sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 818 of 1146

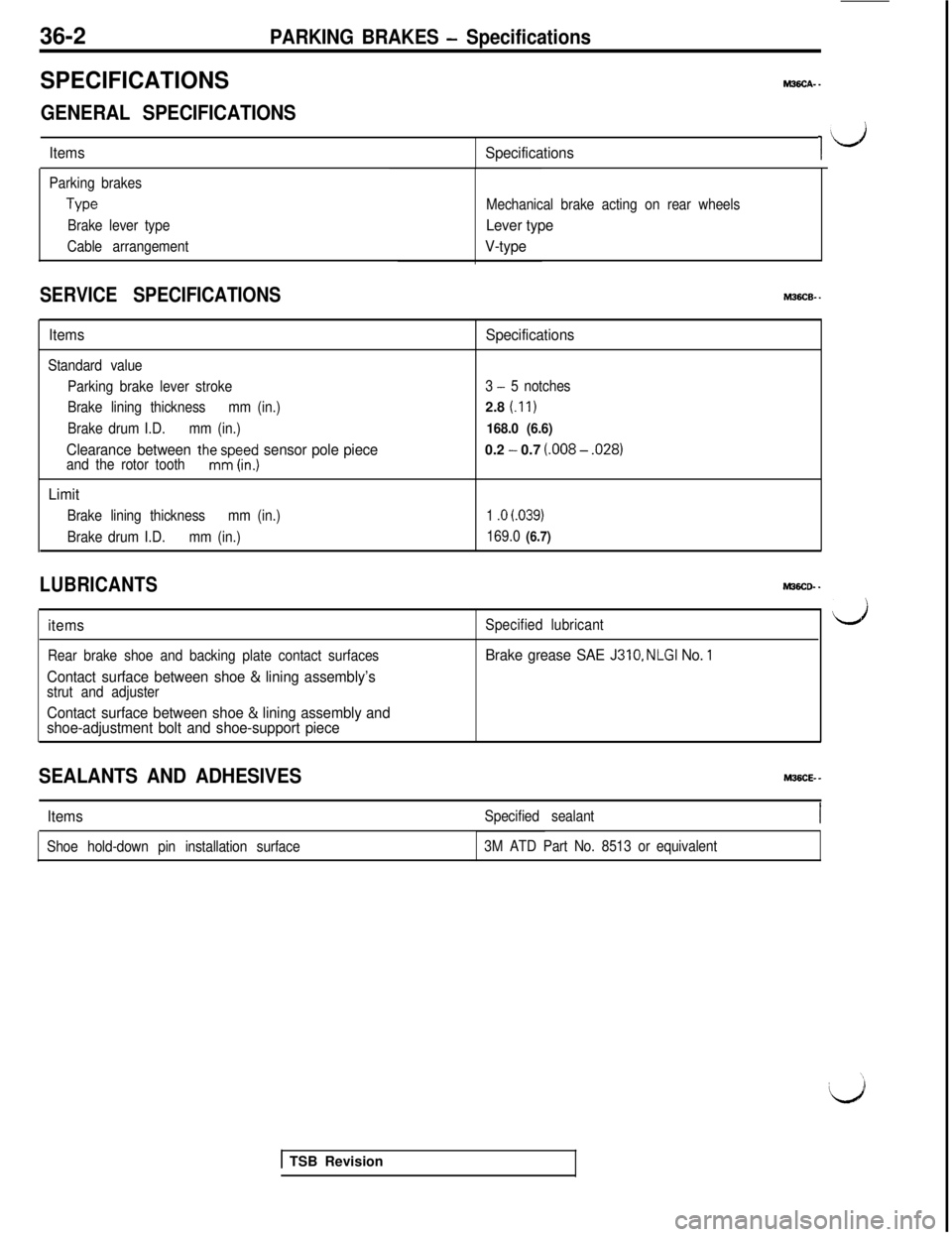

36-2PARKING BRAKES - Specifications

SPECIFICATIONSM36CA- -

GENERAL SPECIFICATIONS

ItemsSpecifications

iI”

Parking brakes

Type

Brake lever type

Cable arrangementMechanical brake acting on rear wheels

Lever type

V-type

SERVICE SPECIFICATIONSM36cB-.

Items

Standard value

Parking brake lever stroke

Brake lining thicknessmm (in.)

Brake drum I.D.mm (in.)

Clearance between th;$;;d) sensor pole pieceand the rotor tooth

Limit

Brake lining thicknessmm (in.)

Brake drum I.D.mm (in.)

