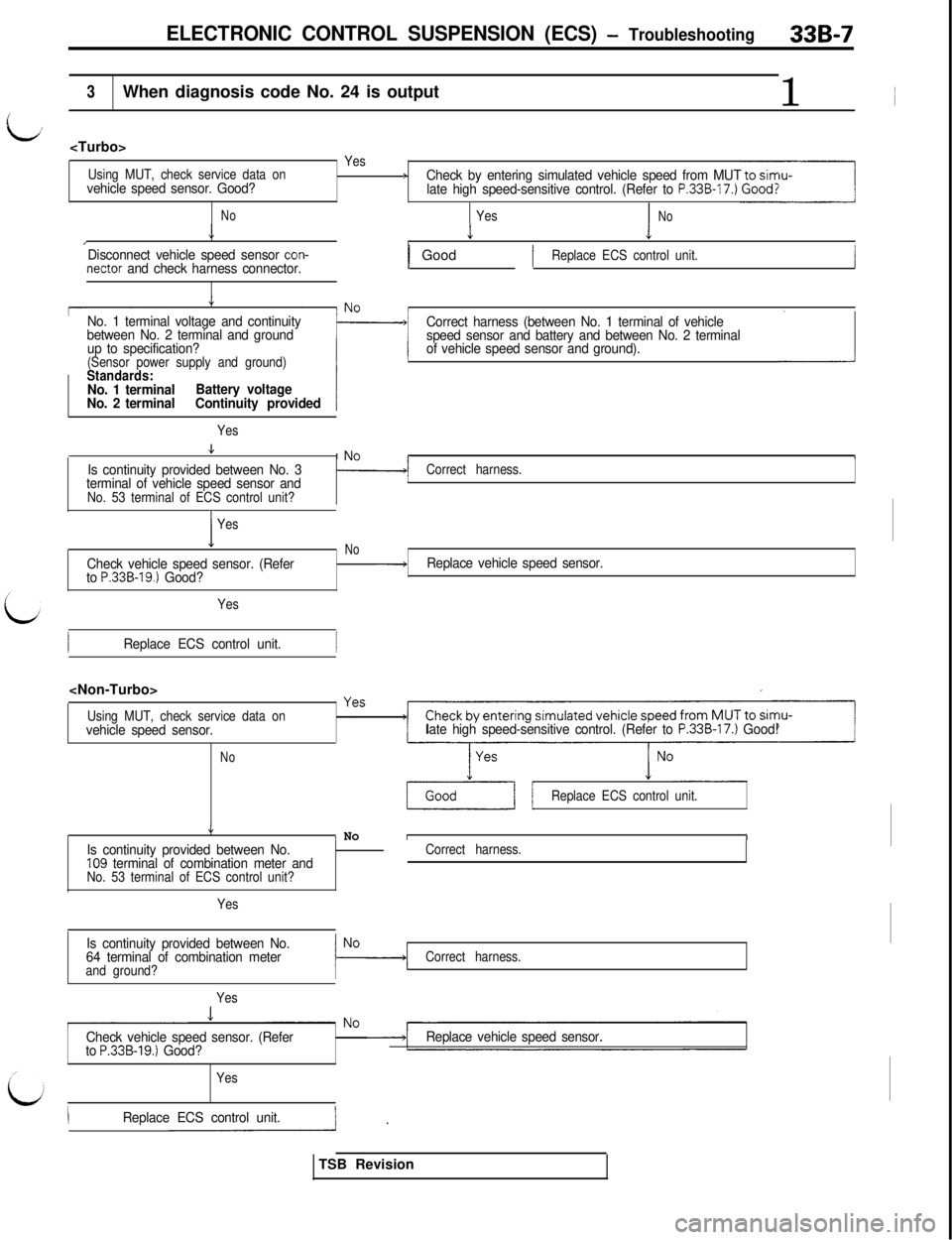

3When diagnosis code No. 24 is output

1 i

Using MUT, check service data onvehicle speed sensor. Good?

