sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 443 of 1146

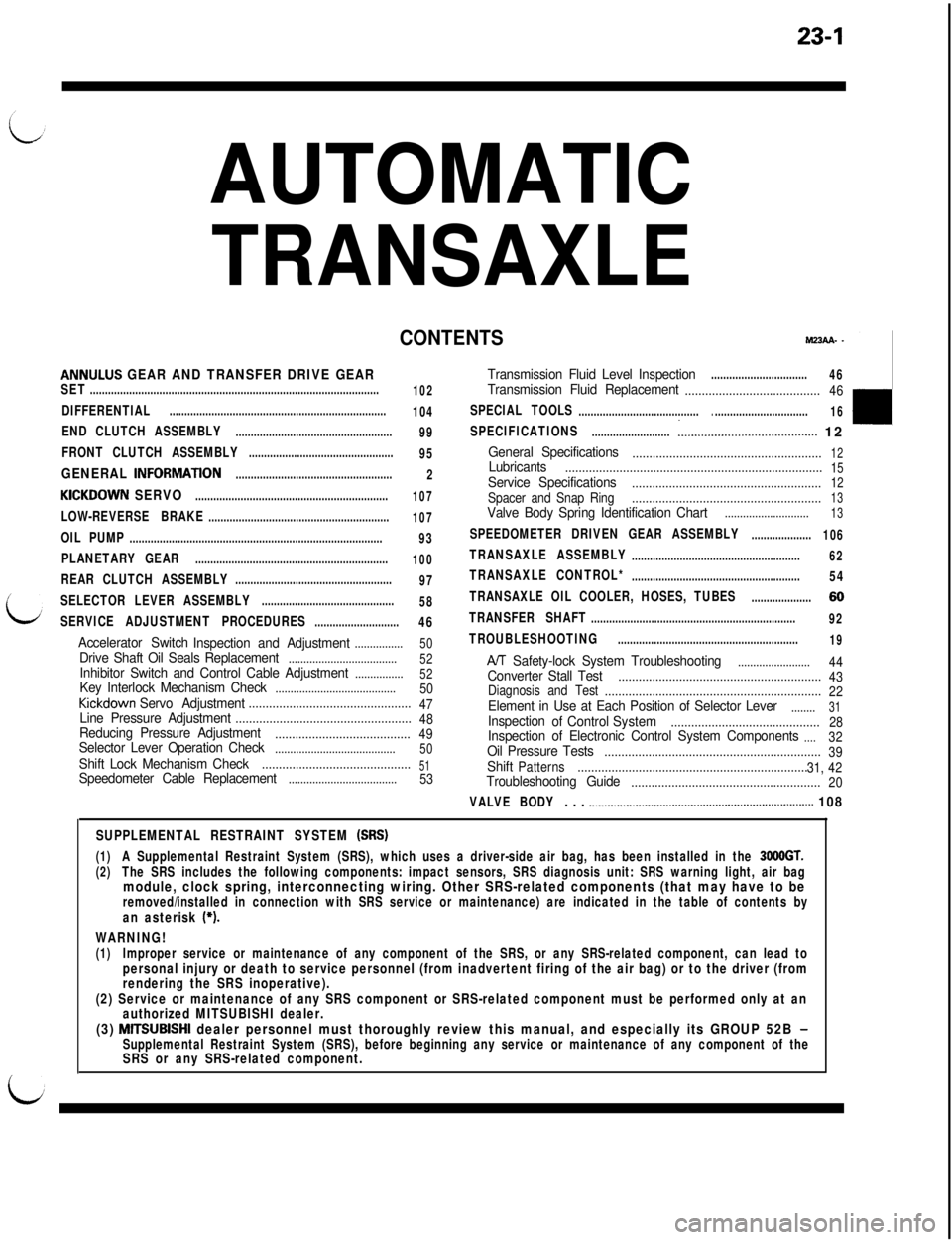

23-1

AUTOMATIC

TRANSAXLE

CONTENTSMZJAA- _

ANNULUS GEAR AND TRANSFER DRIVE GEARTransmission Fluid Level Inspection................................46SET................................................................................................

102Transmission Fluid Replacement........................................

46

DIFFERENTIAL........................................................................104SPECIAL TOOLS........................................................................

16

:......................................... 12IEND CLUTCH ASSEMBLY....................................................99SPECIFICATIONS..........................

FRONT CLUTCH ASSEMBLY................................................95

GENERAL INFORMATlON....................................................2

KICKDOWN SERVO................................................................

107

LOW-REVERSE BRAKE............................................................

107

OIL PUMP....................................................................................93

PLANETARY GEAR................................................................

100

REAR CLUTCH ASSEMBLY....................................................97

SELECTOR LEVER ASSEMBLY............................................58

SERVICE ADJUSTMENT PROCEDURES............................46

Accelerator Switch

Inspection and Adjustment................

50Drive Shaft Oil Seals Replacement....................................

52Inhibitor Switch and Control Cable Adjustment................

52Key Interlock Mechanism Check........................................50KickdownServo Adjustment................................................

47Line Pressure Adjustment....................................................

48Reducing Pressure Adjustment........................................

49Selector Lever Operation Check........................................

50Shift Lock Mechanism Check............................................51Speedometer Cable Replacement....................................53

General Specifications........................................................12Lubricants............................................................................15Service Specifications........................................................12Spacer and Snap Ring........................................................13Valve Body Spring Identification Chart............................13

SPEEDOMETER DRIVEN GEAR ASSEMBLY....................106

TRANSAXLE ASSEMBLY........................................................62

TRANSAXLE CONTROL*........................................................54

TRANSAXLE OIL COOLER, HOSES, TUBES

....................66

TRANSFER SHAFT....................................................................92

TROUBLESHOOTING............................................................

19

A/T Safety-lock System Troubleshooting........................44Converter Stall Test............................................................

43

Diagnosis and Test

................................................................

22

Element in Use at Each Position of Selector Lever........31Inspection

of ControlSystem............................................

28Inspection of Electronic Control System Components....32Oil Pressure Tests................................................................

39ShiftPatterns....................................................................

31,42Troubleshooting Guide........................................................

20

VALVE BODY. . . .._._.................................................................... 108

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3668GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to beremoved/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead topersonal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from

rendering the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

(3) MlTSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of the

ISRS or any SRS-related component.