Specifications

3 - 5 notches2.8

(.I 1)

168.0 (6.6)0.2

- 0.7 LOO8 - .028)

1 .o f.039)

169.0 (6.7)

LUBRICANTSM36CD- -

ditems

Rear brake shoe and backing plate contact surfaces

Contact surface between shoe & lining assembly’sstrut and adjusterSpecified lubricant

Brake grease SAE J310, NLGI No. 1

Contact surface between shoe & lining assembly and

shoe-adjustment bolt and shoe-support piece

SEALANTS AND ADHESIVES

ItemsSpecified sealant

Shoe hold-down pin installation surface3M ATD Part No. 8513 or equivalent

1 TSB Revision

Page 822 of 1146

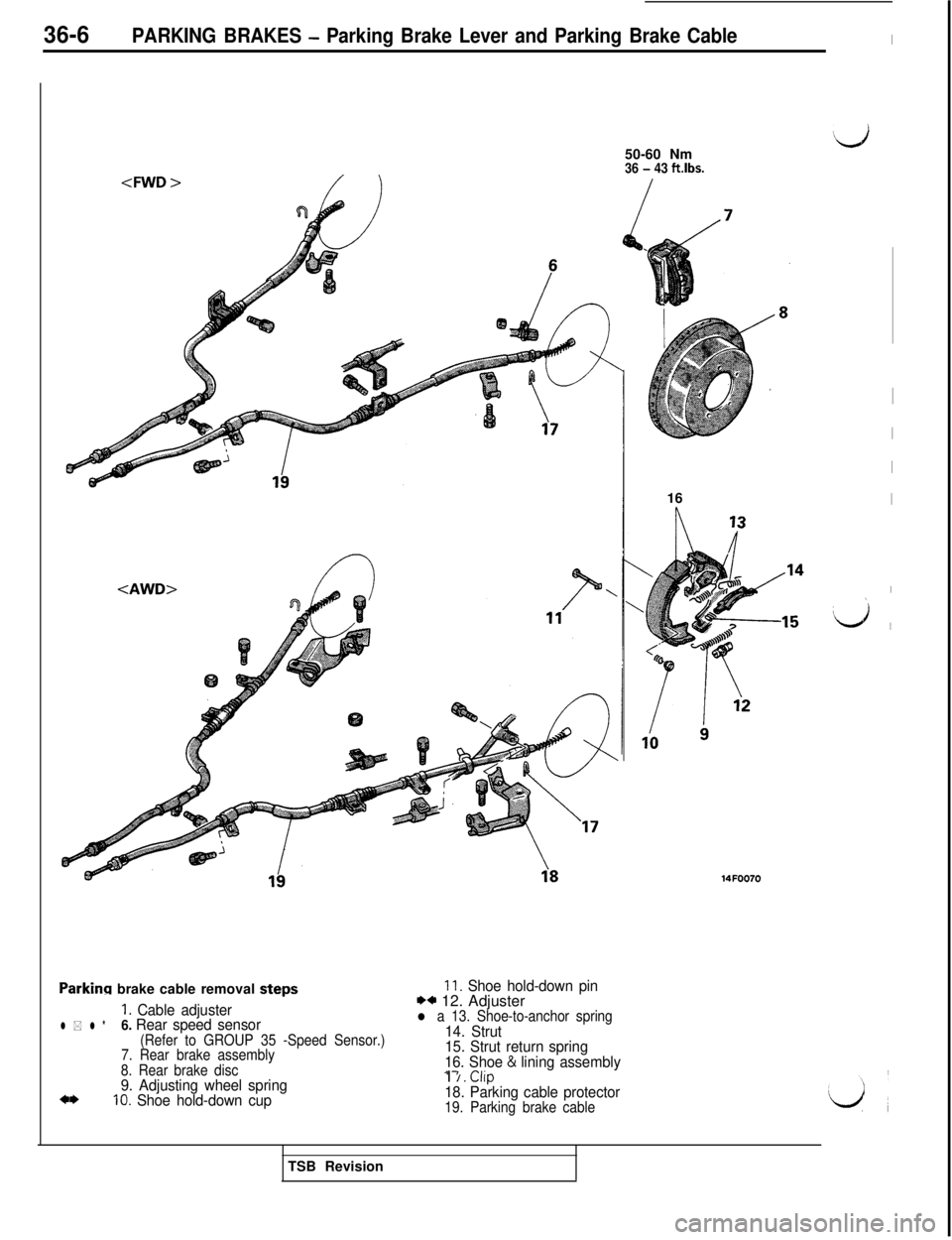

36-6PARKING BRAKES - Parking Brake Lever and Parking Brake CableI

steDs11. Shoe hold-down pin.

