sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1069 of 1146

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)- SRS Diagnosis Unit (SDU) 52B-59

SRS DIAGNOSIS UNIT (SDU)M52PDBA

Caution1. Never attempt to disassemble or repair the

SRS diagnosis unit. If faulty, replace it.

2.Do not to drop or subject the SRS diagnosisunit to impact or vibration.

If denting, cracking, deformation, or rust are

discovered in the SRS diagnosis unit, replace

it with a new SRS diagnosis unit. Discard theold one.3. After deployment of an air bag, replace the

SRS diagnosis unit with a new one.

4.Never use an ohmmeter on or near the SRS

diagnosis unit, and use only the special testequipment described on

P.!i2B-16.

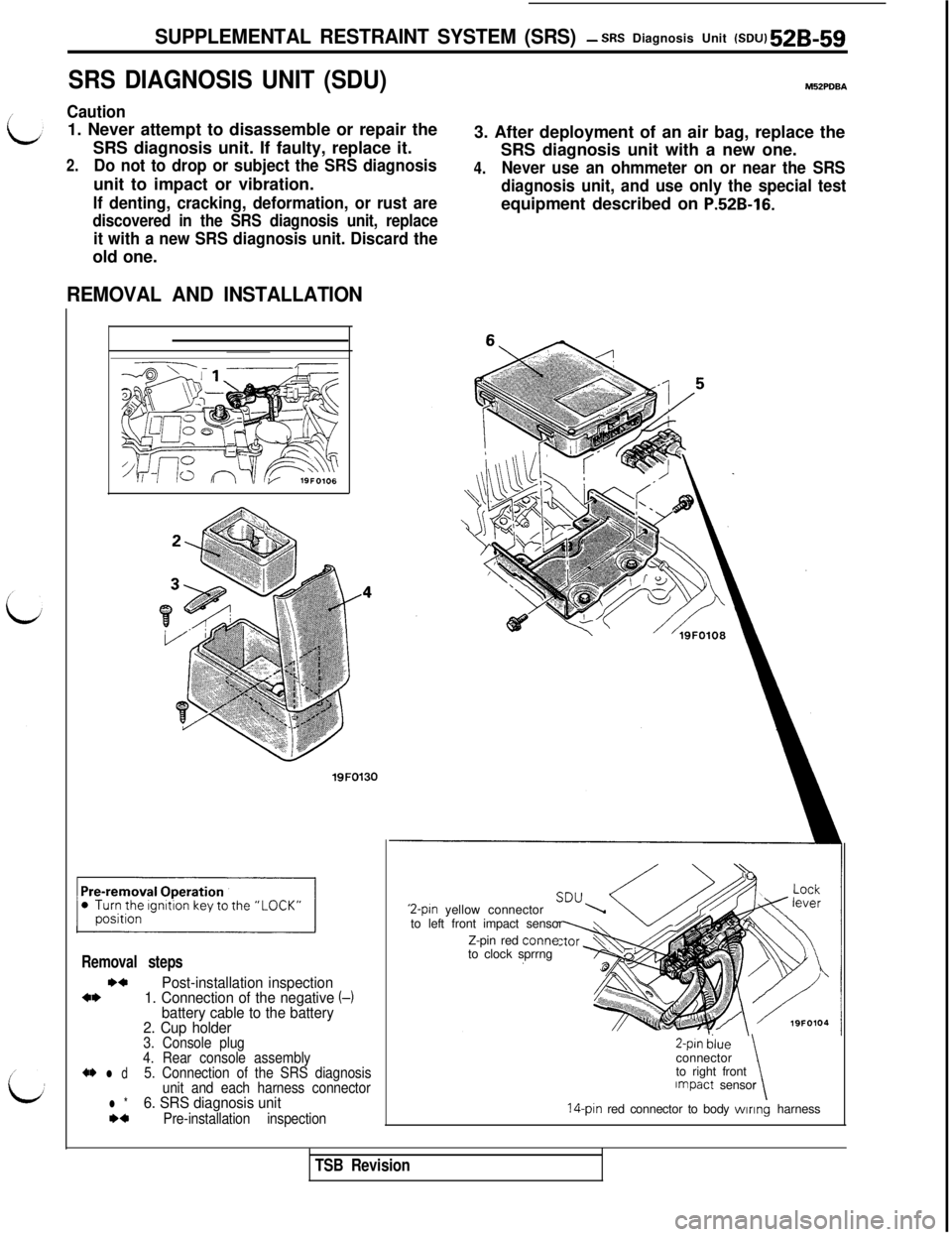

REMOVAL AND INSTALLATION

Removal steps

*aPost-installation inspectionaI)1. Connection of the negative

battery cable to the battery

2. Cup holder

19FO130

t-1

3. Console plug

4. Rear console assembly

a* l d5. Connection of the SRS diagnosis

unit and each harness connector

l *6. SRS diagnosis unit*cPre-installation inspection

2-pin yellow connector

to left front impact sensor

Z-pin red

tonneto clock sprrng

Z-pin dlueconnector

to right front

\Impact sensor14-pin red connector to body wlnng harness

TSB Revision

Page 1070 of 1146

52B-60 SUPPLEMENTAL RESTRAINT SYSTEM (SRS) - SRS Diagnosis Unit (SW

0I/-Battery e

13R0721lSF1072:

SRS diagnosis unitView A13R0704

To front impact sensor

(L.H.)