Page 471 of 1146

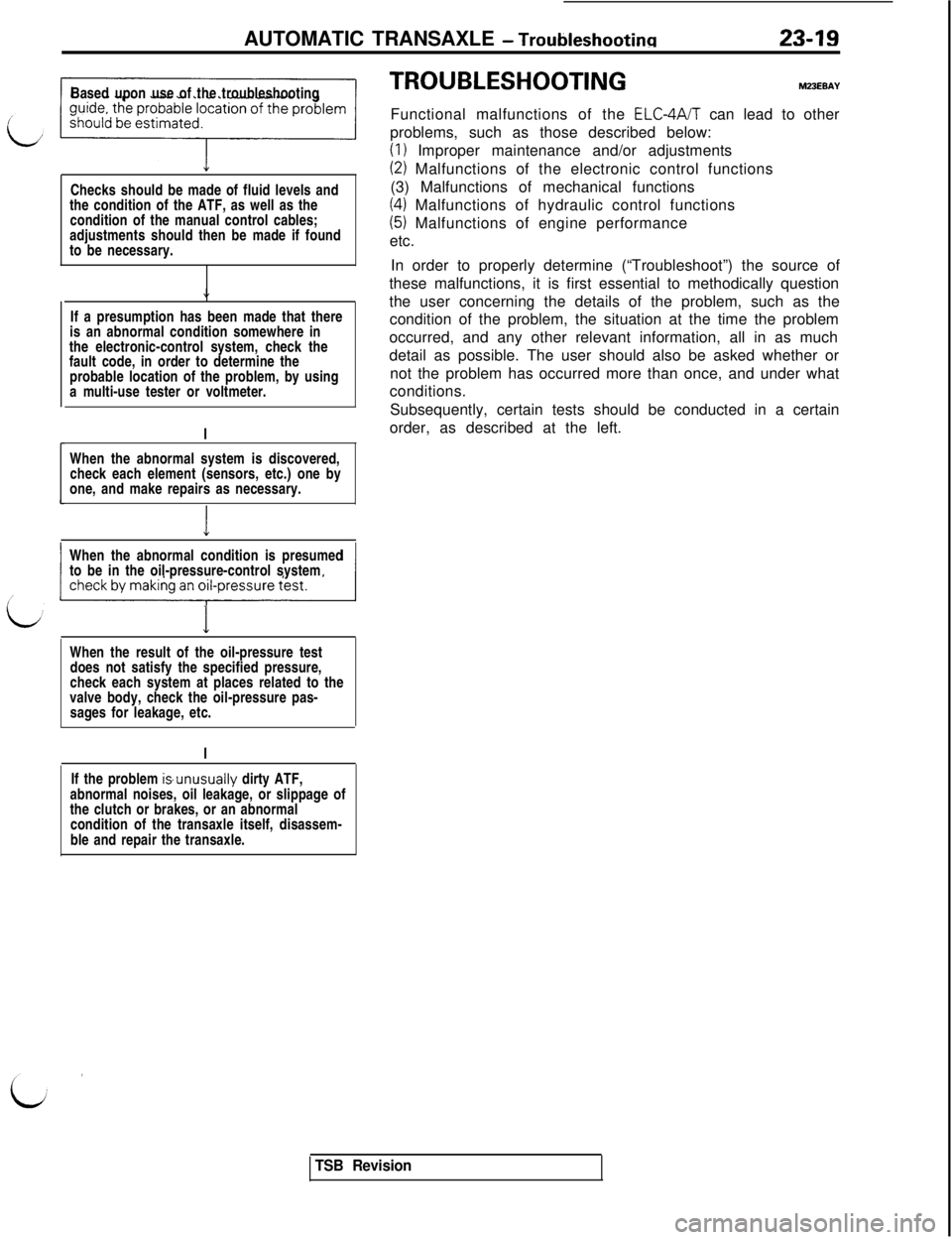

AUTOMATIC TRANSAXLE - Troubleshootincl23-19Based upon use of the troubleshooting

Checks should be made of fluid levels and

the condition of the ATF, as well as the

condition of the manual control cables;

adjustments should then be made if found

to be necessary.

If a presumption has been made that there

is an abnormal condition somewhere in

the electronic-control system, check the

fault code, in order to determine the

probable location of the problem, by using

a multi-use tester or voltmeter.

I

When the abnormal system is discovered,

check each element (sensors, etc.) one by

one, and make repairs as necessary.

IWhen the abnormal condition is presumed

to be in the oil-pressure-control system

When the result of the oil-pressure test

does not satisfy the specified pressure,

check each system at places related to the

valve body, check the oil-pressure pas-

sages for leakage, etc.

I

If the problem isunusually dirty ATF,

abnormal noises, oil leakage, or slippage of

the clutch or brakes, or an abnormal

condition of the transaxle itself, disassem-

ble and repair the transaxle.

TROUBLESHOOTINGM23EEAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:(I

) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.