1. Cable adjuster** 12. Adjuster

l * l *6. Rear speed sensorl a 13. Shoe-to-anchor spring

(Refer to GROUP 35 -Speed Sensor.)14. Strut

7. Rear brake assembly15. Strut return spring

8. Rear brake disc16. Shoe & lining assembly*-I PI’.

9. Adjusting wheel spring10. Shoe hold-down cupI

/. Llrp18. Parking cable protector19. Parking brake cable16

I

I

I

I

I\

‘d ~

14FOO70TSB Revision

Page 824 of 1146

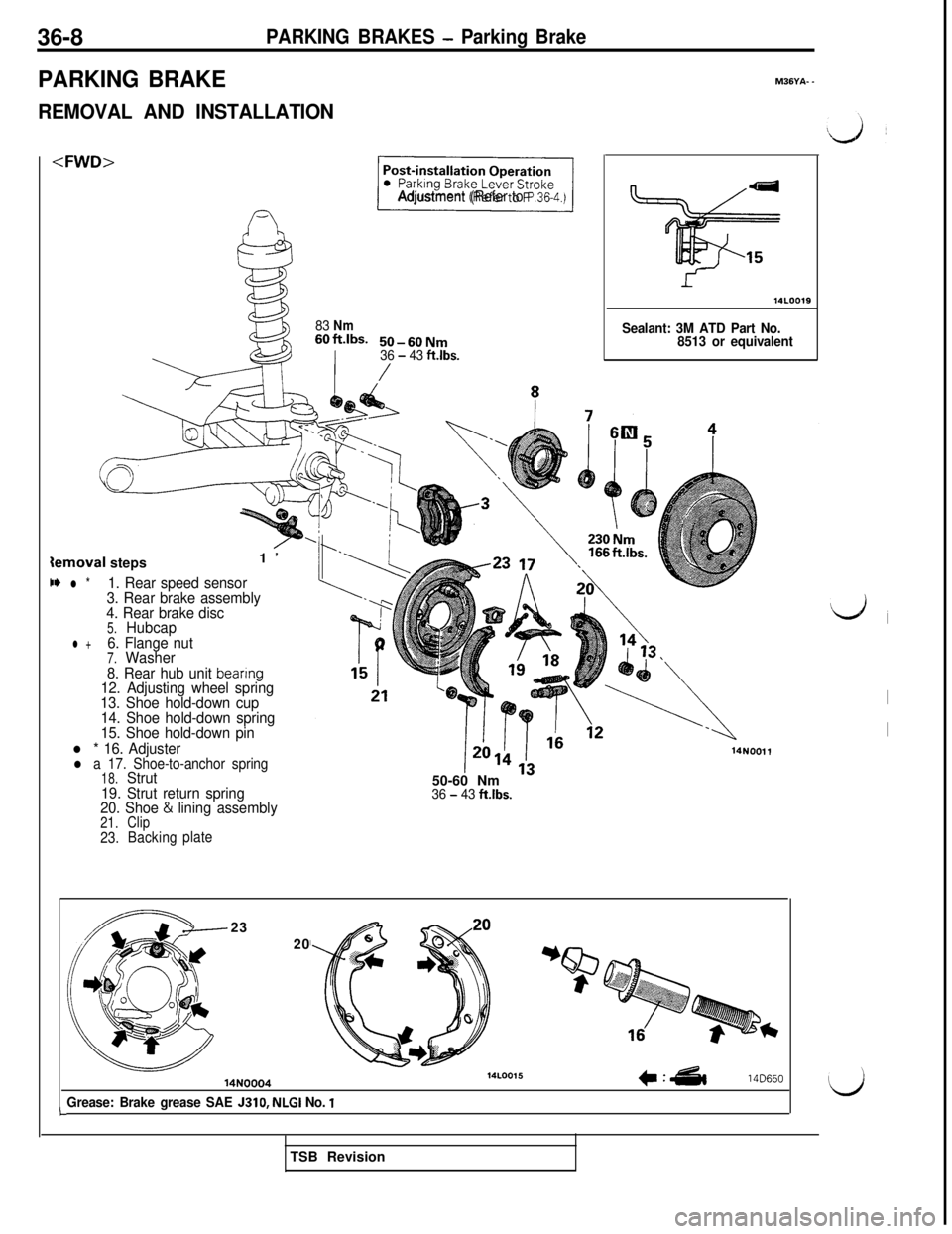

36-8PARKING BRAKES - Parking Brake

PARKING BRAKE

REMOVAL AND INSTALLATION

C* l *1. Rear speed sensor

3. Rear brake assembly

4. Rear brake disc

5.Hubcap

l +6. Flange nut7.Washer

8. Rear hub unit

beanng12. Adjusting wheel spring

13. Shoe hold-down cup

14. Shoe hold-down spring

15. Shoe hold-down pin

l * 16. Adjusterl a 17. Shoe-to-anchor spring18.Strut

19. Strut return spring

20. Shoe

& lining assembly21.Clip23.Backingplate

71

Adjustment (Refer to P.36.4.)

83 Nm60ft.lbS. 50-60Nm

36 - 43 ft.lbs.

/

M36YA- -

Sealant: 3M ATD Part No.

8513 or equivalent50-60 Nm

36 - 43 ftlbs.