\To front impact sensor (R.H.1\I

I- - -,I1

\To clock springTo body wiring harness (14-pin)19FOllt

r-TSB I

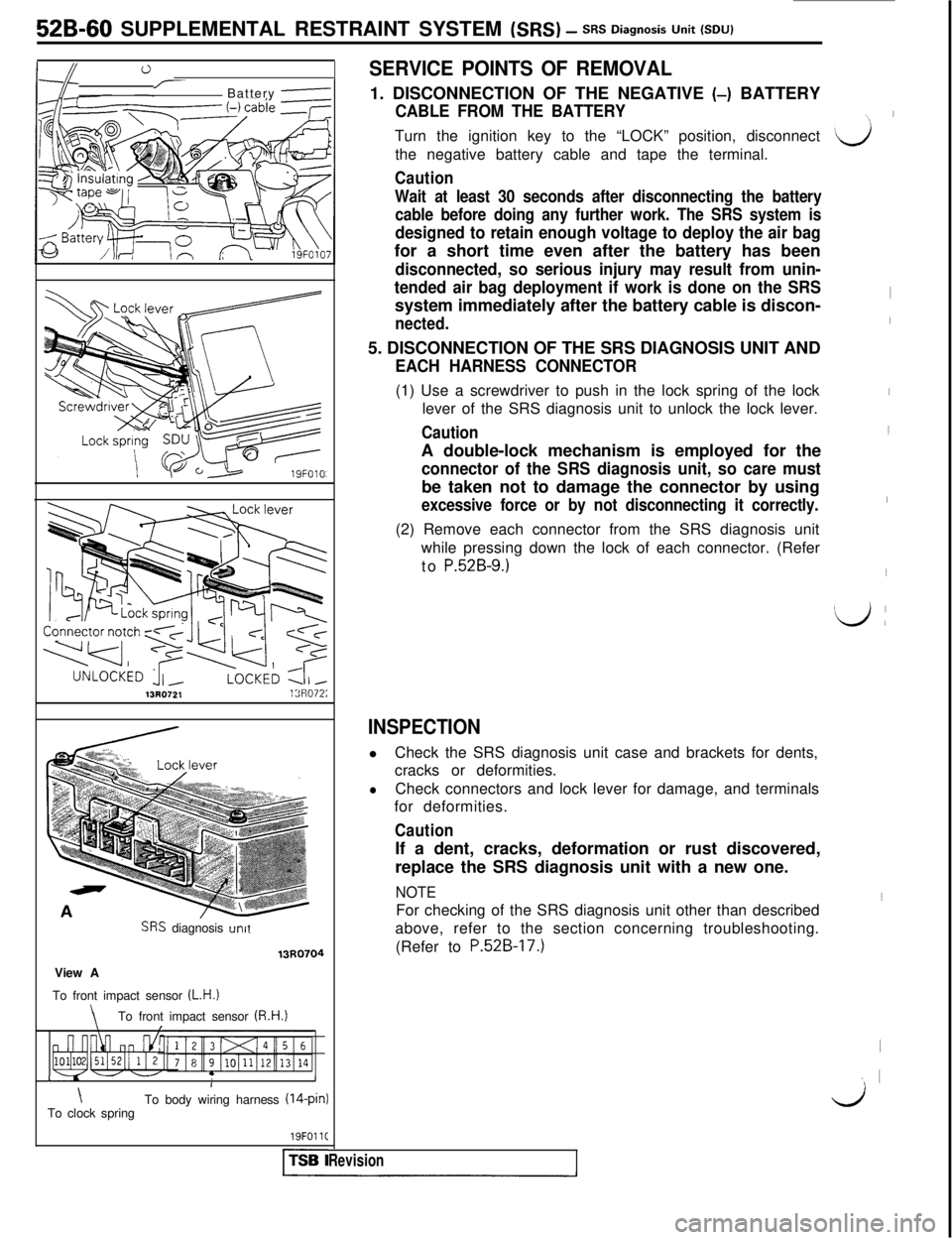

SERVICE POINTS OF REMOVAL1. DISCONNECTION OF THE NEGATIVE

(-) BATTERY

CABLE FROM THE BATTERYTurn the ignition key to the “LOCK” position, disconnect

the negative battery cable and tape the terminal.

Caution

Wait at least 30 seconds after disconnecting the battery

cable before doing any further work. The SRS system is

designed to retain enough voltage to deploy the air bagfor a short time even after the battery has been

disconnected, so serious injury may result from unin-

tended air bag deployment if work is done on the SRSsystem immediately after the battery cable is discon-

nected.5. DISCONNECTION OF THE SRS DIAGNOSIS UNIT AND

EACH HARNESS CONNECTOR(1) Use a screwdriver to push in the lock spring of the lock

lever of the SRS diagnosis unit to unlock the lock lever.

CautionA double-lock mechanism is employed for the

connector of the SRS diagnosis unit, so care mustbe taken not to damage the connector by using

excessive force or by not disconnecting it correctly.(2) Remove each connector from the SRS diagnosis unit

while pressing down the lock of each connector. (Refer

to

P.52B-9.)

INSPECTIONlCheck the SRS diagnosis unit case and brackets for dents,

cracks or deformities.

lCheck connectors and lock lever for damage, and terminals

for deformities.

CautionIf a dent, cracks, deformation or rust discovered,

replace the SRS diagnosis unit with a new one.

NOTEFor checking of the SRS diagnosis unit other than described

above, refer to the section concerning troubleshooting.

(Refer to

P.52B-17.)