In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically question

the user concerning the details of the problem, such as the

condition of the problem, the situation at the time the problem

occurred, and any other relevant information, all in as much

detail as possible. The user should also be asked whether or

not the problem has occurred more than once, and under what

conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

TSB Revision

Page 472 of 1146

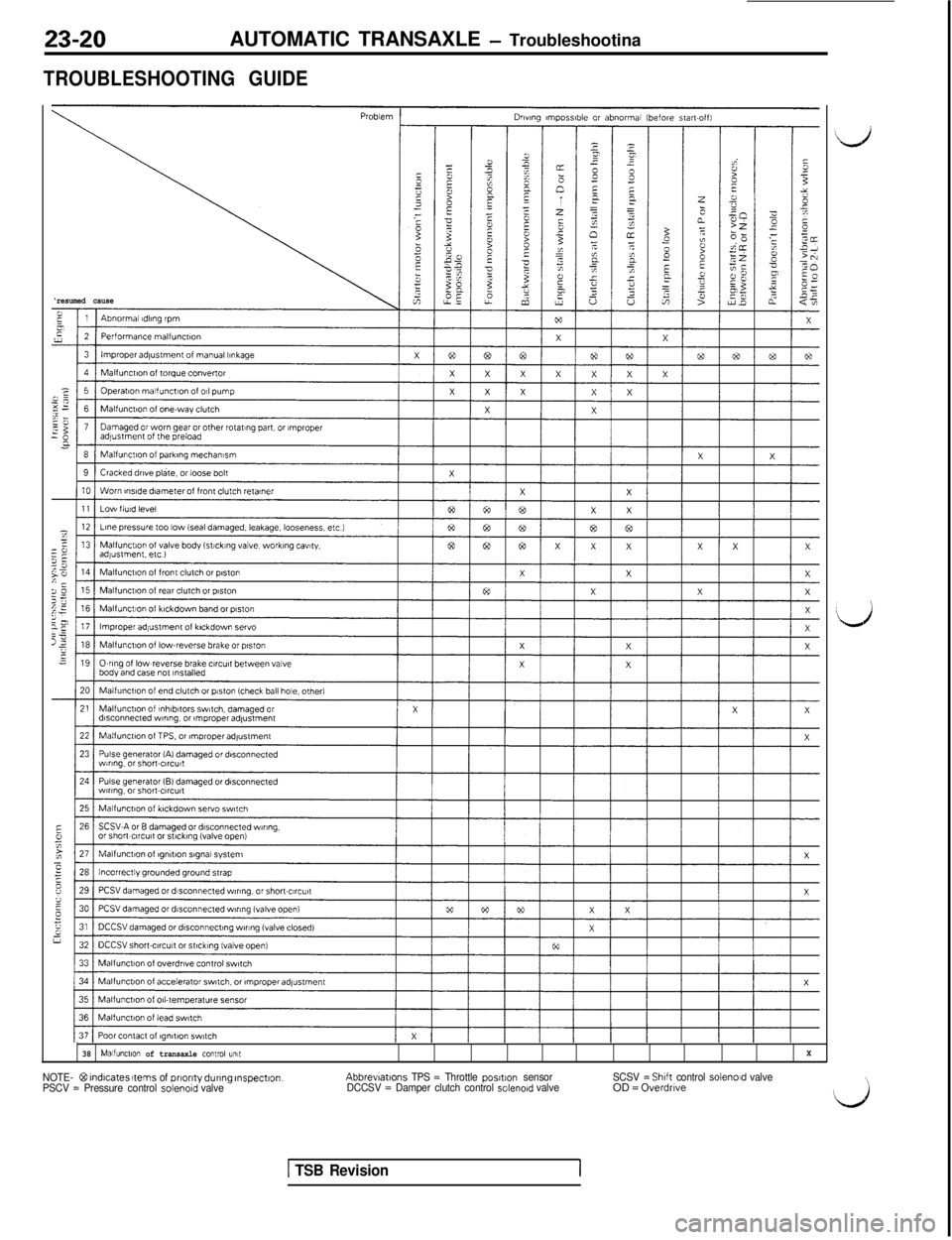

23-20AUTOMATIC TRANSAXLE - Troubleshootina

TROUBLESHOOTING GUIDE

‘resumed cause

38Malfunction of transaxle control unttX

NOTE- @ indicates items of prlortty during Inspection.PSCV = Pressure control solenoid valveAbbrewatlons TPS = Throttle powon sensor

DCCSV = Damper clutch control solenoid valveSCSV = Shift control solenoid valveOD = Overdwe

1 TSB Revision

Page 476 of 1146

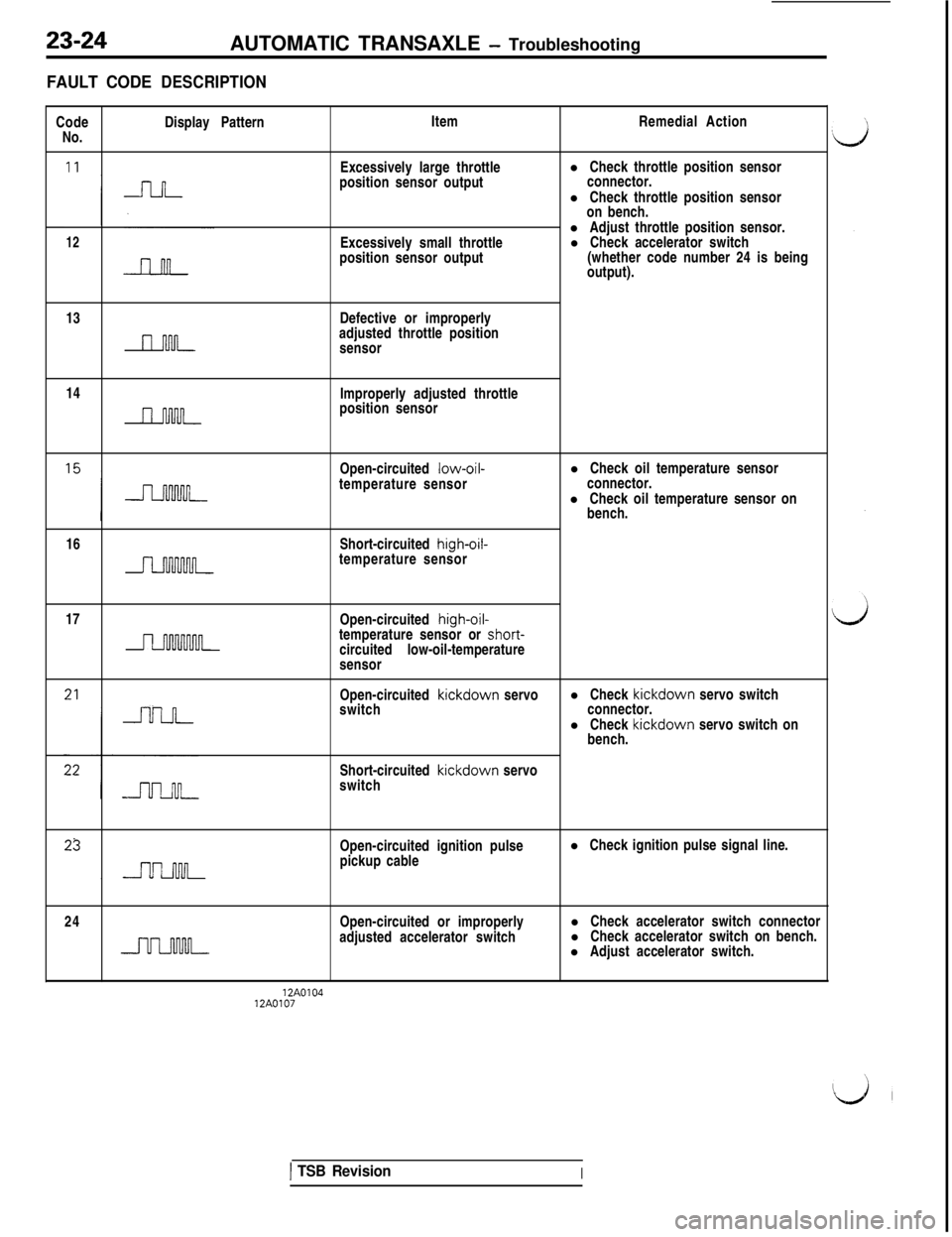

23-24AUTOMATIC TRANSAXLE - Troubleshooting

FAULT CODEDESCRIPTIONCode

No.Display PatternItemRemedial Action

Excessively large throttle

position sensor outputl Check throttle position sensor

connector.

l Check throttle position sensor

on bench.