14NOOll

L23

20

*

14N0004

Grease: Brake grease SAE J310, NLGI No. 1

14LOO15c:&14D650

d,

I

ITSB Revision

Page 825 of 1146

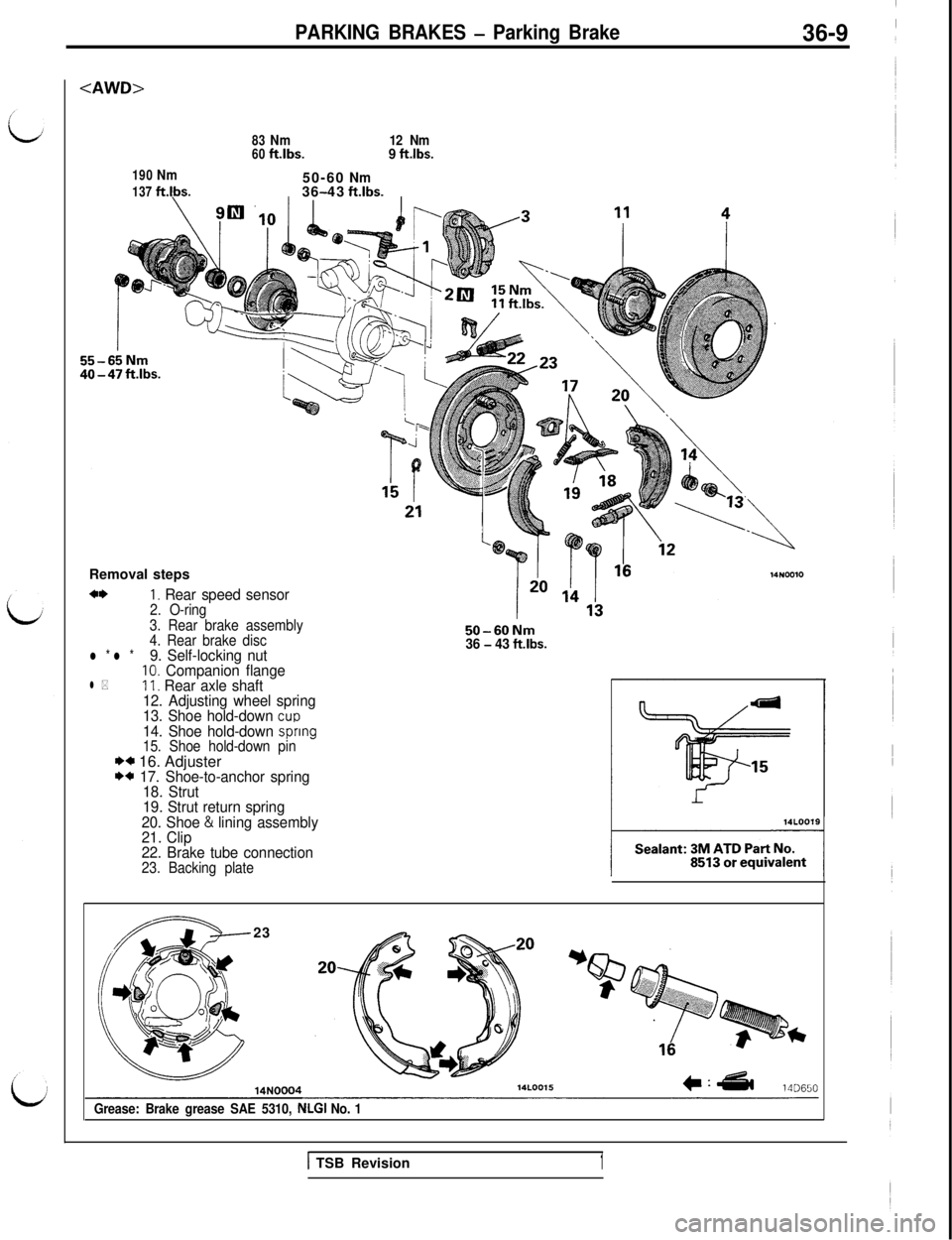

PARKING BRAKES - Parking Brake36-9

4WD>

190Nm

137ft.lbs.

83Nm12 Nm60ft.lbs.9 ft.lbs.50-60

Nm36 43-ft.lbs.Removal steps

+*I. Rear speed sensor2. O-ring

3. Rear brake assembly

4. Rear brake disc

50-60Nm36 - 43 ft.lbs.l * l *9. Self-locking nut10. Companion flangel *11. Rear axle shaft

12. Adjusting wheel spring

13. Shoe hold-down

CUD14. Shoe hold-down spnng15. Shoe hold-down pinI)* 16. AdjusterI)* 17. Shoe-to-anchor spring