YesjCheck by entering simulated vehicle speed from MUT

late high speed-sensitive control. (Refer to P.338-17.)

NoYesNo

151//Disconnect vehicle speed sensor con-nectar and check harness connector.j Good) /Replace ECS control unit.1

No. 1 terminal voltage and continuity

between No. 2 terminal and ground

up to specification?

(Sensor power supply and ground)Standards:No. 1 terminalBattery voltage

No. 2 terminalContinuity provided

Correct harness (between No. 1 terminal of vehicle

speed sensor and battery and between No. 2 terminal

of vehicle speed sensor and ground).

l-.-l

Yes

JI Nni1Is continuity provided between No. 3

terminal of vehicle speed sensor and

No. 53 terminal of ECS control unit?Correct harness.

1

Yes

Check vehicle speed sensor. (Refer

to P.33B-19.) Good?

No-Replace vehicle speed sensor.

Yes

IReplace ECS control unit.I

Using MUT, check service data onvehicle speed sensor.

No

late high speed-sensitive control. (Refer to P.33B-17.) Good!

Replace ECS control unit.

4t NoI1Is continuity provided between No.109 terminal of combination meter andNo. 53 terminal of ECS control unit?Correct harness.

Yes

Is continuity provided between No.

64 terminal of combination meter

and ground?

No

4

Correct harness.

Yes

Check vehicle speed sensor. (Refer

to P.33B-19.) Good?--+Replace vehicle speed sensor.

Yes

IReplace ECS control unit.I .