12Excessively small throttle

position sensor outputl Adjust throttle position sensor.

l Check accelerator switch

(whether code number 24 is being

output).

13Defective or improperly

adjusted throttle position

sensor

14

Improperly adjusted throttle

position sensor

Open-circuited low-oil-

temperature sensorl Check oil temperature sensor

connector.

l Check oil temperature sensor on

bench.

16Short-circuited high-oil-

I-lMnnM-.temperature sensor

17

Open-circuited high-oil-

rlnnnruuvltemperature sensor or short-

circuited low-oil-temperature

sensor

Open-circuited kickdown servo

switch

Short-circuited kickdown servo

switchl Check kickdown servo switch

connector.

l Check kickdown servo switch on

bench.

Open-circuited ignition pulse

pickup cablel Check ignition pulse signal line.

24Open-circuited or improperly

adjusted accelerator switchl Check accelerator switch connector

l Check accelerator switch on bench.

l Adjust accelerator switch.

12A010412A0107

1 TSB RevisionI

Page 480 of 1146

23-28AUTOMATIC TRANSAXLE - Troubleshooting

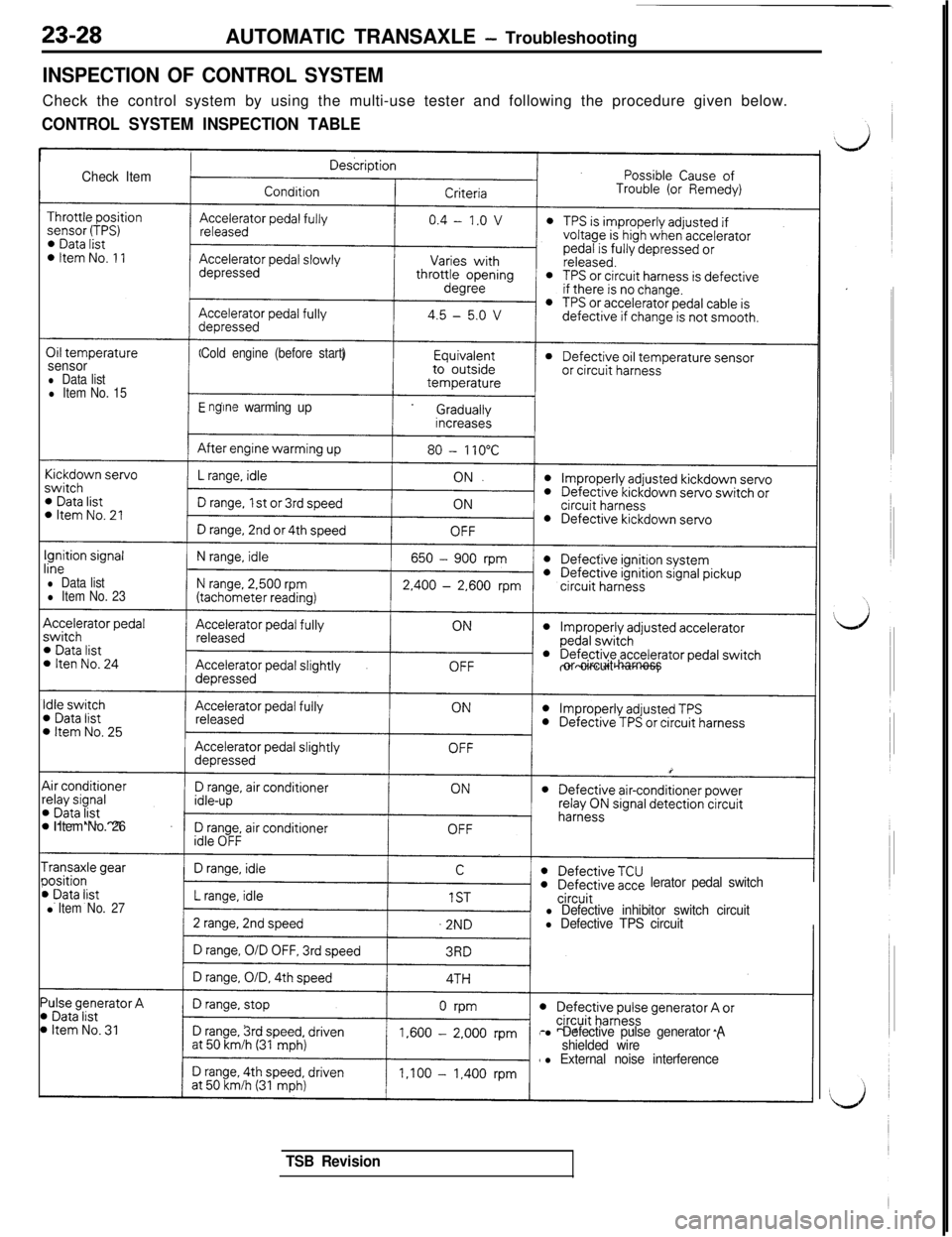

INSPECTION OF CONTROL SYSTEMCheck the control system by using the multi-use tester and following the procedure given below.