18. Strut

19. Strut return spring

20. Shoe

& lining assembly

21. Clip

22. Brake tube connection

23. Backing plate23

Grease: Brake grease SAE 5310, NLGI No. 1

1 TSB Revision1

Page 826 of 1146

36-10PARKING BRAKES - Parking Brake

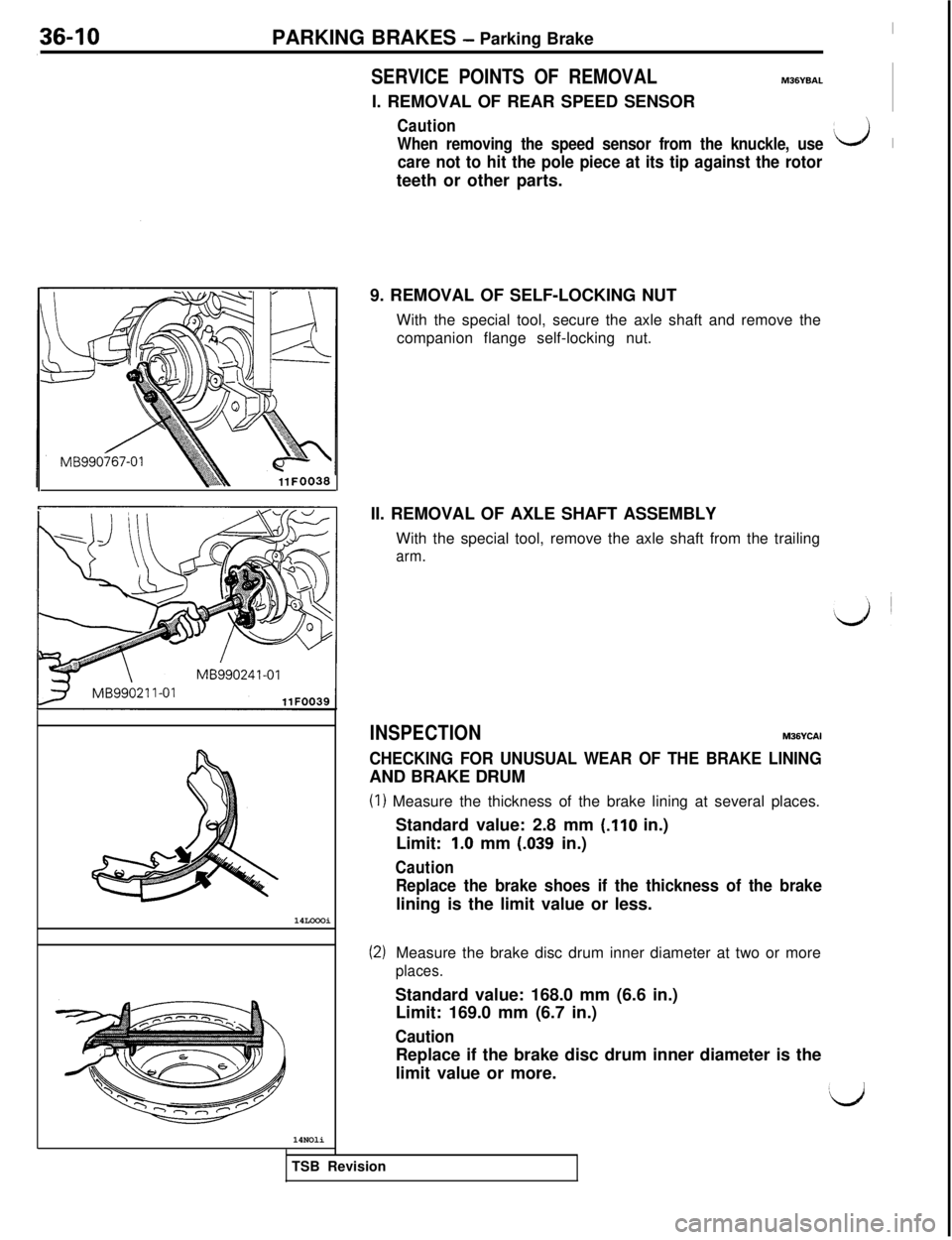

SERVICE POINTS OF REMOVALM36YBALI. REMOVAL OF REAR SPEED SENSOR

Caution

When removing the speed sensor from the knuckle, usei&J 1

care not to hit the pole piece at its tip against the rotorteeth or other parts.

11 FO03814LOOOi

14NOli9. REMOVAL OF SELF-LOCKING NUT

With the special tool, secure the axle shaft and remove the

companion flange self-locking nut.

II. REMOVAL OF AXLE SHAFT ASSEMBLY

With the special tool, remove the axle shaft from the trailing

arm.

INSPECTIONM36YCAI

CHECKING FOR UNUSUAL WEAR OF THE BRAKE LININGAND BRAKE DRUM

(1) Measure the thickness of the brake lining at several places.

Standard value: 2.8 mm

(.I10 in.)

Limit:

1.0 mm (.039 in.)

Caution

Replace the brake shoes if the thickness of the brakelining is the limit value or less.

(2)Measure the brake disc drum inner diameter at two or more

places.Standard value: 168.0 mm (6.6 in.)

Limit: 169.0 mm (6.7 in.)

CautionReplace if the brake disc drum inner diameter is the

limit value or more.

TSB Revision

Page 827 of 1146

PARKING BRAKES - Parking Brake36-11

14N000'