Revision

\\I

‘d

I

I

I1

I~

\Lj (

I

I

~ I

kJ

Page 1083 of 1146

55-1

HEATER, AIR

CONDITIONER

AND VENTILATION

CONTENTSM55AA- -

HEATERS AND AIR CONDITIONING................3HEATER UNIT*........................................................................22

SPECIFICATIONS

....................................................................3REFRIGERANT LINE................................................................35General Specifications

........................................................3RESISTOR................................................................................20Lubricants

............................................................................4SAFETY PRECAUTIONS........................................................9Sealant and Adhesive............................................................4

Service Specifications3SERVICE ADJUSTMENT PROCEDURES............................10........................................................

SPECIAL TOOLS4Charging Procedures............................................................11

i

........................................................................Charging the Refrigerant....................................................12Compressor Drive Belt Adjustment....................................11

HEATERS AND MANUAL AIR CONDITIONER5Compressor Noise................................................................16

................................................16

AIR CONDITIONER SWITCH................................................21Handling Tubing andFittings

Idle-up Operation Check....................................................17

BELT LOCK CONTROLLER20Performance Test................................................................15....................................................

BLOWER ASSEMBLYPower Relay Check............................................................17............................................................23Refrigerant Leak Repair Procedure....................................15COMPRESSOR........................................................................

27TestProcedures....................................................................10

CONDENSER AND CONDENSER FAN MOTOR................33TROUBLESHOOTING............................................................5

ENGINE COOLANT TEMPERATURE SWITCH....................

39VENTILATORS (AIR INLET AND AIR OUTLET)................38

EVAPORATOR

........................................................................

25VENTILATORS (INSTRUMENT PANEL)*............................36

HEATER CONTROL ASSEMBLY*

........................................18CONTINUED ON NEXT PAGE

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components (that may have to be

removed/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the

SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B

-Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

Page 1084 of 1146

55-2FULL AUTO AIR CONDITIONER........................40OTHER PARTS........................................................................62

AIR-CONDITIONER CONTROL PANEL*,POWER TRANSISTOR, BELT LOCK CONTROLLER........57

AIR-CONDITIONER CONTROL UNIT*................................56

REFRIGERANT LINE................................................................62

COMPRESSOR

........................................................................62SAFETY PRECAUTlONS........................................................56

CONDENSER AND CONDENSER FAN MOTOR

................

62SENSORS....................................................................................60

DAMPER CONTROL MOTOR ASSEMBLY*........................

58SERVICE ADJUSTMENT PROCEDURES............................56

ENGINE COOLANT TEMPERATURE SWITCH

....................62

TROUBLESHOOTING............................................................40

Page 1085 of 1146

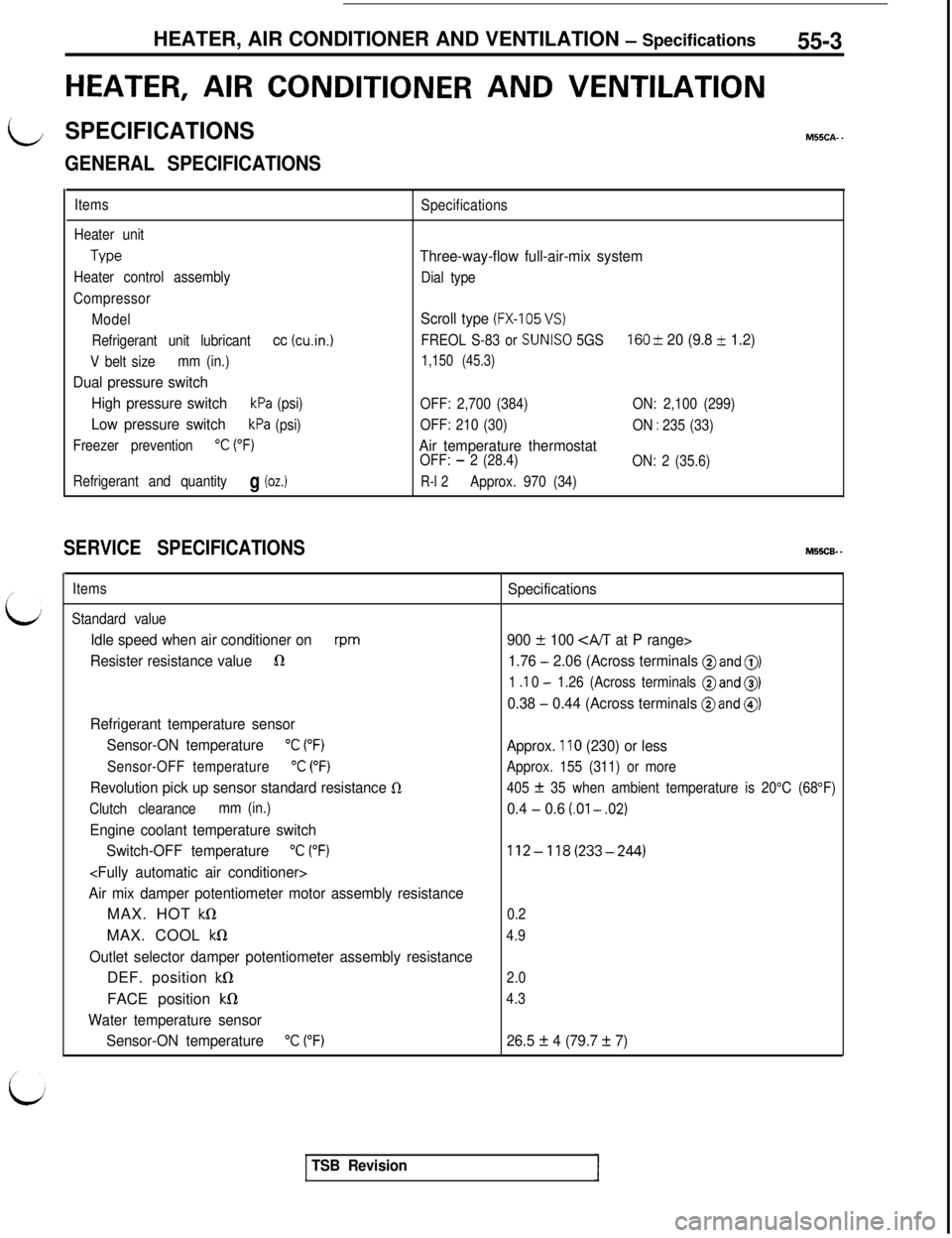

HEATER, AIR CONDITIONER AND VENTILATION - Specifications55-3

HEATER, AIR CONDITIONER AND VENTILATION

LSPECIFICATIONSM55CA. -

/’