CONTROL SYSTEM INSPECTION TABLE

Check Item

sensor

l Data listl Item No. 15Cold engine (before start)nglne warming up

l Data listl Item No. 23

or circuitharness

Item No. 26

lerator pedal switchl

Item No. 27l Defective inhibitor switch circuitl Defective TPS circuitl

Defective pulse generator A

shielded wire

l External noise interference

TSB Revision

Page 482 of 1146

23-30AUTOMATIC TRANSAXLE - Troubleshooting

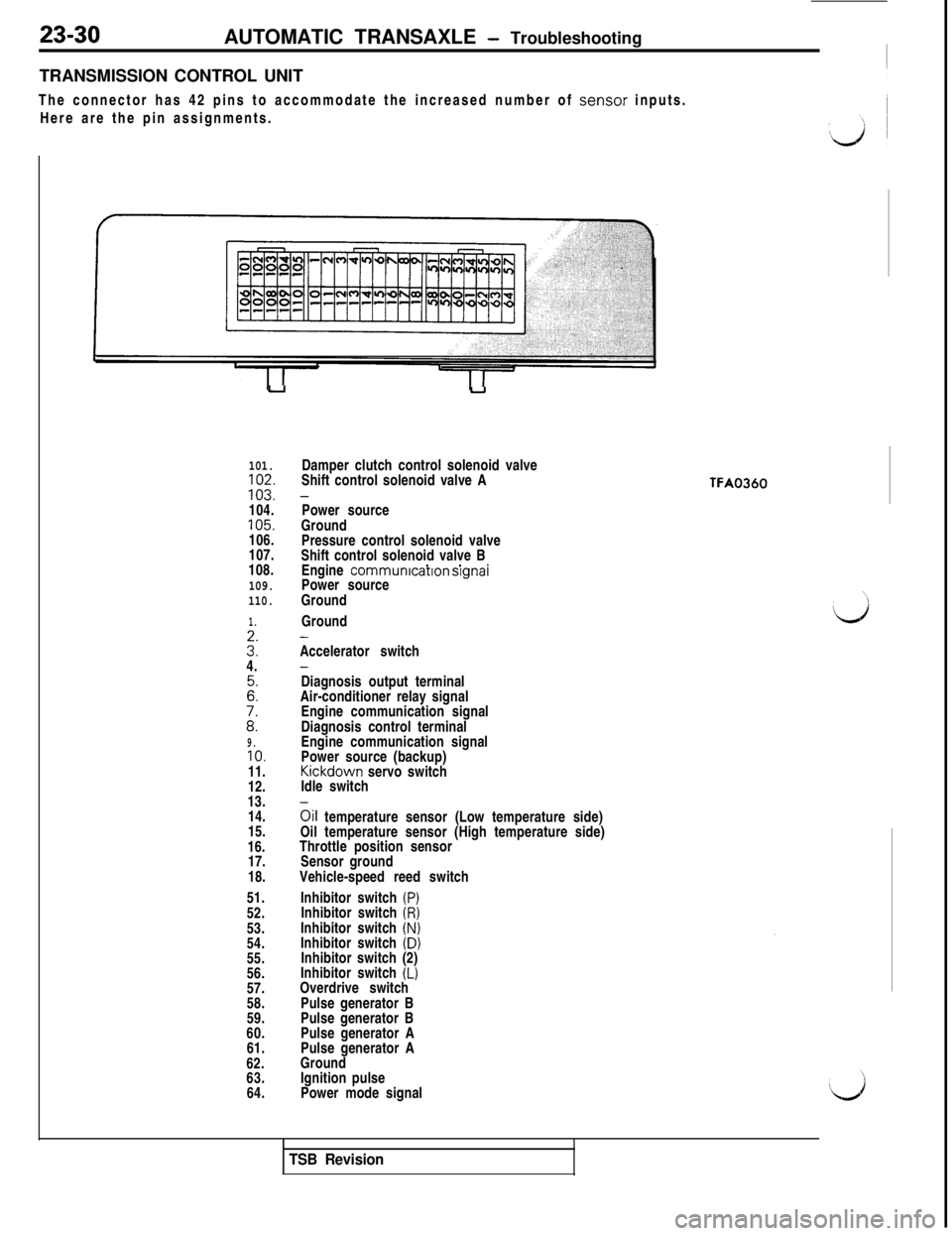

TRANSMISSION CONTROL UNIT

The connector has 42 pins to accommodate the increased number of senso.r inputs.

Here are the pin assignments.

uu

101.102.103.

104.105.

106.

107.

108.

109.

110.

1.

3':4.

Z:

i:9.10.11.

12.

13.

14.

15.

16.

17.

18.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.Damper clutch control solenoid valve

Shift control solenoid valve A

-Power source

Ground

Pressure control solenoid valve

Shift control solenoid valve B

. .

*Engine communrcatron srgnaiPower source

Ground

Ground

-Accelerator switch

-Diagnosis output terminal

Air-conditioner relay signal

Engine communication signal

Diagnosis control terminal

Engine communication signal

Power source (backup)Kickdown servo switch

Idle switch

oil temperature sensor (Low temperature side)

Oil temperature sensor (High temperature side)

Throttle position sensor

Sensor ground

Vehicle-speed reed switch

Inhibitor switch

(P)Inhibitor switch (R)Inhibitor switch (N)Inhibitor switch (D)

Inhibitor switch (2)