TSB Revision

Page 673 of 1146

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting 33B-11

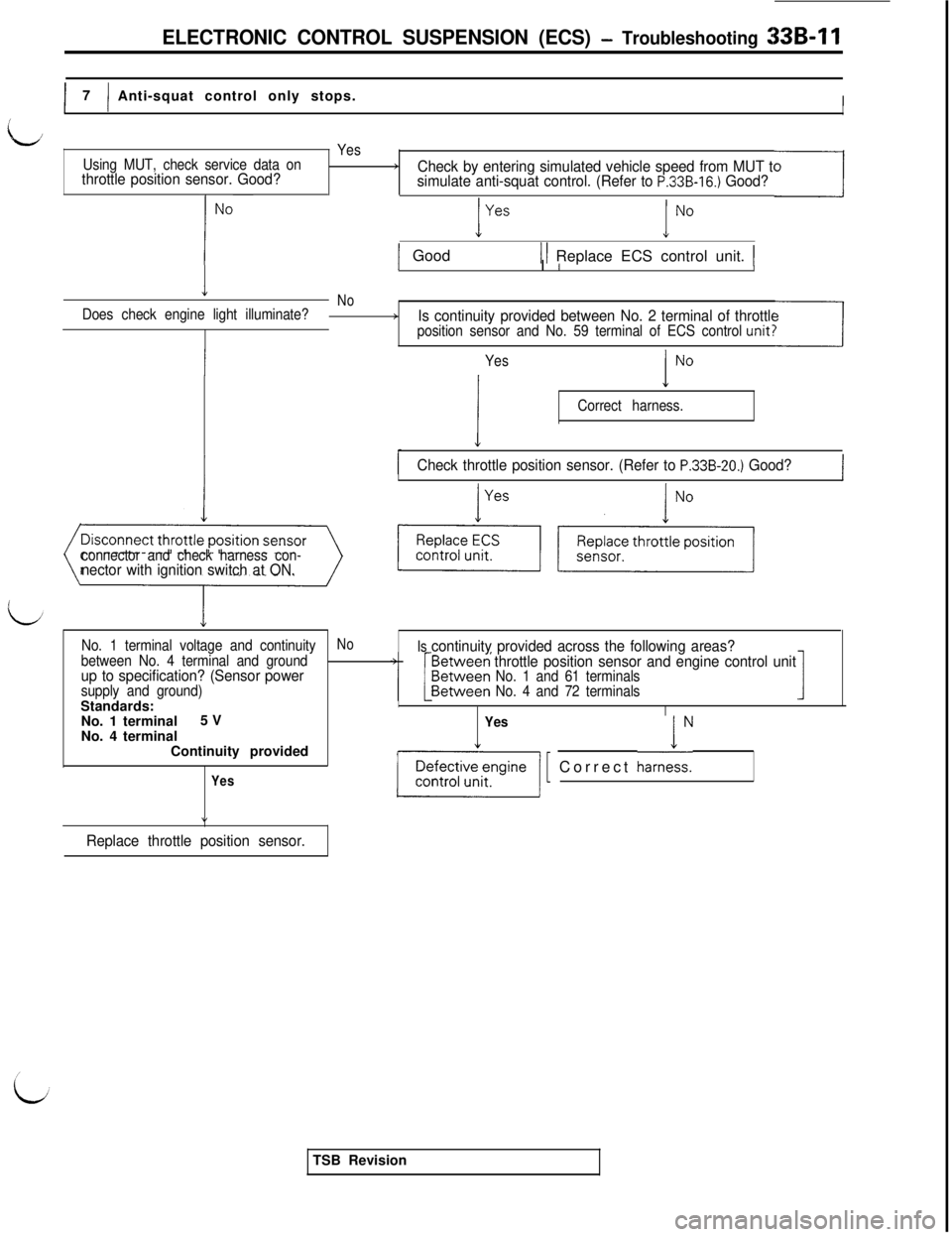

I I7

Anti-squat control only stops.III

L,

I

Using MUT, check service data onthrottle position sensor. Good?

Yes

rCheck by entering simulated vehicle speed from MUT to

simulate anti-squat control. (Refer to P.33B-16.) Good?!

1 Good1 ) Replace ECS control unit. 1

I

1I II

NoDoes check engine light illuminate?>Is continuity provided between No. 2 terminal of throttleposition sensor and No. 59 terminal of ECS controlunityII

Yes

i

Correct harness.

1Check throttle position sensor. (Refer to P.33B-20.) Good?III1

connector and check harness con-nector with ignition switch at ON.

No. 1 terminal voltage and continuityNo

Is

between No. 4 terminal and groundcontinuity provided across the following areas?

up to specification? (Sensor powerthrottle position sensor and engine control unit

No. 1 and 61 terminals

supply and ground)

No. 4 and 72 terminalsStandards:

INo. 1 terminal5 V

YesNo. 4 terminal

Continuity provided

Yes-1 1 Correct harnei:

”