Spindle,

I’_14NOO05

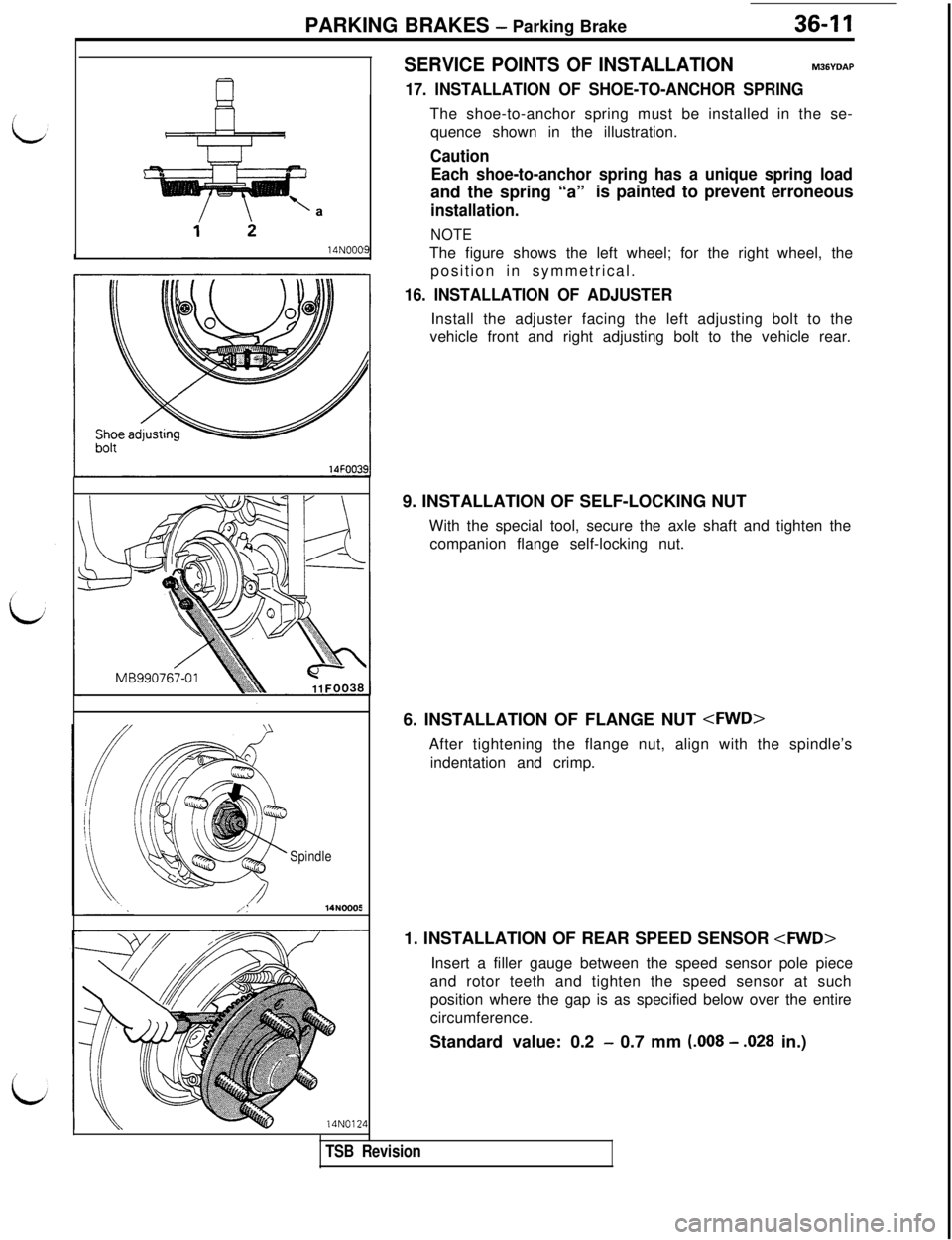

SERVICE POINTS OF INSTALLATIONM36YDAP

17. INSTALLATION OF SHOE-TO-ANCHOR SPRINGThe shoe-to-anchor spring must be installed in the se-

quence shown in the illustration.

Caution

Each shoe-to-anchor spring has a unique spring loadand the spring “a”is painted to prevent erroneous

installation.

NOTEThe figure shows the left wheel; for the right wheel, the

position in symmetrical.

16. INSTALLATION OF ADJUSTERInstall the adjuster facing the left adjusting bolt to the

vehicle front and right adjusting bolt to the vehicle rear.

9. INSTALLATION OF SELF-LOCKING NUT

With the special tool, secure the axle shaft and tighten the

companion flange self-locking nut.

6. INSTALLATION OF FLANGE NUT

indentation and crimp.

1. INSTALLATION OF REAR SPEED SENSOR

and rotor teeth and tighten the speed sensor at such

position where the gap is as specified below over the entire

circumference.

Standard value: 0.2

- 0.7 mm (.008 - .028 in.)

TSB Revision

Page 829 of 1146

37A-1

STEERING

CONTENTSM37AA-A

POWER STEERING GEAR BOX*....................17Steering Wheel Return to Center

Check................................................................8

POWER STEERING HOSES................................32Tie Rod End Ball Joint Startinq Torque

POWER STEERING OIL PUMP. .._....................28Check. . . . . . . . .._.............................. r . . . . . . . . ..I . . . . . .6Tie Rod End Ball Joint Variation Check

SERVICE ADJUSTMENT PROCEDURES5(Shaft direction)................................................5........

Bleeding............................................................10V-Belt Tension Check........................................8

Fluid Level Check............................................9SPECIAL TOOLS....................................................3Fluid Replacement

............................................9

/

bOil Pressure Switch Check

SPECIFICATIONS2............................12................................................Oil Pump Pressure Test

....................................1 1General Specifications....................................2Stationary Steering Effort Check

....................8Lubricants............................................................3Steering Angle Check

5Sealant and Adhesives....................................3........................................Steering Wheel Centering

6Service Specifications....................................2................................Steering Wheel Free Play Check

....................5STEERING WHEEL AND SHAFT*....................13

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 873 of 1146

42-1

BODY

CONTENTSM42AA- -

CENTER PILLAR GLASS........................................................32

CENTRAL DOOR LOCKING SYSTEM

................................55

DOOR ASSEMBLY....................................................................40

DOOR GLASS AND REGULATOR

........................................42

DOOR HANDLE AND LATCH

................................................54

DOOR TRIM AND WATERPROOF FILM

............................41

DRIP LINE WEATHERSTRIP....................................................65

ENGINE HOOD........................................................................18

FENDER*....................................................................................23

FUEL TANK FILLER DOOR

....................................................22

LIFTGATE....................................................................................20

LIFTGATE GLASS....................................................................37

LOOSE PANEL

........................................................................24

POWER WINDOW

....................................................................43

QUARTER WINDOW GLASS

................................................33SERVICE ADJUSTMENT PROCEDURES

............................