Inhibitor switch

(L)Overdrive switch

Pulse generator B

Pulse generator B

Pulse generator A

Pulse generator A

Ground

Ignition pulse

Power mode signal

TFA0360

TSB Revision

Page 484 of 1146

23-32AUTOMATIC TRANSAXLE - Troubleshooting

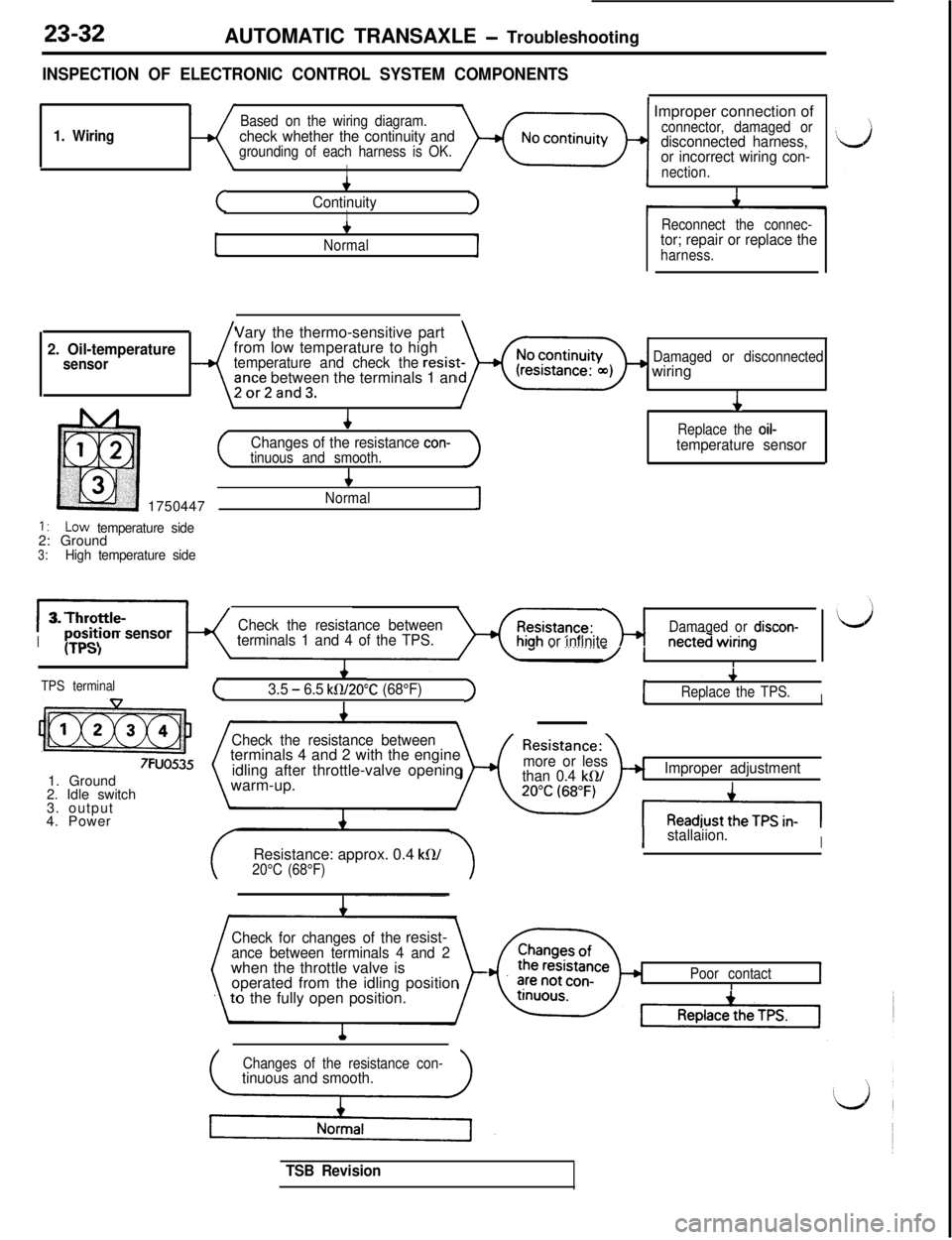

INSPECTION OF ELECTRONIC CONTROL SYSTEM COMPONENTS

1. WiringBased on the wiring diagram.check whether the continuity andgrounding of each harness is OK.

I

(

4

ContinuityII

+

Normal~ Improper connection of

connector, damaged ordisconnected harness,

or incorrect wiring con-

nection.

I

Reconnect the connec-tor; repair or replace theharness.Vary the thermo-sensitive part

2. Oil-temperaturefrom low temperature to highsensortemperature and check theresist-Damaged or disconnected

ante between the terminals 1 anwiring2or2and3.

4

J

Changes of the resistance con-Replace the oil-

tinuous and smooth.temperature sensor

41750447

Normal1

1:LOW temperature side2: Ground

3:High temperature side

I:3. Throttle-

K

Check the resistance between

Ip~~~t,ion sensorterminals 1 and 4 of the TPS.hiah or infinitem- -----inecteciI-

\ IDamaged or discon-..----Awiring

I

c3.5 - 6.5 kW20”C (68°F)t

v

Replace the TPS.I>ITPS terminal

7FUO5351. Ground

2. Idle switch

3. output

4. Power

Check the resistance betweenterminals 4 and 2 with the engine

idling after throttle-valve opening

warm-up.

Resistance: approx. 0.4

kR/20°C (68°F)

Changes of the resistance con-

tinuous and smooth.

/Resistance:\more or less

than 0.4 kQ/Improper adjustment

Istallaiion.I

Check for changes of theresist-ance between terminals 4 and 2when the throttle valve is

operated from the idling position

o the fully open position.