L;

GENERAL SPECIFICATIONS

Items

Heater unit

Type

Heater control assembly

Compressor

Model

Refrigerant unit lubricant

cc (cu.in.1

V belt sizemm (in.)

Dual pressure switch

High pressure switch

kPa (psi)

Low pressure switchkPa (psi)

Freezer prevention

“C (“F)

Refrigerant and quantityg (oz.)

Specifications

Three-way-flow full-air-mix system

Dial type

Scroll type (FX-105 VS)

FREOL S-83 or SUNISO 5GS160 & 20 (9.8 + 1.2)

1,150 (45.3)

OFF: 2,700 (384)ON: 2,100 (299)

OFF: 210 (30)

ON

: 235 (33)

Air temperature thermostatOFF: - 2 (28.4)

ON: 2 (35.6)

R-l 2Approx. 970 (34)

SERVICE SPECIFICATIONSM55CB. -

Items

Standard value

Idle speed when air conditioner onrpm

Resister resistance value1R

Refrigerant temperature sensor

Sensor-ON temperature

“C (“F)

Sensor-OFF temperature“C (“F)

Revolution pick up sensor standard resistance 0

Clutch clearancemm (in.)

Engine coolant temperature switch

Switch-OFF temperature

“C (“F)

Air mix damper potentiometer motor assembly resistanceMAX. HOT

kQMAX. COOL

kS1

Outlet selector damper potentiometer assembly resistanceDEF. position

kS1FACE position

kfl

Water temperature sensor

Sensor-ON temperature

“C (“F)

Specifications

900

f 100 CA/T at P range>

1.76

- 2.06 (Across terminals @and 0)

1 .I 0 - 1.26 (Across terminals @and 0)

0.38 - 0.44 (Across terminals @and @)

Approx. 110 (230) or less

Approx. 155 (311) or more

405

f 35 when ambient temperature is 20°C (68°F)

0.4 - 0.6 (.Ol - .02)

112-118(233-244)

0.2

4.9

2.0

4.3

26.5 f 4 (79.7 + 7)