Replace throttle position sensor.TSB Revision

Page 674 of 1146

33B-12ELECTRONIC CONTROL SUSPENSION (EC9 - i?:~~u:‘?s*men*

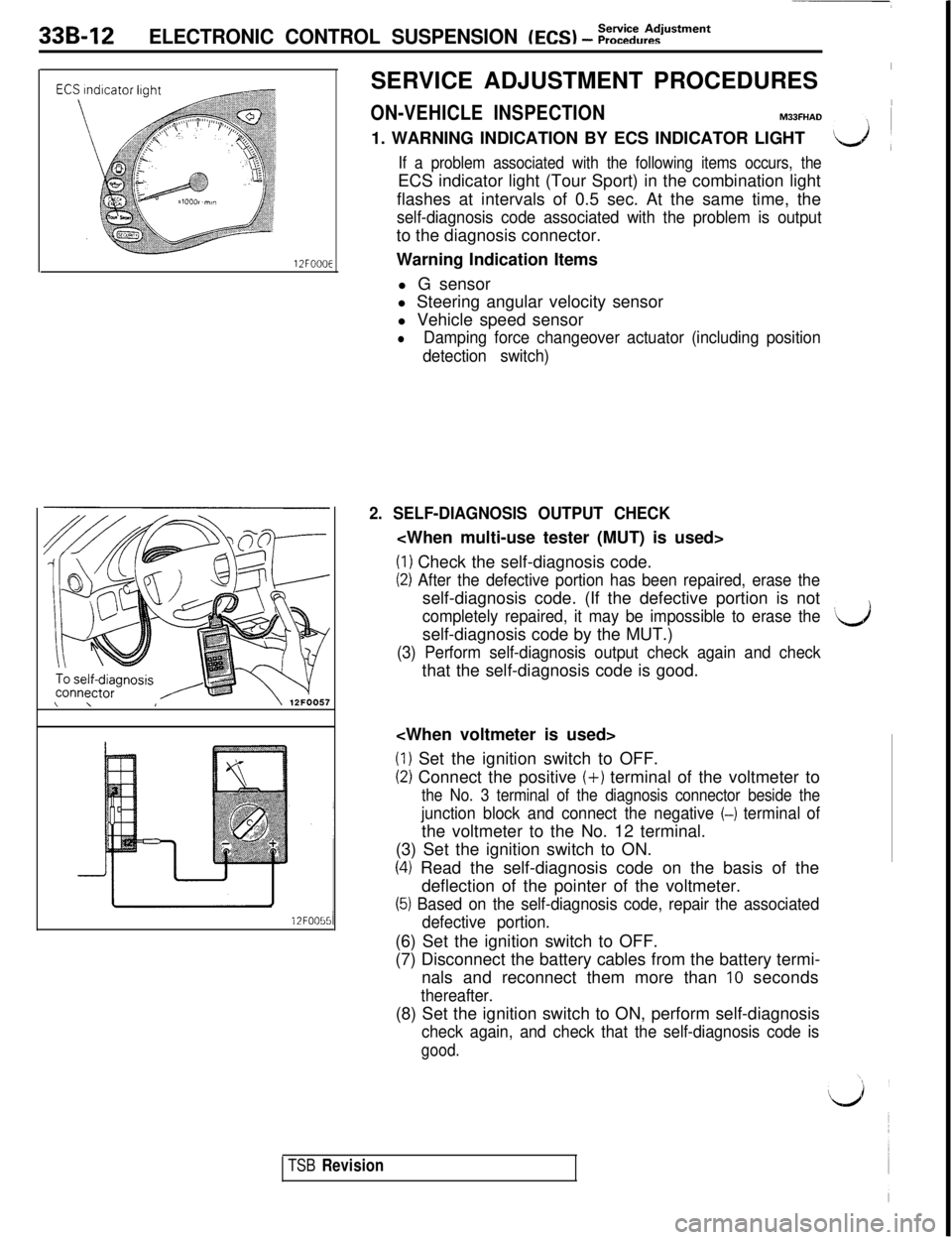

12FOOOESERVICE ADJUSTMENT PROCEDURES

I

ON-VEHICLE INSPECTIONIM33FHAD1. WARNING INDICATION BY ECS INDICATOR LIGHT

If a problem associated with the following items occurs, theECS indicator light (Tour Sport) in the combination light

flashes at intervals of 0.5 sec. At the same time, the

self-diagnosis code associated with the problem is outputto the diagnosis connector.

Warning Indication Items

l G sensor

l Steering angular velocity sensor

l Vehicle speed sensor

lDamping force changeover actuator (including position

detection switch)

2. SELF-DIAGNOSIS OUTPUT CHECK

(I) Check the self-diagnosis code.

(2) After the defective portion has been repaired, erase theself-diagnosis code. (If the defective portion is not

completely repaired, it may be impossible to erase the’self-diagnosis code by the MUT.)d

(3) Perform self-diagnosis output check again and checkthat the self-diagnosis code is good.

(1) Set the ignition switch to OFF.

(2) Connect the positive (+) terminal of the voltmeter to

the No. 3 terminal of the diagnosis connector beside the

junction block and connect the negative (--) terminal ofthe voltmeter to the No. 12 terminal.

(3) Set the ignition switch to ON.

(4) Read the self-diagnosis code on the basis of the

deflection of the pointer of the voltmeter.

(5) Based on the self-diagnosis code, repair the associated

defective portion.(6) Set the ignition switch to OFF.