Poor contactII

TSB Revision

Page 500 of 1146

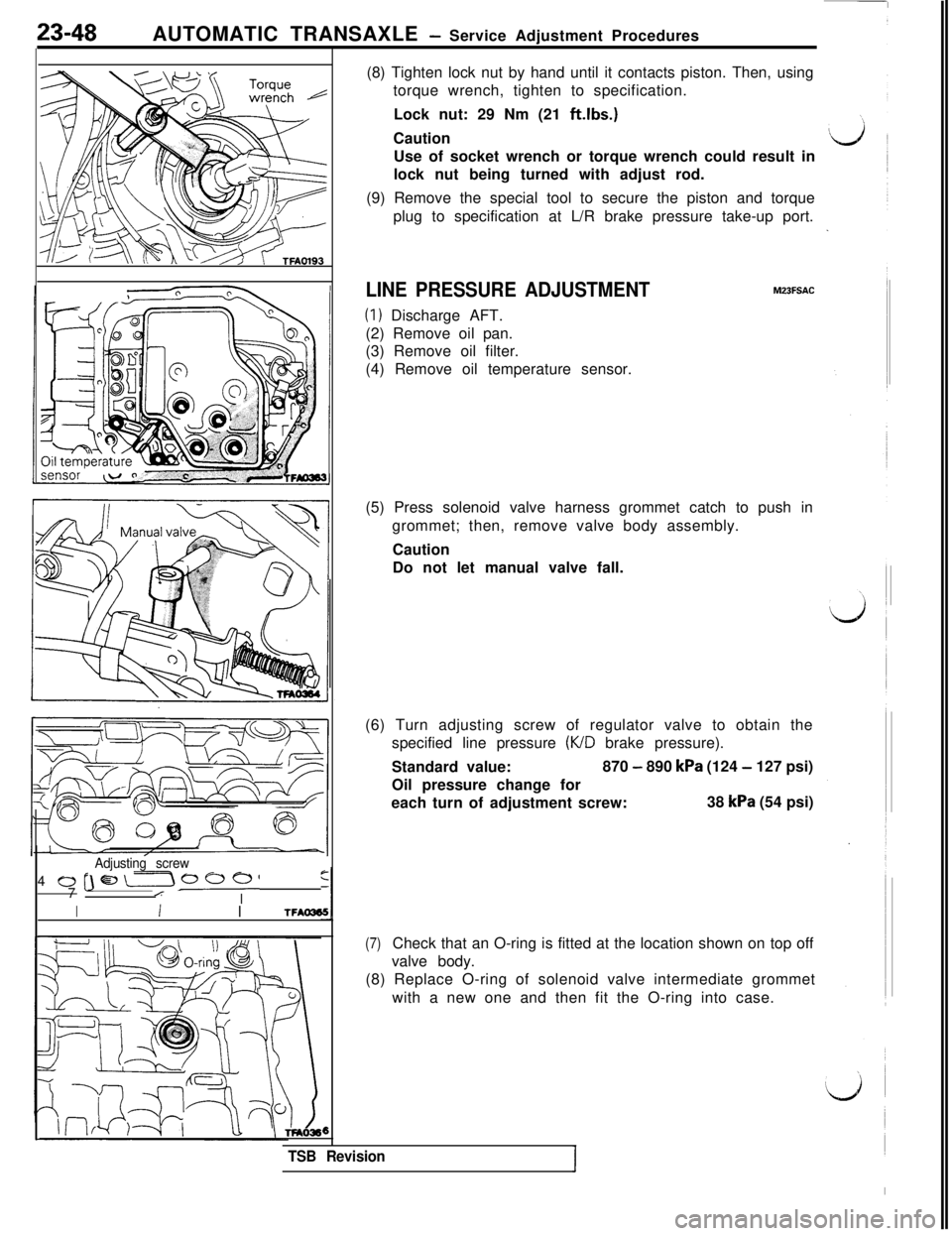

23-48AUTOMATIC TRANSAXLE - Service Adjustment Procedures

Adjusting screw4

or~0\====m00~7/IIIITFAm

c-1

Pi(8) Tighten lock nut by hand until it contacts piston. Then, using

torque wrench, tighten to specification.

Lock nut: 29 Nm (21

ftlbs.)Caution

Use of socket wrench or torque wrench could result in

lock nut being turned with adjust rod.

(9) Remove the special tool to secure the piston and torque

plug to specification at L/R brake pressure take-up port.

LINE PRESSURE ADJUSTMENT

(I) Discharge AFT.

(2) Remove oil pan.

(3) Remove oil filter.

(4) Remove oil temperature sensor.

M23FSAC(5) Press solenoid valve harness grommet catch to push in

grommet; then, remove valve body assembly.

Caution

Do not let manual valve fall.

(6) Turn adjusting screw of regulator valve to obtain the

specified line pressure

(K/D brake pressure).

Standard value:870

- 890 kPa (124 - 127 psi)

Oil pressure change for

each turn of adjustment screw:38

kPa (54 psi)

(7)Check that an O-ring is fitted at the location shown on top off

valve body.

(8) Replace O-ring of solenoid valve intermediate grommet

with a new one and then fit the O-ring into case.6

TSB RevisionI

Page 501 of 1146

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-49

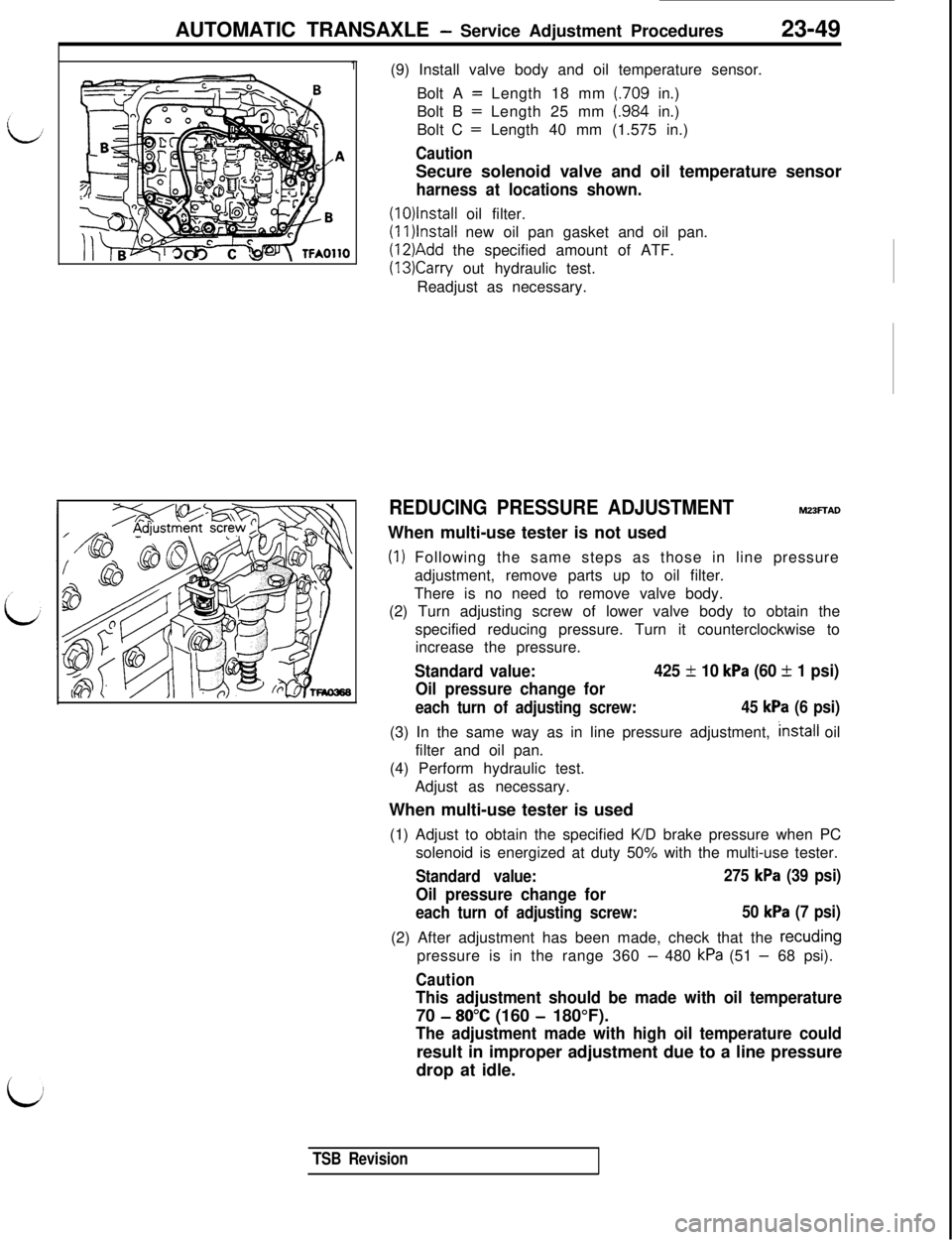

1(9) Install valve body and oil temperature sensor.