TSB Revision

Page 1088 of 1146

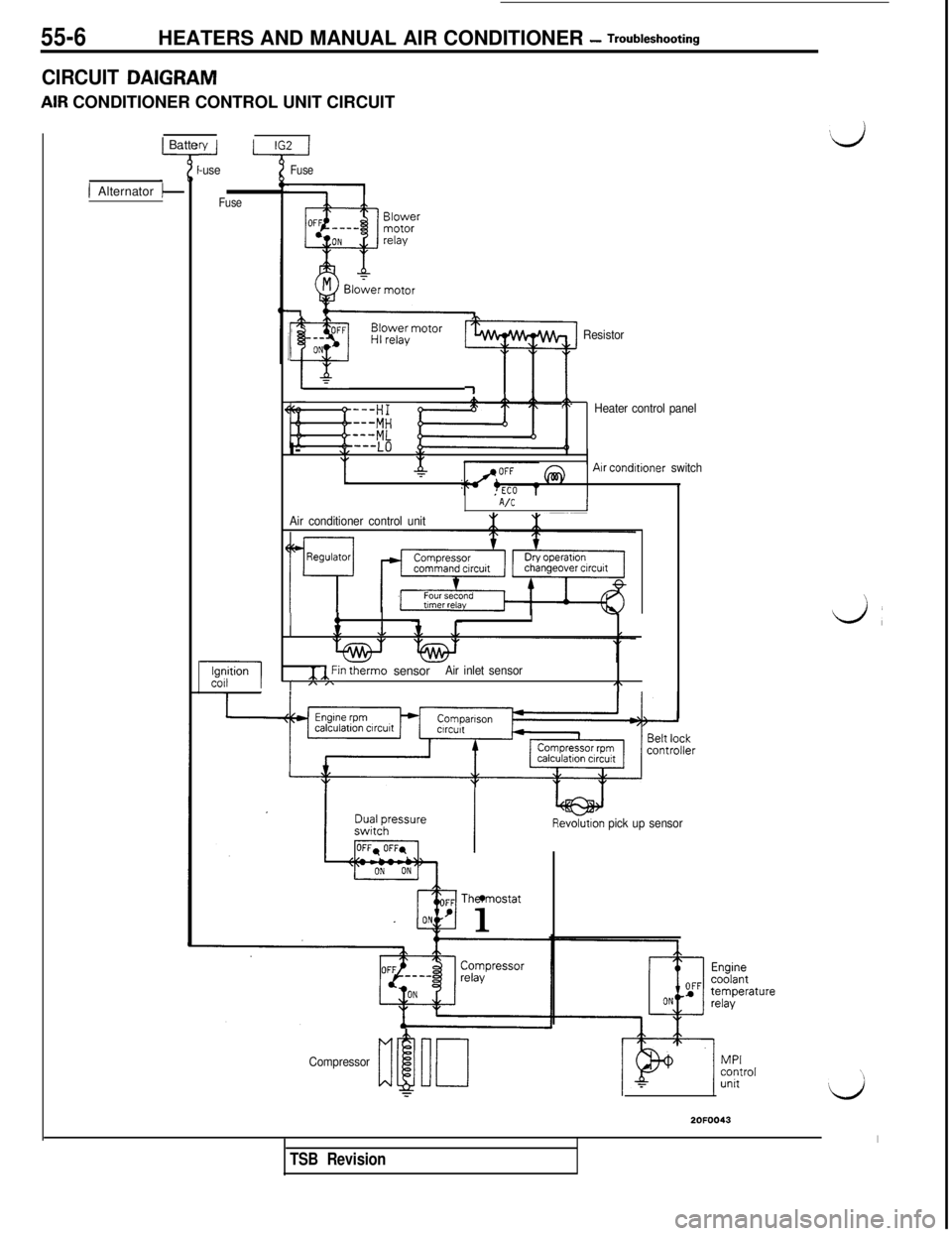

55-6HEATERS AND MANUAL AIR CONDITIONER - Troubleshooting

CIRCUIT DAIGRAM

P\IR CONDITIONER CONTROL UNIT CIRCUIT

1 Batte

( Alternator k

2-Jl-

-use

Fuse

-yq

L-l

Fuse

vi ~~o~~;motor ;?IResistor;

r---HI---MH:---ML---I n

IIHeater control panelI-

fI.IAir conditioner switch

1

Air conditioner control unit

A/CI

Regulator

IT

If

I

1II

1 IFin therm0 sensorAir inlet sensor

I” ”I\

Revolution pick up sensori

Compressor

@IDY

vi;

TSB Revision

2OFOO43

I

Page 1089 of 1146

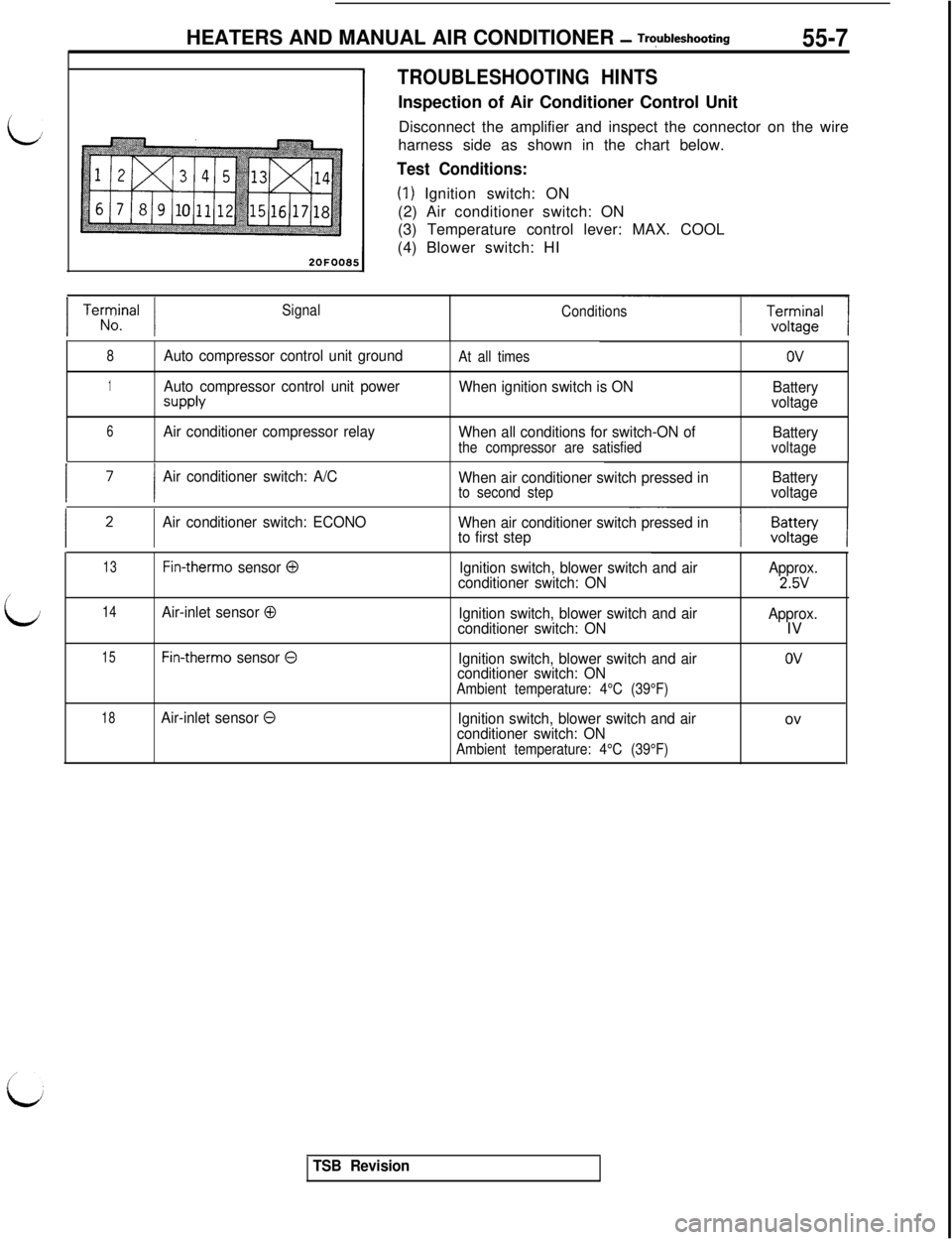

L

2OFOO85HEATERS AND MANUAL AIR CONDITIONER

- Trqubleshooting55-7

TROUBLESHOOTING HINTSInspection of Air Conditioner Control Unit

Disconnect the amplifier and inspect the connector on the wire

harness side as shown in the chart below.