(7) Disconnect the battery cables from the battery termi-

nals and reconnect them more than

10 seconds

thereafter.(8) Set the ignition switch to ON, perform self-diagnosis

check again, and check that the self-diagnosis code is

good.

TSB Revision

Page 675 of 1146

![MITSUBISHI 3000GT 1991 Service Manual Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect MITSUBISHI 3000GT 1991 Service Manual Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect](/img/19/57085/w960_57085-674.png)

Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defective*l Ride controls (pinching and bouncingcontrol, bad road detection control) sl:op.

21Steering angularvelocity sensor open-circuited*

l Anti-roll control stops.

24Vehicle speed sensor*nn open-crrcurtedl Steering stability controls (anti-roll, high

speed sensitive controls) and attitude

controls (anti-dive, anti-squat) stop.l Shock absorber damping force fixed

F. L. damping forcefl-~-~-j 11c$i;z;;Fr actuator

R. R. damping force

I /

64 j-jMJ-~-~-~ ~t$ec~Z$rn&ftYrrZ& /

NOTE(1)Control stop, warning indication and fixed damping force return to normal when the ignition switch is set to OFF.

When any of the problems marked* occurs, if no subsequent problem occurs (for example, when the problem IStransient) normal operation will be restored even if the ignition switch is not set to OFF.(2)Even if control stop warning indication and fixed damping force return to normal as described above, the

self-diagnosis code’is stored in the memory in the ECS control unrt.

(3)The self-diagnosis code can be force-cleared by use of the MUT or by stopping the power supply to the ECS controlunit. In addition

it is automatically cleared if the ON/OFF control of the ignition swatch is repeated 60 times after the

self-diagnosis code has been output, provided that no new self-diagnosis code is output during the period.TSB Revision