Bolt A

= Length 18 mm (.709 in.)

Bolt B

= Length 25 mm (.984 in.)

Bolt C

= Length 40 mm (1.575 in.)

CautionSecure solenoid valve and oil temperature sensor

harness at locations shown.

(1O)lnstall oil filter.(1l)lnstall new oil pan gasket and oil pan.

(12)Add the specified amount of ATF.

(13)Carry out hydraulic test.

Readjust as necessary.

REDUCING PRESSURE ADJUSTMENTh323FfADWhen multi-use tester is not used

(1) Following the same steps as those in line pressure

adjustment, remove parts up to oil filter.

There is no need to remove valve body.

(2) Turn adjusting screw of lower valve body to obtain the

specified reducing pressure. Turn it counterclockwise to

increase the pressure.

Standard value:425 f 10 kPa (60 f 1 psi)

Oil pressure change for

each turn of adjusting screw:45 kPa (6 psi)(3) In the same way as in line pressure adjustment,

/nstall oil

filter and oil pan.

(4) Perform hydraulic test.

Adjust as necessary.

When multi-use tester is used

(1) Adjust to obtain the specified K/D brake pressure when PC

solenoid is energized at duty 50% with the multi-use tester.

Standard value:275 kPa (39 psi)

Oil pressure change for

each turn of adjusting screw:50 kPa (7 psi)(2) After adjustment has been made, check that the recuding

pressure is in the range 360

- 480 kPa (51 - 68 psi).

Caution

This adjustment should be made with oil temperature70

- 80°C (160 - 180°F).

The adjustment made with high oil temperature couldresult in improper adjustment due to a line pressure

drop at idle.

TSB Revision

Page 514 of 1146

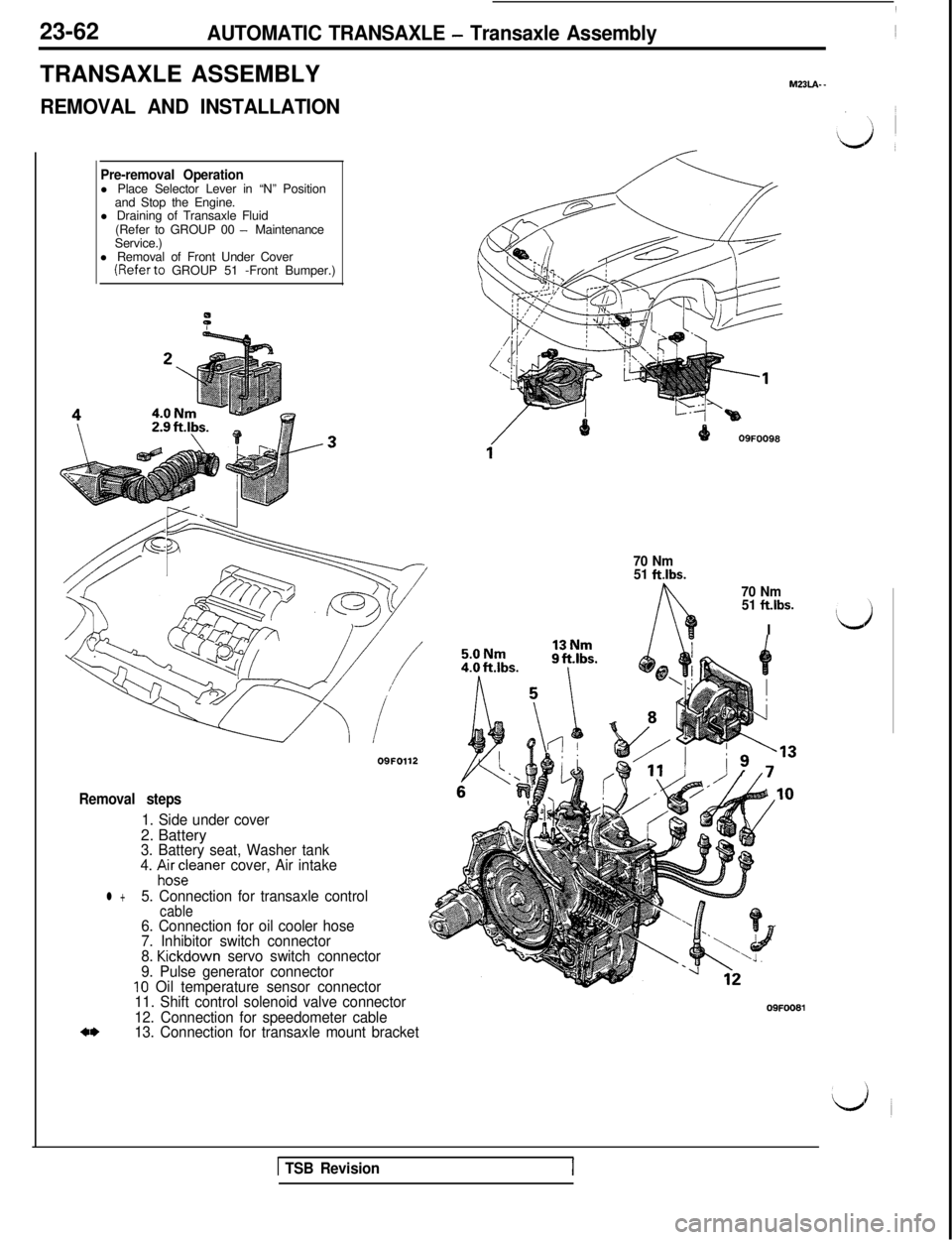

23-62AUTOMATIC TRANSAXLE - Transaxle AssemblyTRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

MZJLA- -

Pre-removal Operationl Place Selector Lever in “N” Position

and Stop the Engine.

l Draining of Transaxle Fluid

(Refer to GROUP 00

- Maintenance

Service.)

l Removal of Front Under Cover

(Referto GROUP 51 -Front Bumper.)09FO112

Removal steps

1. Side under cover2. Battery

3. Battery seat, Washer tank

4. kiorsteaner cover, Air intake

l +5. Connection for transaxle controlcable

4*

6. Connection for oil cooler hose

7. Inhibitor switch connector

8.

Kickdown servo switch connector

9. Pulse generator connector

10 Oil temperature sensor connector

11. Shift control solenoid valve connector

12. Connection for speedometer cable

13. Connection for transaxle mount bracket70 Nm

51

ft.lbs.

70 Nm

51 ft.lbs.I

09FOO81

1 TSB Revision