Test Conditions:

(1) Ignition switch: ON

(2) Air conditioner switch: ON

(3) Temperature control lever: MAX. COOL

(4) Blower switch: HI

1 Terrrnal 1Signal

Conditions

8Auto compressor control unit groundAt all timesov

1Auto compressor control unit power

SUPPlY

When ignition switch is ON

Battery

voltage

6Air conditioner compressor relay

When all conditions for switch-ON of

Battery

the compressor are satisfiedvoltage

I ’I

Air conditioner switch: A/C

When air conditioner switch pressed inBattery

to second stepvoltage

Air conditioner switch: ECONO

When air conditioner switch pressed in

to first step

13Fin-therm0 sensor 0Ignition switch, blower switch and airApprox.

conditioner switch: ON2.5V/

LJ14Air-inlet sensor 0Ignition switch, blower switch and air

conditioner switch: ONApprox.IV

15Fin-therm0 sensor 0Ignition switch, blower switch and air

conditioner switch: ON

Ambient temperature: 4°C (39°F)

OV

18Air-inlet sensor 0Ignition switch, blower switch and air

conditioner switch: ON

Ambient temperature: 4°C (39°F)ov

TSB Revision

Page 1090 of 1146

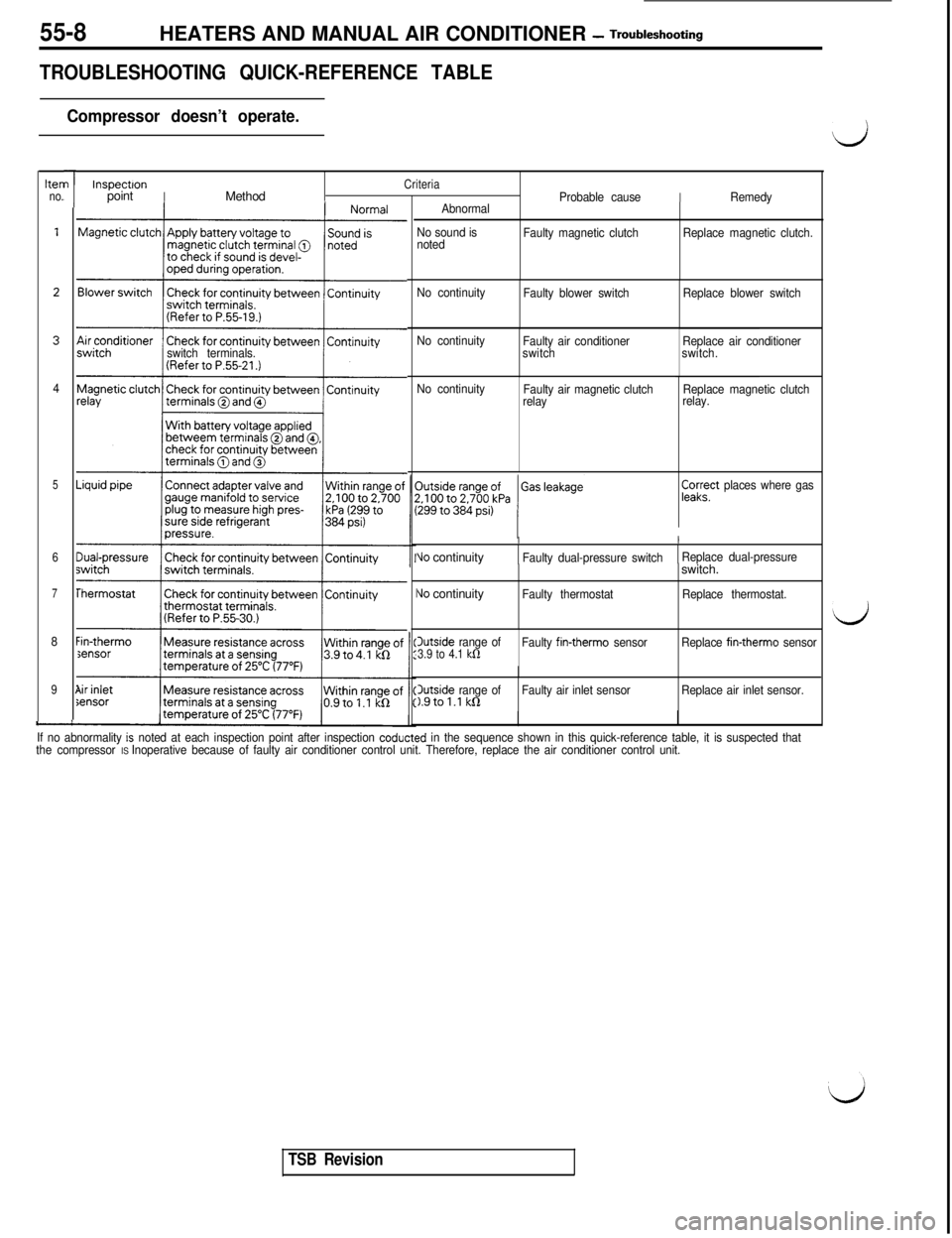

55-8HEATERS AND MANUAL AIR CONDITIONER - Troubleshooting

TROUBLESHOOTING QUICK-REFERENCE TABLE

Compressor doesn’t operate.

hen

no.

4

5

6

7

8

9

-

I

I

/

L

switch terminals.