Page 676 of 1146

339-l 4ELECTRONIC CONTROL SUSPENSION (ECS) - ~;:i%?tment

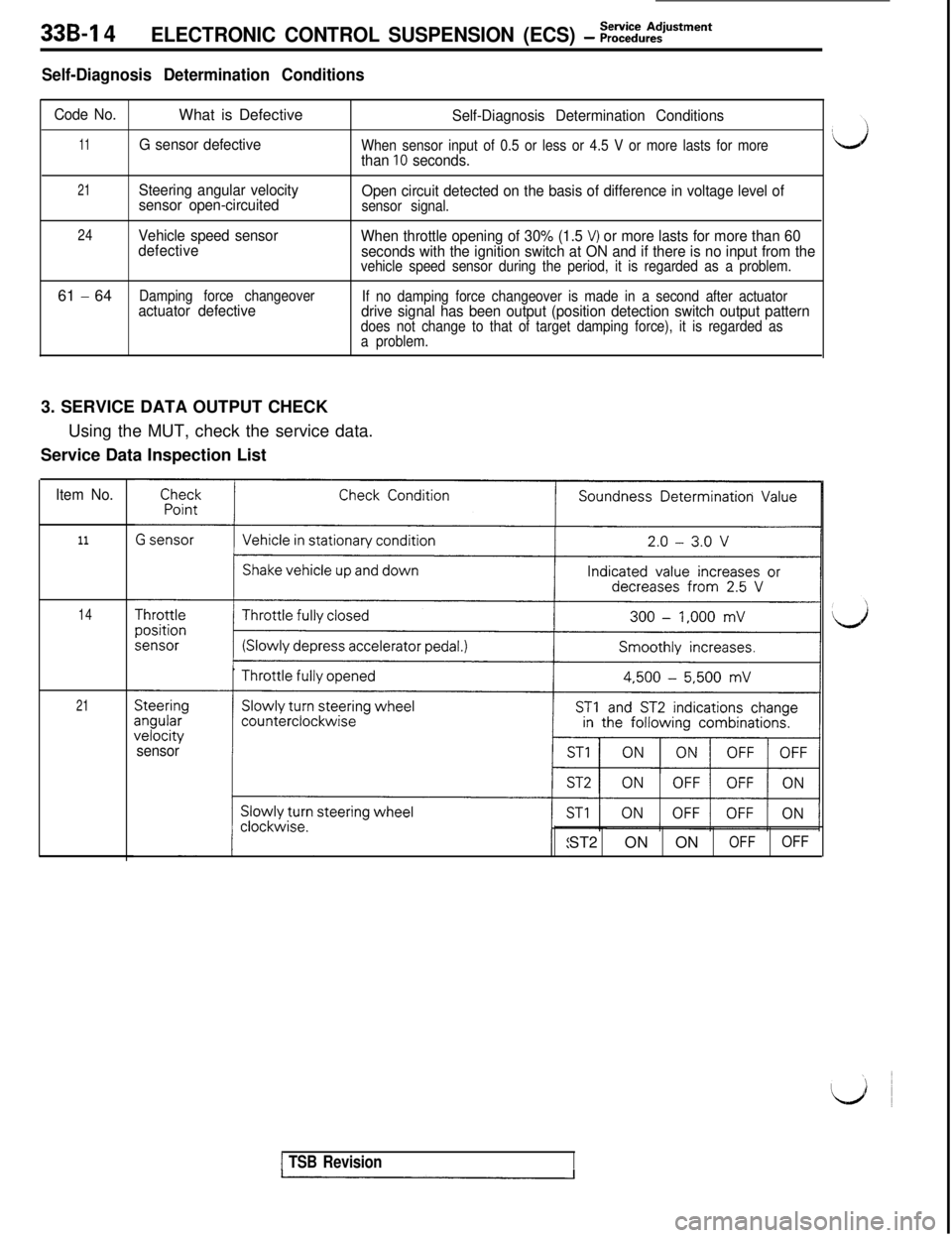

Self-Diagnosis Determination Conditions

Code No.What is DefectiveSelf-Diagnosis Determination Conditions

11G sensor defectiveWhen sensor input of 0.5 or less or 4.5 V or more lasts for morethan 10 seconds.

21Steering angular velocity

sensor open-circuitedOpen circuit detected on the basis of difference in voltage level of

sensor signal.

24Vehicle speed sensor

defectiveWhen throttle opening of 30% (1.5 V) or more lasts for more than 60

seconds with the ignition switch at ON and if there is no input from the

vehicle speed sensor during the period, it is regarded as a problem.61

- 64Damping force changeoveractuator defectiveIf no damping force changeover is made in a second after actuatordrive signal has been output (position detection switch output patterndoes not change to that of target damping force), it is regarded as

a problem.3. SERVICE DATA OUTPUT CHECK

Using the MUT, check the service data.

Service Data Inspection List

Item No.