Door Adjustment................................................................Door inside Handle Play Check............................................Door Window Glass Adjustment........................................Floor Pan inspection............................................................Fuel Filler Door Adjustment................................................Hood Adjustment................................................................Liftgate Adjustment............................................................

SPECIAL TOOLS........................................................................

SPECIFICATIONS....................................................................

General Specifications........................................................Sealants and Adhesives........................................................

ServiceSpecifications........................................................

TROUBLESHOOTING............................................................

WINDOW GLASS....................................................................

WINDSHIELD............................................................................

13

14

16

14

17

14

13

13

4

2

2

3

3

5

25

28

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

SRS or any SRS-related component.

Page 970 of 1146

EXTERIOR - Windshield Wiper and Washer

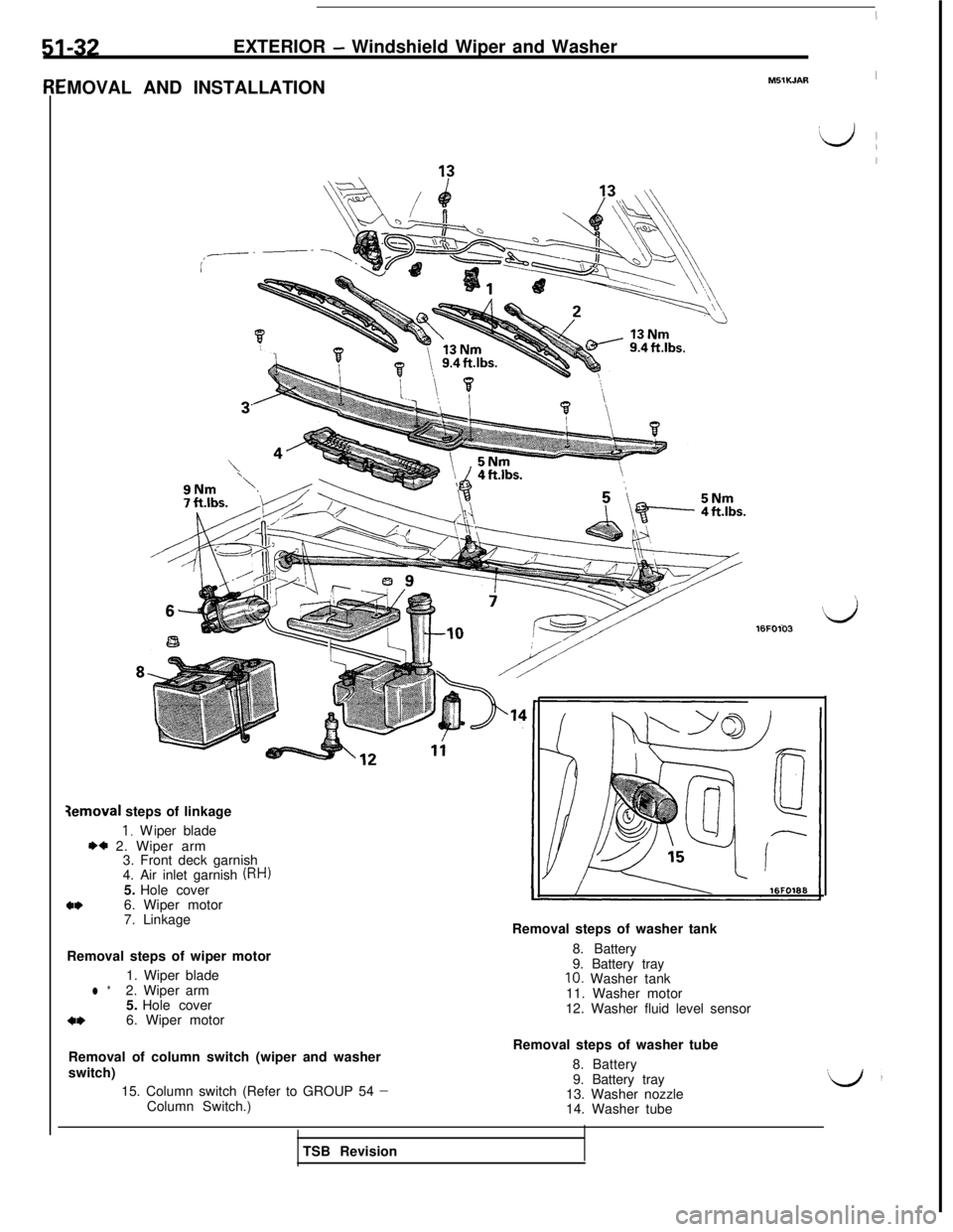

MOVAL AND INSTALLATIONY5lK.JAR

I

‘LJ (

I

\

9Nm7 ft.lbs.

3emoval steps of linkage

I. Wiper blade

I)* 2. Wiper arm

3. Front deck garnish

4. Air inlet garnish

(RH)5. Hole cover

a*6. Wiper motor16FO103

7. Linkage

Removal steps of wiper motor

1. Wiper blade

l *2. Wiper arm

5. Hole cover

*I)6. Wiper motorRemoval steps of washer tank

8. Battery

9. Battery tray

10. Washer tank

11. Washer motor

12. Washer fluid level sensor

Removal of column switch (wiper and washer

switch)

15. Column switch (Refer to GROUP 54

-Column Switch.)