Sensor

”

1

InspectronCriteriapointIMethodProbable causeIRemedy

Abnormal

No sound is

notedFaulty magnetic clutchReplace magnetic clutch.

No continuity

Faulty blower switchReplace blower switch

No continuity

Faulty air conditioner

switchReplace air conditioner

switch.

No continuity

Faulty air magnetic clutch

relayReplace magnetic clutch

relay.

pa;?’ places where gas

II

Vo continuityFaulty dual-pressure switchReplace dual-pressure

\Jo continuityIFaulty thermostatswitch.Replace thermostat.

Outside range of3.9 to 4.1 kfiFaulty fin-therm0 sensorReplace fin-therm0 sensor

3utside range ofFaulty air inlet sensor1.9tol.l kQReplace air inlet sensor.

If no abnormality

is noted at each inspection point after inspection coducted in the sequence shown in this quick-reference table, it is suspected that

the compressor IS Inoperative because of faulty air conditioner control unit. Therefore, replace the air conditioner control unit.

d

d

TSB Revision

Page 1093 of 1146

HEATERS AND MANUAL AIR CONDITIONER -Service Adjustment Procedures 55 1 1

lr In et sensor

UC03xD:c.-;am$2lYXSC0x.x

xa0:: :,:::25 cc,ii 77h>Temperature20A043F

argqse

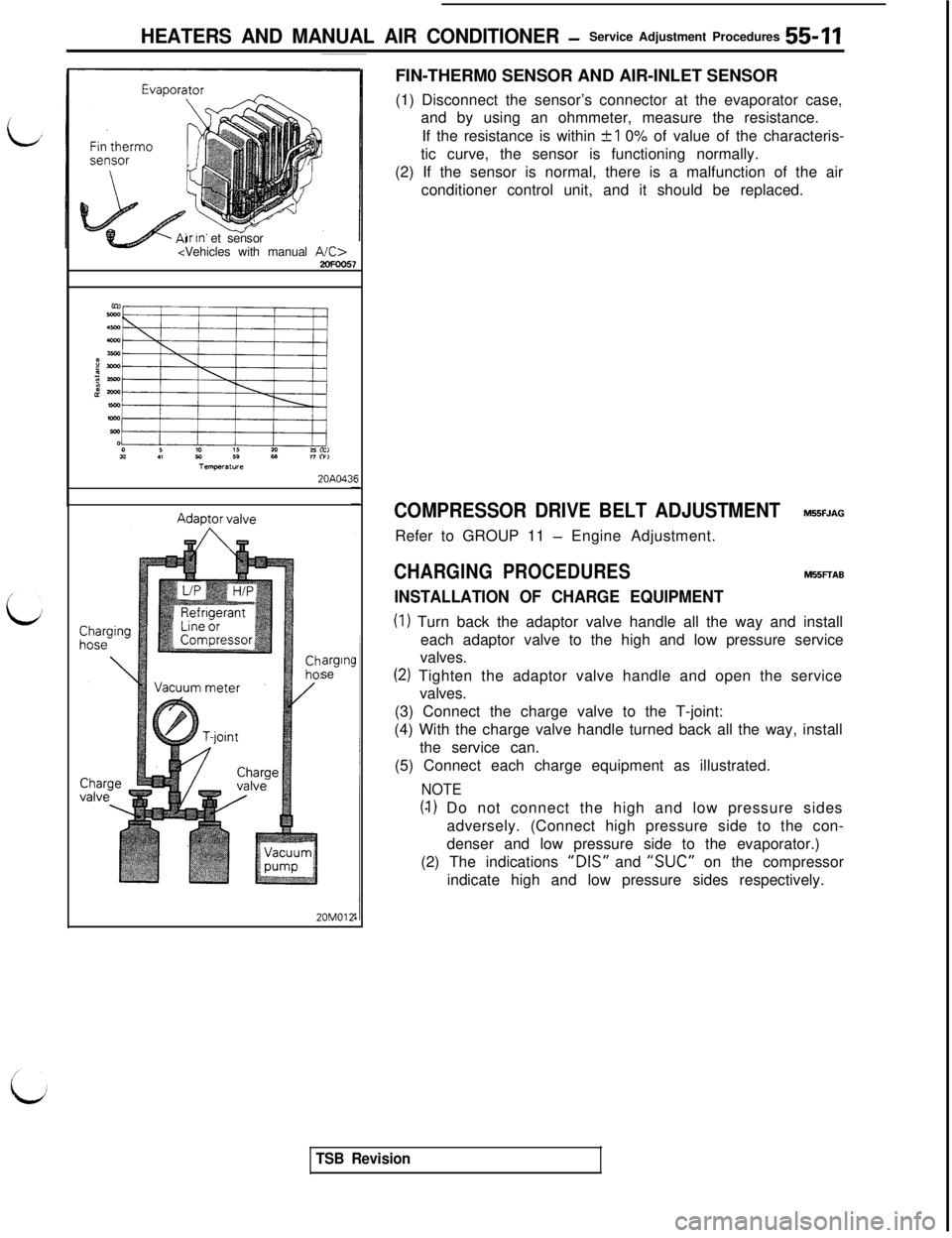

20M012FIN-THERM0 SENSOR AND AIR-INLET SENSOR

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance.

If the resistance is within

+I 0% of value of the characteris-

tic curve, the sensor is functioning normally.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

COMPRESSOR DRIVE BELT ADJUSTMENTM55FJAGRefer to GROUP 11

- Engine Adjustment.