11

14

21

sensorST2 ON ON

OFFOFF

1 TSB Revision

Page 677 of 1146

I,

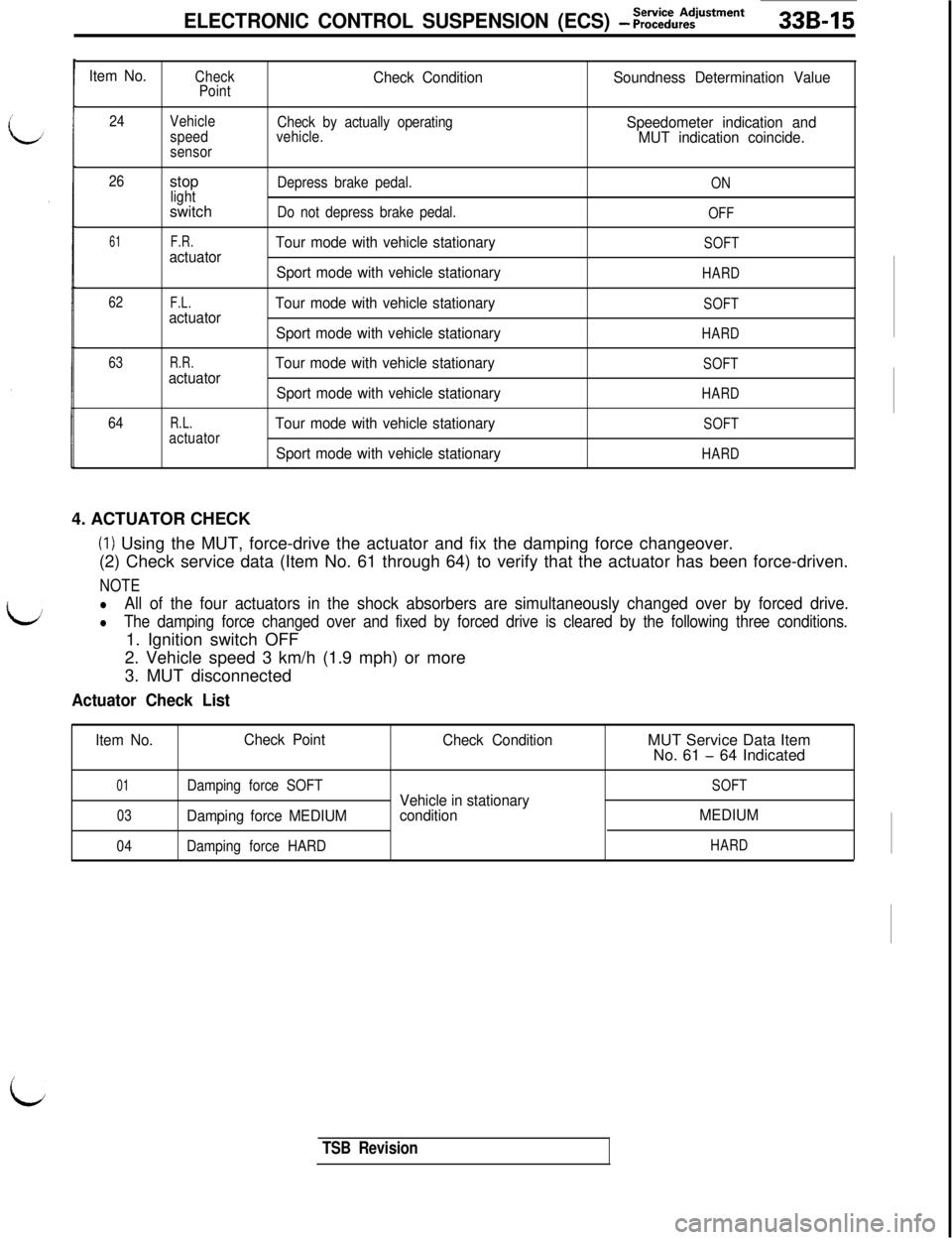

ELECTRONIC CONTROL SUSPENSION (ECS) - ;;~i%:~ustment339-15

Item No.Check

PointCheck ConditionSoundness Determination Value

24

Check by actually operating

vehicle.Speedometer indication and

MUT indication coincide.

26

61

62

63

64Vehicle

speed

sensorstop

lightswitch

F.R.actuator

F.L.actuator

R.R.actuator

R.L.actuatorDepress brake pedal.

ON

Do not depress brake pedal.OFF

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD4. ACTUATOR CHECK

(I) Using the MUT, force-drive the actuator and fix the damping force changeover.

(2) Check service data (Item No. 61 through 64) to verify that the actuator has been force-driven.

NOTE

lAll of the four actuators in the shock absorbers are simultaneously changed over by forced drive.

lThe damping force changed over and fixed by forced drive is cleared by the following three conditions.1. Ignition switch OFF

2. Vehicle speed 3 km/h (1.9 mph) or more

3. MUT disconnected

Actuator Check List

Item No.Check Point

Check ConditionMUT Service Data Item

No. 61 - 64 Indicated

01Damping force SOFT

03Damping force MEDIUM

04Damping force HARD

Vehicle in stationary

conditionSOFT

MEDIUM

HARD

i

TSB Revision