TSB RevisionRemoval steps of washer tube

8. Battery

9. Battery tray

13. Washer nozzle

14. Washer tube

Page 972 of 1146

51-34

EXTERIOR - Windshield Wiper and Washer

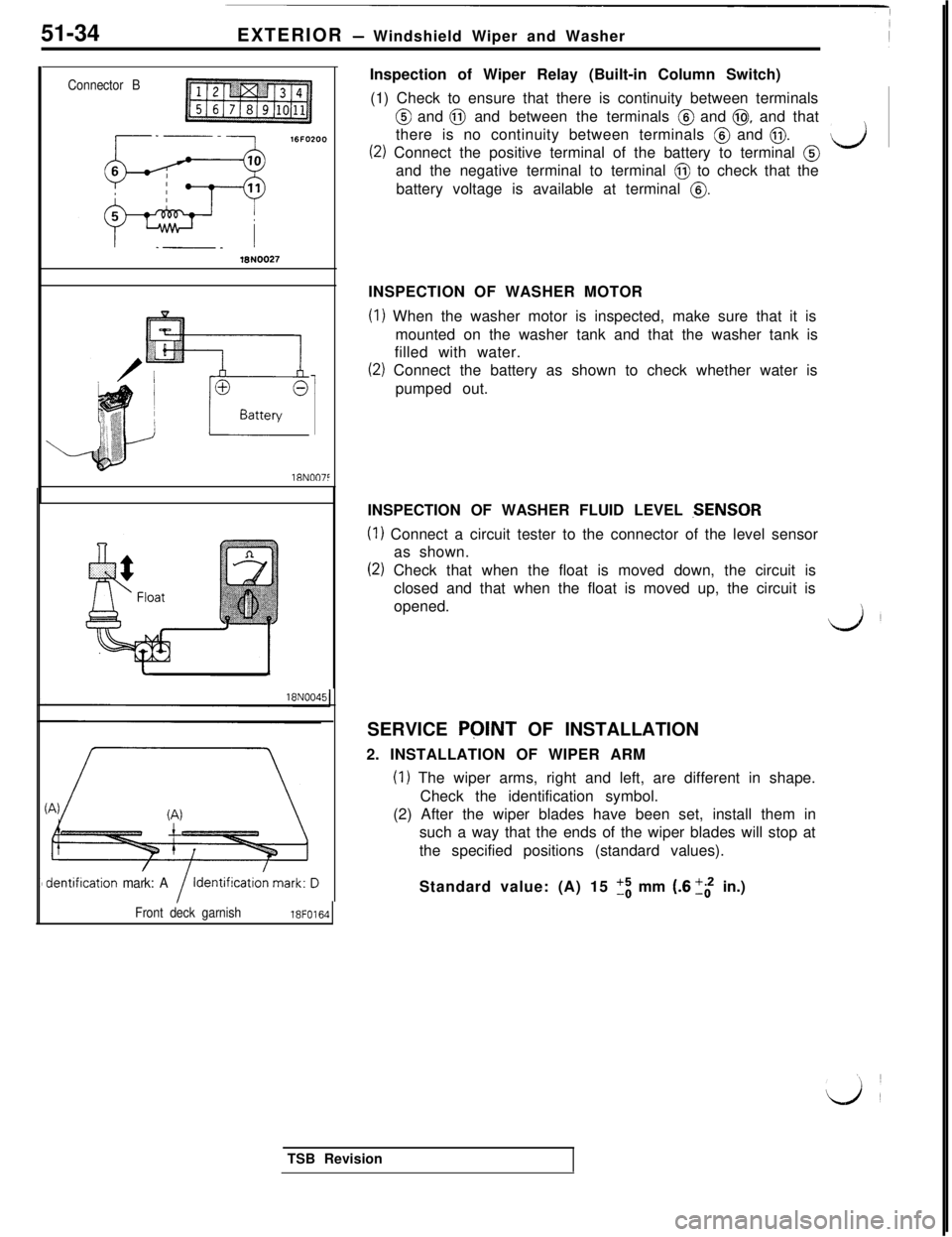

Connector B

-____1.310027lXN007t

1

dentification mark: AInspection of Wiper Relay (Built-in Column Switch)

(1) Check to ensure that there is continuity between terminals@ and @ and between the terminals @ and

@, and that

there is no continuity between terminals @ and

@.

(2) Connect the positive terminal of the battery to terminal @dand the negative terminal to terminal @ to check that the

battery voltage is available at terminal

@.INSPECTION OF WASHER MOTOR

(I) When the washer motor is inspected, make sure that it is

mounted on the washer tank and that the washer tank is

filled with water.

(2) Connect the battery as shown to check whether water is

pumped out.

INSPECTION OF WASHER FLUID LEVEL

,SENSOR

(1) Connect a circuit tester to the connector of the level sensor

as shown.

(2) Check that when the float is moved down, the circuit is

closed and that when the float is moved up, the circuit is

opened.

Front deck garnish18FO164SERVICE POINT OF INSTALLATION

2. INSTALLATION OF WIPER ARM

(1) The wiper arms, right and left, are different in shape.

Check the identification symbol.

(2) After the wiper blades have been set, install them in

such a way that the ends of the wiper blades will stop at

the specified positions (standard values).

Standard value: (A) 15

tz mm (.6 tf in.)

dTSB Revision