CHARGING PROCEDURESM55FTAB

INSTALLATION OF CHARGE EQUIPMENT

(I) Turn back the adaptor valve handle all the way and install

each adaptor valve to the high and low pressure service

valves.

(2) Tighten the adaptor valve handle and open the service

valves.

(3) Connect the charge valve to the T-joint:

(4) With the charge valve handle turned back all the way, install

the service can.

(5) Connect each charge equipment as illustrated.

NOTE

(4) Do not connect the high and low pressure sides

adversely. (Connect high pressure side to the con-

denser and low pressure side to the evaporator.)

(2) The indications

“DIS” and “SUC” on the compressor

indicate high and low pressure sides respectively.

TSB Revision

Page 1107 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Evaporator55-25

EVAPORATOR

M55RA- -

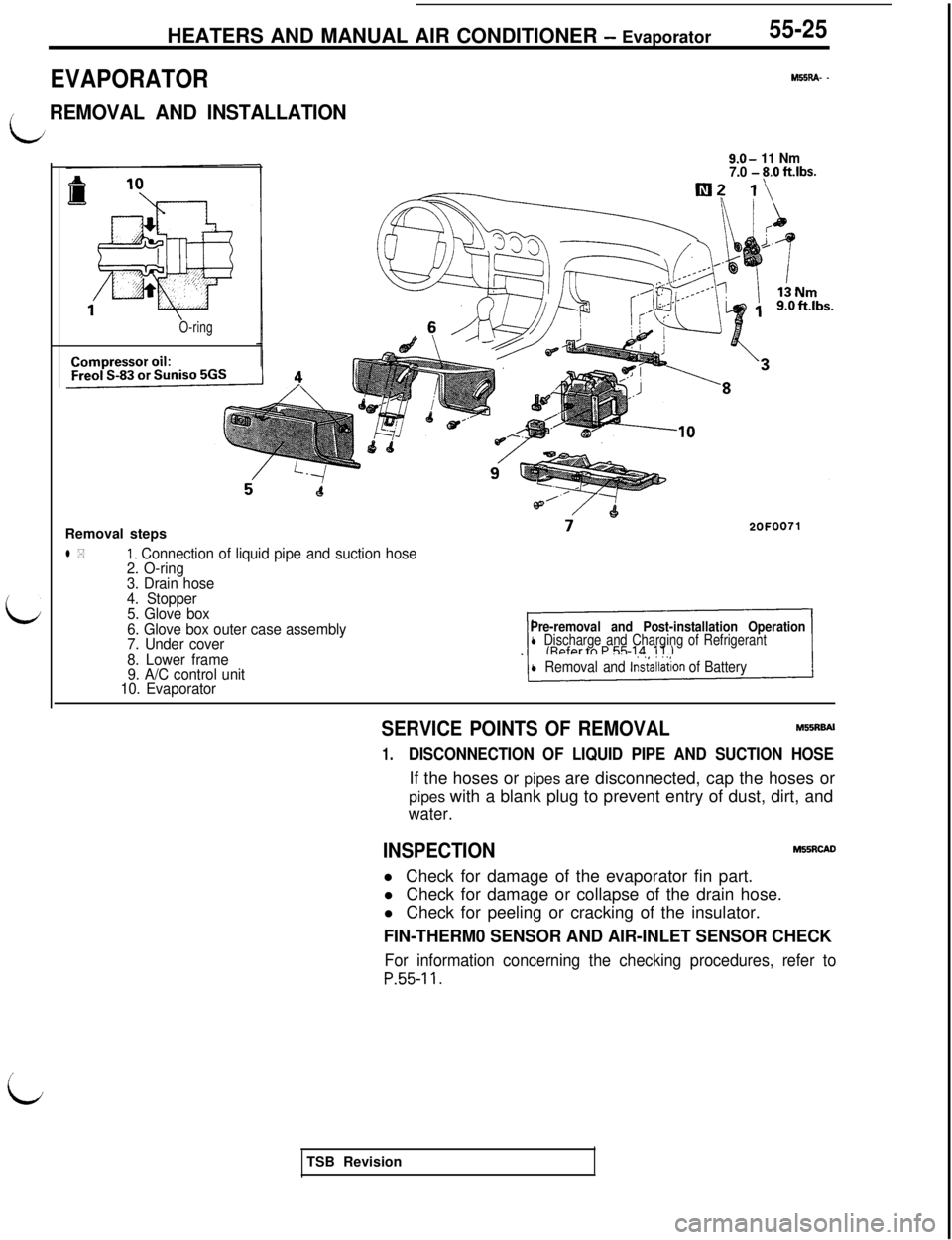

/REMOVAL AND INSTALLATION

9.0- 11 Nm

7.0 - 8.0 ftlbs.

i

O-ringRemoval steps

l *I, Connection of liquid pipe and suction hose

2. O-ring

3. Drain hose

4. Stopper

5. Glove box

6. Glove box outer case assembly

7. Under cover

8. Lower frame

9. A/C control unit

10. Evaporator

Pre-removal and Post-installation Operationl Discharge and Charging of Refrigerant

l Removal and lns~allation of Battery

SERVICE POINTS OF REMOVALM55RBAl

1.DISCONNECTION OF LIQUID PIPE AND SUCTION HOSEIf the hoses or pipes are disconnected, cap the hoses or

pipes with a blank plug to prevent entry of dust, dirt, and

water.

INSPECTIONM55RcADl Check for damage of the evaporator fin part.

l Check for damage or collapse of the drain hose.

l Check for peeling or cracking of the insulator.

FIN-THERM0 SENSOR AND AIR-INLET SENSOR CHECK

For information concerning the checking procedures, refer to

P.55-11.

iTSB Revision